12 Key Benefits of Electrically Conductive Rubber Profiles

Table of Contents

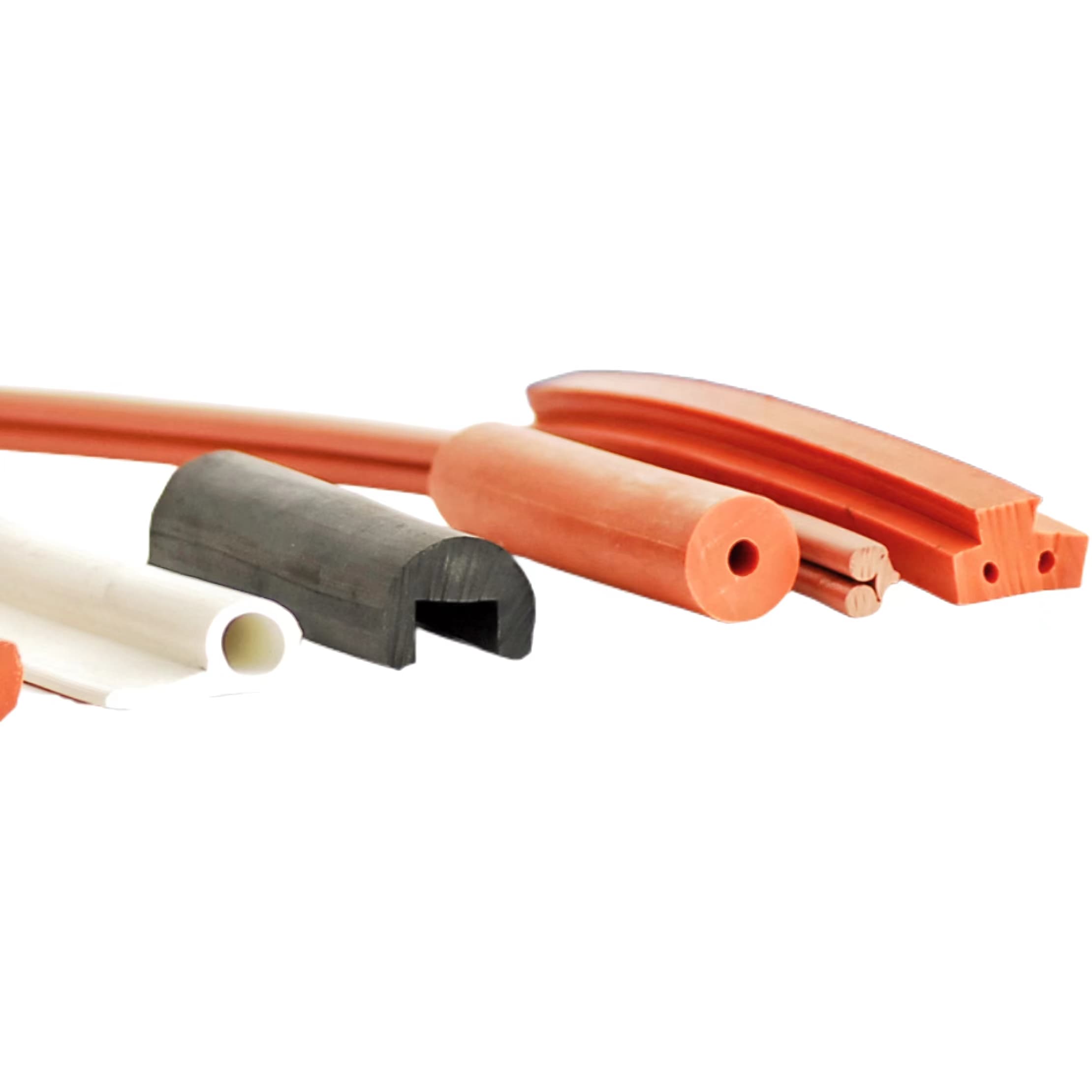

Electrically conductive rubber profiles

Electrically conductive rubber profiles are specialized materials designed to provide both electrical conductivity and mechanical flexibility. These profiles are commonly used in a variety of industries, from electronics to aerospace, automotive, medical devices, and more. Their unique combination of properties allows them to perform critical functions such as electromagnetic interference (EMI) shielding, environmental sealing, and electrical grounding, all while maintaining structural integrity under demanding conditions.

In this comprehensive guide, we will delve into the key benefits, applications, materials, and industry considerations for electrically conductive rubber profiles. We’ll also explore the importance of design flexibility, durability, and regulatory compliance, providing an in-depth understanding of why these profiles are an essential component in modern technology.

What are Electrically Conductive Rubber Profiles?

Electrically conductive rubber profiles are elastomeric materials that are enhanced with conductive fillers such as carbon black, silver, copper, or nickel. These fillers allow the rubber to conduct electricity, making it an effective material for both electrical and environmental applications. The rubber itself is typically made from silicone, EPDM (ethylene propylene diene monomer), or fluorosilicone, which provide the base mechanical properties such as flexibility, durability, and resistance to environmental factors like heat, chemicals, and moisture.

The primary purpose of these profiles is to provide conductive pathways for electrical continuity, while also offering sealing solutions that protect sensitive components from external contaminants, moisture, and other environmental hazards.

Key Benefits of Electrically Conductive Rubber Profiles

Electrically conductive rubber profiles offer a multitude of benefits that make them indispensable in various industries. Below are the top advantages:

1. Effective EMI/RFI Shielding

One of the most critical applications of electrically conductive rubber profiles is their ability to provide EMI and RFI shielding. In today’s interconnected world, electromagnetic interference (EMI) and radio frequency interference (RFI) are significant concerns, especially in electronic devices and systems. EMI and RFI can cause disruptions in signal transmission, leading to malfunctioning electronic components, data loss, and even system failure.

Electrically conductive rubber profiles create a conductive barrier that blocks external electromagnetic signals from penetrating sensitive electronic components. This makes them an ideal choice for industries such as:

- Telecommunications: Shielding network and communication devices from signal interference.

- Consumer Electronics: Protecting mobile phones, laptops, and other personal devices from EMI/RFI.

- Aerospace: Ensuring reliable performance of avionics systems, which are highly sensitive to interference.

2. Sealing and Environmental Protection

In addition to providing electrical shielding, electrically conductive rubber profiles offer excellent sealing capabilities. These profiles are often used as gaskets or seals to prevent the ingress of moisture, dust, and other contaminants. Maintaining a pressure-tight and weather-resistant seal is critical in environments where protection against environmental factors is necessary to ensure device longevity and performance.

For example, in the automotive and aerospace industries, these profiles are used to seal junction boxes, control panels, and cabin electronics, protecting them from harsh weather conditions, dust, and fluids.

3. Electrical Continuity and Grounding

Ensuring electrical continuity is essential in applications where static buildup can cause electrostatic discharge (ESD), which can damage electronic components and cause system malfunctions. Electrically conductive rubber profiles provide a continuous conductive path that effectively grounds static charges, preventing ESD and ensuring safe operation of electronic devices.

In medical devices and sensitive laboratory equipment, for instance, preventing ESD is critical to ensure accurate readings and avoid interference with device operation. Conductive rubber profiles ensure that any accumulated charges are safely dissipated, enhancing both safety and reliability.

4. Design Flexibility

One of the key advantages of electrically conductive rubber profiles is their design flexibility. These profiles can be customized to fit a wide range of applications, from simple O-rings to complex gaskets and custom shapes. Whether you need a specific profile shape for sealing, EMI shielding, or a combination of both, these materials can be easily tailored to meet your needs.

This versatility allows engineers and designers to create bespoke solutions for specific requirements, such as sealing complex enclosures, providing multi-functional profiles for shielding and sealing, or designing lightweight, high-performance solutions for aerospace applications.

5. Durability and Resistance

Electrically conductive rubber profiles are designed to withstand harsh environments and are resistant to various degrading factors, such as:

- Weathering: These profiles can endure prolonged exposure to sunlight, rain, and extreme weather conditions without losing their sealing or conductive properties.

- Oxidation and Ozone Resistance: Conductive rubber materials are resistant to oxidation and ozone, ensuring long-term performance even in outdoor or high-altitude applications.

- Chemical Resistance: Profiles made from silicone or fluorosilicone offer excellent resistance to chemicals, oils, and fuels, making them ideal for use in automotive, aerospace, and industrial applications.

These properties make electrically conductive rubber profiles suitable for use in marine environments, outdoor electrical enclosures, and industrial machinery.

6. Ease of Installation

Electrically conductive rubber profiles are often supplied in pre-formed shapes that simplify the installation process. Whether used as gaskets, seals, or specialized profiles, they can be easily integrated into existing designs without extensive modifications. The flexibility of these materials also allows them to conform to irregular surfaces, ensuring a tight seal and proper electrical contact.

By reducing assembly time and minimizing the need for custom fittings, conductive rubber profiles contribute to more efficient manufacturing processes and lower costs.

7. Flame Retardant Properties

Many electrically conductive rubber profiles are formulated to meet stringent flame retardancy standards such as UL94V-0. These standards are critical for applications where fire safety is paramount, such as in aerospace, automotive, and electronics enclosures. The combination of flame retardancy and electrical conductivity ensures that these profiles can provide both protection and performance in high-risk environments.

8. Cost-Effectiveness

While electrically conductive rubber profiles may have a higher initial cost due to the incorporation of conductive materials, their long-term benefits outweigh the upfront expense. These benefits include reduced maintenance, improved product reliability, and compliance with regulatory standards. Over time, these factors contribute to cost savings by extending the life of the product and reducing the need for frequent repairs or replacements.

9. Custom Fillers and Formulations

The ability to use custom conductive fillers allows manufacturers to optimize the conductivity, mechanical properties, and cost of rubber profiles depending on the application. For instance, silver or nickel fillers may be used for high-conductivity applications, while carbon black or graphite fillers may be chosen for cost-effective solutions that still meet conductivity requirements.

This customization enables the development of profiles tailored to the specific demands of the application, ensuring the right balance between performance and cost.

10. Sustainability and Eco-Friendly Materials

With the growing demand for sustainable manufacturing practices, there is an increasing emphasis on using eco-friendly fillers and materials in the production of electrically conductive rubber profiles. Advances in materials science have led to the development of recyclable and sustainable elastomers that provide the same level of performance while minimizing environmental impact. By using sustainable fillers, manufacturers can contribute to greener production practices without compromising on performance.

11. Temperature Stability

Electrically conductive rubber profiles maintain their performance over a wide range of temperatures. From extreme heat to freezing cold, these materials retain their conductivity, sealing abilities, and mechanical properties. This makes them suitable for applications that experience wide temperature fluctuations, such as:

- Aerospace: Sealing and shielding components in high-altitude, high-temperature environments.

- Automotive: Providing reliable seals in engine compartments and exhaust systems, which are exposed to both heat and cold.

12. Improved Safety

By providing EMI shielding and grounding capabilities, electrically conductive rubber profiles contribute to the overall safety of electronic devices. By protecting against interference and preventing electrostatic discharge, these profiles help reduce the risk of electrical failures and fires.

In critical industries such as medical devices and automotive, where malfunctions can have severe consequences, the use of conductive rubber profiles ensures that systems operate safely and reliably.

Applications of Electrically Conductive Rubber Profiles

Electrically conductive rubber profiles are used in a wide range of industries, including:

- Electronics: Shielding and sealing enclosures for sensitive electronic components.

- Aerospace: Providing EMI shielding and sealing in avionics systems, control panels, and enclosures.

- Automotive: Ensuring electrical continuity and sealing in engine compartments, electronics, and exhaust systems.

- Medical Devices: Grounding and shielding sensitive devices, ensuring safe operation in environments with high sensitivity to static electricity and EMI.

- Telecommunications: Protecting communication devices from interference and environmental factors.

Conclusion

Electrically conductive rubber profiles offer a wide range of benefits, from providing EMI shielding and environmental sealing to ensuring electrical continuity and grounding. Their design flexibility, durability, and customization options make them an essential material in industries where performance, safety, and reliability are critical.If you need these products,please contact us.