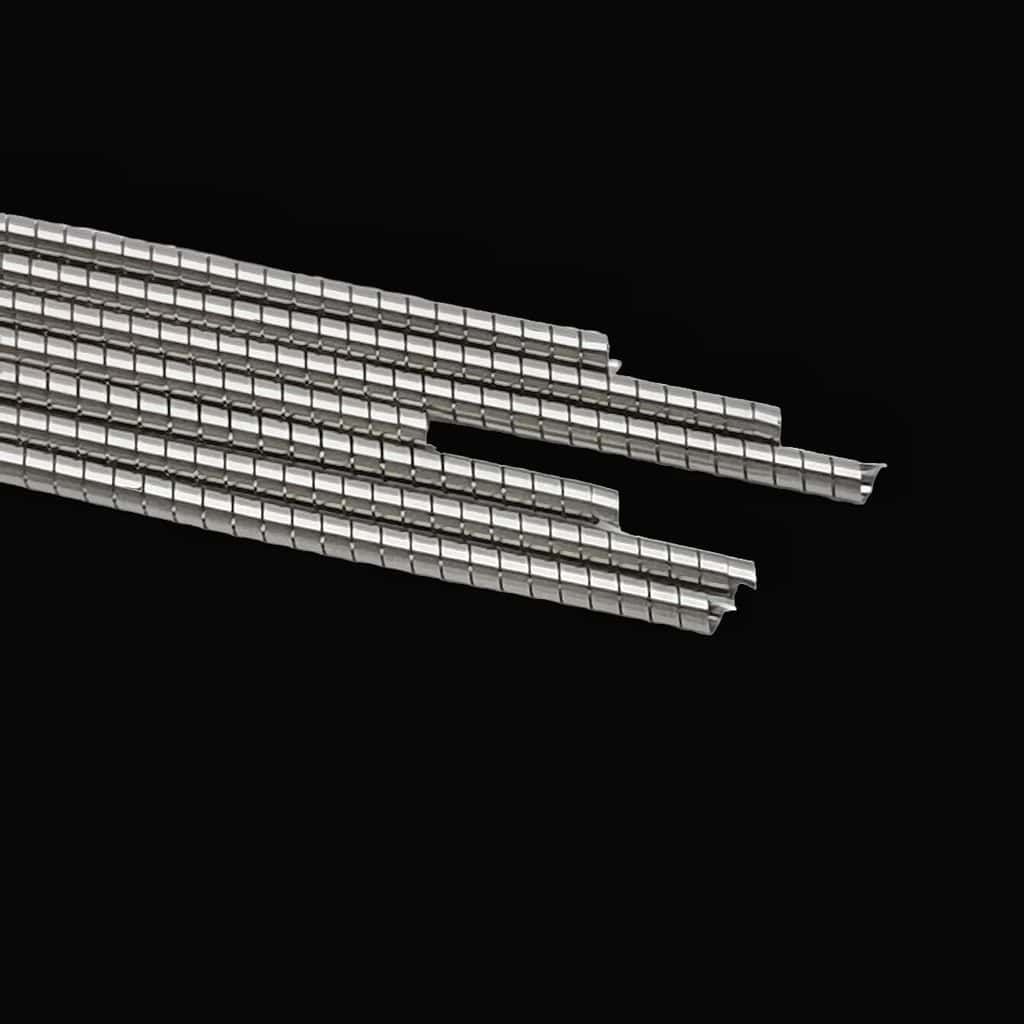

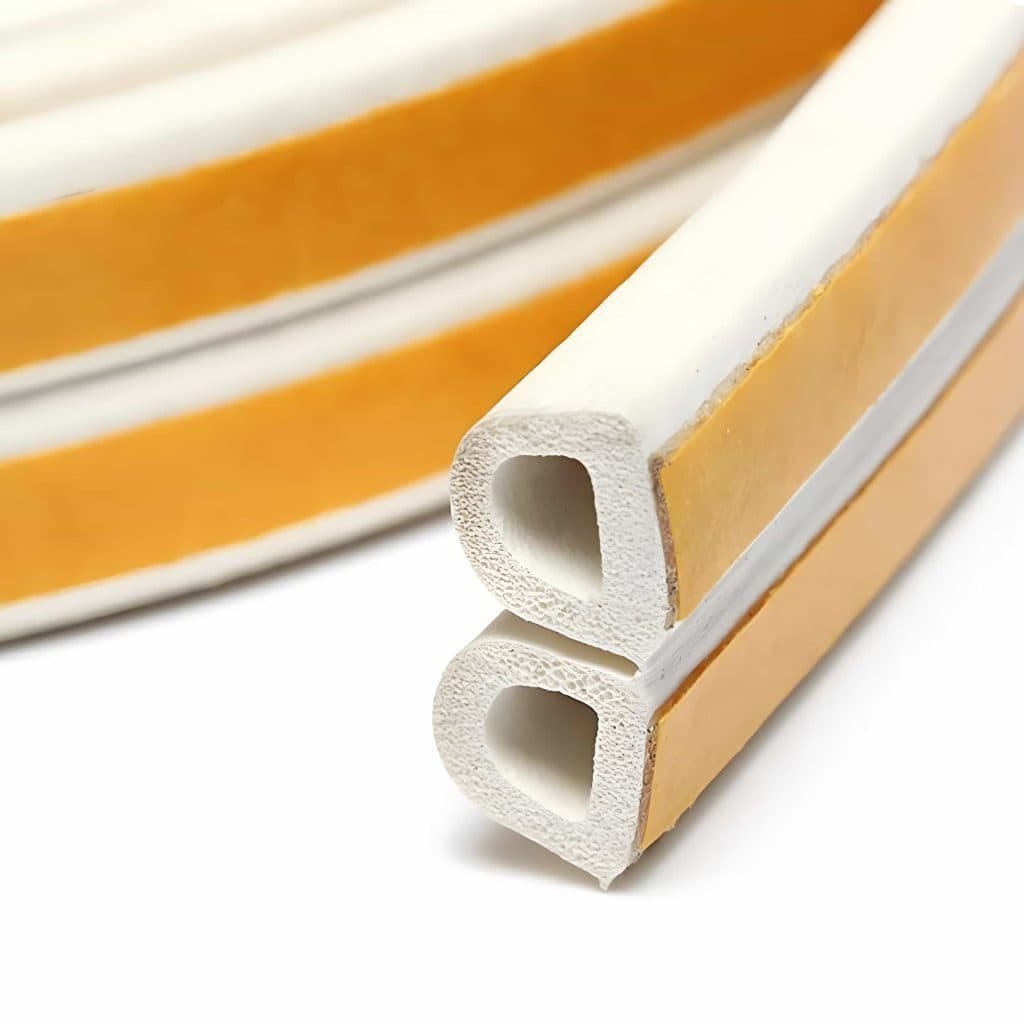

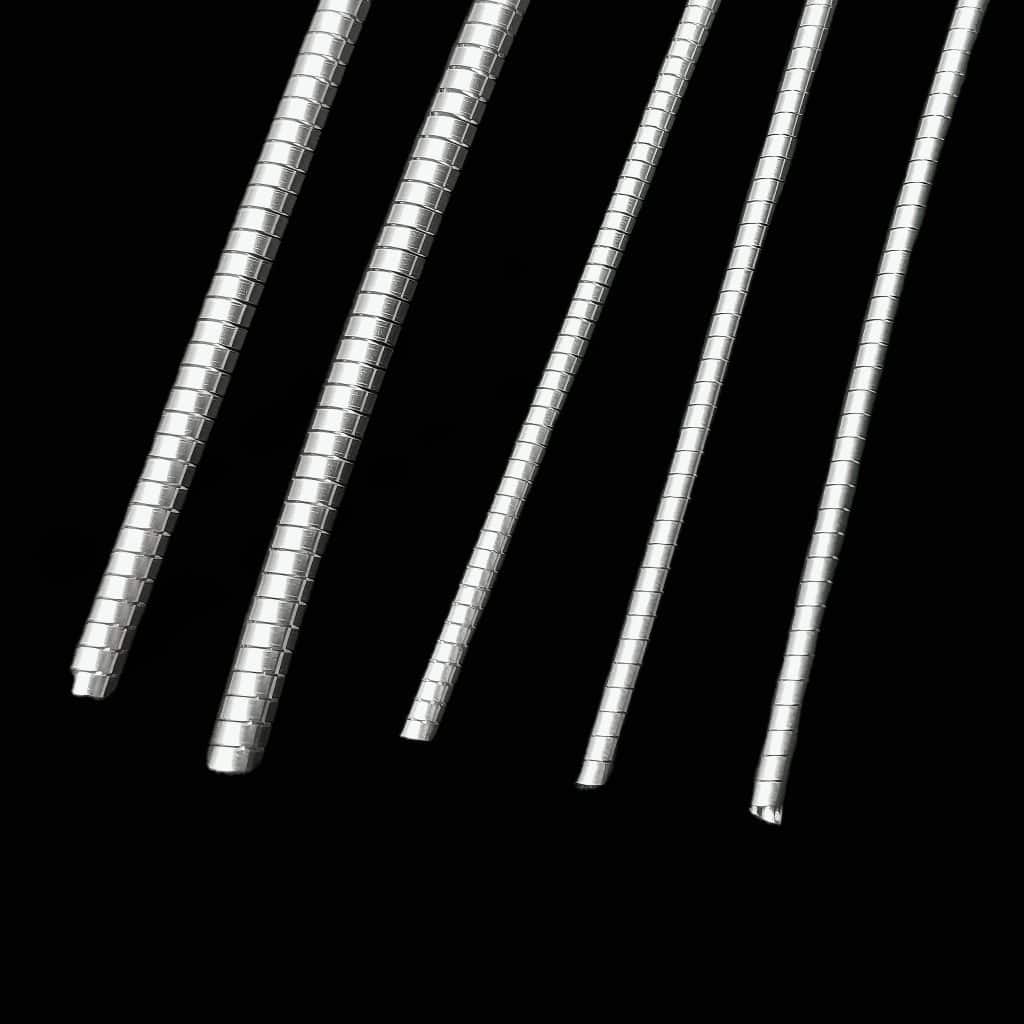

6 Types Applications of D Multi-Seal gaskets

D Multi-Seal gaskets are integral components in many industries due to their versatile sealing capabilities and robust performance under various conditions. Their design typically features multiple sealing elements to ensure comprehensive coverage and effective leakage prevention. Here’s a detailed look at six types of applications where D Multi-Seal gaskets are utilized, emphasizing their importance and functionality in each context.

Table of Contents

1. Automotive Engines

Application:

In automotive engines,D Multi-Seal gaskets are crucial for sealing various engine components such as valve covers, oil pans, and timing covers. These gaskets are employed in areas where multiple sealing surfaces are present, and a reliable seal is essential to prevent fluid leakage.

Role and Importance:

- Leak Prevention: The primary role of D Multi-Seal gaskets in automotive engines is to prevent the leakage of oil, coolant, and other fluids. A failure to seal properly can lead to fluid leaks, which may cause engine overheating, contamination of the engine oil, and ultimately engine damage.

- Temperature and Pressure Tolerance: Automotive engines operate under high temperatures and pressures. “D” Multi-Seal gaskets are designed to withstand these extreme conditions, maintaining their sealing properties even when exposed to high engine temperatures and vibrations.

- Durability: These gaskets are made from materials that resist degradation from engine fluids and environmental factors. This ensures a long service life and reduces the need for frequent maintenance or replacement.

Examples:

- Valve Cover Gaskets: Seals the junction between the valve cover and the engine cylinder head, preventing oil from leaking out and contaminants from entering the engine.

- Oil Pan Gaskets: Seals the oil pan to the bottom of the engine, preventing oil leaks and ensuring proper lubrication of engine components.

2. Industrial Equipment

Application:

In industrial settings, D Multi-Seal gaskets are used in machinery and equipment across various industries, including manufacturing, chemical processing, and energy production. These gaskets are often found in flanged connections, pumps, valves, and other critical equipment.

Role and Importance:

- High-Pressure and High-Temperature Sealing: Industrial equipment frequently operates under high pressures and temperatures. D Multi-Seal gasketsare designed to handle these demanding conditions, providing a reliable seal that prevents fluid or gas leaks.

- Chemical Resistance: Many industrial environments involve exposure to corrosive chemicals and aggressive substances. The materials used in D Multi-Seal gasketsare selected for their resistance to chemical attack, ensuring long-term performance in harsh environments.

- Reduced Downtime: By preventing leaks and maintaining efficient operation, these gaskets help minimize equipment downtime and maintenance costs, contributing to overall operational efficiency.

Examples:

- Pumps: Seals between the pump casing and the cover, ensuring that fluids are contained within the pump and preventing leakage.

- Flanged Connections: Used in various piping systems to ensure tight seals between flanges, preventing leakage of fluids or gases.

3. HVAC Systems

Application:

In heating, ventilation, and air conditioning (HVAC) systems, D Multi-Seal gaskets are utilized in flanged joints, ductwork, and other critical sealing points. These gaskets ensure that HVAC systems operate efficiently and effectively.

Role and Importance:

- Air and Fluid Leak Prevention: HVAC systems rely on tight seals to prevent the leakage of air and refrigerants. D Multi-Seal gaskets provide reliable sealing to maintain system pressure and efficiency.

- Energy Efficiency: Proper sealing helps prevent energy losses due to leaks, improving the overall efficiency of the HVAC system and reducing energy consumption.

- Comfort and Performance: By maintaining effective seals, these gaskets ensure that HVAC systems perform optimally, providing consistent temperature control and air quality in buildings.

Examples:

- Ductwork Sealing: Ensures that connections between duct sections are airtight, preventing air loss and maintaining system performance.

- Flanged Joints: Used in flanged connections in HVAC units to prevent refrigerant leaks and ensure proper operation.

4. Aerospace Components

Application:

In the aerospace industry, D Multi-Seal gaskets are critical for sealing components in aircraft and spacecraft, including fuel systems, hydraulic systems, and engine components. These gaskets must perform reliably under extreme conditions.

Role and Importance:

- Extreme Condition Tolerance: Aerospace components are exposed to high temperatures, pressures, and vibrations. D Multi-Seal gaskets are designed to maintain their sealing properties under these demanding conditions.

- Safety and Reliability: Effective sealing is crucial for the safety and reliability of aerospace systems. These gaskets prevent leaks that could compromise the performance and safety of aircraft and spacecraft.

- Longevity and Maintenance: Aerospace components are often difficult to access and maintain. Durable “D” Multi-Seal gaskets help extend the service life of these components and reduce the need for frequent maintenance.

Examples:

- Fuel System Seals: Prevent leaks in fuel lines and tanks, ensuring the safe storage and transfer of fuel.

- Hydraulic System Seals: Ensure the integrity of hydraulic systems used in aircraft control mechanisms and landing gear.

5. Marine Applications

Application:

D Multi-Seal gaskets are employed in marine applications where equipment is exposed to seawater and harsh marine conditions. These gaskets are used in engines, pumps, and various marine machinery.

Role and Importance:

- Corrosion Resistance: Marine environments expose gaskets to saltwater and corrosive substances. “D” Multi-Seal gaskets are made from materials that resist corrosion, ensuring reliable performance in maritime conditions.

- Moisture Protection: These gaskets help prevent water ingress into sensitive components, protecting them from damage and ensuring their proper functioning.

- Durability: The gaskets are designed to withstand the mechanical stresses and environmental conditions of marine environments, providing long-lasting performance.

Examples:

- Marine Engine Seals: Used in the seals of marine engines to prevent oil and coolant leaks and protect against water intrusion.

- Pump Seals: Ensure that seawater or other fluids are contained within the pump, preventing leaks and maintaining operational efficiency.

6. Food and Beverage Processing

Application:

In the food and beverage industry, D Multi-Seal gaskets are used in equipment such as pumps, valves, and mixers. These gaskets ensure that food processing equipment operates efficiently and meets hygiene standards.

Role and Importance:

- Hygiene and Sanitation: Food processing equipment must meet strict hygiene standards. D Multi-Seal gaskets provide a sanitary seal that prevents contamination and ensures the safety of food products.

- Leak Prevention: Prevents leaks of fluids and ingredients, which is essential for maintaining process efficiency and avoiding waste.

- Durability: Designed to handle the cleaning and sanitizing processes common in the food industry, these gaskets resist degradation from cleaning chemicals and high temperatures.

Examples:

- Pump Seals: Used in pumps that handle liquid food products, preventing leaks and maintaining cleanliness.

- Valve Seals: Ensure that valves in processing lines do not leak, maintaining the integrity of the process and preventing contamination.

In summary, D Multi-Seal gaskets are versatile components used across a wide range of applications due to their effective sealing properties and durability. From automotive engines to food processing, these gaskets play a critical role in ensuring the reliability and efficiency of systems and equipment in various industries. Their ability to perform under extreme conditions and resist degradation makes them indispensable in maintaining operational integrity and safety.For these products,please contact us or look through the website of Handa Shielding.