Multi-use Stick-on Mounting Fingerstrips with Excellent EMI Shielding Effect

This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications. These adhesive-backed beryllium-copper strips are designed to be easily installed without the need for specialized tools, providing an efficient and cost-effective way to shield electronics from EMI.

Electromagnetic interference (EMI) can create significant issues for electronic devices and systems, leading to decreased performance, potential malfunction, or even failure. This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications. These adhesive-backed beryllium-copper strips are designed to be easily installed without the need for specialized tools, providing an efficient and cost-effective way to shield electronics from EMI.

In this article, we will explore the features, applications, benefits, and importance of stick-on mounting fingerstrips in EMI shielding. Whether you are working in telecommunications, computer hardware, or any industry where electromagnetic interference poses a risk, stick-on fingerstrips can provide a practical solution.

Table of Contents

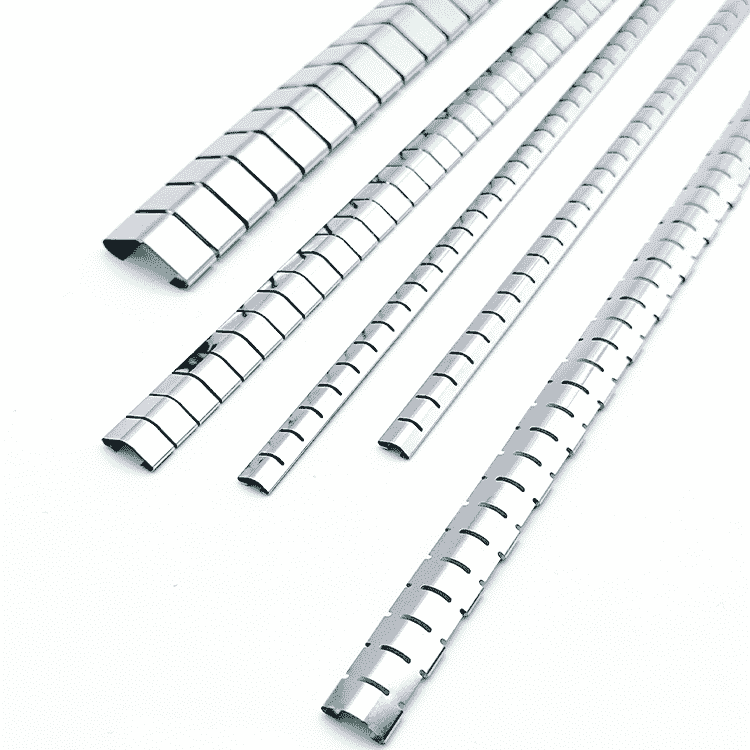

Stick-on Mounting Fingerstrips

Key Features of Stick-on Mounting Fingerstrips

When choosing an EMI shielding solution, it’s important to focus on certain key features to ensure that the product you select meets your application requirements. Stick-on mounting fingerstrips offer the following essential characteristics:

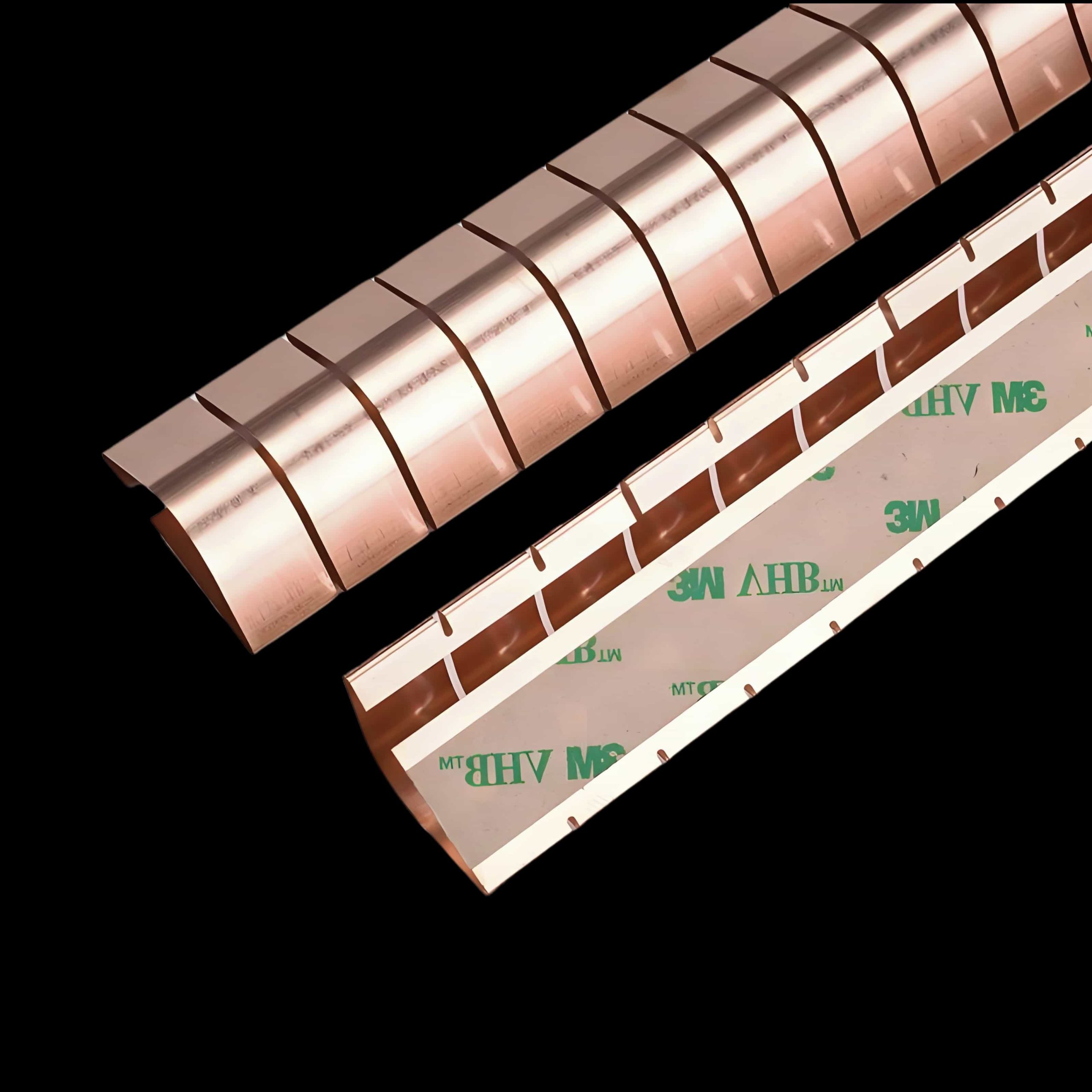

1. Adhesive Backing

One of the standout features of stick-on mounting fingerstrips is their pressure-sensitive adhesive (PSA) backing. The adhesive provides a strong, durable bond to a wide range of surfaces, ensuring a secure and easy installation process. This self-adhesive feature eliminates the need for additional fasteners, reducing labor and installation time, making it highly suitable for both large-scale industrial applications and small-scale electronics assembly.

The adhesive backing is also designed for reliable performance over time. It remains strong even in challenging environments, such as in the presence of chemicals or fluctuating temperatures. This property makes stick-on mounting fingerstrips highly reliable and durable for long-term use.

2. Low-Profile Design

Space constraints are a significant consideration in modern electronics, where components are becoming smaller and more compact. Stick-on mounting fingerstrips are designed with a low-profile structure, making them ideal for applications where space is at a premium. Their slim design allows them to fit into narrow spaces while still delivering effective EMI shielding performance.

3. Beryllium-Copper Construction

Beryllium copper is the material of choice for stick-on fingerstrips due to its excellent combination of strength, durability, and high conductivity. This alloy offers outstanding EMI shielding properties, effectively blocking electromagnetic waves from penetrating electronic enclosures. The material’s resilience ensures that the shielding remains effective even after repeated use or exposure to harsh environmental conditions. Beryllium copper’s natural corrosion resistance further enhances the long-term performance of these shielding strips.

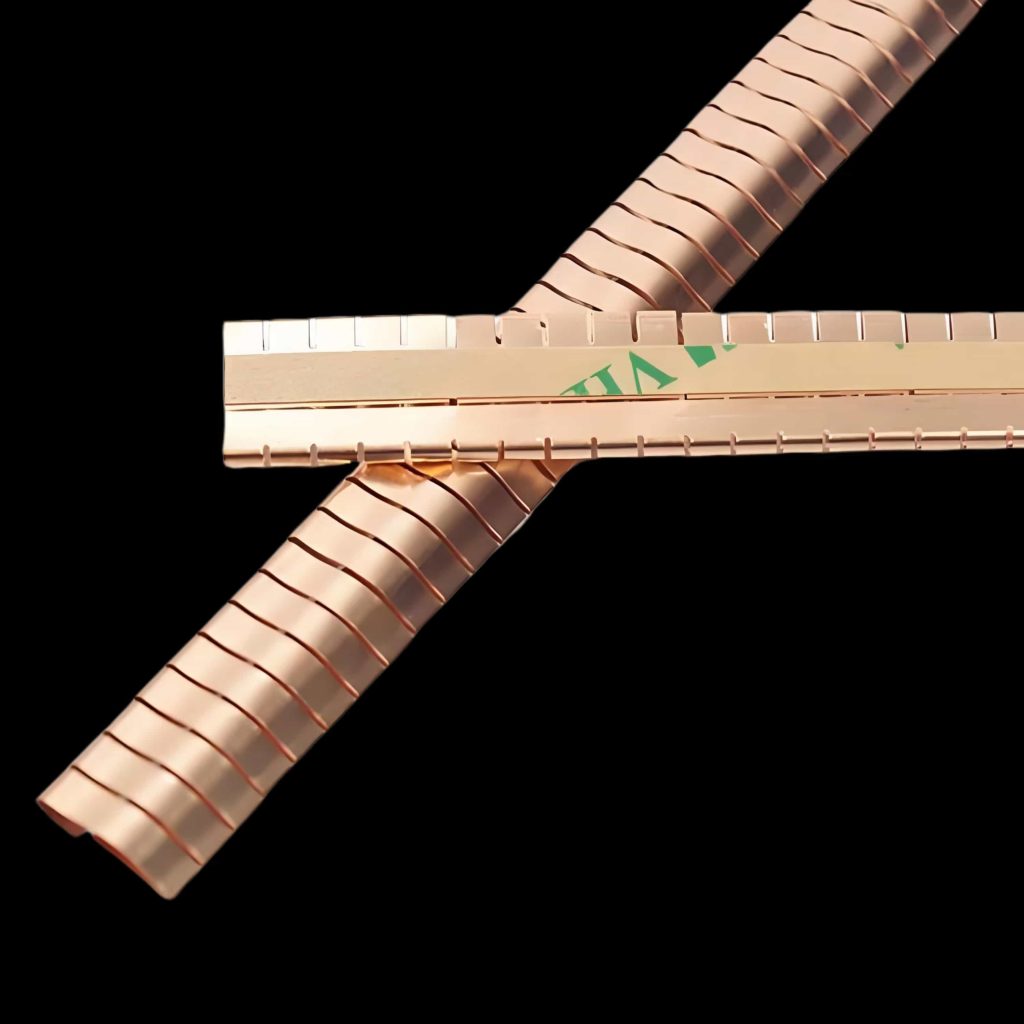

4. Bi-directional Sealing

Another notable feature of stick-on mounting fingerstrips is their ability to provide bi-directional EMI shielding. This means that the strips are effective in both inward and outward directions, protecting electronic components from both incoming and outgoing electromagnetic interference. This makes them suitable for applications that require shielding from external EMI sources as well as those that emit EMI themselves.

5. Adjustable Size

Stick-on fingerstrips come in a variety of widths and lengths, allowing for customization to fit specific gaps and enclosure sizes. This flexibility ensures a snug fit, which is crucial for maintaining consistent shielding performance. Whether the application requires narrow strips for small enclosures or wider strips for larger openings, there is a solution available to suit different needs.

Applications of Stick-on Mounting Fingerstrips

Stick-on mounting fingerstrips are versatile in their applications and are widely used across various industries to provide effective EMI shielding. Some of the most common applications include:

1. Telecommunications Equipment

In the telecommunications industry, particularly in rack-mounted systems, EMI can significantly affect the performance of line cards and other sensitive components. Stick-on mounting fingerstrips are often used to shield these components, ensuring reliable operation even in environments with high electromagnetic noise. The adhesive-backed strips can be easily applied to enclosures and mounting racks, providing seamless EMI protection.

2. Narrow Electronics Enclosures

As electronic devices become smaller, the need for effective EMI shielding in narrow spaces has increased. Stick-on mounting fingerstrips are ideal for use in compact electronics enclosures where space is limited. Their low-profile design allows them to be fitted into tight spaces without compromising shielding performance, making them a popular choice in consumer electronics, medical devices, and more.

3. General EMI Shielding Applications

Stick-on fingerstrips are used in a broad range of general EMI shielding applications. From aerospace and defense equipment to automotive electronics, these strips are capable of providing reliable protection against electromagnetic interference. Their versatility and ease of installation make them an attractive solution for companies that need consistent, long-term shielding.

4. Computer Hardware

Modern computer systems are packed with sensitive components that can be affected by EMI, including processors, memory modules, and network cards. Stick-on mounting fingerstrips can be applied to computer cases and internal components to prevent electromagnetic interference from causing data loss, performance degradation, or system failure.

Benefits of Stick-on Mounting Fingerstrips

There are several benefits to using stick-on mounting fingerstrips for EMI shielding, making them a preferred solution for many industries. Key advantages include:

1. Easy Installation

The pressure-sensitive adhesive backing on stick-on fingerstrips allows for simple and quick installation. No special tools or expertise are required, reducing the overall labor cost and time spent on installation. This makes them an ideal choice for applications where time is a critical factor, or where frequent removal and reinstallation may be necessary.

2. Consistent Sealing

Stick-on mounting fingerstrips maintain consistent contact with mating surfaces, providing a reliable EMI shield even in environments where there may be movement or vibration. This ensures continuous protection without the need for constant adjustments or maintenance.

3. Flexibility

One of the standout benefits of stick-on fingerstrips is their ability to conform to irregular surfaces. In many applications, the surfaces to be shielded may not be perfectly flat. The flexibility of beryllium-copper construction allows these strips to bend and contour around corners and edges while maintaining their shielding performance.

4. Durability

Beryllium copper offers excellent durability, making stick-on fingerstrips resistant to chemicals, moisture, and abrasion. This ensures that they remain effective in harsh environments, such as industrial or outdoor settings, where exposure to corrosive materials or extreme temperatures might occur. Additionally, the adhesive backing is engineered to withstand environmental stress, ensuring that the strips remain securely in place over time.

5. Versatility

Stick-on mounting fingerstrips can be used in both static and dynamic applications. Whether the shielded components are stationary or in motion, these fingerstrips provide consistent EMI protection, making them suitable for a wide variety of use cases. Their adaptability to different enclosure sizes and shapes further enhances their versatility.

How Stick-on Mounting Fingerstrips Help with EMI Shielding

Electromagnetic interference can severely disrupt the operation of electronic devices, leading to signal degradation, loss of data, and even complete system failure. EMI shielding is essential to protect sensitive electronic components from these disturbances. Stick-on mounting fingerstrips are one of the most effective solutions for providing this shielding, particularly in applications where space is limited or where traditional shielding methods are impractical.

Minimizing Electromagnetic Interference

Stick-on fingerstrips work by creating a conductive barrier that blocks electromagnetic waves from entering or exiting an enclosure. The beryllium-copper construction of the strips allows them to absorb and reflect EMI, preventing it from reaching sensitive electronic components. This shielding is bi-directional, meaning it not only protects the internal components from external interference but also prevents the devices from emitting EMI that could affect nearby electronics.

Maintaining Performance in High-EMI Environments

Certain environments, such as telecommunications facilities or industrial sites, have high levels of electromagnetic noise. In these settings, the risk of EMI disrupting operations is significantly increased. Stick-on fingerstrips provide a reliable solution for maintaining the performance of electronic systems in such environments by ensuring that sensitive components are properly shielded.

Enhancing System Reliability

The use of stick-on mounting fingerstrips can also enhance the overall reliability of electronic systems. By protecting components from EMI, these strips help prevent system malfunctions, reduce the likelihood of data loss, and extend the lifespan of electronic devices. This makes them an invaluable tool for companies seeking to improve the long-term reliability of their products.

Conclusion

In summary, stick-on mounting fingerstrips provide a versatile, reliable, and easy-to-install solution for EMI shielding in a wide variety of applications. Their adhesive backing, low-profile design, and beryllium-copper construction make them ideal for use in space-constrained environments and high-EMI settings. From telecommunications equipment to computer hardware, stick-on fingerstrips deliver effective, bi-directional EMI protection, ensuring the longevity and performance of sensitive electronic components.

The ease of installation, durability, and flexibility of stick-on fingerstrips further contribute to their widespread use across industries. Whether you need EMI shielding for static enclosures or dynamic applications, these fingerstrips offer a practical and cost-effective solution to keep your devices protected from electromagnetic interference.

By incorporating stick-on mounting fingerstrips into your EMI shielding strategy, you can ensure that your electronic systems remain reliable, functional, and free from the disruptive effects of electromagnetic interference.

You May Also Like

-

High EMI Shielding Effect Snap-on mounting fingerstrips

High EMI Shielding Effect Snap-on mounting fingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to maintaining the functionality and performance of sensitive electronic devices. Snap-on mounting fingerstrips are designed for easy installation, flexibility, and efficient shielding, making them a popular choice across numerous industries, including telecommunications, military, aerospace, automotive, and consumer electronics. This article will provide a detailed exploration of snap-on mounting fingerstrips, focusing on their key features, materials, installation methods, applications, and benefits. Additionally, we will explore why snap-on mounting fingerstrips are an essential component in modern electronics and how they meet the demands of EMI/RFI shielding requirements. https://www.handashielding.com/contact-us.html What are Snap-On Mounting Fingerstrips?Key Features of Snap-On Mounting FingerstripsTypes of Snap-On Mounting FingerstripsInstallation Method of Snap-On Mounting FingerstripsCommon Applications of Snap-On Mounting FingerstripsMaterial Options for Snap-On Mounting FingerstripsBenefits of Using Snap-On Mounting FingerstripsConclusion: Snap-On Mounting Fingerstrips in EMI Shielding What are Snap-On Mounting Fingerstrips? Snap-on mounting fingerstrips are flexible EMI shielding gaskets made from materials such as beryllium copper, phosphor bronze, or other conductive alloys. They are specifically designed to create a secure electrical......

-

Highly Versatile and Indispensable Conductive Copper Foil Tape

Highly Versatile and Indispensable Conductive Copper Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components. This comprehensive guide explores the key features, applications, types, properties, performance, and industries in which conductive copper foil tape plays a crucial role. Key Features of Conductive Copper Foil TapeTypes of Conductive Copper Foil TapeApplications of Conductive Copper Foil TapeProperties and Performance of Conductive Copper Foil TapeConsiderations for Choosing Conductive Copper Foil Tape Conductive Copper Foil Tape Key Features of Conductive Copper Foil Tape Conductive copper foil tape is designed to meet the high demands of modern electronic and industrial applications. Below are its defining features: 1. Electrical Conductivity One of the primary advantages of conductive copper foil tape is its excellent electrical conductivity. Copper, being one of the most conductive materials, allows electrical signals to flow efficiently across surfaces. This makes the tape an essential component in applications that require grounding, EMI (Electromagnetic Interference) shielding, or electrical signal transmission between two or more components. 2. Chemical Resistance Conductive copper foil......

-

Electrical Conductivity Aluminum Foil Tape

Electrical Conductivity Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Electrical conductivity aluminum foil tape is a versatile and essential material in various industries, particularly in electronics, electrical engineering, and construction. This article delves deep into the properties, applications, benefits, and selection criteria for electrical conductivity aluminum foil tape, focusing on why it is indispensable for ensuring electrical continuity, shielding, and grounding. https://www.handashielding.com/contact-us.html What is Electrical Conductivity Aluminum Foil Tape?Key Properties of Electrical Conductivity Aluminum Foil TapeApplications of Electrical Conductivity Aluminum Foil TapeBenefits of Using Electrical Conductivity Aluminum Foil TapeSelection Criteria for Electrical Conductivity Aluminum Foil TapeConclusion What is Electrical Conductivity Aluminum Foil Tape? Electrical conductivity aluminum foil tape is a specialized adhesive tape made from thin aluminum foil coated with an electrically conductive adhesive. This tape is designed to offer excellent conductivity across its surface and through its adhesive, making it ideal for applications requiring reliable electrical connections and shielding. The aluminum foil provides a conductive surface, while the adhesive ensures that the tape adheres firmly to various substrates while maintaining electrical conductivity. Key Properties of Electrical Conductivity Aluminum Foil Tape 1. Electrical Conductivity The primary feature of aluminum foil tape is its excellent electrical conductivity. Both the aluminum foil and the conductive adhesive are designed to allow current......

-

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

High Shielding Effectiveness EMI Shielding Fingerstock GasketsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

In today's increasingly complex electronic landscape, electromagnetic interference (EMI) shielding has become a critical concern for device manufacturers and designers. One effective solution for addressing EMI issues is the use of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets. These specialized components play a vital role in protecting electronic devices from unwanted electromagnetic radiation and maintaining electromagnetic compatibility (EMC). What is EMI Shielding?The Role of EMI Shielding Fingerstock GasketsAdvantages of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConstruction and Materials of High Shielding Effectiveness EMI Shielding Fingerstock GasketsApplications of High Shielding Effectiveness EMI Shielding Fingerstock GasketsPerformance Metrics of Fingerstock GasketsChallenges and ConsiderationsFuture Trends in EMI ShieldingCase Studies of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConclusion What is EMI Shielding? Electromagnetic interference (EMI) refers to the disruption of electronic circuits and systems caused by electromagnetic radiation from external sources. This interference can manifest as noise, signal degradation, or complete system malfunctions. EMI can be generated by a variety of sources including electrical devices, communication systems, and even natural phenomena. To combat EMI, shielding techniques are employed to block or attenuate electromagnetic waves. EMI shielding involves creating a barrier that prevents the interference from penetrating sensitive areas of electronic devices. Effective EMI shielding ensures......

-

Right-angle shielding fingerstrips/angled fingerstocks

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic systems. These fingerstrips are particularly useful in configurations where electronic components intersect at a 90-degree angle. Their primary role is to ensure effective shielding, maintaining electromagnetic compatibility (EMC) and protecting sensitive electronic equipment from interference. IntroductionDesign and FunctionalitySpecifications and MaterialsInstallation ConsiderationsManufacturing ProcessBenefitsConclusion Design and Functionality Purpose and Importance The main purpose of right-angle shielding fingerstrips is to provide reliable EMI/RFI shielding in electronic setups with perpendicular component arrangements. When electronic devices have components aligned at right angles, traditional shielding solutions might not be effective due to gaps or incomplete coverage. Right-angle fingerstrips address this issue by ensuring continuous shielding across these angular junctions, which is crucial for maintaining the performance and reliability of electronic systems. Applications Right-angle shielding fingerstrips are used in a wide range of applications: Computer Hardware: To shield critical internal components from electromagnetic emissions that could cause operational issues or data corruption. Telecommunications Equipment: To prevent signal interference and ensure the integrity of communication systems. Automotive Electronics: To protect sensitive electronic control systems from EMI that could impact vehicle performance. Shielded Enclosures:......