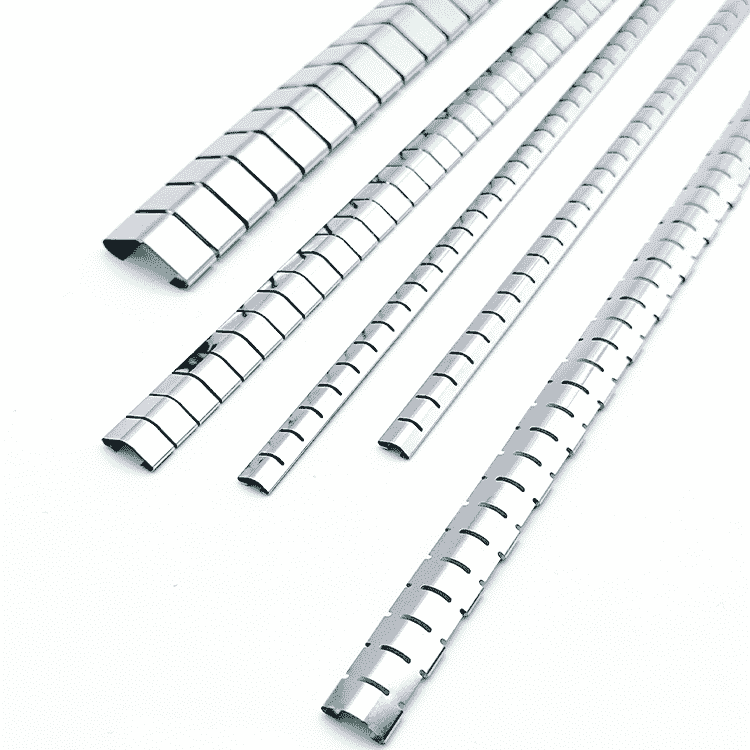

EMI shielding canted coil springs with unique canted coil design

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique canted coil design, which enables them to provide multiple points of contact for superior EMI shielding, mechanical latching, and electrical conductivity.

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique canted coil design, which enables them to provide multiple points of contact for superior EMI shielding, mechanical latching, and electrical conductivity.

Table of Contents

What Are EMI Shielding Canted Coil Springs?

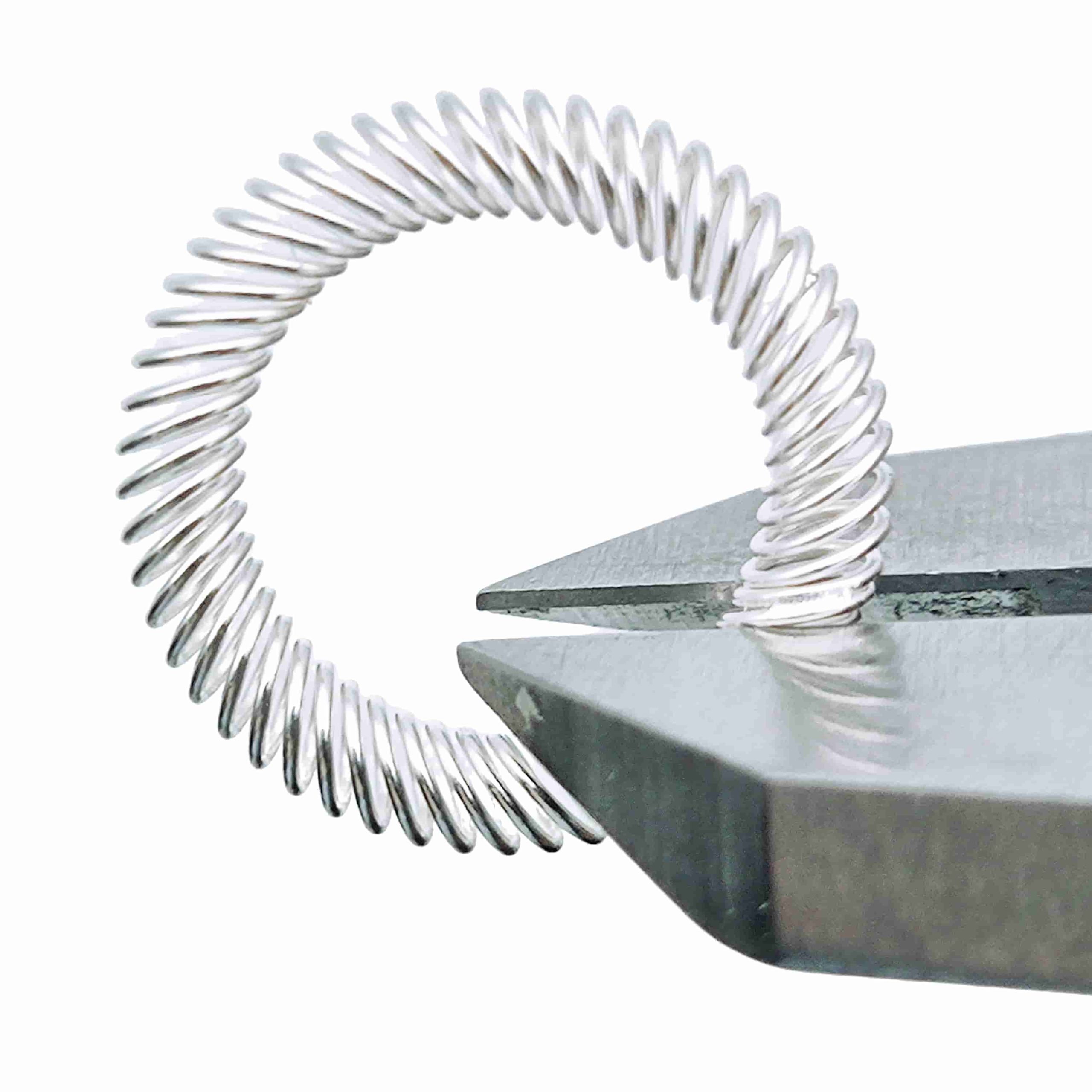

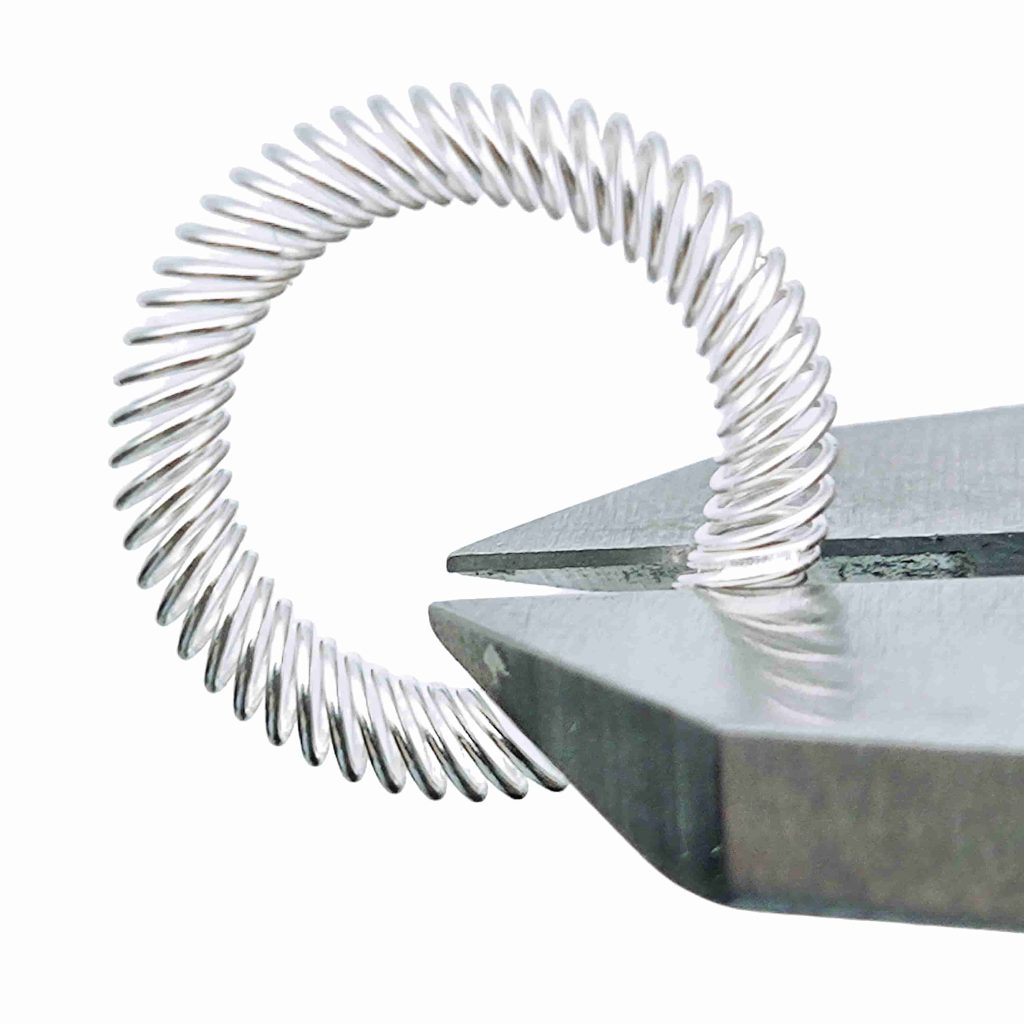

EMI shielding springs are specialized springs that offer both mechanical and electromagnetic shielding capabilities. Their canted coil design features coils arranged at an angle, which creates multiple points of contact when compressed. This allows the spring to function as both a mechanical component and a highly effective EMI/RFI shield.

Electromagnetic interference is a significant concern in modern electronic devices, where external or internal EMI can disrupt signals and affect performance. EMI shielding springs are designed to protect sensitive electronic components from EMI and RFI while also providing mechanical and electrical benefits, such as conductivity, grounding, and secure latching.

Key Features of EMI Shielding Canted Coil Springs

- Dual Functionality (Spring and Shield): One of the defining characteristics of EMI shielding springs is their ability to serve both as a spring and as an EMI/RFI shield. This dual functionality makes them highly versatile and valuable in compact electronic designs.

- Multiple Points of Contact: The canted coil design provides multiple points of contact, improving electrical conductivity and shielding performance. These multiple contact points ensure consistent and reliable contact, even under shock, vibration, or other mechanical stresses.

- Broad EMI Spectrum Attenuation: EMI shielding springs are highly effective across a wide range of frequencies, including high-frequency EMI. This makes them particularly suitable for applications where small package sizes and high-frequency signals require reliable shielding.

- Tunable to Specific Impedance: EMI shielding springs can be customized to meet specific impedance requirements. This is particularly important in applications where impedance matching is required to ensure optimal electrical performance.

- Multi-functional Capabilities: In addition to providing EMI shielding, these springs can also serve as mechanical latching and electrical conducting components. This versatility makes them ideal for use in connectors, latches, and grounding applications.

Applications of EMI Shielding Canted Coil Springs

EMI shielding canted coil springs are used in a wide range of applications across multiple industries. Their ability to protect sensitive electronics from interference while providing mechanical functionality makes them invaluable in the following areas:

1. Electronic Enclosures

Electronic devices often generate EMI that can interfere with other components or external devices. EMI shielding canted coil springs are commonly used in electronic enclosures to provide effective shielding and prevent the escape or intrusion of unwanted electromagnetic signals. They can be integrated into the edges of enclosures, doors, and panels to ensure proper shielding and grounding.

2. Power Management Systems

Power management systems in automotive, aerospace, and industrial applications are highly susceptible to EMI. EMI shielding canted coil springs are used in these systems to ensure that electromagnetic interference does not affect the performance of critical components such as transformers, regulators, and power distribution units.

3. Antenna Bases

Antenna systems, particularly in communications equipment, require precise shielding to ensure signal integrity. EMI shielding springs are used in antenna bases to minimize interference and ensure that antennas transmit and receive signals without disruption.

4. Waveguide Flanges

In high-frequency systems such as waveguides, EMI shielding springs are used to maintain proper electromagnetic isolation and minimize signal leakage. Their flexibility and ability to conform to uneven surfaces make them ideal for sealing waveguide flanges and other high-frequency components.

5. Coaxial and Electrical Connectors

EMI shielding springs are commonly used in coaxial and electrical connectors, where they serve a dual purpose by providing both electrical contact and EMI shielding. They help maintain consistent conductivity between connector interfaces while shielding the connection from external interference.

6. Medical Devices

In medical devices, EMI shielding is crucial to ensure the safety and reliability of sensitive electronic components. EMI shielding canted coil springs are used in medical equipment, such as imaging systems and monitoring devices, to provide reliable shielding and electrical connectivity while maintaining compact form factors.

7. Aerospace and Defense

The aerospace and defense industries often require components that can withstand extreme environmental conditions while providing reliable performance. EMI shielding canted coil springs are used in various aerospace and defense applications to protect electronic systems from interference, ensuring critical systems function without disruption.

Materials and Construction of EMI Shielding Canted Coil Springs

The performance of EMI shielding canted coil springs is largely determined by the materials used in their construction. Common materials include:

1. Copper Alloy

Copper alloys are frequently used in EMI shielding springs due to their excellent electrical conductivity and corrosion resistance. Copper alloy springs provide reliable EMI shielding and are often used unplated in many applications where conductivity and corrosion resistance are the primary concerns.

2. Stainless Steel

Stainless steel is known for its strength and durability, making it an excellent choice for EMI shielding springs that need to withstand harsh environmental conditions. While stainless steel is not as conductive as copper, it can be plated with more conductive metals, such as nickel or gold, to enhance its performance in EMI shielding and electrical contact applications.

3. Beryllium Copper

Beryllium copper offers a unique combination of high strength, corrosion resistance, and electrical conductivity. This makes it a popular choice for EMI shielding canted coil springs used in demanding environments, such as aerospace and military applications. Beryllium copper springs can also be plated with gold, silver, or other conductive materials to improve performance.

4. Nickel Plating

For enhanced corrosion resistance and conductivity, some EMI shielding springs are plated with nickel. Nickel-plated springs provide a good balance of electrical performance and durability, making them suitable for use in harsh environments.

Benefits of EMI Shielding Canted Coil Springs

EMI shielding springs offer numerous benefits that make them highly effective for EMI/RFI shielding and mechanical applications. These benefits include:

1. Effective EMI/RFI Shielding

The primary advantage of EMI shielding canted coil springs is their ability to provide reliable protection against electromagnetic and radio frequency interference. Their canted coil design ensures consistent shielding performance across a broad frequency range, making them ideal for applications with high-frequency signals.

2. Reliable Contact Under Stress

EMI shielding canted coil springs are designed to maintain consistent contact with mating surfaces, even under conditions of shock, vibration, or movement. This ensures reliable electrical performance and mechanical latching in dynamic environments where other types of springs may fail.

3. Superior Attenuation

These springs offer superior attenuation across the EMI spectrum, especially in high-frequency applications. This makes them an excellent choice for compact electronic devices where space is limited, but high shielding performance is required.

4. Customizable to Meet Specific Requirements

EMI shielding canted coil springs can be tuned to meet specific impedance and electrical requirements, ensuring optimal performance for each application. Their customizable design allows engineers to specify the exact dimensions, force, and electrical properties needed for their particular use case.

5. Multi-functional:

In addition to shielding, EMI shielding canted coil springs can perform multiple roles, such as providing mechanical latching, electrical conductivity, and grounding. This versatility reduces the need for multiple components, simplifying design and reducing costs.

Standards Compliance for EMI Shielding Canted Coil Springs

To ensure that EMI shielding springs provide reliable performance across various industries and applications, they are designed to meet a wide range of national and international EMC (Electromagnetic Compatibility) and EMI standards. These include:

- CISPR: International standards for controlling radio-frequency interference.

- IEC 61000: Electromagnetic compatibility standards for electrical and electronic equipment.

- ISO: International Organization for Standardization standards for various industries, including electronics and automotive.

- SAE: Standards set by the Society of Automotive Engineers for automotive electronics.

- FCC Part 15: U.S. Federal Communications Commission standards for devices that emit radio-frequency energy.

- MIL-STD: U.S. military standards for electromagnetic interference and environmental conditions.

Meeting these standards ensures that EMI shielding canted coil springs provide effective protection against interference and comply with the regulatory requirements for each industry.

Considerations When Using EMI Shielding Canted Coil Springs

While EMI shielding springs offer many advantages, there are a few key considerations to keep in mind:

1. Design Complexity

The design of EMI shielding springs requires careful consideration of factors such as coil dimensions, compression force, and shielding effectiveness. Engineers must ensure that the spring’s design is optimized for the specific application to provide the best performance.

2. Material Selection

Selecting the appropriate material for the spring is critical to achieving the desired balance of electrical conductivity, corrosion resistance, and mechanical strength. Different materials and coatings may be required based on the operating environment and electrical requirements.

3. Installation Requirements

Proper installation is essential for ensuring that EMI shielding canted coil springs perform as expected. Depending on the application, specialized tools or techniques may be needed to install the springs correctly and maintain consistent contact.

4. Cost Considerations

While EMI shielding canted coil springs offer significant benefits, they can be more expensive than traditional shielding solutions. However, their long-term reliability, versatility, and ability to serve multiple functions often offset the initial cost.

Conclusion

EMI shielding springs are a highly effective solution for protecting sensitive electronics from electromagnetic and radio frequency interference. Their unique canted coil design provides multiple points of contact for consistent shielding, electrical conductivity, and mechanical latching, making them an invaluable component in many industries, from aerospace and defense to medical devices and consumer electronics.

By offering reliable EMI/RFI attenuation, multi-functional capabilities, and the ability to withstand harsh environments, EMI shielding springs are a versatile and reliable choice for engineers looking to protect electronic components from interference while ensuring mechanical stability.

You May Also Like

-

Multi-use Stick-on Mounting Fingerstrips with Excellent EMI Shielding Effect

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Electromagnetic interference (EMI) can create significant issues for electronic devices and systems, leading to decreased performance, potential malfunction, or even failure. This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications. These adhesive-backed beryllium-copper strips are designed to be easily installed without the need for specialized tools, providing an efficient and cost-effective way to shield electronics from EMI. In this article, we will explore the features, applications, benefits, and importance of stick-on mounting fingerstrips in EMI shielding. Whether you are working in telecommunications, computer hardware, or any industry where electromagnetic interference poses a risk, stick-on fingerstrips can provide a practical solution. Key Features of Stick-on Mounting Fingerstrips1. Adhesive Backing2. Low-Profile Design3. Beryllium-Copper Construction4. Bi-directional Sealing5. Adjustable SizeApplications of Stick-on Mounting Fingerstrips1. Telecommunications Equipment2. Narrow Electronics Enclosures3. General EMI Shielding Applications4. Computer HardwareBenefits of Stick-on Mounting Fingerstrips1. Easy Installation2. Consistent Sealing3. Flexibility4. Durability5. VersatilityHow Stick-on Mounting Fingerstrips Help with EMI ShieldingMinimizing Electromagnetic InterferenceMaintaining Performance in High-EMI EnvironmentsEnhancing System ReliabilityConclusion Stick-on Mounting Fingerstrips https://www.handashielding.com/contact-us.html Key Features of Stick-on Mounting Fingerstrips When choosing an EMI shielding solution, it’s important to focus on certain key features to ensure that the product you select meets your......

-

High EMI Shielding Effect Snap-on mounting fingerstrips

High EMI Shielding Effect Snap-on mounting fingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to maintaining the functionality and performance of sensitive electronic devices. Snap-on mounting fingerstrips are designed for easy installation, flexibility, and efficient shielding, making them a popular choice across numerous industries, including telecommunications, military, aerospace, automotive, and consumer electronics. This article will provide a detailed exploration of snap-on mounting fingerstrips, focusing on their key features, materials, installation methods, applications, and benefits. Additionally, we will explore why snap-on mounting fingerstrips are an essential component in modern electronics and how they meet the demands of EMI/RFI shielding requirements. https://www.handashielding.com/contact-us.html What are Snap-On Mounting Fingerstrips?Key Features of Snap-On Mounting FingerstripsTypes of Snap-On Mounting FingerstripsInstallation Method of Snap-On Mounting FingerstripsCommon Applications of Snap-On Mounting FingerstripsMaterial Options for Snap-On Mounting FingerstripsBenefits of Using Snap-On Mounting FingerstripsConclusion: Snap-On Mounting Fingerstrips in EMI Shielding What are Snap-On Mounting Fingerstrips? Snap-on mounting fingerstrips are flexible EMI shielding gaskets made from materials such as beryllium copper, phosphor bronze, or other conductive alloys. They are specifically designed to create a secure electrical......

-

Highly Versatile and Indispensable Conductive Copper Foil Tape

Highly Versatile and Indispensable Conductive Copper Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components. This comprehensive guide explores the key features, applications, types, properties, performance, and industries in which conductive copper foil tape plays a crucial role. Key Features of Conductive Copper Foil TapeTypes of Conductive Copper Foil TapeApplications of Conductive Copper Foil TapeProperties and Performance of Conductive Copper Foil TapeConsiderations for Choosing Conductive Copper Foil Tape Conductive Copper Foil Tape Key Features of Conductive Copper Foil Tape Conductive copper foil tape is designed to meet the high demands of modern electronic and industrial applications. Below are its defining features: 1. Electrical Conductivity One of the primary advantages of conductive copper foil tape is its excellent electrical conductivity. Copper, being one of the most conductive materials, allows electrical signals to flow efficiently across surfaces. This makes the tape an essential component in applications that require grounding, EMI (Electromagnetic Interference) shielding, or electrical signal transmission between two or more components. 2. Chemical Resistance Conductive copper foil......

-

Electrical Conductivity Aluminum Foil Tape

Electrical Conductivity Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Electrical conductivity aluminum foil tape is a versatile and essential material in various industries, particularly in electronics, electrical engineering, and construction. This article delves deep into the properties, applications, benefits, and selection criteria for electrical conductivity aluminum foil tape, focusing on why it is indispensable for ensuring electrical continuity, shielding, and grounding. https://www.handashielding.com/contact-us.html What is Electrical Conductivity Aluminum Foil Tape?Key Properties of Electrical Conductivity Aluminum Foil TapeApplications of Electrical Conductivity Aluminum Foil TapeBenefits of Using Electrical Conductivity Aluminum Foil TapeSelection Criteria for Electrical Conductivity Aluminum Foil TapeConclusion What is Electrical Conductivity Aluminum Foil Tape? Electrical conductivity aluminum foil tape is a specialized adhesive tape made from thin aluminum foil coated with an electrically conductive adhesive. This tape is designed to offer excellent conductivity across its surface and through its adhesive, making it ideal for applications requiring reliable electrical connections and shielding. The aluminum foil provides a conductive surface, while the adhesive ensures that the tape adheres firmly to various substrates while maintaining electrical conductivity. Key Properties of Electrical Conductivity Aluminum Foil Tape 1. Electrical Conductivity The primary feature of aluminum foil tape is its excellent electrical conductivity. Both the aluminum foil and the conductive adhesive are designed to allow current......

-

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

High Shielding Effectiveness EMI Shielding Fingerstock GasketsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

In today's increasingly complex electronic landscape, electromagnetic interference (EMI) shielding has become a critical concern for device manufacturers and designers. One effective solution for addressing EMI issues is the use of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets. These specialized components play a vital role in protecting electronic devices from unwanted electromagnetic radiation and maintaining electromagnetic compatibility (EMC). What is EMI Shielding?The Role of EMI Shielding Fingerstock GasketsAdvantages of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConstruction and Materials of High Shielding Effectiveness EMI Shielding Fingerstock GasketsApplications of High Shielding Effectiveness EMI Shielding Fingerstock GasketsPerformance Metrics of Fingerstock GasketsChallenges and ConsiderationsFuture Trends in EMI ShieldingCase Studies of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConclusion What is EMI Shielding? Electromagnetic interference (EMI) refers to the disruption of electronic circuits and systems caused by electromagnetic radiation from external sources. This interference can manifest as noise, signal degradation, or complete system malfunctions. EMI can be generated by a variety of sources including electrical devices, communication systems, and even natural phenomena. To combat EMI, shielding techniques are employed to block or attenuate electromagnetic waves. EMI shielding involves creating a barrier that prevents the interference from penetrating sensitive areas of electronic devices. Effective EMI shielding ensures......