Handa Endur Shield to safeguard sensitive electronic equipment

Handa Endur Shield is a premium electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solution designed to safeguard sensitive electronic equipment from external interference. As the world becomes increasingly reliant on electronics, particularly in critical industries like telecommunications, aerospace, medical technology, and defense, protecting devices from EMI and RFI is crucial. Handa Endur Shield stands out in this domain as a reliable, durable, and customizable product designed for high-performance shielding.

Handa Endur Shield is a premium electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solution designed to safeguard sensitive electronic equipment from external interference. As the world becomes increasingly reliant on electronics, particularly in critical industries like telecommunications, aerospace, medical technology, and defense, protecting devices from EMI and RFI is crucial. Handa Endur Shield stands out in this domain as a reliable, durable, and customizable product designed for high-performance shielding.

Table of Contents

Handa Endur Shield

What is EMI and Why Does Shielding Matter?

Electromagnetic interference (EMI) refers to the disturbance caused by electromagnetic radiation from one electronic device that affects the functionality of another. This interference can range from mild disruptions to complete system failure, depending on the intensity of the interference and the sensitivity of the affected equipment. RFI (Radio Frequency Interference) is a specific type of EMI that occurs in the radio frequency spectrum. Both EMI and RFI are significant concerns in electronic design, particularly in industries that depend on flawless performance, like aerospace, military, medical, and telecommunications.

Shielding is the process of protecting devices from these external disruptions by using materials that either block or absorb the interference. Handa Endur Shield is engineered to offer robust shielding solutions, effectively preventing EMI/RFI from impacting the performance of sensitive electronics.

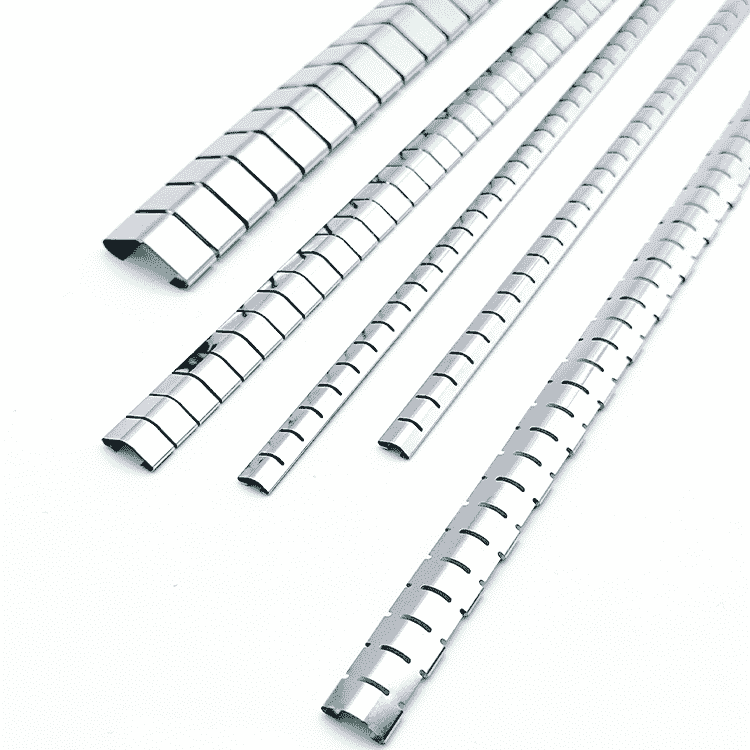

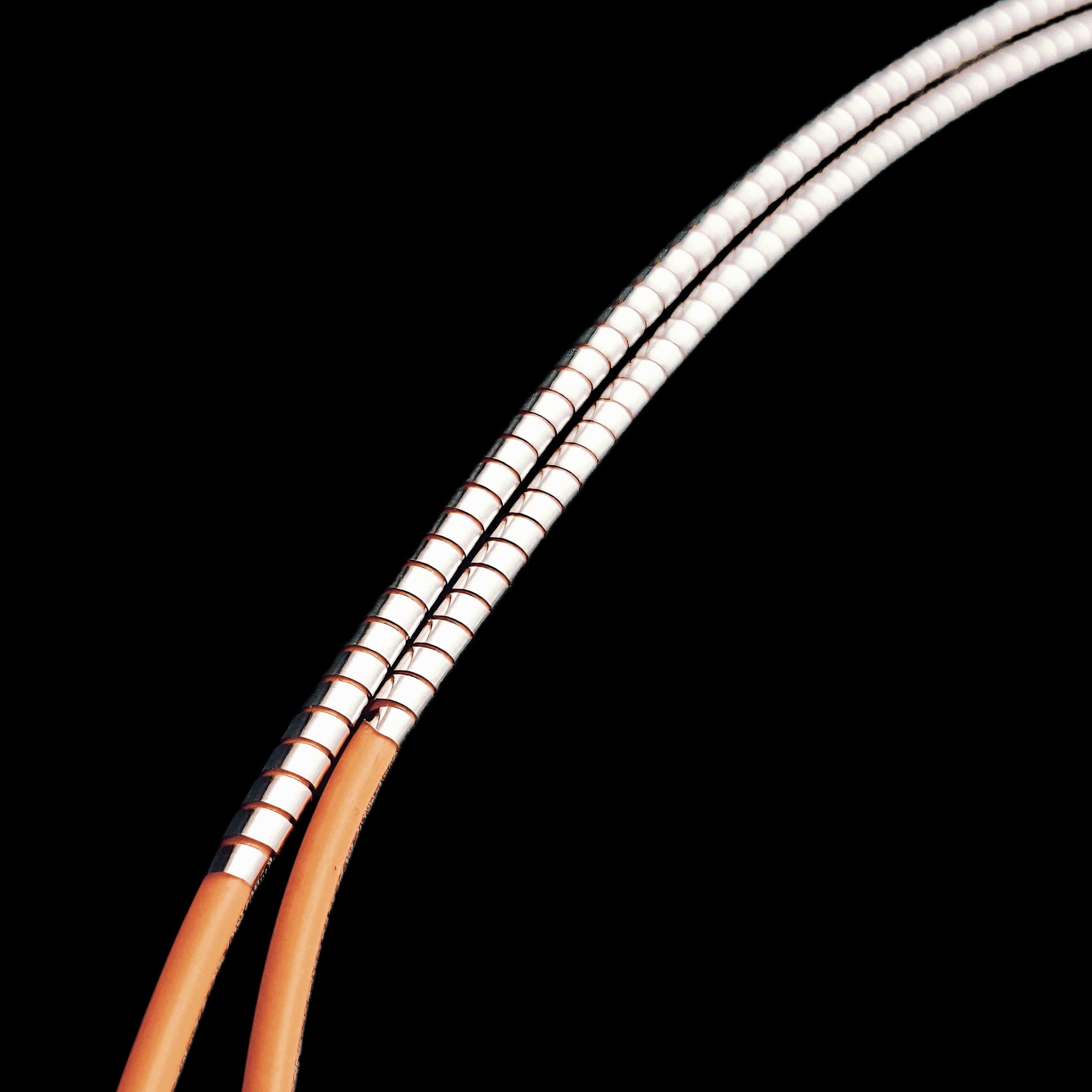

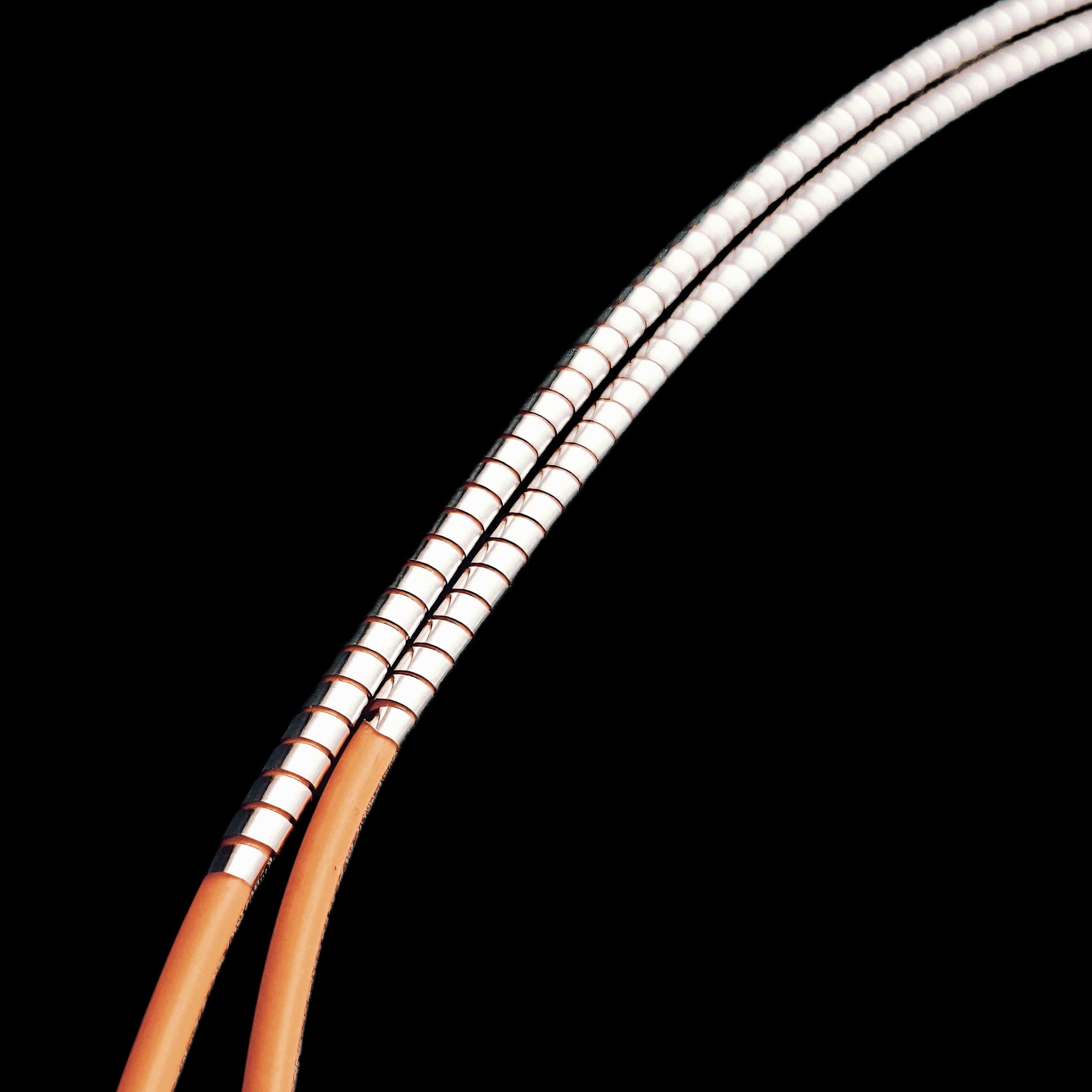

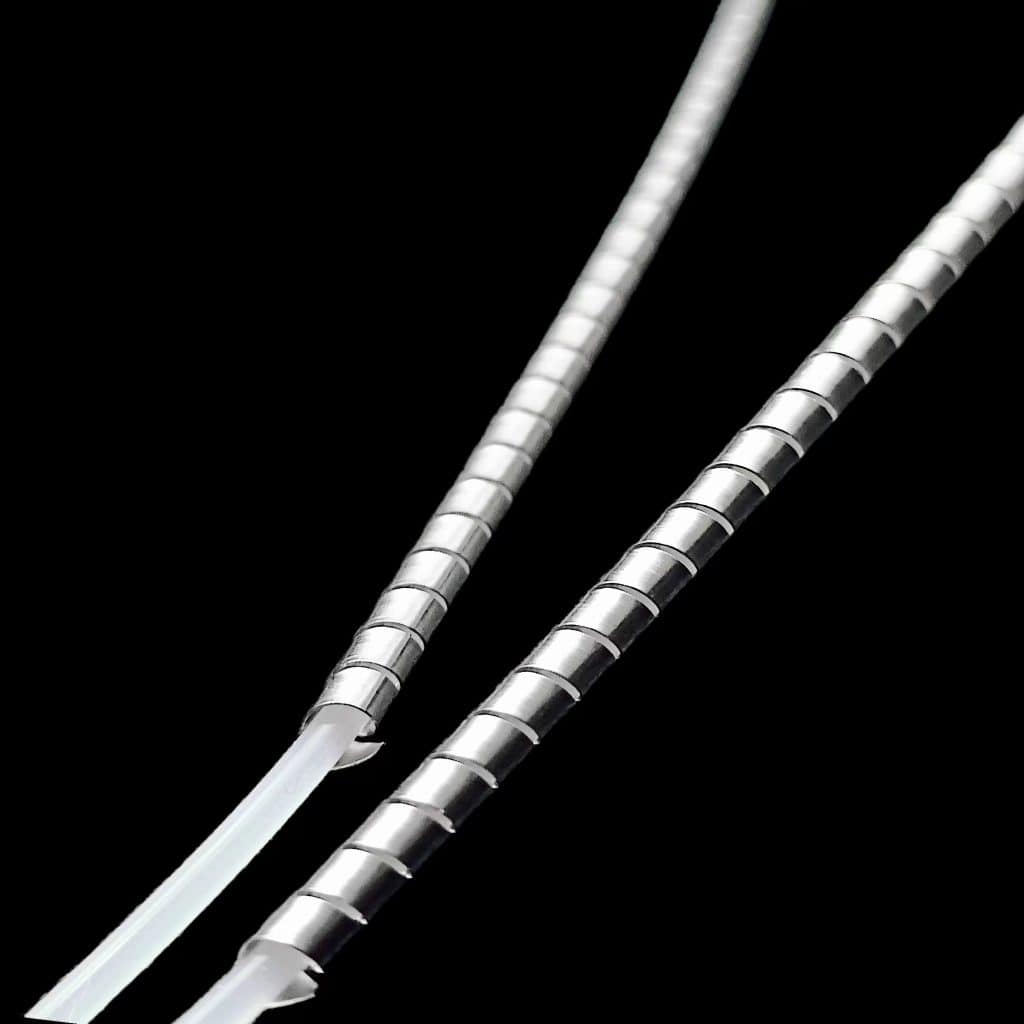

Key Features of Handa Endur Shield

- High Shielding Effectiveness:

Handa Endur Shield boasts exceptional shielding capabilities, with high attenuation levels across a broad frequency spectrum. This makes it particularly effective for applications that involve high-frequency signals, where other shielding methods might fail. - Durability and Longevity:

One of the standout features of Handa Endur Shield is its durability. It is designed to maintain its shielding effectiveness in extreme environmental conditions, including exposure to high and low temperatures, moisture, and corrosive substances. The materials used in its construction resist wear and tear, ensuring long-term protection. - Customizable Design:

Handa Shielding Systems understands that no two applications are alike. As such, the Handa Endur Shield can be customized in terms of size, shape, thickness, and material composition to suit the specific requirements of a project. This flexibility ensures that it can meet the unique challenges of various industries. - Ease of Installation:

The design of Handa Endur Shield allows for easy integration into existing systems. Whether used as a gasket, tape, or in a more complex assembly, it can be applied with minimal disruption to the device it’s protecting. This ease of installation translates to lower labor costs and reduced downtime during implementation. - Multi-functional:

Beyond shielding, Handa Endur Shield can serve multiple functions, including providing mechanical strength and environmental sealing. Its robust construction allows it to act as a physical barrier, protecting electronics from not only EMI/RFI but also dust, debris, and other contaminants.

Materials Used in Handa Endur Shield

The effectiveness of any shielding product depends largely on the materials used. Handa Endur Shield uses advanced conductive materials known for their ability to block or absorb electromagnetic waves. Some of the primary materials used in the construction of Handa Endur Shield include:

- Beryllium Copper: Known for its excellent conductivity and strength, beryllium copper is one of the most commonly used materials for EMI shielding. Its spring-like properties also make it ideal for applications that require both shielding and mechanical support.

- Stainless Steel: Stainless steel is favored for its durability and resistance to corrosion. While not as conductive as copper, it offers a balance of strength and shielding effectiveness, particularly in harsh environments.

- Nickel-plated Copper: For applications requiring superior conductivity and corrosion resistance, nickel-plated copper is an excellent choice. The nickel plating enhances the material’s resistance to oxidation, making it suitable for outdoor or high-moisture environments.

- Conductive Fabrics and Foils: In more flexible applications, conductive fabrics and foils may be used. These materials offer high malleability and can be easily integrated into complex shapes and designs.

Each material choice depends on the specific requirements of the application, such as the environmental conditions, frequency range of the EMI/RFI, and mechanical stresses involved.

Applications of Handa Endur Shield Across Industries

1. Telecommunications

Telecommunication equipment is highly susceptible to EMI due to the high-frequency signals used in communication networks. Interference can result in poor signal quality, dropped calls, and slow data transmission. Handa Endur Shield provides the necessary protection for:

- Antenna Systems: Prevents signal degradation in antennas and receivers, ensuring clear communication.

- Base Stations: Protects critical communication infrastructure from external electromagnetic disturbances.

2. Medical Technology

In the medical industry, precision and reliability are paramount. Devices such as MRI machines, CT scanners, and patient monitoring systems require EMI shielding to ensure accurate readings and safe operation. Handa Endur Shield offers superior protection for:

- Imaging Equipment: Shielding ensures that medical imaging devices provide clear, accurate images without interference from external electromagnetic sources.

- Portable Medical Devices: Ensures the safe operation of life-saving portable devices, such as pacemakers and defibrillators, by protecting them from nearby electronic devices.

3. Aerospace and Defense

In aerospace and military applications, the stakes are incredibly high. Equipment failure due to EMI can result in mission failure or even loss of life. Handa Endur Shield is trusted in this industry for:

- Avionics: Provides EMI shielding for critical aircraft systems, ensuring safe and reliable operation in the electromagnetic-rich environment of modern aircraft.

- Military Communication Systems: Ensures that communication systems remain operational even in environments with high levels of electromagnetic interference.

4. Consumer Electronics

As consumer devices become more sophisticated and interconnected, the need for effective EMI shielding grows. Handa Endur Shield is used in:

- Smartphones: Ensures that smartphones can function in a variety of environments without interference from other electronic devices.

- Wearable Technology: Protects sensitive wearable devices, such as smartwatches and fitness trackers, from nearby electronic devices and radio frequencies.

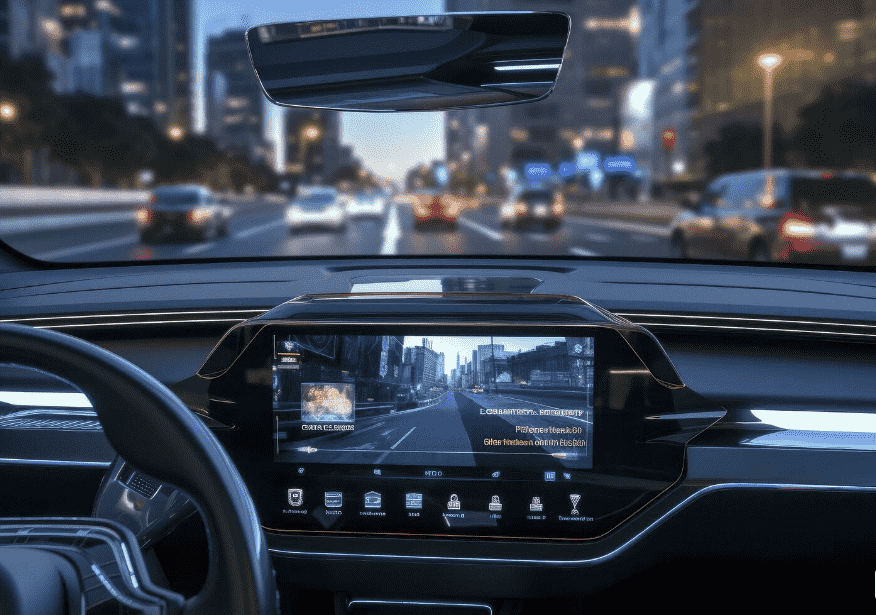

5. Automotive Electronics

Modern vehicles are packed with electronics, from infotainment systems to advanced driver-assistance systems (ADAS). Handa Endur Shield provides the EMI protection needed to ensure that these systems function correctly without interference.

Customization and Tailored Solutions

One of the key advantages of Handa Endur Shield is its ability to be customized for specific applications. Handa Shielding Systems offers a range of customization options, including:

- Size and Shape: Handa Endur Shield can be manufactured to fit virtually any size or shape requirement, ensuring a perfect fit for the device or enclosure.

- Material Composition: Depending on the environmental conditions and performance requirements, the material composition of the shield can be adjusted. For example, a more conductive material might be used in high-frequency applications, while a more corrosion-resistant material could be chosen for outdoor or marine environments.

- Thickness: The thickness of the shield can be adjusted to provide the necessary level of protection without adding unnecessary bulk or weight to the system.

These customization options ensure that Handa Endur Shield can meet the unique challenges of any application, from small consumer devices to large industrial systems.

Conclusion

Handa Endur Shield is a high-performance, customizable EMI/RFI shielding solution designed to meet the needs of various industries, including telecommunications, medical technology, aerospace, defense, and consumer electronics. Its combination of durability, flexibility, and shielding effectiveness makes it an ideal choice for applications requiring reliable protection from electromagnetic interference.

With its advanced materials, customizable design, and compliance with industry standards, Handa Endur Shield represents a versatile and cost-effective solution for EMI/RFI shielding needs across a wide range of environments. As electronic devices become more complex and interconnected, the demand for effective shielding solutions like Handa Endur Shield will only continue to grow.

You May Also Like

-

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing Capabilities

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing CapabilitiesShielding Gasket Solutions and Materials

Electrically conductive rubber profiles

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with the ability to conduct electricity. This makes them essential in various applications, particularly in sectors where electrical performance and mechanical reliability are critical. These specialized components are manufactured by incorporating conductive fillers, such as carbon black or metal particles, into rubber polymers. This article explores the features, benefits, applications, and manufacturing processes of electrically conductive rubber profiles, shedding light on their importance in modern industrial settings. What Are Electrically Conductive Rubber Profiles?Key Features and BenefitsApplications of Electrically Conductive Rubber ProfilesManufacturing Process of Electrically Conductive Rubber ProfilesConclusion Electrically Conductive Rubber Profiles What Are Electrically Conductive Rubber Profiles? Electrically conductive rubber profiles are rubber components engineered to facilitate the flow of electrical current while retaining the inherent advantages of rubber, such as flexibility, resilience, and sealing capabilities. They are particularly valuable in environments where both electrical and mechanical performance are paramount. Composition and Materials The primary materials used in electrically conductive rubber profiles include: Rubber Polymers: The base material that provides flexibility and durability. Commonly used types include natural rubber, silicone rubber, and neoprene. Conductive Fillers: These materials are......

-

EMI shielding canted coil springs with unique canted coil design

EMI shielding canted coil springs with unique canted coil designHanda Canted Coil Springs

EMI Shielding Springs

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique canted coil design, which enables them to provide multiple points of contact for superior EMI shielding, mechanical latching, and electrical conductivity. What Are EMI Shielding Canted Coil Springs?Applications of EMI Shielding Canted Coil SpringsMaterials and Construction of EMI Shielding Canted Coil SpringsBenefits of EMI Shielding Canted Coil SpringsStandards Compliance for EMI Shielding Canted Coil SpringsConsiderations When Using EMI Shielding Canted Coil SpringsConclusion https://www.handashielding.com/contact-us.html What Are EMI Shielding Canted Coil Springs? EMI shielding springs are specialized springs that offer both mechanical and electromagnetic shielding capabilities. Their canted coil design features coils arranged at an angle, which creates multiple points of contact when compressed. This allows the spring to function as both a mechanical component and a highly effective EMI/RFI shield. Electromagnetic interference is a significant concern in modern electronic devices, where external or internal EMI can disrupt signals and affect performance. EMI shielding springs are designed to protect sensitive electronic components from EMI and RFI while also providing mechanical and electrical......

-

Multi-use Stick-on Mounting Fingerstrips with Excellent EMI Shielding Effect

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Electromagnetic interference (EMI) can create significant issues for electronic devices and systems, leading to decreased performance, potential malfunction, or even failure. This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications. These adhesive-backed beryllium-copper strips are designed to be easily installed without the need for specialized tools, providing an efficient and cost-effective way to shield electronics from EMI. In this article, we will explore the features, applications, benefits, and importance of stick-on mounting fingerstrips in EMI shielding. Whether you are working in telecommunications, computer hardware, or any industry where electromagnetic interference poses a risk, stick-on fingerstrips can provide a practical solution. Key Features of Stick-on Mounting Fingerstrips1. Adhesive Backing2. Low-Profile Design3. Beryllium-Copper Construction4. Bi-directional Sealing5. Adjustable SizeApplications of Stick-on Mounting Fingerstrips1. Telecommunications Equipment2. Narrow Electronics Enclosures3. General EMI Shielding Applications4. Computer HardwareBenefits of Stick-on Mounting Fingerstrips1. Easy Installation2. Consistent Sealing3. Flexibility4. Durability5. VersatilityHow Stick-on Mounting Fingerstrips Help with EMI ShieldingMinimizing Electromagnetic InterferenceMaintaining Performance in High-EMI EnvironmentsEnhancing System ReliabilityConclusion Stick-on Mounting Fingerstrips https://www.handashielding.com/contact-us.html Key Features of Stick-on Mounting Fingerstrips When choosing an EMI shielding solution, it’s important to focus on certain key features to ensure that the product you select meets your......

-

High EMI Shielding Effect Snap-on mounting fingerstrips

High EMI Shielding Effect Snap-on mounting fingerstripsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to maintaining the functionality and performance of sensitive electronic devices. Snap-on mounting fingerstrips are designed for easy installation, flexibility, and efficient shielding, making them a popular choice across numerous industries, including telecommunications, military, aerospace, automotive, and consumer electronics. This article will provide a detailed exploration of snap-on mounting fingerstrips, focusing on their key features, materials, installation methods, applications, and benefits. Additionally, we will explore why snap-on mounting fingerstrips are an essential component in modern electronics and how they meet the demands of EMI/RFI shielding requirements. https://www.handashielding.com/contact-us.html What are Snap-On Mounting Fingerstrips?Key Features of Snap-On Mounting FingerstripsTypes of Snap-On Mounting FingerstripsInstallation Method of Snap-On Mounting FingerstripsCommon Applications of Snap-On Mounting FingerstripsMaterial Options for Snap-On Mounting FingerstripsBenefits of Using Snap-On Mounting FingerstripsConclusion: Snap-On Mounting Fingerstrips in EMI Shielding What are Snap-On Mounting Fingerstrips? Snap-on mounting fingerstrips are flexible EMI shielding gaskets made from materials such as beryllium copper, phosphor bronze, or other conductive alloys. They are specifically designed to create a secure electrical......

-

Highly Versatile and Indispensable Conductive Copper Foil Tape

Highly Versatile and Indispensable Conductive Copper Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components. This comprehensive guide explores the key features, applications, types, properties, performance, and industries in which conductive copper foil tape plays a crucial role. Key Features of Conductive Copper Foil TapeTypes of Conductive Copper Foil TapeApplications of Conductive Copper Foil TapeProperties and Performance of Conductive Copper Foil TapeConsiderations for Choosing Conductive Copper Foil Tape Conductive Copper Foil Tape Key Features of Conductive Copper Foil Tape Conductive copper foil tape is designed to meet the high demands of modern electronic and industrial applications. Below are its defining features: 1. Electrical Conductivity One of the primary advantages of conductive copper foil tape is its excellent electrical conductivity. Copper, being one of the most conductive materials, allows electrical signals to flow efficiently across surfaces. This makes the tape an essential component in applications that require grounding, EMI (Electromagnetic Interference) shielding, or electrical signal transmission between two or more components. 2. Chemical Resistance Conductive copper foil......