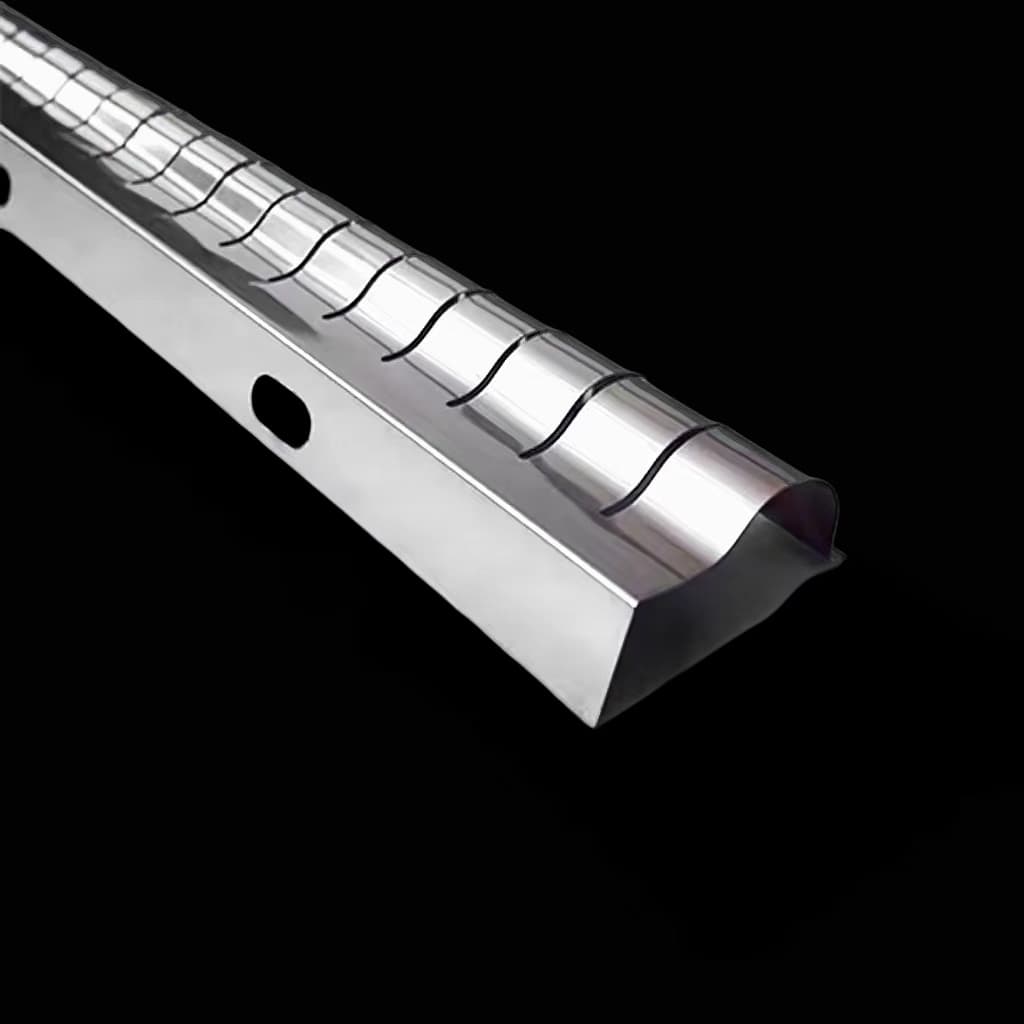

Right-angle shielding fingerstrip

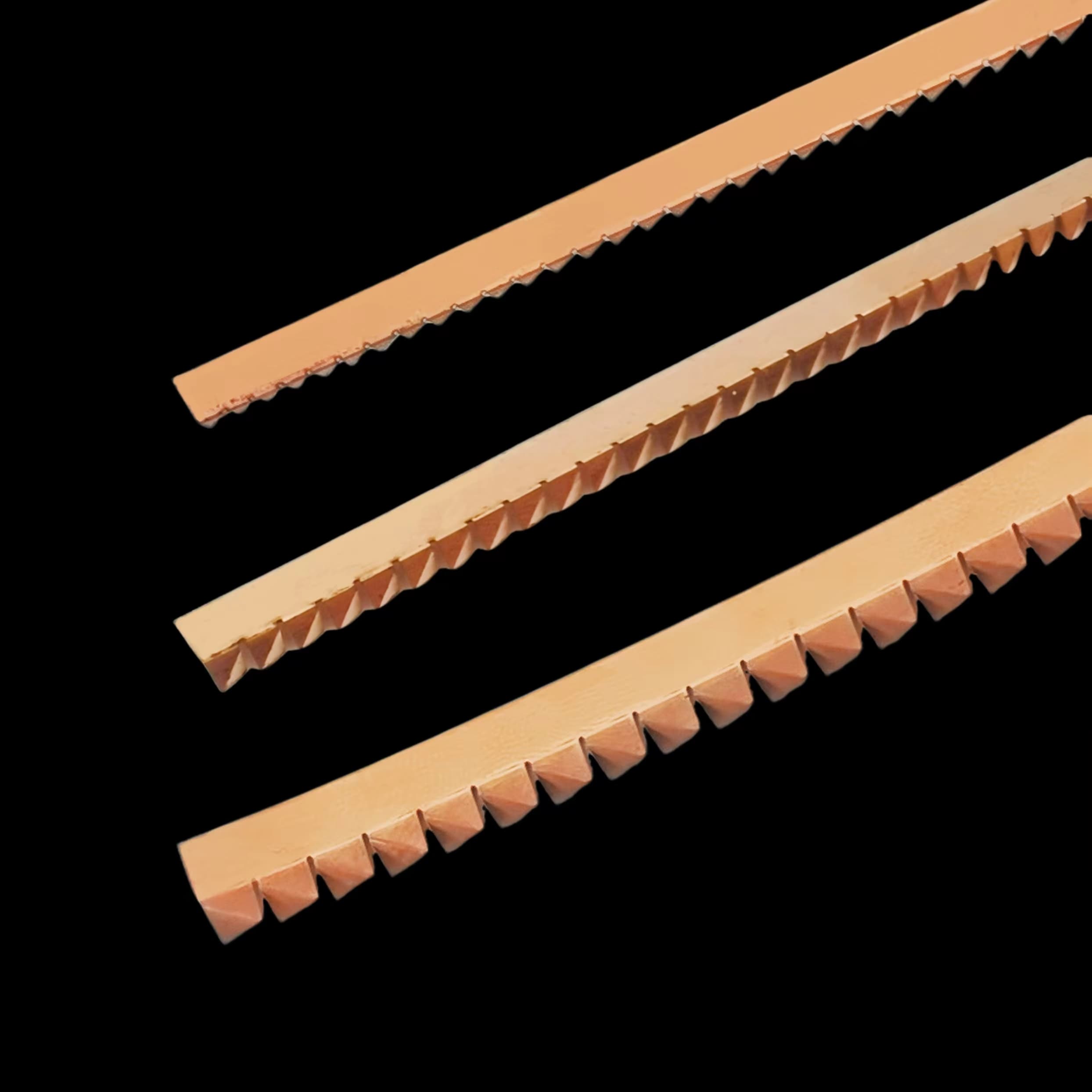

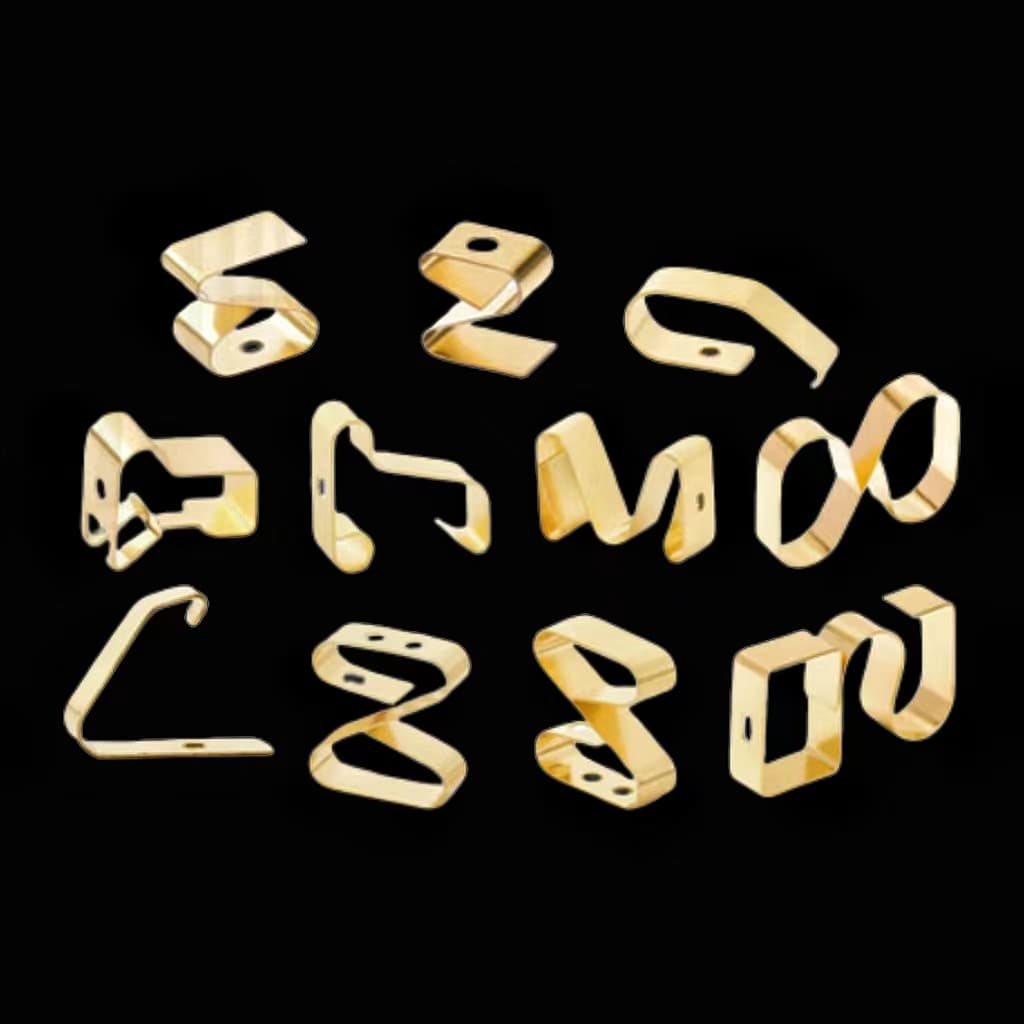

Handa Right-angle shielding fingerstrip Series of RFI/EMI shielding products is specifically designed for applications requiring a 90-degree angle installation, where the shielding component needs to be mounted perpendicular to the finger compression area.

This series is ideal for scenarios where electromagnetic interference (EMI) or radio frequency interference (RFI) shielding is crucial, and the physical layout of the device or system necessitates a right-angle approach to achieve effective shielding.

Product Specs

Size specification

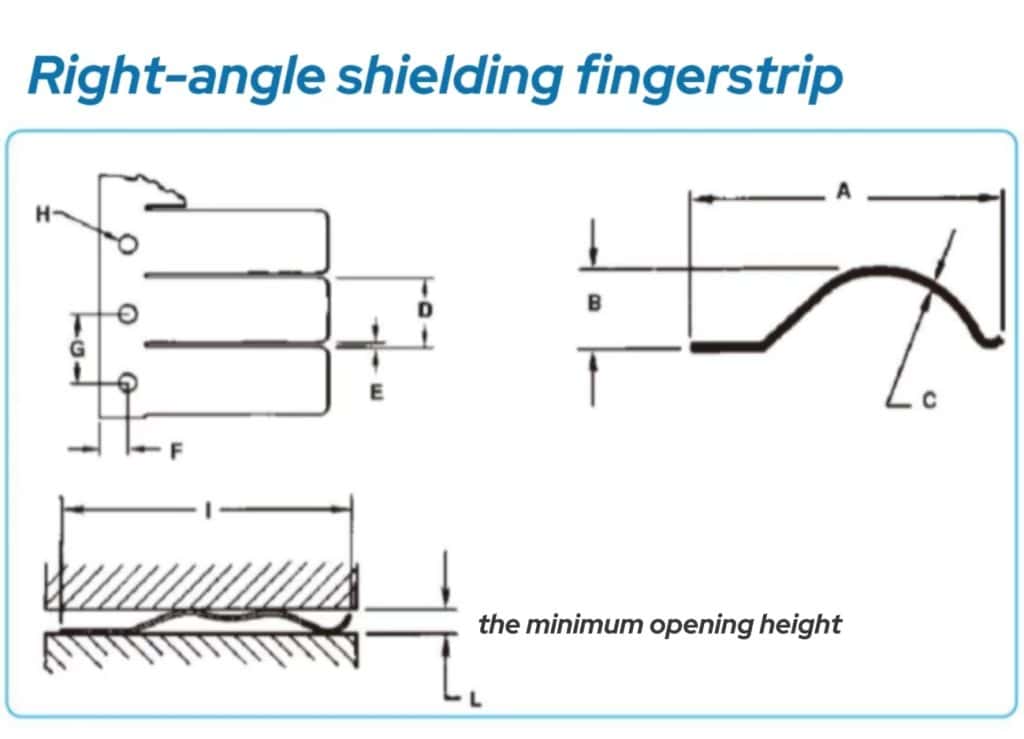

Handa Right-angle shielding fingerstrips dimensions vary by manufacturer and product model. The following are some possible dimensional specifications, but please note that specific specifications should be confirmed with Handa shielding to meet the requirements of the specific application:

| No. | A | B | C | D | E | F | G | H | I | L | length(mm) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 97-4380 | 27.67 | 6.35 | 0.13 | 9.53 | 1.02 | 4.06 | 9.65 | 3.56 | 32.26 | 2.03 | 610.00 |

| 97-4400 | 41.40 | 10.41 | 0.18 | 12.70 | 1.02 | 4.83 | 12.70 | 3.56 | 48.26 | 2.54 | 610.00 |

| 97-6400 | 27.69 | 6.6 | 0.13 | 9.53 | 1.02 | – | 9.53 | 3.56 | 42.3 | 2.03 | 406.00 |

Custom Manufacturing

Custom Right-angle shielding fingerstrip

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Right-angle shielding fingerstrip Manufacturing

Manufacturing right-angle shielding fingerstrips involves a series of steps:

1. Design and Dimensioning

(1)Dimensioning: Determine the exact dimensions (length, width, thickness) based on the specific application requirements.

(2)Angle Adjustment.

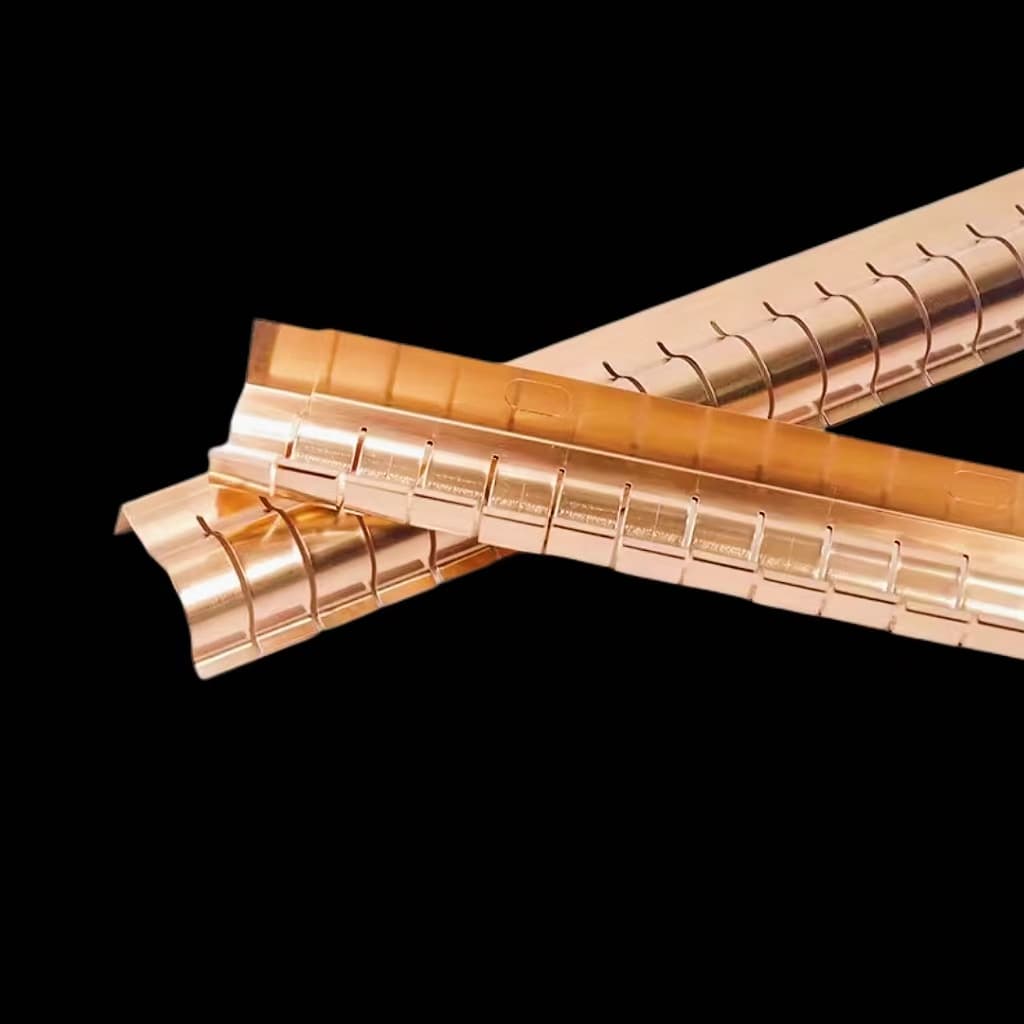

2. Fabrication Process:

(1)Photoetching: This process is commonly used for fabricating parts with complex shapes and features, including right-angle fingerstrips.

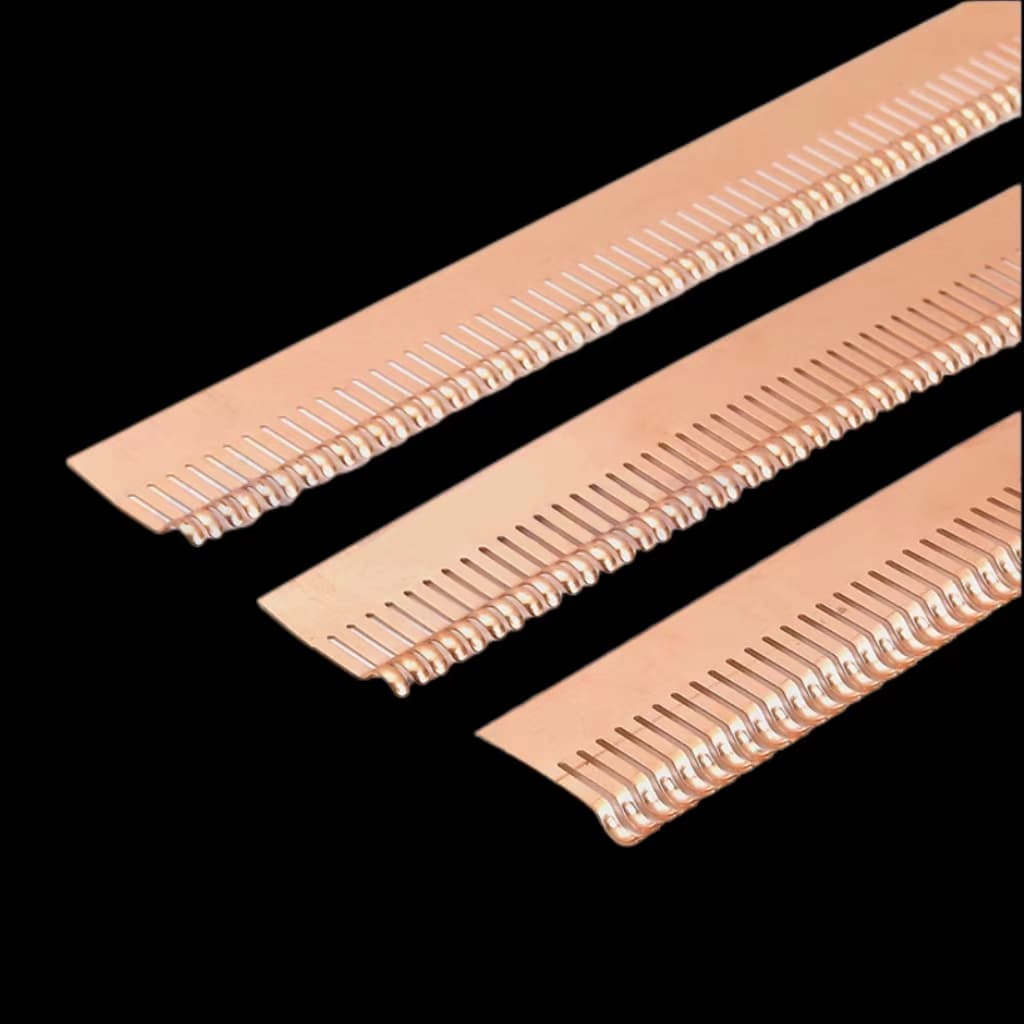

(2)Material Preparation: Handa Shielding usually choose Beryllium Copper (BeCu) due to its high electrical conductivity, corrosion resistance, and fatigue strength.

3. Surface Treatment:Tin plating is a common finish for these components.

4. Assembly:Ensure the final product are correctly oriented for the intended 90-degree mounting application.

5. Testing:Conduct thorough testing to verify the shielding effectiveness.

6. Packaging:Proper packaging is crucial to protect the fingerstrips during transportation and storage.

Considerations

Customization: Handa Shielding offers a wide range of standard and custom EMI shielding fingerstrips to meet various application requirements.

Benefits

The design of Handa Right-angle shielding fingerstrip Series takes into account the side pressure required. In addition, this series of reeds has very good durability and a large compression range.

- Good conductive grounding performance

- Excellent mechanical tensile strength

- Stable performance under extreme temperature conditions

- Accept custom treatment of various electroplating processes

Applications

Handa Right-angle shielding fingerstrip Series finds extensive use in electronics manufacturing. Anywhere precise control over electromagnetic emissions and susceptibility is required, these products play a critical role.

- computer hardware

- telecommunications equipment

- automotive electronics

- Shielded chassis and nacelle

- Shielded car and house

- Telecommunications equipment, communication equipment

- Shielding laboratory, darkroom and other shielding doors and Windows

Material and Plating

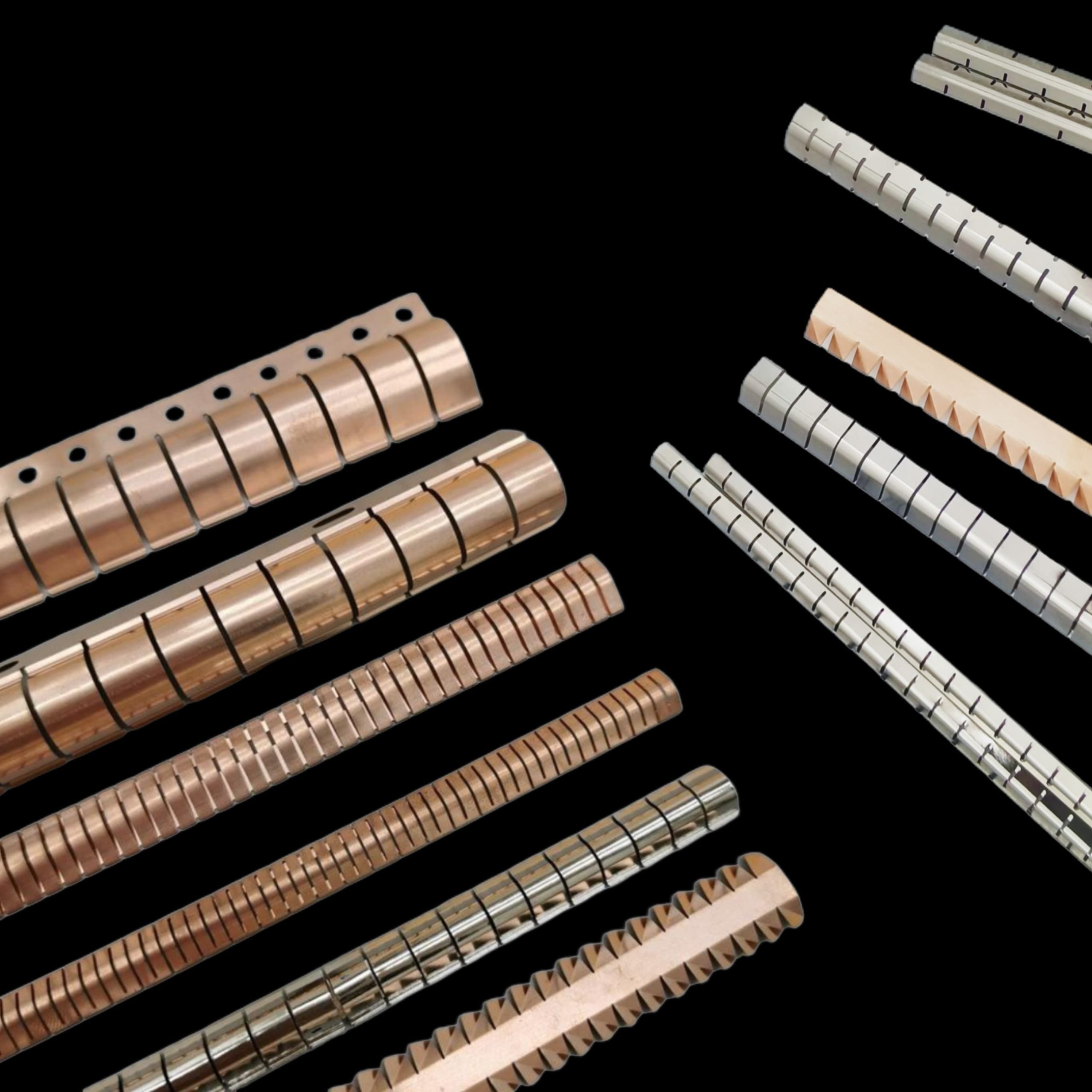

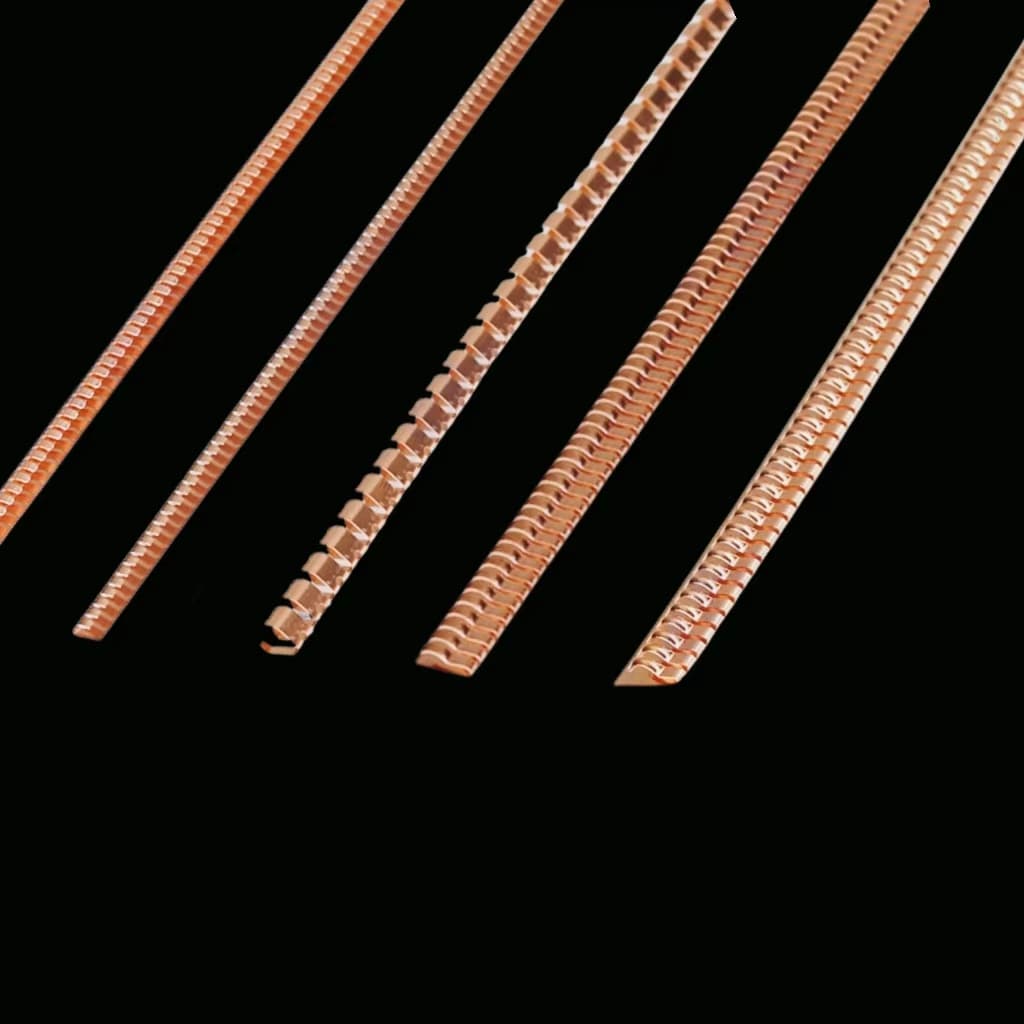

Handa Right-angle shielding fingerstrip Series are available in the following materials.They can also be customized according to your requirement for different applications.

- Beryllium-copper

- Stainless steel

- Beryllium-copper tin plated

- Phosphorous bronze

- Beryllium-copper nickle plated

Key Points

Design Purpose

The primary purpose of Handa Right-angle shielding fingerstrips is to provide effective EMI/RFI shielding in configurations where components are arranged at a 90-degree angle relative to each other. This is particularly useful in electronic devices and systems where maintaining electromagnetic compatibility (EMC) is essential.

Material Composition

These products are made from beryllium-copper alloys, known for their excellent electrical conductivity, durability, and resistance to corrosion. This material choice ensures that the shielding remains effective over time and under various operating conditions.

Installation Considerations

Due to their angled design, these fingerstrips need careful consideration during installation to ensure proper alignment and compression. Incorrect installation will affect the shielding effectiveness.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

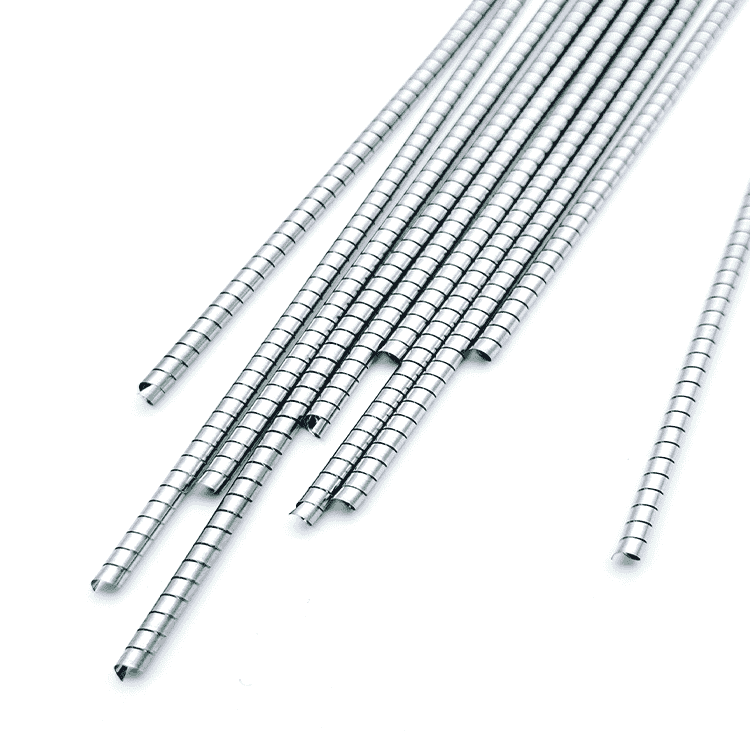

EMI (Electromagnetic Interference) shielding spiral tube gaskets are critical components in many electronic and industrial applications, designed to protect sensitive equipment from electromagnetic......

-

Introduction Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI)......