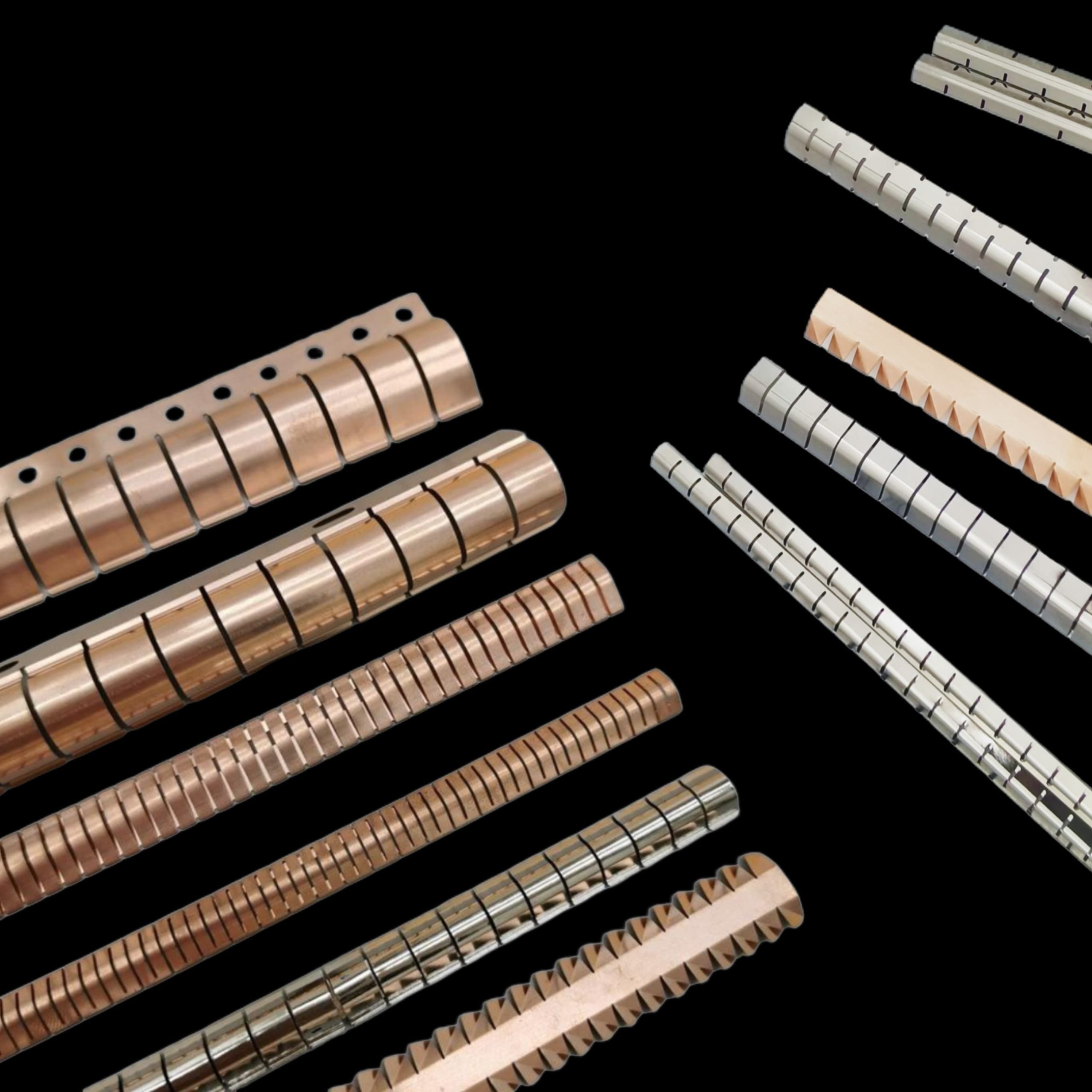

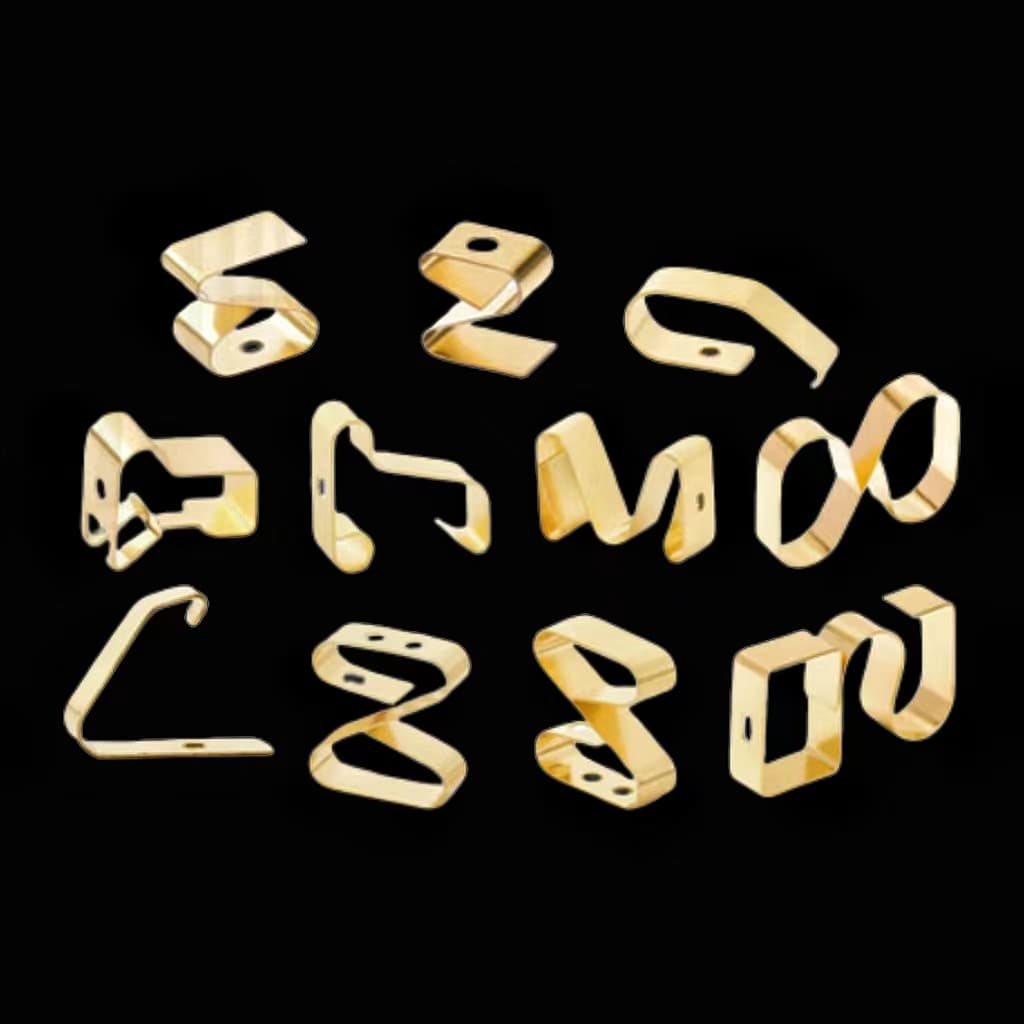

Circular fingerstrip

Handa Circular fingerstrips are a specialized type of EMI/RFI shielding product designed to protect against electromagnetic interference and radio frequency interference in circular openings or gaps between conductive surfaces.

These products are commonly used in electronic enclosures, cabinets, and other areas where circular apertures exist that require shielding to maintain electromagnetic compatibility (EMC).

Custom Manufacturing

Custom Circular fingerstrip

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions needs for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

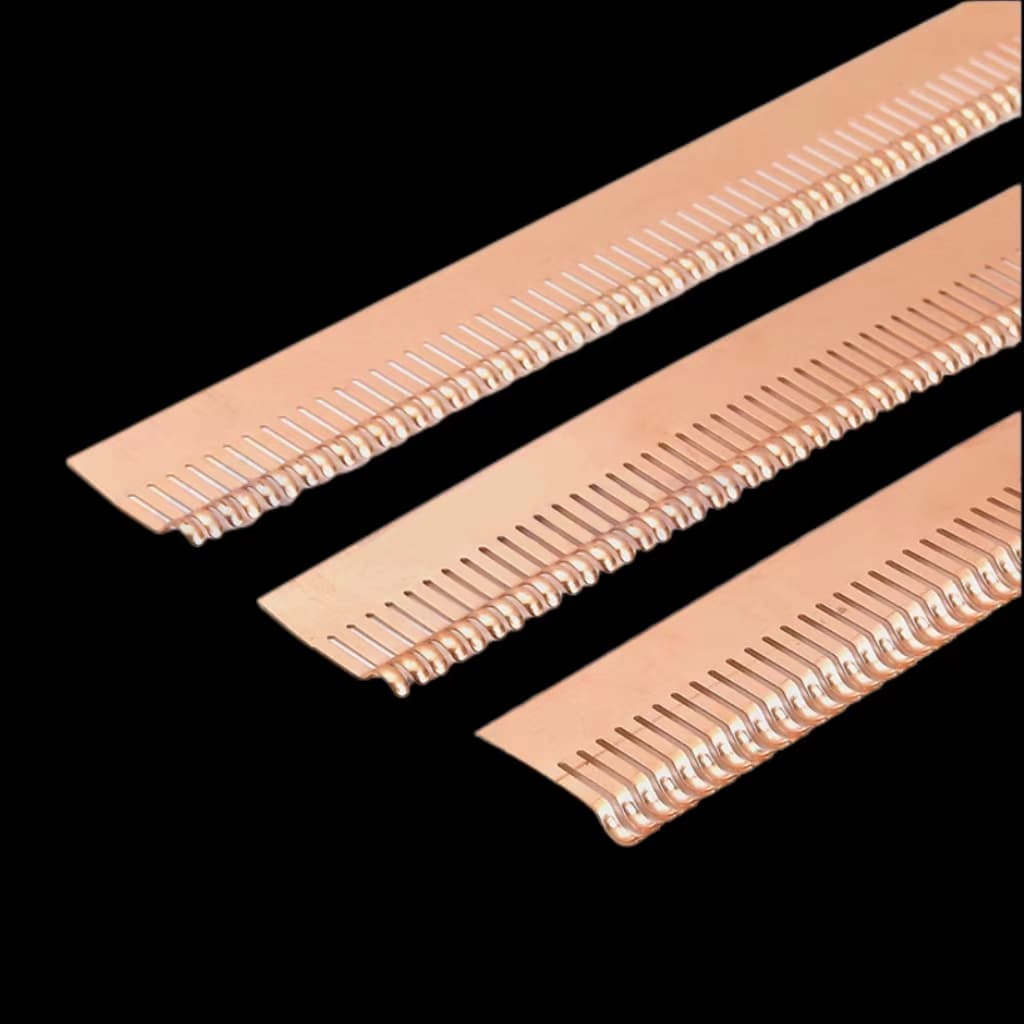

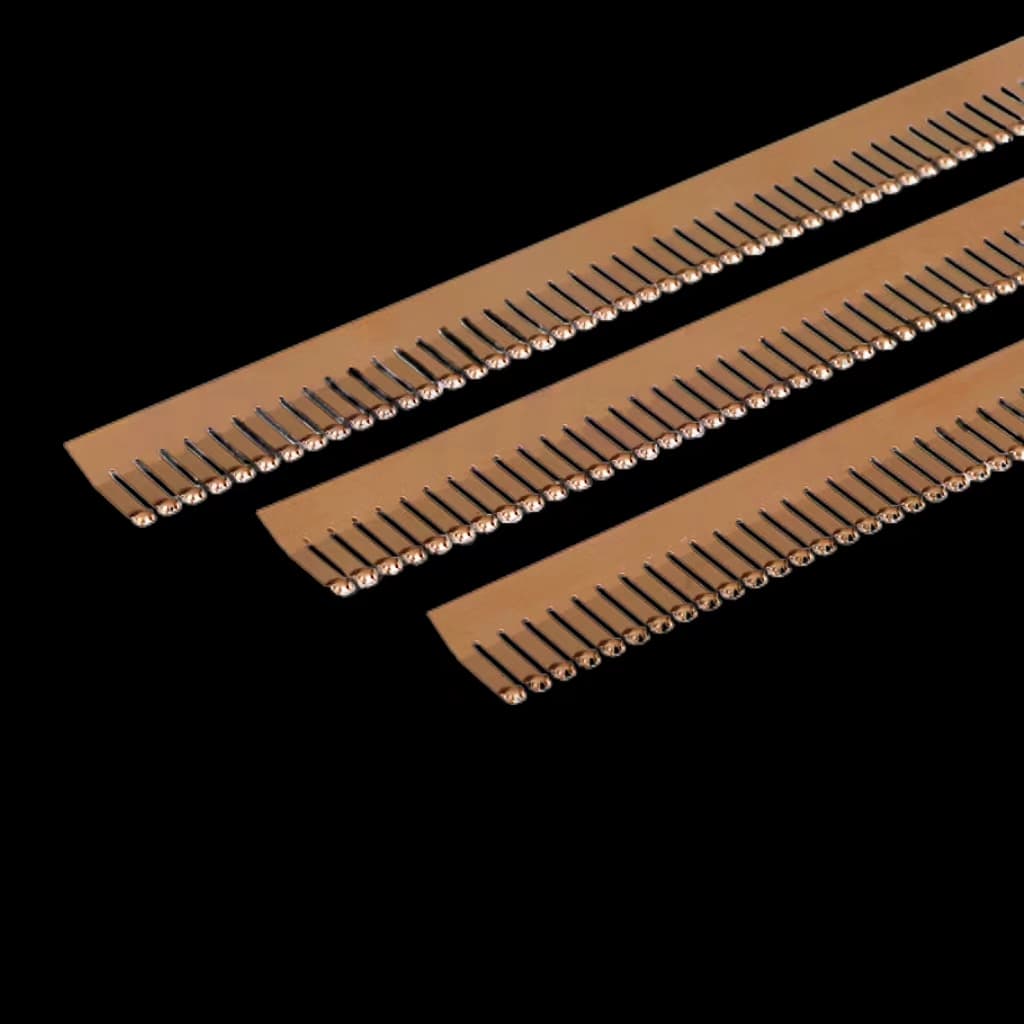

Circular fingerstrip Manufacturing

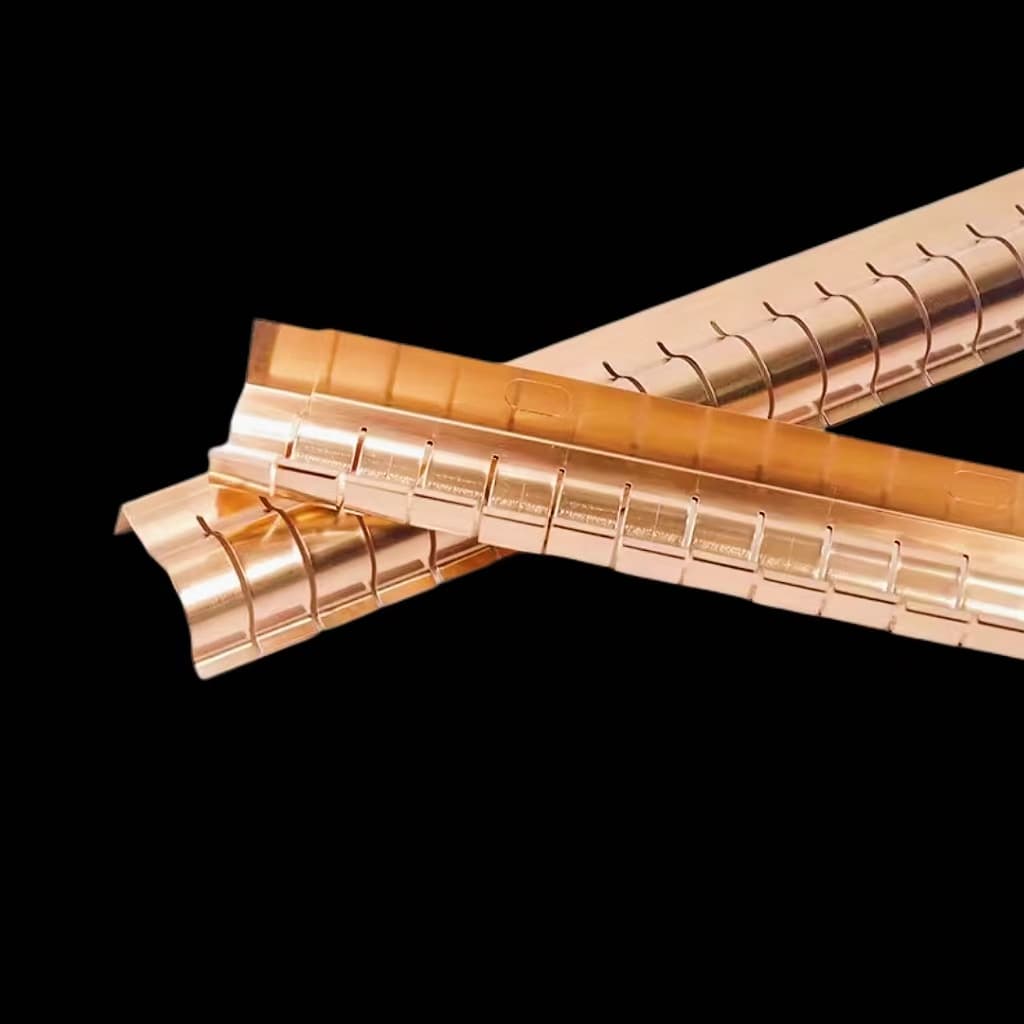

Manufacturing circular fingerstrips involves the following steps tailored to create products that effectively ground and shield against electromagnetic interference (EMI) in high-frequency equipment and form large diameter round contact rings:

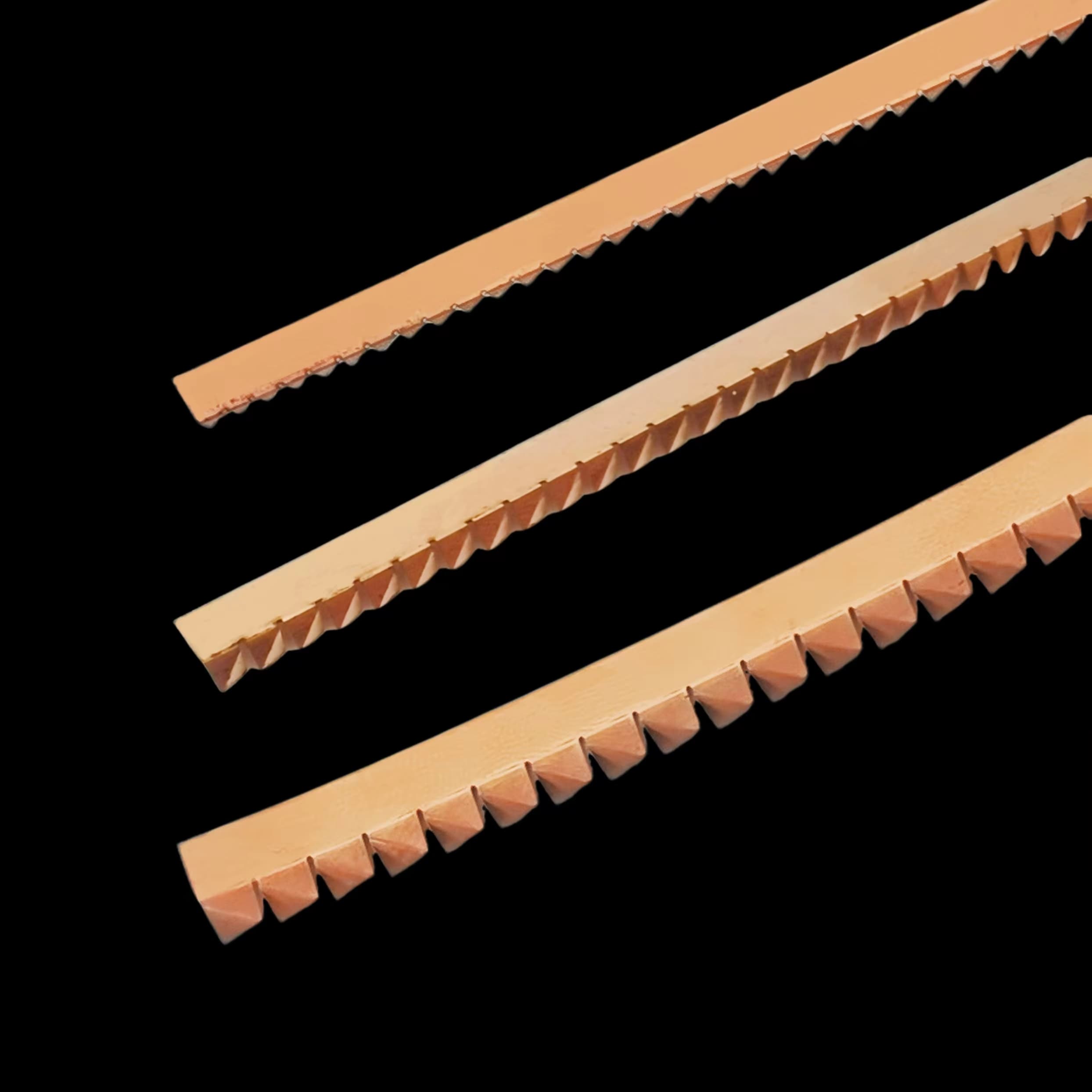

1. Material Selection:Handa Shielding usually selects beryllium copper (BeCu) as the primary material because of its high electrical conductivity, corrosion resistance, and fatigue strength.

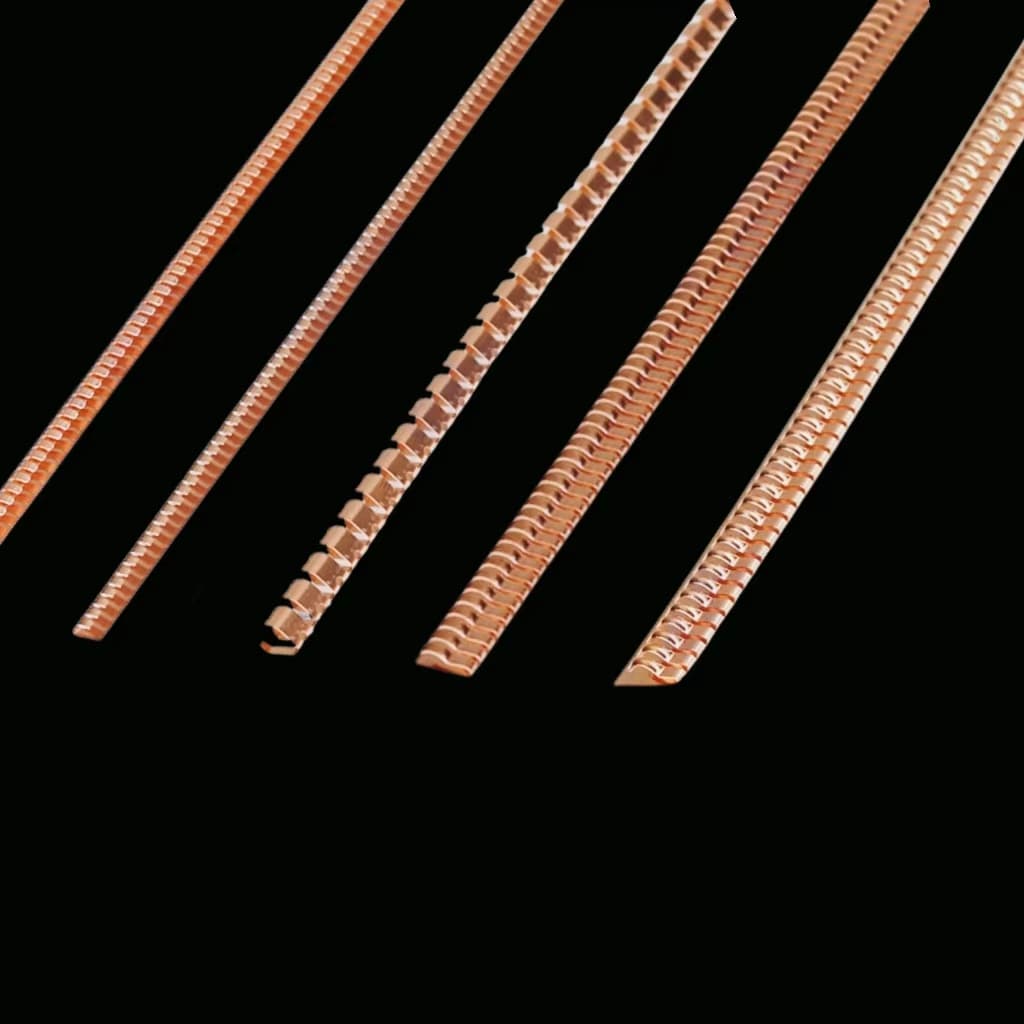

2. Design Dimensions and Thickness: Determine the specific dimensions (length, width, thickness) and material thickness required for the circular fingerstrip.

3. Stamping or Extrusion: The primary method for producing circular fingerstrips involves stamping or extruding the beryllium-copper alloy into the desired shape.

4. Edge Finishing: After forming, the edges of the circular fingerstrip may require finishing to remove any sharp corners or burrs.

5. Surface Treatment: Optional surface treatments like plating or coating can be applied.

6. Testing: This may involve measuring the spring constant, conducting bend tests, and evaluating the shielding effectiveness at various frequencies.

7. Packaging and Delivery

(1)Packaging: Secure packaging is crucial to protect the circular fingerstrips from damage.

(2)Delivery Time: Typically within 5-10 working days, catering to the urgent needs of customers.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote