Conductive Contact Finger Springs / Canted Coil Springs for Conducting Electricity:Versatile Solutions for Reliable Electrical Connections

Conductive contact finger springs, also known as canted coil springs or slant coil springs, provide an excellent solution for achieving high-integrity electrical connections in the challenging environments described above. These springs offer several advantages that set them apart from traditional electrical connection methods.

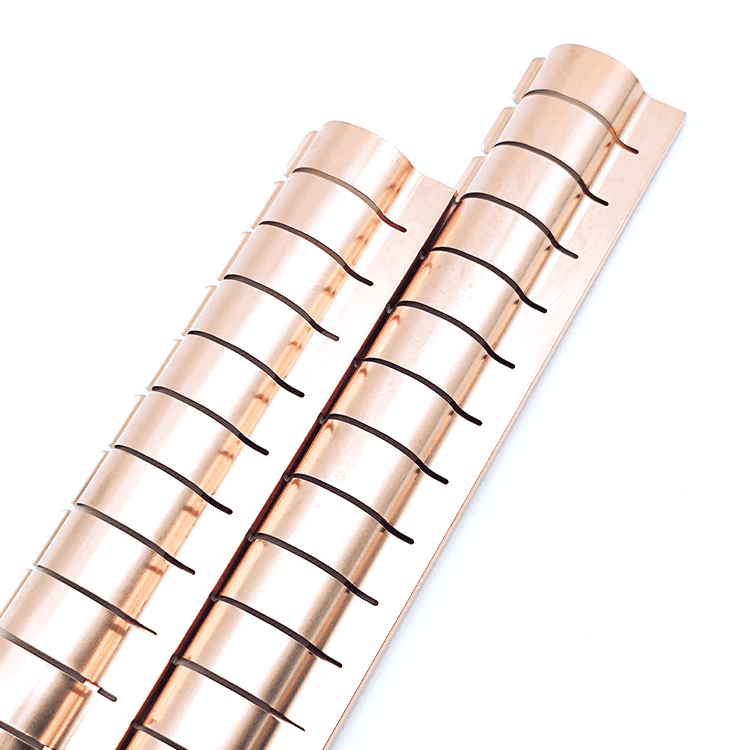

conductive contact finger springs

/conducting canted coil springs

Table of Contents

Electrically conductive contact finger springs are specialized components designed to serve as highly efficient electrical conductors in applications requiring robust electrical connections, even under challenging conditions such as vibration, dynamic loads, and mechanical shock. These finger springs are often used in various industrial, automotive, and high-tech environments where maintaining electrical integrity is crucial. This article will explore the advantages, applications, and technical considerations of electrically conductive contact finger springs, with an emphasis on their use in environments where consistent electrical conductivity is critical.

The Challenge of Maintaining Reliable Conductivity

In many industrial settings, maintaining a reliable electrical connection can be a significant challenge. Various operational conditions, such as vibration, mechanical shock, and dynamic loads, can make it difficult for traditional electrical connections to remain secure. For instance, in the petrochemical industry, downhole tools are exposed to extreme forces and harsh environments that can loosen traditional electrical connections, compromising both signal transmission and power integrity.

In applications involving electric vehicle (EV) and hybrid electric vehicle (HEV) battery packs, consistent motion and vibration can also threaten the integrity of electrical connections. As a result, the electrical system’s overall efficiency and reliability may suffer. Similarly, in the power industry, high-current applications responsible for conduction, grounding, and isolation can experience heat buildup and reliability issues due to high currents passing through poorly designed connections.

Additionally, rotating parts, high temperatures, and load variations pose further challenges for maintaining electrical connections, particularly in applications like wind turbines or robotic systems. In such cases, traditional connection methods may degrade over time, leading to performance issues and even equipment failure.

Moreover, the demand for lightweight design in industries such as unmanned vehicles necessitates components that are compact yet reliable, capable of delivering high performance within limited space. Some applications, such as semiconductor manufacturing, may also require solutions that perform multiple functions, such as combining latching, holding, or locking with EMI shielding and electrical conduction.

Conductive Contact Finger Springs: A Reliable Solution

Conductive contact finger springs, also known as canted coil springs or slant coil springs, provide an excellent solution for achieving high-integrity electrical connections in the challenging environments described above. These springs offer several advantages that set them apart from traditional electrical connection methods.

Consistent Force Across Wide Deflection Range

One of the key benefits of conductive finger springs is their ability to maintain consistent force across a broad range of deflection. This characteristic is critical in applications where surface irregularities, misalignments, or dimensional variations are common. Regardless of changes in the surface or environment, the individual coils of the spring maintain constant contact with the mating surface, ensuring that the connection remains intact.

This continuous contact makes these springs particularly suitable for applications with vibration, angular misalignment, or tolerance variations, where traditional connectors might lose contact and lead to signal or power loss. Additionally, finger springs exhibit minimal compression set, making them ideal for applications where the connection may need to be maintained over long periods or under varying loads.

Multiple Contact Points for Reliable Conductivity

Each coil of the finger spring serves as an individual contact point, creating multiple conductive paths. This feature ensures that even if some of the coils lose contact due to surface irregularities or dynamic motion, others will continue to provide a reliable electrical connection. As a result, consistent conductivity can be maintained even in environments where other connection methods may fail.

Superior Conductive Properties

The materials used in the construction of finger springs further enhance their conductive properties. In addition to being made from highly conductive materials, such as beryllium copper or stainless steel, these springs can be customized to meet specific electrical requirements. Variables such as spring diameter, wire thickness, coil height, inclination angle, and number of turns can all be adjusted to achieve the desired current-carrying capacity and electrical resistance.

For applications requiring extremely low impedance, finger springs can be plated with gold or silver to optimize conductivity. This plating not only improves electrical performance but also provides enhanced corrosion resistance, ensuring that the springs maintain their conductivity even in harsh environmental conditions.

Efficient Heat Management

One of the most notable advantages of conductive finger springs is their ability to manage heat effectively. The large surface area of the coils allows for the dissipation of heat generated during the conduction of high-power currents, reducing the risk of overheating. This thermal advantage is particularly important in applications involving high-power transmission, where heat buildup can be a significant concern.

In sensitive applications such as implantable medical devices, where excessive heat can pose safety risks to patients, the ability of finger springs to minimize heat generation is invaluable. In these applications, finger springs not only ensure reliable electrical conduction but also help maintain the safety and longevity of the device.

EMI/RF Shielding Capabilities

In addition to their conductive properties, finger springs can also function as EMI/RF shielding components. This capability is particularly useful in applications like downhole tools used in oil exploration, where equipment must be protected from electromagnetic interference (EMI). The conductive nature of the spring provides an effective barrier against radio frequency (RF) signals and electromagnetic fields, ensuring that sensitive electronic components are shielded from interference that could degrade performance.

Supporting SWaP (Space, Weight, and Power) Requirements

In industries where space, weight, and power (SWaP) requirements are critical, finger springs provide a compact and efficient solution. Their small size allows for greater contact density in a given area compared to traditional solutions. This feature is particularly important in applications where available space is limited, such as aerospace, defense, and semiconductor manufacturing.

Additionally, finger springs simplify the overall system by serving multiple functions. For example, in some applications, finger springs can be used to provide both electrical conduction and mechanical fastening functions (e.g., latching, locking, or holding). This versatility reduces the complexity of the system and allows for more efficient use of available space.

Low Insertion Force for Delicate Applications

Another key advantage of conductive finger springs is their ability to provide specific levels of force, including low insertion forces. This feature is particularly important in applications where delicate components are involved, and excessive force could damage the equipment or reduce its lifespan. The ability to fine-tune the force applied by the spring allows for precise control over the connection, ensuring that it remains secure without causing undue stress on the components.

Durability in Challenging Conditions

Conductive finger springs are engineered to withstand a wide range of challenging environmental conditions. As mentioned earlier, these springs maintain consistent electrical contact even in the presence of shock, vibration, angular misalignment, and tolerance variations. Their robust construction and ability to maintain performance in harsh environments make them ideal for industries such as automotive, aerospace, medical, and defense.

By using corrosion-resistant materials and protective coatings, such as gold or silver plating, finger springs maintain their conductive properties even when exposed to corrosive environments. Additionally, the springs’ minimal compression set contributes to their long lifespan, as they can withstand repeated insertion and removal cycles without experiencing significant deformation or loss of performance.

Cleanliness and Sterilization in Medical Applications

In industries such as medical, pharmaceutical, and food and beverage, cleanliness and the ability to maintain sterile conditions are of paramount importance. Finger springs are easy to clean and sterilize, making them well-suited for use in surgical equipment, implantable devices, and other medical technologies where contamination must be avoided.

Conclusion: The Versatility of Electrically Conductive Contact Finger Springs

Electrically conductive contact finger springs offer a highly reliable and efficient solution for maintaining robust electrical connections in a variety of industries, including transportation, aerospace, semiconductor manufacturing, industrial automation, energy, and defense. Their ability to provide consistent force across a wide range of deflections, multiple contact points for reliable conductivity, and superior thermal management makes them ideal for even the most challenging environments.

Whether in robotic systems, wind turbines, EV/HEV battery packs, or surgical tools, conductive contact finger springs provide a durable, efficient, and customizable solution for applications requiring high-integrity electrical connections. By simplifying system design and offering EMI shielding capabilities, these springs help industries meet evolving technological demands while maintaining performance and reliability.

You May Also Like

-

Handa Beryllium-Copper Fingerstrips/Fingerstocks with a variety of benefits

Handa Beryllium-Copper Fingerstrips/Fingerstocks with a variety of benefitsFingerstrips

Beryllium-copper fingerstrips series

https://www.handashielding.com/contact-us.html Handa Beryllium-Copper Fingerstrips/Fingerstocks with a variety of benefits Introduction to Handa Beryllium-Copper Fingerstrips/FingerstocksOverview of Beryllium-Copper as a MaterialKey Features of Handa Beryllium-Copper Fingerstrips/FingerstocksApplications of Handa Beryllium-Copper Fingerstrips/FingerstocksAdvantages of Using Handa Beryllium-Copper Fingerstrips/FingerstocksInstallation and Best PracticesConclusion Introduction to Handa Beryllium-Copper Fingerstrips/Fingerstocks Handa beryllium-copper fingerstrips, also known as fingerstocks, are highly efficient EMI (Electromagnetic Interference) shielding components. These products are essential in various industries, where sensitive electronic equipment requires protection from external electromagnetic and radio frequency interference (RFI). Beryllium-copper is a popular material for this purpose due to its outstanding combination of mechanical strength, electrical conductivity, and durability. As electronic devices become smaller and more integrated, the demand for highly effective shielding materials has increased. Handa beryllium-copper fingerstrips/fingerstocks provide a versatile solution for shielding gaps, seams, and other openings where electromagnetic radiation can escape or penetrate. This article will explore the design, features, applications, and benefits of these specialized shielding components. Overview of Beryllium-Copper as a Material Before diving into the specifics of Handa's fingerstrips, it is crucial to understand the material used—beryllium copper. Beryllium copper is a copper alloy with small amounts of beryllium (typically 0.5% to 3%). This combination offers several advantages: High Conductivity: Copper is known for its......

-

EMI Shielding Helical Springs with Unique Function

EMI Shielding Helical Springs with Unique FunctionEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Handa Shielding offers various types of shielding products. These products come in different shapes and materials, and they each have their own unique function. In this article, we will take a look at the EMI shielding aspect and explore the function and advantages of EMI Shielding Helical Springs, which are designed to protect electronic devices from electromagnetic interference. Understanding Electromagnetic Interference (EMI)What Are EMI Shielding Helical Springs?Key Characteristics of EMI Shielding Helical SpringsStructure and Function of EMI Shielding Helical SpringsMaterials Used in EMI Shielding Helical SpringsApplications of EMI Shielding Helical SpringsInstallation and Usage of EMI Shielding Helical SpringsBest Practices for EMI Shielding Helical SpringsConclusion EMI Shielding Helical Springs with Unique Function Understanding Electromagnetic Interference (EMI) Electromagnetic interference (EMI) refers to unwanted noise or interference in an electrical pathway or circuit caused by external sources. Also known as radio frequency interference, EMI can significantly impact the performance and functionality of electronic devices. Key aspects of EMI: It can cause electronics to operate inefficiently, malfunction, or cease functioning entirely EMI can arise from both natural and man-made sources Proper mitigation strategies are essential to minimize its effects What Are EMI Shielding Helical Springs? EMI (Electromagnetic Interference) Shielding Helical Springs are specialized mechanical......

-

Handa Endur Shield to safeguard sensitive electronic equipment

Handa Endur Shield to safeguard sensitive electronic equipmentEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Handa Endur Shield is a premium electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solution designed to safeguard sensitive electronic equipment from external interference. As the world becomes increasingly reliant on electronics, particularly in critical industries like telecommunications, aerospace, medical technology, and defense, protecting devices from EMI and RFI is crucial. Handa Endur Shield stands out in this domain as a reliable, durable, and customizable product designed for high-performance shielding. What is EMI and Why Does Shielding Matter?Key Features of Handa Endur ShieldMaterials Used in Handa Endur ShieldApplications of Handa Endur Shield Across IndustriesCustomization and Tailored SolutionsConclusion Handa Endur Shield What is EMI and Why Does Shielding Matter? Electromagnetic interference (EMI) refers to the disturbance caused by electromagnetic radiation from one electronic device that affects the functionality of another. This interference can range from mild disruptions to complete system failure, depending on the intensity of the interference and the sensitivity of the affected equipment. RFI (Radio Frequency Interference) is a specific type of EMI that occurs in the radio frequency spectrum. Both EMI and RFI are significant concerns in electronic design, particularly in industries that depend on flawless performance, like aerospace, military, medical, and telecommunications. Shielding is the process......

-

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing Capabilities

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing CapabilitiesShielding Gasket Solutions and Materials

Electrically conductive rubber profiles

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with the ability to conduct electricity. This makes them essential in various applications, particularly in sectors where electrical performance and mechanical reliability are critical. These specialized components are manufactured by incorporating conductive fillers, such as carbon black or metal particles, into rubber polymers. This article explores the features, benefits, applications, and manufacturing processes of electrically conductive rubber profiles, shedding light on their importance in modern industrial settings. What Are Electrically Conductive Rubber Profiles?Key Features and BenefitsApplications of Electrically Conductive Rubber ProfilesManufacturing Process of Electrically Conductive Rubber ProfilesConclusion Electrically Conductive Rubber Profiles What Are Electrically Conductive Rubber Profiles? Electrically conductive rubber profiles are rubber components engineered to facilitate the flow of electrical current while retaining the inherent advantages of rubber, such as flexibility, resilience, and sealing capabilities. They are particularly valuable in environments where both electrical and mechanical performance are paramount. Composition and Materials The primary materials used in electrically conductive rubber profiles include: Rubber Polymers: The base material that provides flexibility and durability. Commonly used types include natural rubber, silicone rubber, and neoprene. Conductive Fillers: These materials are......

-

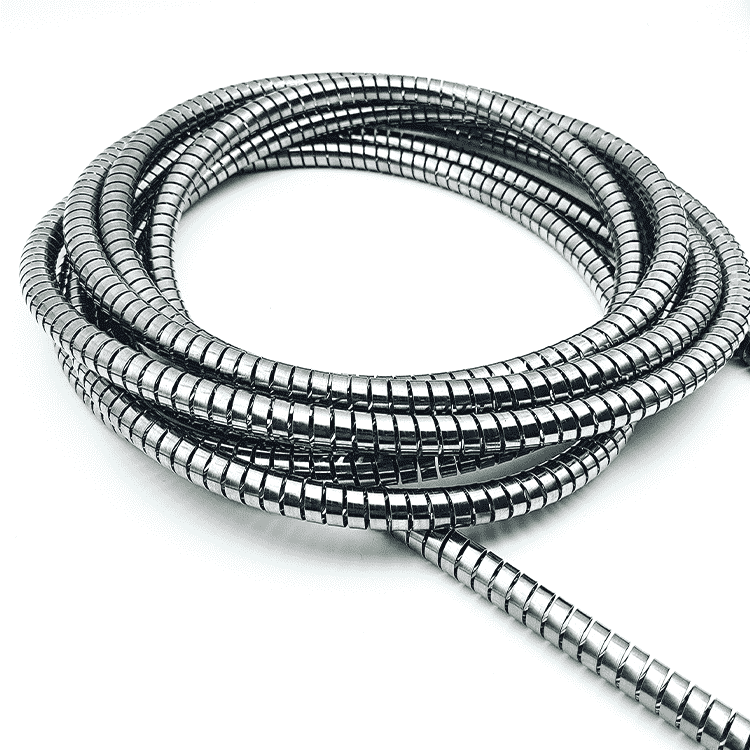

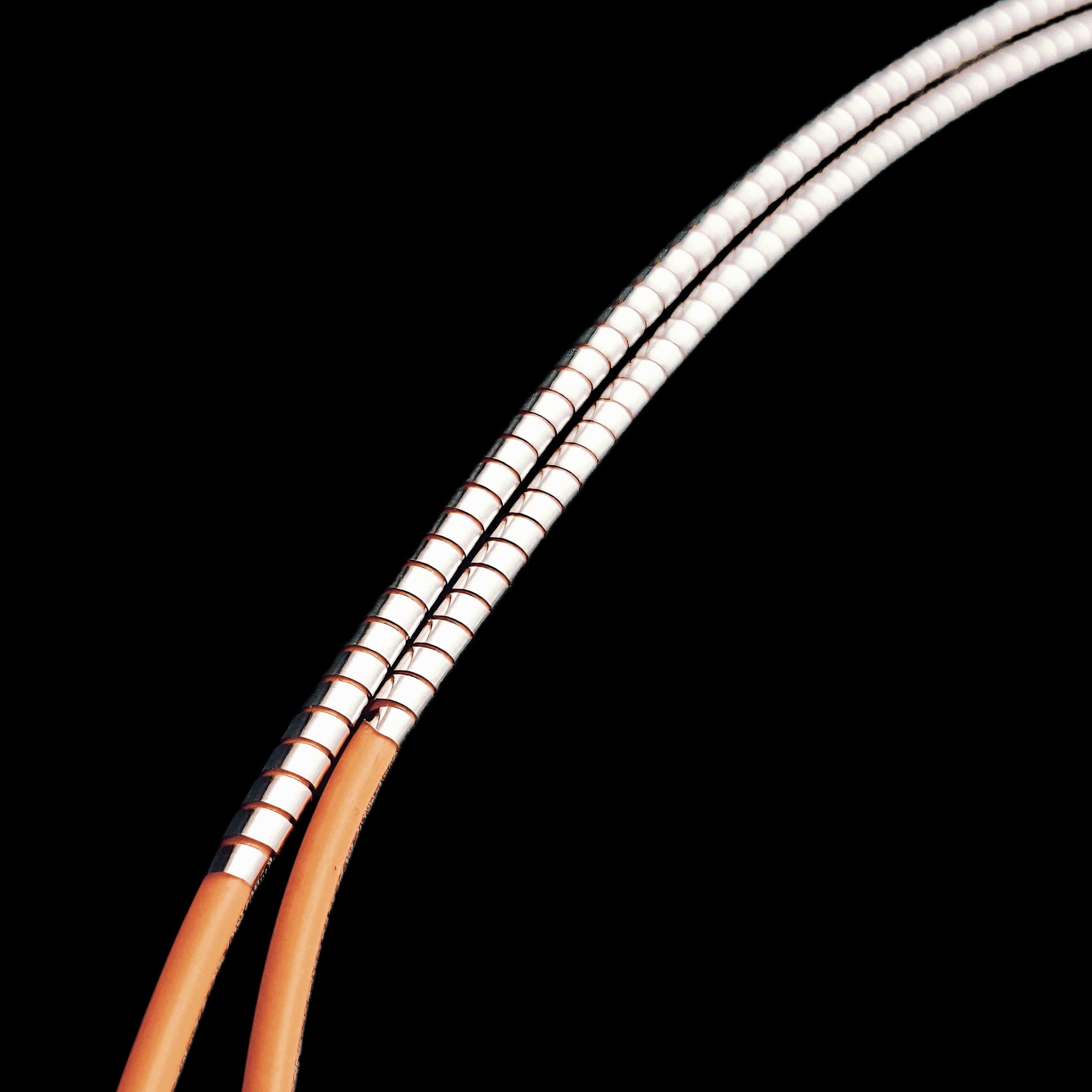

EMI shielding canted coil springs with unique canted coil design

EMI shielding canted coil springs with unique canted coil designHanda Canted Coil Springs

EMI Shielding Springs

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique canted coil design, which enables them to provide multiple points of contact for superior EMI shielding, mechanical latching, and electrical conductivity. What Are EMI Shielding Canted Coil Springs?Applications of EMI Shielding Canted Coil SpringsMaterials and Construction of EMI Shielding Canted Coil SpringsBenefits of EMI Shielding Canted Coil SpringsStandards Compliance for EMI Shielding Canted Coil SpringsConsiderations When Using EMI Shielding Canted Coil SpringsConclusion https://www.handashielding.com/contact-us.html What Are EMI Shielding Canted Coil Springs? EMI shielding springs are specialized springs that offer both mechanical and electromagnetic shielding capabilities. Their canted coil design features coils arranged at an angle, which creates multiple points of contact when compressed. This allows the spring to function as both a mechanical component and a highly effective EMI/RFI shield. Electromagnetic interference is a significant concern in modern electronic devices, where external or internal EMI can disrupt signals and affect performance. EMI shielding springs are designed to protect sensitive electronic components from EMI and RFI while also providing mechanical and electrical......