Highly Versatile and Indispensable Conductive Copper Foil Tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components.

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components. This comprehensive guide explores the key features, applications, types, properties, performance, and industries in which conductive copper foil tape plays a crucial role.

Table of Contents

Conductive Copper Foil Tape

Key Features of Conductive Copper Foil Tape

Conductive copper foil tape is designed to meet the high demands of modern electronic and industrial applications. Below are its defining features:

1. Electrical Conductivity

One of the primary advantages of conductive copper foil tape is its excellent electrical conductivity. Copper, being one of the most conductive materials, allows electrical signals to flow efficiently across surfaces. This makes the tape an essential component in applications that require grounding, EMI (Electromagnetic Interference) shielding, or electrical signal transmission between two or more components.

2. Chemical Resistance

Conductive copper foil tape also provides robust chemical resistance, allowing it to function in environments exposed to harsh chemicals or corrosive substances. This feature makes it ideal for outdoor applications or settings where the tape will come into contact with chemicals that could degrade lesser materials.

3. Shielding Capabilities

One of the critical uses of conductive copper foil tape is its ability to block radio frequency (RF) and magnetic waves. This makes it indispensable in electronics, where electromagnetic interference can cause devices to malfunction or lose signal integrity. By providing a physical barrier to these disruptive forces, the tape helps maintain proper functioning in sensitive electronics.

4. Adhesive Properties

The adhesive backing on conductive copper foil tape is often designed to be either conductive or non-conductive, depending on the application requirements. This adhesive allows the tape to bond securely to various surfaces, including metals, plastics, and other substrates, ensuring durability and effectiveness in a wide range of applications.

5. Heat and Temperature Resistance

Conductive copper foil tape can operate efficiently in extreme temperature environments. Its heat resistance makes it a reliable solution for applications requiring thermal management or exposure to high temperatures, such as electronics, automotive, and aerospace industries.

Types of Conductive Copper Foil Tape

There are two main varieties of conductive copper foil tape, each designed to suit different applications based on their adhesive properties:

1. Copper Foil Tape with Conductive Adhesive

This type of copper foil tape features an adhesive layer that is also electrically conductive. This means that it allows electrical current to pass through both the copper and the adhesive sides of the tape. This variety is commonly used in applications where electrical continuity is needed across the bonded surface.

Applications:

- Grounding applications where electrical current needs to flow through both sides.

- Shielding that requires electrical connection between the substrate and the copper foil tape.

- EMI shielding and sealing in electronics.

2. Copper Foil Tape with Non-Conductive Adhesive

Copper foil tape with non-conductive adhesive only conducts electricity through the copper side, as the adhesive does not contribute to electrical conductivity. This type is useful for applications where it is necessary to insulate one side of the tape to prevent electrical flow, while still benefiting from copper’s conductive properties on the other side.

Applications:

- Instances where electrical insulation is required on one side.

- Grounding or bonding applications that do not require adhesive conductivity.

- Situations where the copper side must make contact with conductive surfaces but the adhesive must be insulated.

Applications of Conductive Copper Foil Tape

Conductive copper foil tape is a versatile tool that can be used in a variety of applications across several industries. Some of the most common uses include:

1. EMI/RFI Shielding

Electromagnetic interference (EMI) and radio frequency interference (RFI) can disrupt the performance of sensitive electronic equipment. Conductive copper foil tape serves as an effective shielding material that prevents external electromagnetic fields from interfering with the operation of devices such as computers, mobile phones, and medical equipment. The tape forms a conductive barrier that blocks these unwanted signals, ensuring the device functions as intended.

2. Grounding

In electronic circuits, proper grounding is essential to prevent static build-up, protect components from surges, and ensure safety. Conductive copper foil tape is widely used for grounding applications in electronics, where it serves as a conductive path to direct unwanted electrical currents safely into the ground, preventing damage to sensitive components.

3. Communication Cable Shielding

When communication cables are exposed to environmental conditions like moisture, humidity, or electromagnetic interference, conductive copper foil tape can be wrapped around the cables to provide both physical protection and EMI shielding. This ensures that signals transmitted through the cables remain clear and free from distortion caused by external forces.

4. PCB Repair and Prototyping

Printed circuit boards (PCBs) are critical to the operation of most electronic devices. Conductive copper foil tape is commonly used to repair damaged PCBs by creating new electrical connections or rerouting signals around broken traces. Additionally, during prototyping, copper tape is used to modify circuits quickly without the need for new PCBs.

5. Antenna Manufacturing

In communication devices, antennas are essential for transmitting and receiving signals. Conductive copper foil tape is used in the fabrication of antennas, particularly in applications where lightweight, flexible, and conductive materials are required. The tape’s flexibility allows it to be easily shaped into the necessary forms for optimal signal transmission.

6. DIY and Hobbyist Projects

Conductive copper foil tape is popular among hobbyists and DIY enthusiasts for creating custom circuits, building homemade radios, and crafting other electronic projects. Its ease of use, combined with its conductive properties, makes it an accessible material for creative electrical applications.

Properties and Performance of Conductive Copper Foil Tape

1. Strong Adhesion

The adhesive used on conductive copper foil tape is designed to bond firmly to various substrates, including metals, plastics, and composites. This ensures that the tape remains in place even in challenging conditions, providing long-lasting performance.

2. Versatility

Conductive copper foil tape is highly versatile and can be cut to any size or shape, making it easy to use in a wide range of applications. Its flexibility allows it to conform to irregular shapes and surfaces, which is particularly useful in electronic devices with complex geometries.

3. High Conductivity

The conductivity of the copper ensures that the tape can efficiently carry electrical signals and current. This makes it an excellent choice for applications requiring reliable electrical connections, such as grounding, EMI shielding, and electrical repairs.

4. Chemical and Corrosion Resistance

The copper foil used in the tape is resistant to corrosion and chemical damage, making it suitable for use in harsh environments. This property extends the tape’s lifespan, ensuring it continues to perform well even when exposed to moisture, humidity, or chemicals.

5. Heat and Temperature Tolerance

Conductive copper foil tape can withstand a wide range of temperatures, making it ideal for applications in environments with fluctuating thermal conditions. Whether in an outdoor setting or within an electronic device that generates heat, the tape maintains its performance without degrading.

Considerations for Choosing Conductive Copper Foil Tape

When selecting the appropriate conductive copper foil tape for a particular application, several factors should be considered:

1. Material Compatibility

Ensure that the copper foil tape is compatible with the substrate it will be applied to. Different materials may require specific adhesive formulations to bond securely without degrading over time.

2. Adhesive Type

Depending on the application, choose between conductive and non-conductive adhesive varieties. Conductive adhesives are necessary for applications where electrical continuity is needed across both the copper and adhesive sides, while non-conductive adhesives are suited for situations where insulation is required on one side.

3. Environmental Resistance

Consider the environmental conditions in which the tape will be used, such as exposure to moisture, chemicals, or extreme temperatures. Conductive copper foil tape with enhanced resistance to these factors will ensure longer-lasting performance.

4. Thickness and Flexibility

The tape’s thickness and flexibility should match the specific requirements of the application. Thicker tapes provide better shielding performance but may be less flexible, while thinner tapes offer more flexibility but may not provide the same level of protection.

Conclusion

Conductive copper foil tape is a highly valuable material used in a variety of industries and applications. Its ability to provide electrical conductivity, EMI shielding, grounding, and chemical resistance makes it an essential tool for engineers, designers, and hobbyists alike. Whether used in the electronics, automotive, aerospace, or communication sectors, conductive copper foil tape offers reliable performance and versatility.

By understanding its key features, types, applications, and considerations for selection, you can make informed decisions when choosing conductive copper foil tape for your specific needs. This material continues to be an indispensable component in modern technology, providing solutions to electrical and shielding challenges across numerous fields.If you need excellent conductive copper foil tape,please:

You May Also Like

-

Electrical Conductivity Aluminum Foil Tape

Electrical Conductivity Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Electrical conductivity aluminum foil tape is a versatile and essential material in various industries, particularly in electronics, electrical engineering, and construction. This article delves deep into the properties, applications, benefits, and selection criteria for electrical conductivity aluminum foil tape, focusing on why it is indispensable for ensuring electrical continuity, shielding, and grounding. https://www.handashielding.com/contact-us.html What is Electrical Conductivity Aluminum Foil Tape?Key Properties of Electrical Conductivity Aluminum Foil TapeApplications of Electrical Conductivity Aluminum Foil TapeBenefits of Using Electrical Conductivity Aluminum Foil TapeSelection Criteria for Electrical Conductivity Aluminum Foil TapeConclusion What is Electrical Conductivity Aluminum Foil Tape? Electrical conductivity aluminum foil tape is a specialized adhesive tape made from thin aluminum foil coated with an electrically conductive adhesive. This tape is designed to offer excellent conductivity across its surface and through its adhesive, making it ideal for applications requiring reliable electrical connections and shielding. The aluminum foil provides a conductive surface, while the adhesive ensures that the tape adheres firmly to various substrates while maintaining electrical conductivity. Key Properties of Electrical Conductivity Aluminum Foil Tape 1. Electrical Conductivity The primary feature of aluminum foil tape is its excellent electrical conductivity. Both the aluminum foil and the conductive adhesive are designed to allow current......

-

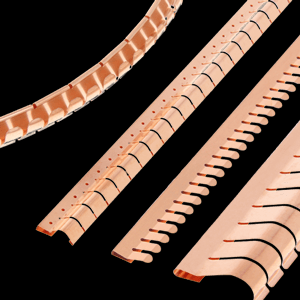

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

High Shielding Effectiveness EMI Shielding Fingerstock GasketsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

In today's increasingly complex electronic landscape, electromagnetic interference (EMI) shielding has become a critical concern for device manufacturers and designers. One effective solution for addressing EMI issues is the use of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets. These specialized components play a vital role in protecting electronic devices from unwanted electromagnetic radiation and maintaining electromagnetic compatibility (EMC). What is EMI Shielding?The Role of EMI Shielding Fingerstock GasketsAdvantages of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConstruction and Materials of High Shielding Effectiveness EMI Shielding Fingerstock GasketsApplications of High Shielding Effectiveness EMI Shielding Fingerstock GasketsPerformance Metrics of Fingerstock GasketsChallenges and ConsiderationsFuture Trends in EMI ShieldingCase Studies of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConclusion What is EMI Shielding? Electromagnetic interference (EMI) refers to the disruption of electronic circuits and systems caused by electromagnetic radiation from external sources. This interference can manifest as noise, signal degradation, or complete system malfunctions. EMI can be generated by a variety of sources including electrical devices, communication systems, and even natural phenomena. To combat EMI, shielding techniques are employed to block or attenuate electromagnetic waves. EMI shielding involves creating a barrier that prevents the interference from penetrating sensitive areas of electronic devices. Effective EMI shielding ensures......

-

Right-angle shielding fingerstrips/angled fingerstocks

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic systems. These fingerstrips are particularly useful in configurations where electronic components intersect at a 90-degree angle. Their primary role is to ensure effective shielding, maintaining electromagnetic compatibility (EMC) and protecting sensitive electronic equipment from interference. IntroductionDesign and FunctionalitySpecifications and MaterialsInstallation ConsiderationsManufacturing ProcessBenefitsConclusion Design and Functionality Purpose and Importance The main purpose of right-angle shielding fingerstrips is to provide reliable EMI/RFI shielding in electronic setups with perpendicular component arrangements. When electronic devices have components aligned at right angles, traditional shielding solutions might not be effective due to gaps or incomplete coverage. Right-angle fingerstrips address this issue by ensuring continuous shielding across these angular junctions, which is crucial for maintaining the performance and reliability of electronic systems. Applications Right-angle shielding fingerstrips are used in a wide range of applications: Computer Hardware: To shield critical internal components from electromagnetic emissions that could cause operational issues or data corruption. Telecommunications Equipment: To prevent signal interference and ensure the integrity of communication systems. Automotive Electronics: To protect sensitive electronic control systems from EMI that could impact vehicle performance. Shielded Enclosures:......

-

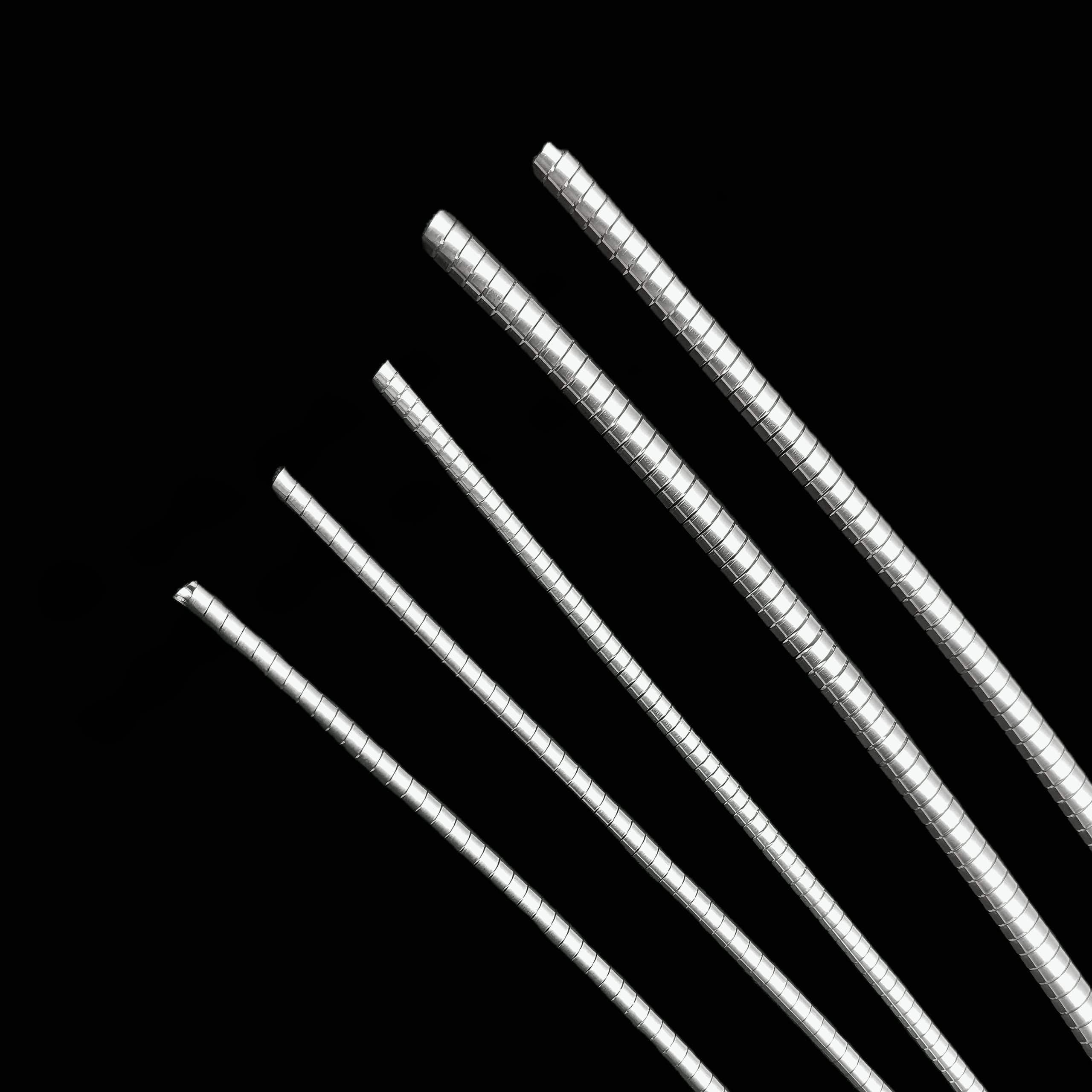

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic Compatibility

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic CompatibilityEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

In today's interconnected world of electronics and telecommunications, maintaining electromagnetic compatibility (EMC) is crucial to ensure optimal performance and reliability of electronic devices. RF/EMI Shield Spiral Gaskets play a pivotal role in achieving this goal by effectively mitigating electromagnetic interference (EMI) that can disrupt signal integrity and functionality. What are RF/EMI Shield Spiral Gaskets?Key Features and BenefitsApplications Across Industries What are RF/EMI Shield Spiral Gaskets? RF/EMI Shield Spiral Gaskets are specialized components designed to provide robust shielding against electromagnetic radiation. They are typically made from conductive materials such as metal alloys or conductive elastomers, crafted into a spiral shape that allows them to conform closely to mating surfaces. This design ensures consistent contact and compression, optimizing the gasket's ability to block EMI effectively. Key Features and Benefits EMI Shielding Effectiveness: The primary function of RF/EMI Shield Spiral Gaskets is to attenuate electromagnetic waves, preventing external interference from disrupting sensitive electronic signals. This capability is crucial for maintaining signal integrity and preventing data corruption in telecommunications, aerospace, medical devices, and industrial automation. Versatility in Applications: These gaskets are available in various sizes, shapes, and materials to suit different application requirements. They are commonly used in:Telecommunications: Ensuring clear and reliable communication by......

-

Handa Shielding – Clip-on mounting fingerstrip

Handa Shielding – Clip-on mounting fingerstripFingerstrips

Clip-on mounting shielding fingerstrip

Clip-on mounting fingerstrip gaskets are essential components in the realm of electromagnetic shielding, playing a critical role in ensuring the effective performance of electronic devices and systems. These gaskets, produced by leading manufacturers like Handa Shielding, are designed to provide reliable electromagnetic interference (EMI) shielding and grounding. This article explores the construction, types, features, and applications of clip-on mounting fingerstrip gaskets, with a focus on Handa Shielding’s offerings. IntroductionConstruction and MaterialsTypes of Clip-On Mounting Fingerstrip GasketsMain Features of Clip-On Mounting Fingerstrip GasketsTypical ApplicationsConclusion Introduction In the world of electronics, electromagnetic shielding is crucial for preventing interference and ensuring the optimal functionality of devices. Fingerstrip gaskets are a key element in this shielding process, providing a conductive pathway that helps maintain signal integrity and reduce EMI. Handa Shielding, a prominent supplier in the shielding industry, offers a range of solutions including both stick-on and clip-on mounting fingerstrip gaskets. While stick-on gaskets are useful for general purposes and fit into confined spaces, clip-on mounting fingerstrip gaskets are engineered for more specialized requirements, particularly in challenging environments. Clip-on mounting fingerstrip gaskets are especially valuable in high-temperature environments and other demanding conditions where traditional stick-on solutions may be inadequate. This article provides an in-depth......