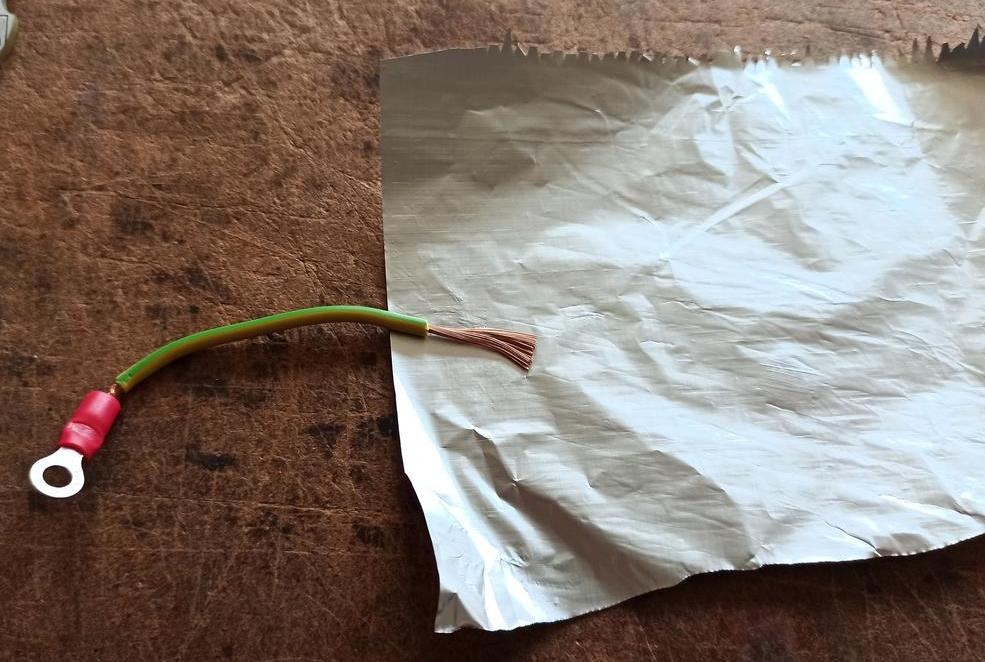

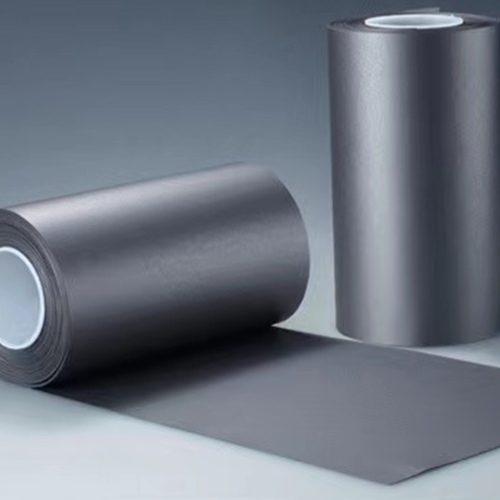

Conductive foils & fabrics

Conductive foils and fabrics are materials designed to conduct electromagnetic signals, primarily used for electromagnetic interference (EMI) shielding.

These materials are employed to protect electronic devices from unwanted electromagnetic signals, ensuring their optimal performance. Conductive textiles, for instance, are nylon ribstops coated with Cu/Ni, offering high conductivity and flexibility, making them ideal for creating EMI-shielded housings for plastic components. Stretch conductive fabric, coated with a medical-grade silver coating, is highly conductive and can increase conductivity by up to 25% when stretched. Additionally, there are washable conductive fabrics with stainless steel threads for various applications, and copper/nickel conductive non-woven fabric for EMI shielding applications.

These materials are crucial in the design and manufacturing of electronic devices, ensuring they operate without interference from external electromagnetic signals

Custom Manufacturing

Custom Conductive foils & fabrics

The manufacturing of conductive foil and fabric products is a field involving special materials and production processes, mainly used in industries such as electronics, communication, and electrical engineering.

The following are the general processes and some important aspects related to the manufacturing of conductive foil and conductive fabric products: material selection, material processing, coating and printing, cutting and forming, manufacturing of conductive fabrics, quality control, customized products, packaging and delivery.

These conductive products have a wide range of applications in electronic circuits, shielding, battery technology, sensors, flexible electronics, and other fields, Therefore, the manufacturing process needs to follow high standards of quality control to ensure its stability and performance.

Conductive foils & fabrics Manufacturing

The manufacturing of conductive foil and fabric products is a field involving special materials and production processes, mainly used in industries such as electronics, communication, and electrical engineering. The following are the general processes and some important aspects related to the manufacturing of conductive foil and conductive fabric products: material selection, material processing, coating and printing, cutting and forming, manufacturing of conductive fabrics, quality control, customized products, packaging and delivery. These conductive products have a wide range of applications in electronic circuits, shielding, battery technology, sensors, flexible electronics, and other fields, Therefore, the manufacturing process needs to follow high standards of quality control to ensure its stability and performance.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

Aluminium foil, a widely recognized material in both household and industrial applications, is particularly valued for its role in electromagnetic shielding. This article......