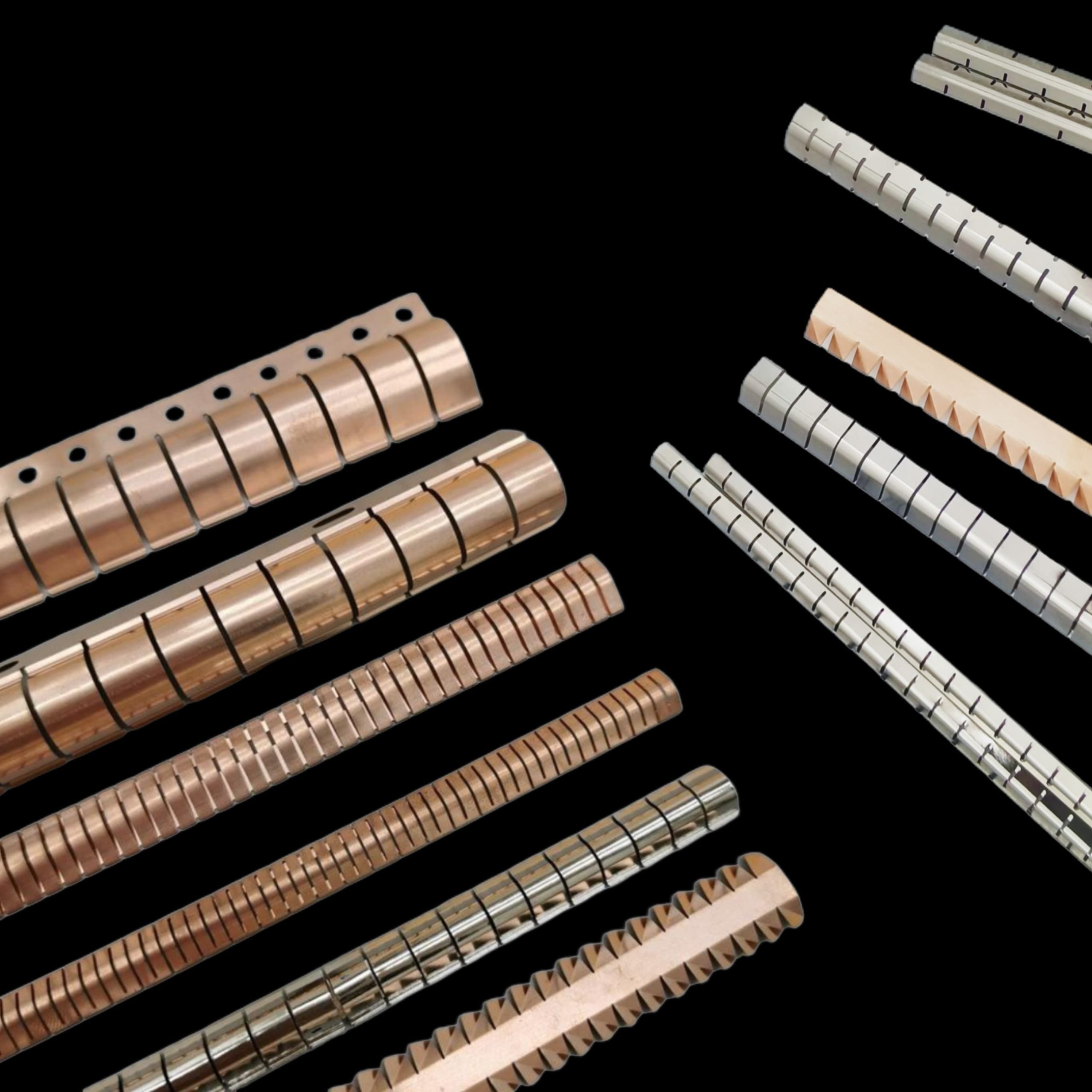

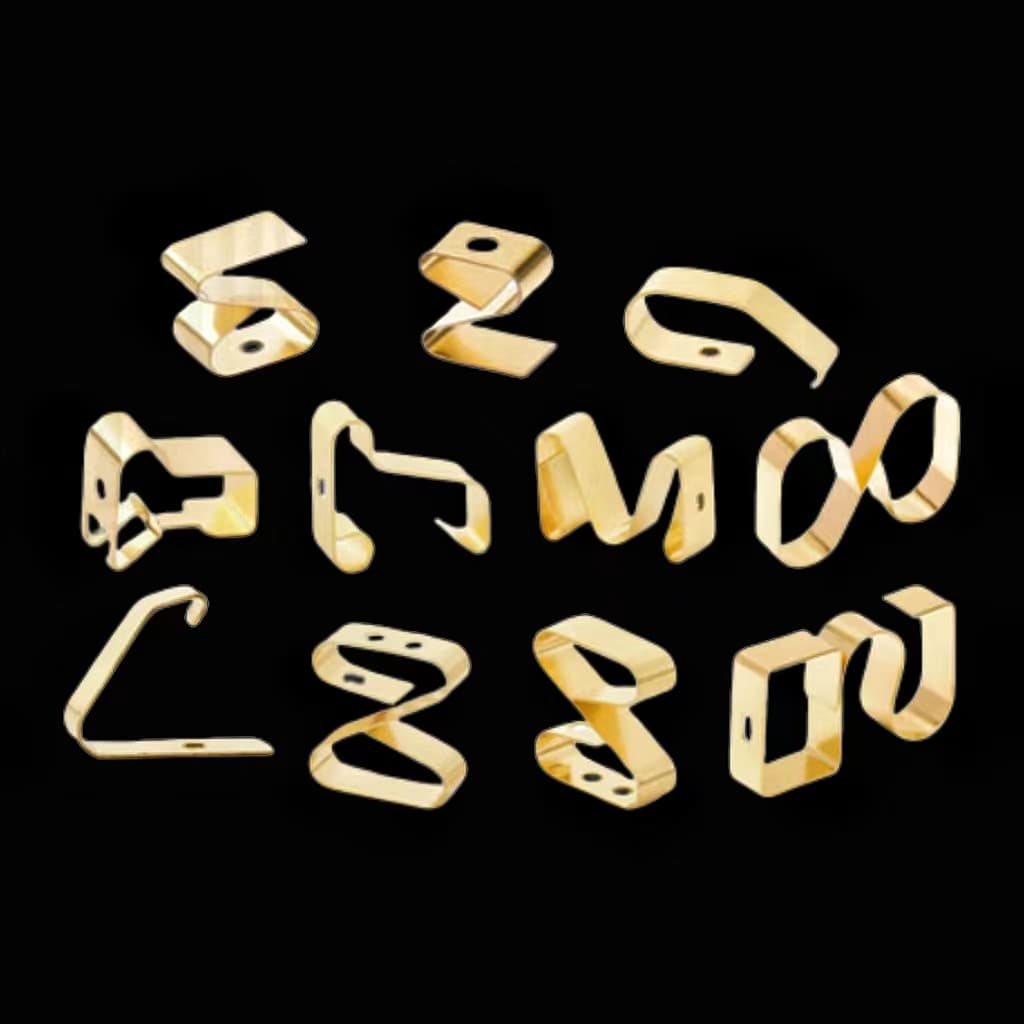

Contact shielding fingerstrip

Handa Contact fingerstrips, especially those fabricated from beryllium copper (BeCu), assume a vital role in electromagnetic interference (EMI) and radio frequency interference (RFI) shielding. These elements are engineered to sustain a dependable connection between two conductive surfaces, such as the door of a shielded enclosure and its frame, guaranteeing effective EMI/RFI shielding.

Custom Manufacturing

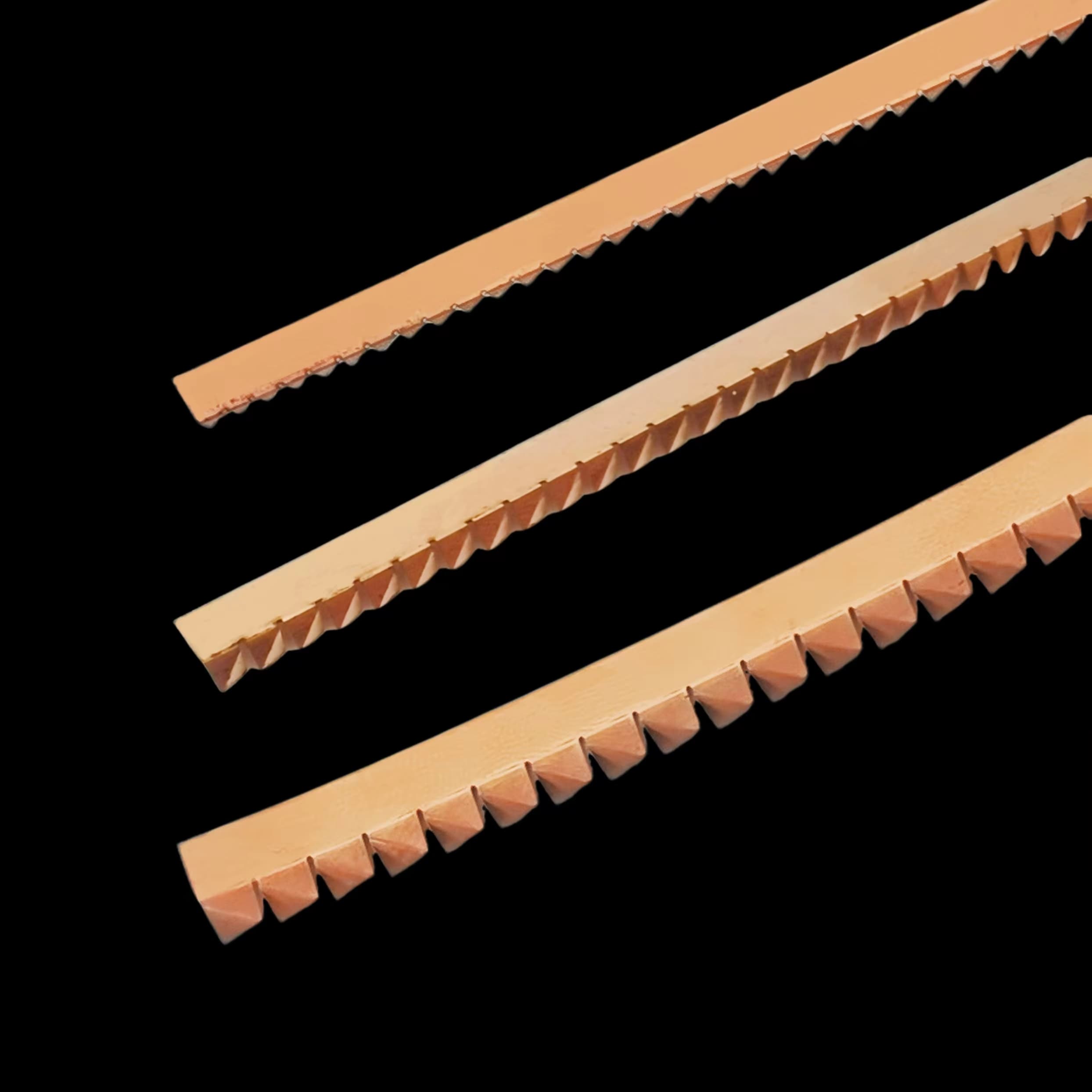

Custom Contact shielding fingerstrip

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

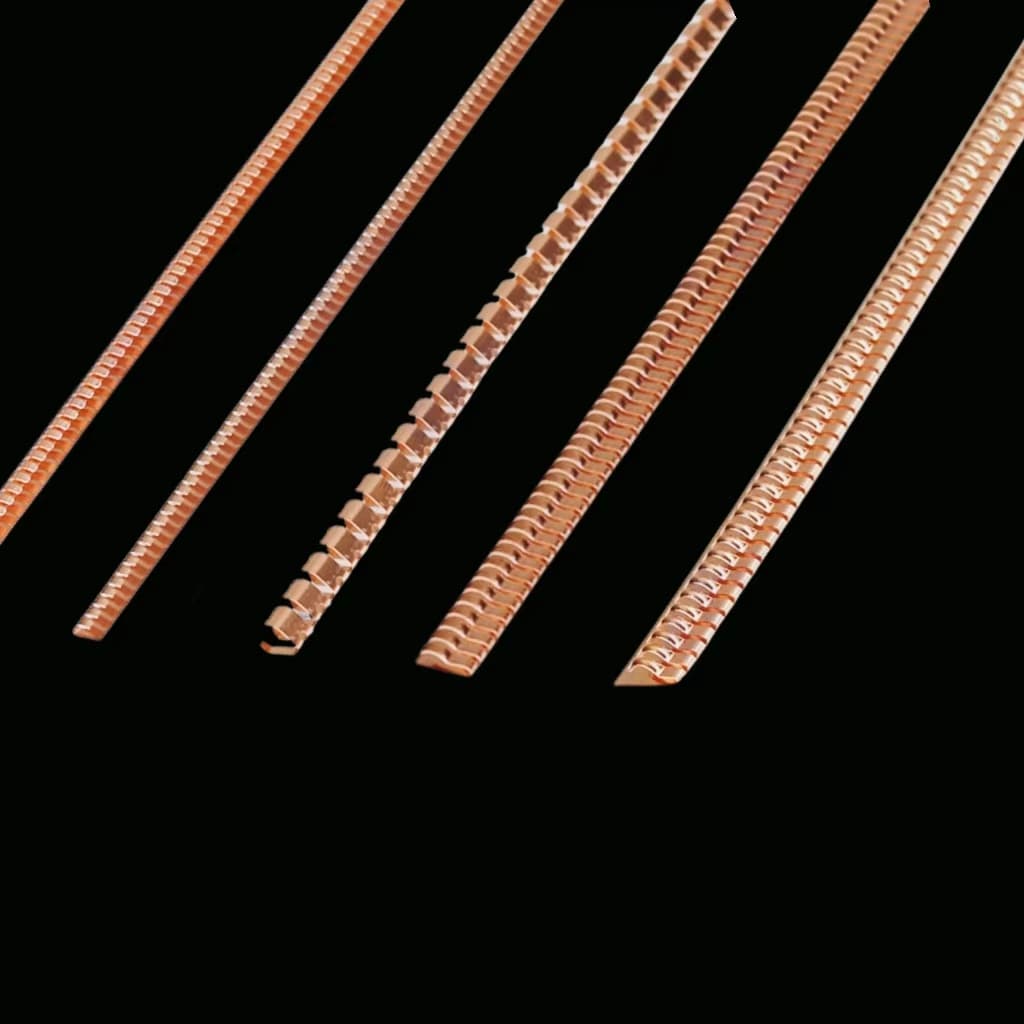

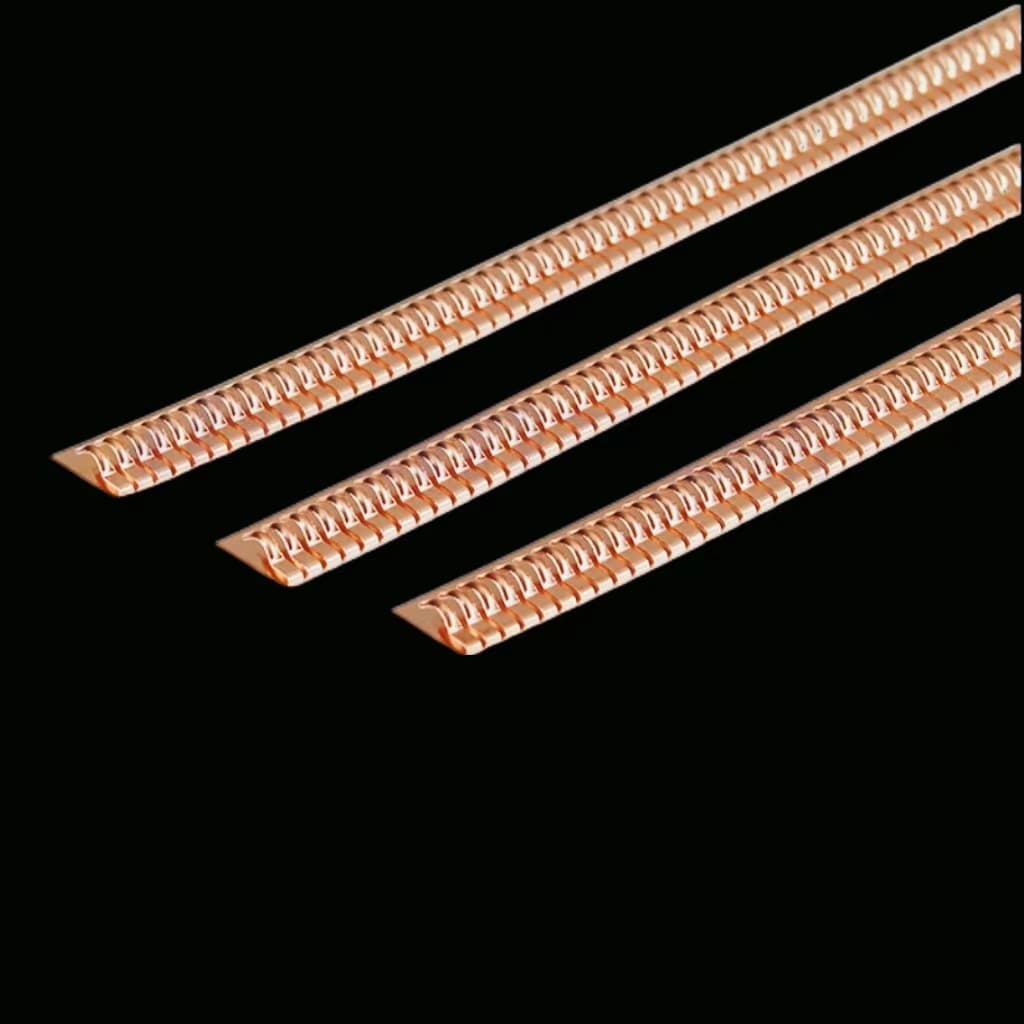

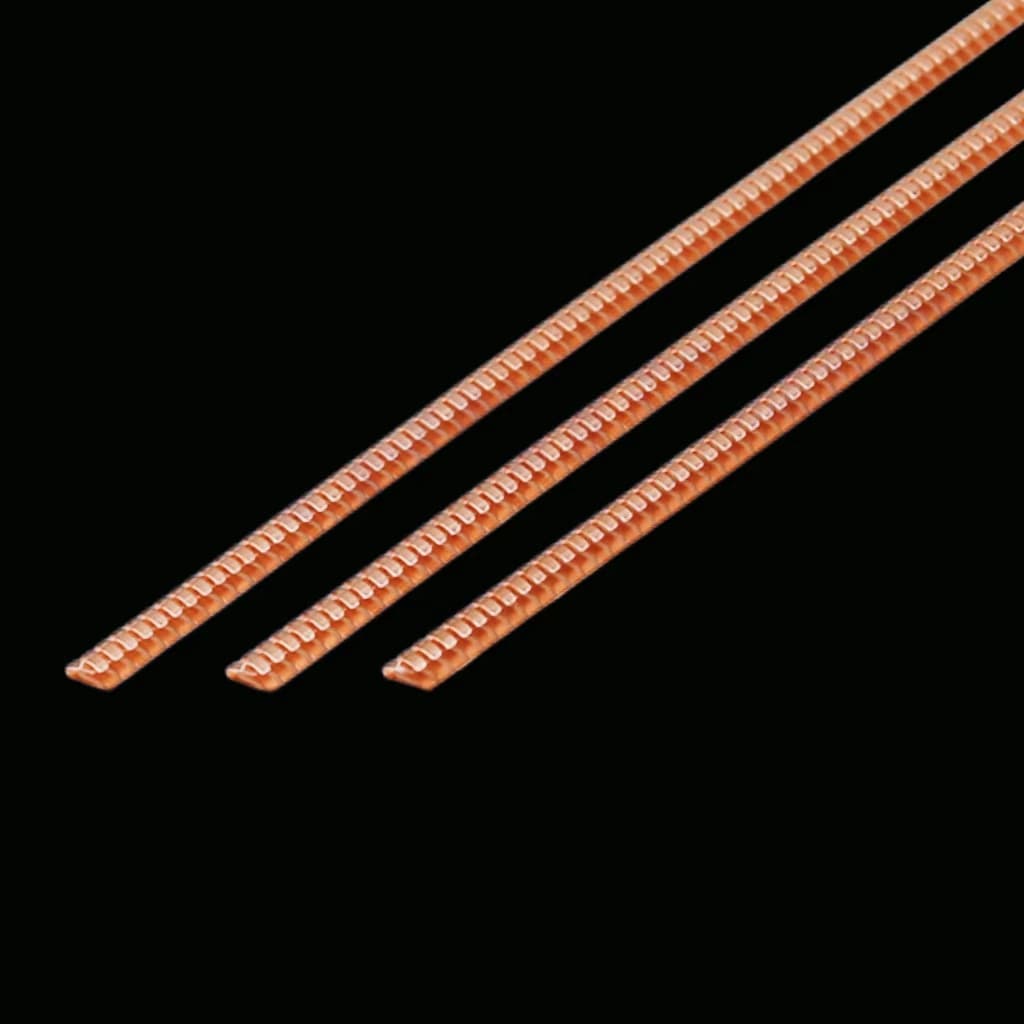

Contact shielding fingerstrip Manufacturing

The process of manufacturing contact fingerstrips usually involves several steps:

1. Preparation of raw materials

(1)Material selection: Handa Shielding usually choose beryllium copper (BeCu).

(2)Material procurement: Purchase raw materials that meet standards from reliable suppliers.

2. Design and development

(1)Customer demand analysis: Design according to the specific needs of customers, such as size, shape, electrical conductivity, etc.

(2)Sample production and testing: Produce samples according to the drawings and conduct performance tests.

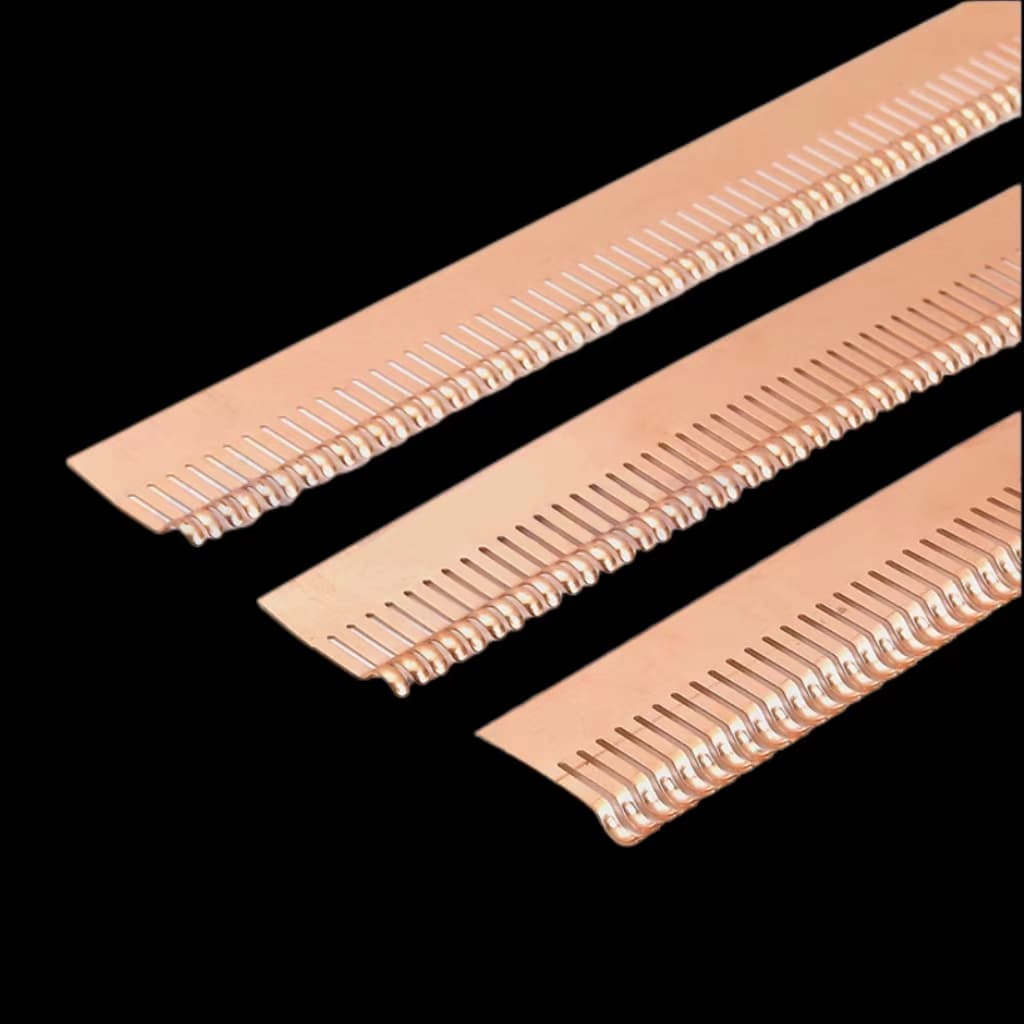

3. Production process

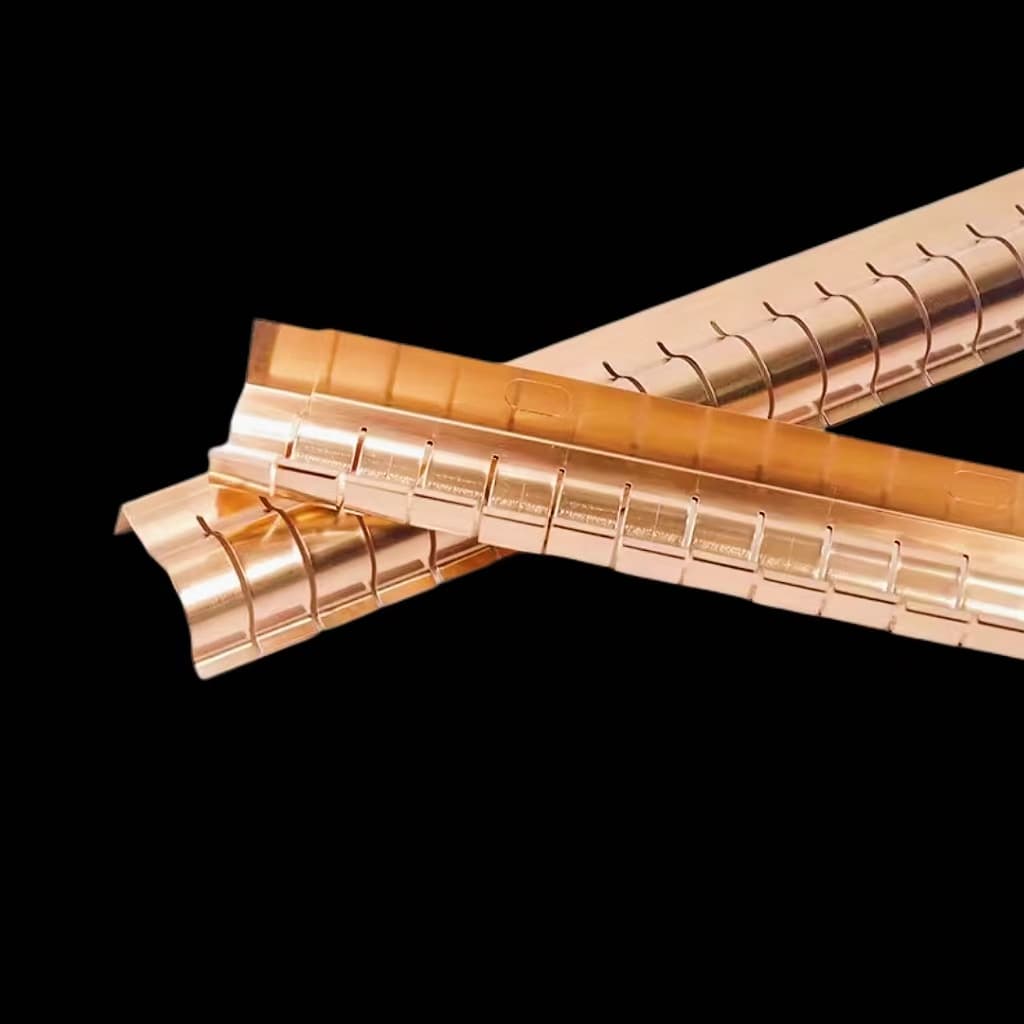

(1)Cutting and stamping: Use precise cutting and stamping equipment for processing according to the drawing requirements.

(2)Surface treatment: Conduct surface treatment on the fingerstrips, such as electroplating (nickel plating, tin plating, etc.), polishing, etc.

(3)Assembly and detection: Assemble the processed fingerstrips (if necessary) and conduct comprehensive quality detection.

4. Quality control

(1)Process control: Implement strict quality control measures during the production process to ensure that each link meets the standards.

(2)Finished product inspection:Including appearance inspection, size measurement, performance testing, etc.

5. Packaging and shipping

(1)Packaging: Package the qualified fingerstrips to protect them from damage during transportation.

(2)Shipping: Ship according to the time and method required by the customer.

6. After-sales service

(1)Technical support: Provide necessary technical support and solutions for customers.

(2)Quality tracking: Track the quality of the sold products and deal with the problems feedback by customers in a timely manner.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote