Copper foil tape

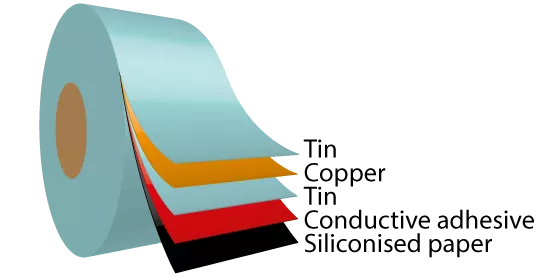

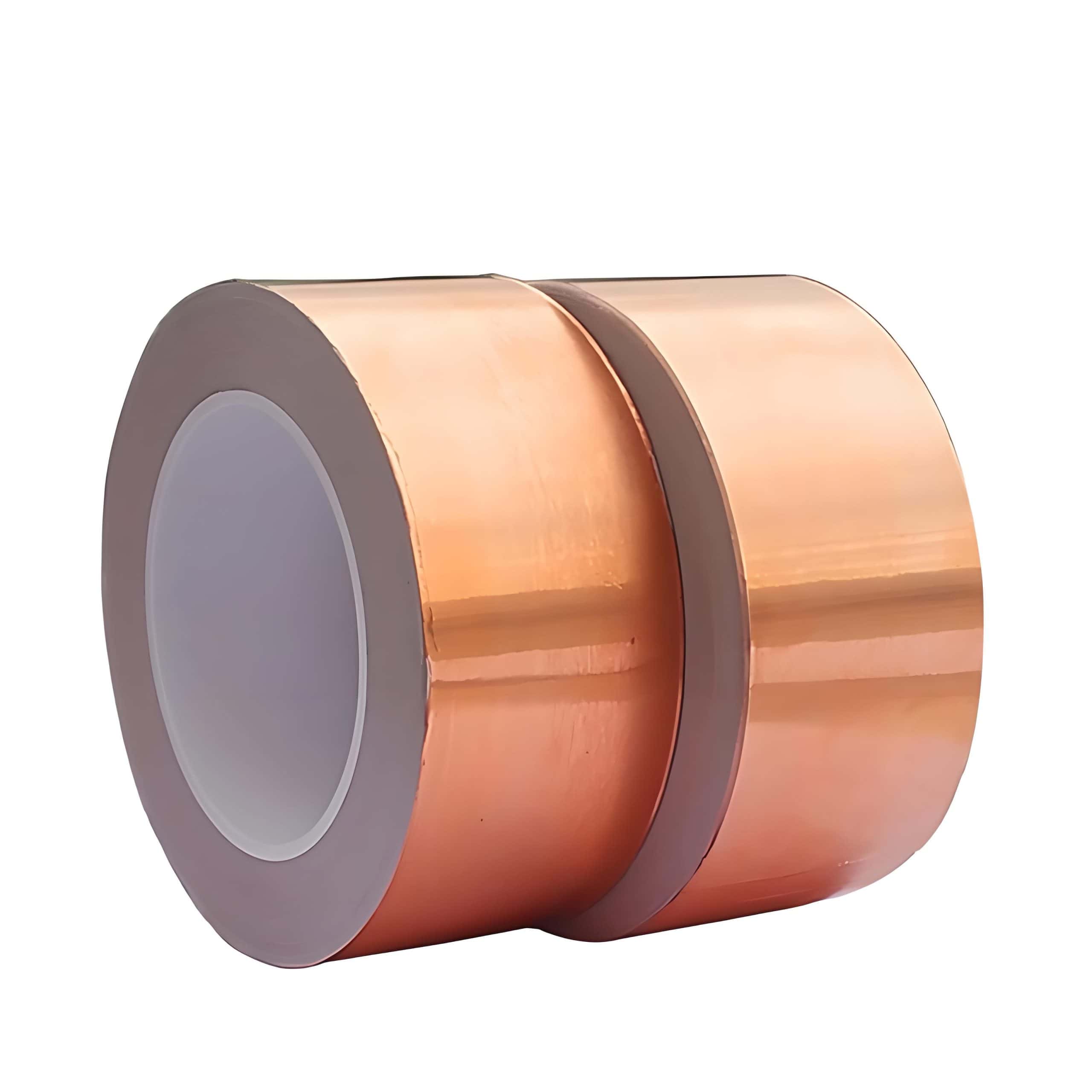

Copper foil tape is a type of shielding material widely used in electronic devices to protect against electromagnetic interference (EMI) and radio frequency interference (RFI). It consists of a layer of copper foil laminated onto a flexible backing material, often polyethylene or polyester, with a conductive adhesive on the reverse side. This tape is designed to create a barrier against unwanted electromagnetic fields, effectively shielding internal components from external interference and vice versa.

Custom Manufacturing

Custom Copper foil tape

To customize your Copper Foil Tape, contact our sales team for a personalized quote and further assistance.

- Custom Widths and Lengths: Tailor the tape to your specific project needs.

- Adhesive Types: Choose from various adhesive strengths for different applications.

- Pre-cut Shapes: Get tape in pre-cut shapes and sizes for convenience.

- Bulk Orders: Special pricing available for large quantities.

Product descriptions

Specification

To customize Copper Foil Tape, specify the required length, width, and adhesive type. Contact our sales team for a personalized quote and further assistance.

|

item

|

value

|

|

Model Number

|

Pure Aluminum Foil Tape

|

|

Adhesive

|

Acrylic

|

|

Adhesive Side

|

Single/Double Sided

|

|

Material

|

Copper Foil

|

|

Feature

|

EMI shielding,Heat-Resistant,Thermal insulation

|

|

Color

|

Copper

|

|

Carrier

|

Copper Foil

|

|

Adhesive

|

Conductive Adhesive (or non-Conductive Adhesive)

|

|

Carrier Thickness(mm)

|

0.15-0.1 mm

|

|

Total Thickness(mm)

|

0.06-0.15

|

|

Resistance(Ω)

|

≤0.2

|

|

Initial Tack(kg/inch)

|

≥0.8

|

|

Application Temperature(℃)

|

-10-130℃

|

|

Shielding Effectiveness(DB)

|

55-88

|

|

Width(mm)

|

5-380 mm(Custom Slit)

|

Copper foil tape Manufacturing

The manufacturing process of copper foil tape involves several key steps, starting from the production of copper foil to the final assembly of the tape with its adhesive backing.

1.Production of Copper Foil: The process begins with melting copper, which is then rolled into thin sheets.

2.Coating with Adhesive: After the copper foil is produced, it is coated with an adhesive.

3.Lamination to Backing Material: The copper foil, now coated with adhesive, is laminated to a backing material.

4.Slitting to Desired Width and Length: The tape is then slit to the required width and length using rotary cutters or hot knives.

5.Packaging: Finally, the copper foil tape is packaged for shipping and storage.

This manufacturing process ensures that copper foil tape is flexible, resistant to corrosion, and capable of withstanding high temperatures, making it suitable for a wide range of applications.

Benefits

Copper foil tape is renowned for its versatility and effectiveness in a wide range of applications. Here are the key benefits of copper foil tape:

- Effective EMI Shielding

- Reliable Grounding

- Enhanced Signal Integrity

- Versatile Applications

- Easy Application and Handling

- Durability and Longevity

- Space Efficiency

Applications

- Electromagnetic Interference (EMI) Shielding

- Grounding

- Circuit Repair and Prototyping

- Stained Glass Projects

- Artistic Applications

- Thermal Management

- Shielding and Sealing

- Automotive Industry

- Aerospace

- Medical Devices

- DIY and Home Improvement

FAQ

Q: Can this tape be used outdoors?

A: Yes, it is designed to withstand various weather conditions.

Q: How do I apply the tape?

A: Clean the surface, peel off the backing, and press the tape firmly onto the surface.

Q: Is the tape safe for electronic devices?

A: Absolutely, it is specifically designed for electronic applications.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

Copper foil tape 1. Introduction to Copper Foil Tape2. Properties of Copper Foil Tape3. Types of Copper Foil Tape4. Applications of Copper Foil......

-

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination......