Copper foil tape with high conductivity&malleability

Copper foil tape is a versatile and highly functional material made from thin sheets of copper, typically combined with an adhesive backing. Copper’s inherent properties, such as high conductivity, malleability, and resistance to corrosion, make copper foil tape an ideal material for a wide variety of applications, from electronic shielding to artistic endeavors.

Copper foil tape

Table of Contents

Copper foil tape is a versatile and highly functional material made from thin sheets of copper, typically combined with an adhesive backing. Copper’s inherent properties, such as high conductivity, malleability, and resistance to corrosion, make copper foil tape an ideal material for a wide variety of applications, from electronic shielding to artistic endeavors. In this article, we will explore copper foil tape in depth, discussing its properties, types, uses, and the advantages it offers across different industries.

1. Introduction to Copper Foil Tape

Copper foil tape is a thin, flexible, and conductive tape made from copper foil that is typically coated with an adhesive on one side. The tape’s adhesive backing allows it to be easily applied to surfaces, making it a convenient material for various applications. The copper material offers excellent electrical conductivity, which is why it is commonly used for electromagnetic shielding, grounding, and other electronic and electrical applications.

Copper foil with adhesive tape is available in various thicknesses and widths, making it customizable for different uses. It is also available with different adhesive types, such as conductive and non-conductive adhesives, depending on the specific requirements of the application.

2. Properties of Copper Foil Tape

Copper foil with adhesive tape has several key properties that make it suitable for a wide range of applications:

- Electrical Conductivity: Copper is one of the most conductive metals, which makes copper foil with adhesive tape an excellent choice for applications that require high electrical conductivity. It is often used in situations where efficient current flow and shielding from electromagnetic interference (EMI) are needed.

- Malleability: Copper is a highly malleable material, meaning it can be bent, shaped, or molded into various forms. This makes copper foil tape versatile for applications that require a flexible material that can easily conform to different shapes and surfaces.

- Corrosion Resistance: Copper naturally forms a protective oxide layer on its surface, providing resistance to corrosion and oxidation. This makes copper foil tape durable, especially in environments where moisture or other corrosive elements may be present.

- Adhesion: Copper foil with adhesive tape typically comes with an adhesive backing, which may be either conductive or non-conductive. The adhesive allows the tape to be easily applied to surfaces, ensuring a strong bond while maintaining its electrical properties.

- Flexibility: Copper foil with adhesive tape is highly flexible, allowing it to be applied to irregular or curved surfaces without compromising its functionality.

3. Types of Copper Foil Tape

Copper foil tape comes in various forms, depending on the application and requirements. Here are the main types:

- Conductive Copper foil with adhesive tape: This type of copper tape has a conductive adhesive, which allows for an uninterrupted electrical connection across the tape. Copper foil with adhesive tape is commonly used in EMI shielding and grounding applications. It is designed to provide a continuous path for electrical currents and is ideal for grounding electronic components or shielding sensitive electronics.

- Non-Conductive Copper foil with adhesive tape: Unlike conductive copper foil tape, non-conductive copper foil with adhesive tape has an adhesive that does not conduct electricity. This type of tape is used in applications where conductivity is not necessary but the copper’s other properties, such as shielding or aesthetics, are desired.

- Copper Foil Tape with Paper Backing: Some copper foil tapes come with a paper backing that protects the adhesive layer until it is ready to be used. The paper backing can be easily peeled off, allowing the tape to be applied to various surfaces.

- Copper Foil Tape with Clear Adhesive: For applications that require the tape to remain discreet, copper foil tape with clear adhesive is often used. This type of tape is less visible and can be used in situations where the tape should not be noticed.

4. Applications of Copper Foil Tape

Copper foil tape has a wide range of applications, primarily in electronics and electrical systems, but it is also used in several other industries. Below are some of the most common applications of copper foil tape:

4.1. Electromagnetic Interference (EMI) Shielding

One of the most popular uses of copper foil tape is for EMI shielding. Electromagnetic interference can disrupt the proper functioning of electronic devices and systems.It is used to shield sensitive electronics from external electromagnetic radiation, preventing interference from nearby devices.

EMI shielding is particularly important in industries such as telecommunications, aerospace, and medical devices, where equipment must function reliably and without interference. Its excellent electrical conductivity makes it an effective material for blocking electromagnetic radiation and ensuring the smooth operation of sensitive electronics.

4.2. Grounding Applications

Copper foil tape is commonly used for grounding electrical components. Grounding ensures that excess electrical charge is safely directed into the earth, preventing electrical shocks, equipment damage, and other hazards. Copper’s high conductivity makes it an ideal material for grounding, and it is often used to create conductive paths between components or to connect electronic devices to the ground.

4.3. Static Discharge Protection

In environments where static electricity can accumulate and potentially damage sensitive electronic components, it can be used to prevent static discharge. The tape can be applied to components or surfaces to dissipate static charges, reducing the risk of electrostatic discharge (ESD) damage.

4.4. Printed Circuit Board (PCB) Applications

This type of tape is frequently used in the production of printed circuit boards (PCBs). It is used to create conductive traces or to repair existing PCB traces. The tape can also be used for EMI shielding in PCBs to prevent interference from affecting the board’s performance.

4.5. Stained Glass and Crafting

Copper foil tape is also popular in the world of arts and crafts, particularly in stained glass projects. In stained glass, the copper foil is used to join individual pieces of glass together. The copper tape wraps around the edges of each piece of glass and is soldered to hold the pieces together, creating intricate designs. Copper foil tape’s malleability and aesthetic appeal make it an ideal material for artistic applications.

4.6. Solar Panel Applications

The tape can also be used in the production of solar panels. It is used to connect the cells of the solar panel, providing a conductive path that allows for the efficient flow of electricity. Copper’s high conductivity makes it an ideal choice for this purpose, ensuring that the solar panel operates efficiently.

4.7. Antenna and RF Shielding

The tape is used in antenna applications to improve signal quality and prevent interference. It is also used in radio frequency (RF) shielding, where its conductive properties help to block unwanted signals and reduce the impact of external interference on communication systems.

5. Advantages of Copper Foil Tape

There are several benefits to using copper foil tape in various applications. These advantages include:

- High Electrical Conductivity: Copper is one of the best materials for conducting electricity, making copper foil tape ideal for applications requiring efficient electrical connections or shielding from electromagnetic interference.

- Versatility: The tape can be used in a wide range of applications, from electronics to arts and crafts. Its ability to conform to various surfaces makes it highly adaptable.

- Easy Application: The adhesive backing on this type of tape makes it easy to apply to surfaces, reducing installation time and complexity.

- Durability: Copper’s resistance to corrosion and oxidation ensures that copper foil tape is long-lasting, even in harsh environments.

- Cost-Effective: This tape is a relatively inexpensive material, making it a cost-effective solution for a variety of applications.

6. Conclusion

Copper foil tape is a highly versatile material with a wide range of applications across many industries. Its excellent electrical conductivity, malleability, and resistance to corrosion make it ideal for use in EMI shielding, grounding, static discharge protection, and other electronic applications. Additionally, its use in arts and crafts adds an aesthetic and functional dimension to its many uses. Whether in electronics, telecommunications, solar panels, or stained glass projects, copper foil tape is an essential material that continues to prove its worth in countless applications.

As technology advances and the need for more effective shielding and electrical connections increases, copper foil tape will likely continue to be a critical material in a variety of fields. Understanding its properties and potential applications can help businesses and individuals alike make informed decisions when selecting materials for their projects.

You May Also Like

-

Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding

Mu-Ferro Foil for Electromagnetic Interference (EMI) ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

1. What is Mu-Ferro Foil?2. Composition of Mu-Ferro Foil3. Magnetic Properties of Mu-Ferro Foil4. Applications of Mu-Ferro Foil4.1 Electromagnetic Interference (EMI) Shielding4.2 Magnetic Field Shielding4.3 Transformer and Inductor Design4.4 Aerospace and Defense Applications5. Advantages of Mu-Ferro Foil6. Challenges and Considerations7. Conclusion Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding Mu-Ferro/Mu-metal foil is a specialized material widely used for electromagnetic interference (EMI) shielding and magnetic shielding applications. It is made primarily from a combination of iron (Fe) and nickel (Ni), offering exceptional magnetic properties, particularly high magnetic permeability. The unique characteristics of Mu-Ferro foil make it a key material for industries that require effective protection against electromagnetic radiation and magnetic fields, including electronics, telecommunications, aerospace, medical devices, and military applications. 1. What is Mu-Ferro Foil? Mu-Ferro/Mu-metal foil is a flexible, thin material that is primarily composed of iron and nickel alloys. Its key characteristic is its high magnetic permeability (denoted by the Greek letter "μ"), which enables it to effectively concentrate and guide magnetic fields. This makes Mu-Ferro foil an excellent material for both electromagnetic interference (EMI) shielding and magnetic field containment. The material is commonly used in foil or thin sheet form, which allows for easy integration into various electronic devices......

-

Spring finger contacts in PCB and SMD applications

Spring finger contacts in PCB and SMD applicationsFingerstrips

PCB/SMD spring finger contacts

Spring finger contacts 1. Basic Concepts2. Application Scenarios2.1 Consumer Electronics 1. Basic Concepts Spring finger contacts, also called "spring fingers" ,serve as connectors between PCBs and SMDs (Surface Mount Devices). They are typically employed where frequent insertion and removal or high reliability in connections are essential. Designed to offer low resistance and high-reliability connections, spring fingers also withstand a certain degree of mechanical stress, which adds to their durability in varying applications. 2. Application Scenarios Spring finger contacts are valuable in numerous industries, given their ability to provide stable, dependable connections. Below are some common scenarios: 2.1 Consumer Electronics In devices like smartphones, tablets, and laptops, spring finger contacts connect various small modules, such as SIM card trays, battery connectors, and antenna connectors. These components support the compact designs of consumer electronics by minimizing the need for complex wiring. 2.2 Industrial Equipment In industrial control and automation equipment, spring fingers are used to connect sensors, actuators, and other modules, maintaining stable connections even in harsh environments where mechanical stress or vibration might otherwise compromise the connection. 2.3 Medical Devices Reliable electrical connections are vital in medical devices for both safety and performance. Spring finger contacts are favored for their low......

-

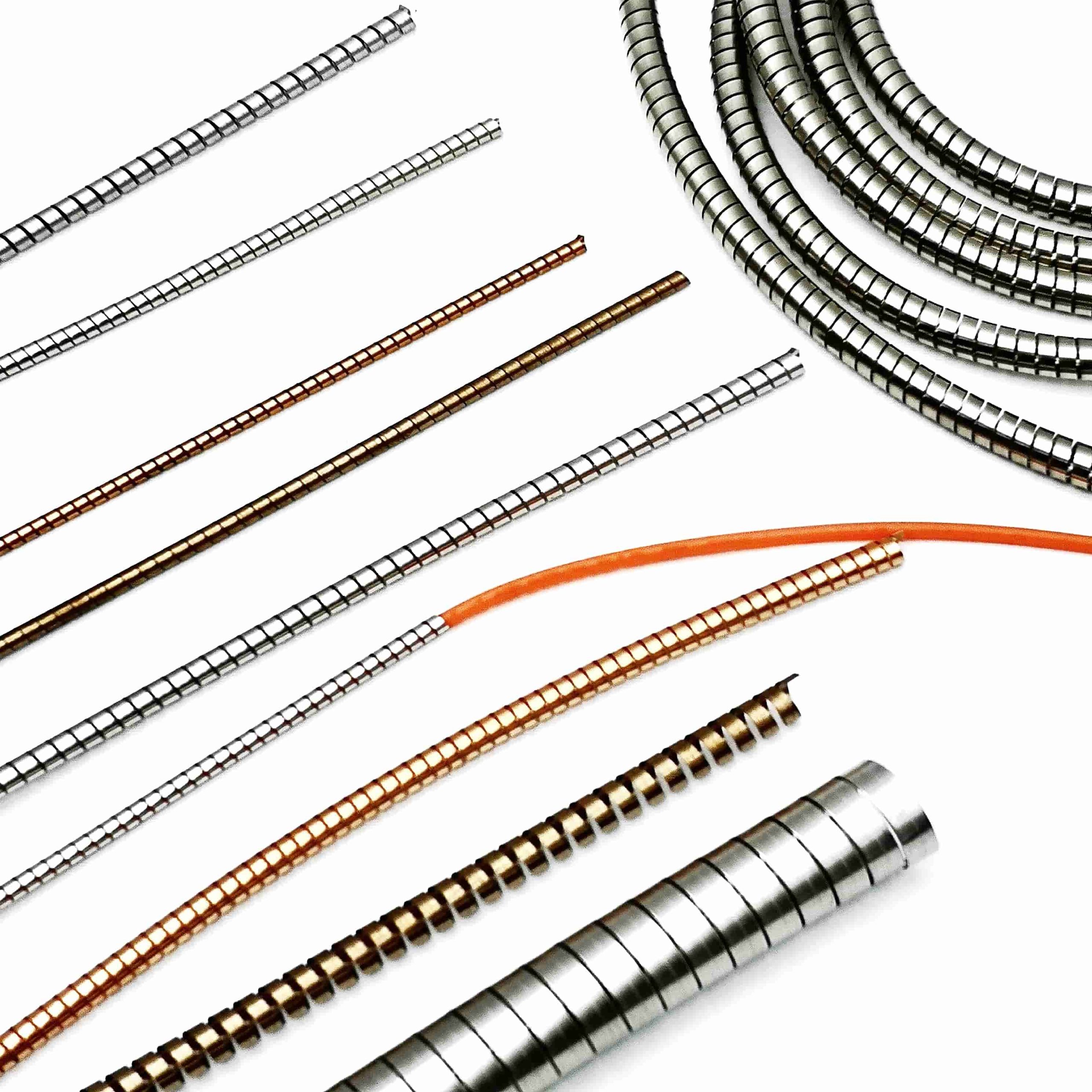

Handa spiral tubes with remarkable performance in EMI shielding applications

Handa spiral tubes with remarkable performance in EMI shielding applicationsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa spiral tubes https://www.handashielding.com/request-a-quote.html Material Properties of Handa Spiral TubesEMI Shielding Performance in Various FrequenciesPerformance in Humid and Corrosive EnvironmentsApplications Across IndustriesInstallation and Maintenance ConsiderationsConclusion and Future Outlook Handa spiral tubes are known for their remarkable performance in EMI shielding applications, particularly in humid or otherwise challenging environments. This functionality is largely due to the unique characteristics of their material composition and surface treatments. These tubes have become invaluable across industries, including telecommunications, aerospace, military, medical, and precision instrumentation, where reliable EMI shielding is crucial. Here is an expanded look at the comprehensive advantages, applications, and technological features of Handa spiral tubes, focusing on their functionality in humid conditions and their material properties. Material Properties of Handa Spiral Tubes The effectiveness of Handa spiral tubes in EMI shielding applications is largely a result of the materials used in their construction. The primary materials are: Beryllium Copper (BeCu): High Conductivity: Beryllium copper is widely recognized for its high electrical conductivity, which enables efficient electromagnetic wave transmission. This quality makes BeCu an excellent material for EMI shielding, allowing it to absorb and reflect interfering signals. Elasticity and Mechanical Resilience: Beryllium copper has exceptional elasticity, which allows the tubes to compress and return......

-

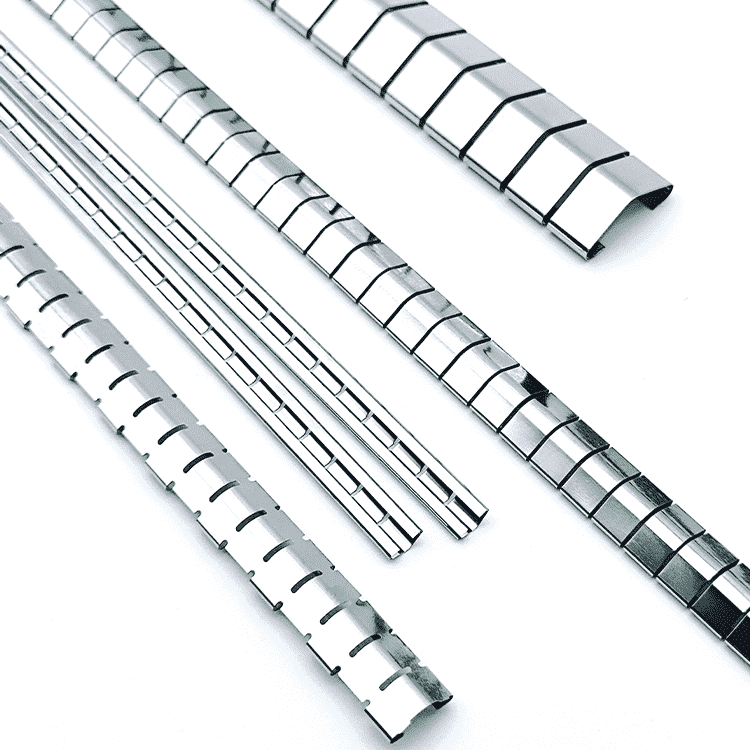

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shieldingEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Spiral shielding gaskets are essential components in various industrial applications, providing electromagnetic interference (EMI) shielding while ensuring reliable sealing. Their effectiveness, however, can be compromised in corrosive environments, making it crucial to enhance their corrosion resistance. This article explores the multifaceted strategies employed to improve the corrosion resistance of spiral shielding gaskets, covering material selection, surface treatment, design optimization, environmental testing, the use of composite materials, and maintenance practices. By understanding these strategies, manufacturers can ensure the durability and reliability of spiral shielding gaskets in demanding conditions. 1. Material Selection2. Surface Treatment3. Design Optimization4. Environmental Adaptability Testing5. Composite Materials6. Maintenance and CareConclusion Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding 1. Material Selection The foundation of a gasket's performance lies in its material. For spiral shielding gaskets, the choice of material directly impacts their corrosion resistance. 1.1 Stainless Steel Alloys Stainless steel is the most commonly used material for spiral shielding gaskets due to its inherent corrosion resistance. Among the various grades, 316L stainless steel stands out for several reasons: Molybdenum Content: The addition of molybdenum enhances 316L's resistance to pitting and crevice corrosion, particularly in chloride-rich environments, which are common in many industrial applications. Low Carbon Content: The low......

-

EMI Shielding Finger Stocks to protect sensitive electronic equipment

EMI Shielding Finger Stocks to protect sensitive electronic equipmentEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

EMI Shielding Finger Stocks(Fingerstrips) Introduction to EMI Shielding Finger StocksBasic ConceptsKey Features and Types of EMI Shielding Finger StocksPerformance StandardsApplications of EMI Shielding Finger StocksInstallation MethodsAdvantages of EMI Shielding Finger StocksLimitations of EMI Shielding Finger StocksFuture DevelopmentsConclusion EMI Shielding Finger Stocks(Fingerstrips) are crucial components used in various industries to protect sensitive electronic equipment from electromagnetic interference (EMI). Made from specialized alloys such as beryllium copper, these materials ensure stable signal transmission while preventing external disturbances. This article will delve into the intricacies of EMI Shielding Finger Stocks, exploring their design, types, performance standards, applications, installation methods, advantages, limitations, and future developments. Introduction to EMI Shielding Finger Stocks Electromagnetic interference can significantly impact the performance and reliability of electronic devices. EMI Shielding Finger Stocks are engineered to mitigate these effects, providing a barrier that reflects or absorbs electromagnetic waves. Their unique design allows them to create effective seals in various electronic applications, ensuring that sensitive components remain protected from external interference. Basic Concepts EMI Shielding Finger Stocks consist of resilient metal strips with a "finger-like" structure. This design enhances the ability of the material to conform to irregular surfaces and create a reliable contact. Beryllium copper is often the material of......