Custom O-Ring Gaskets

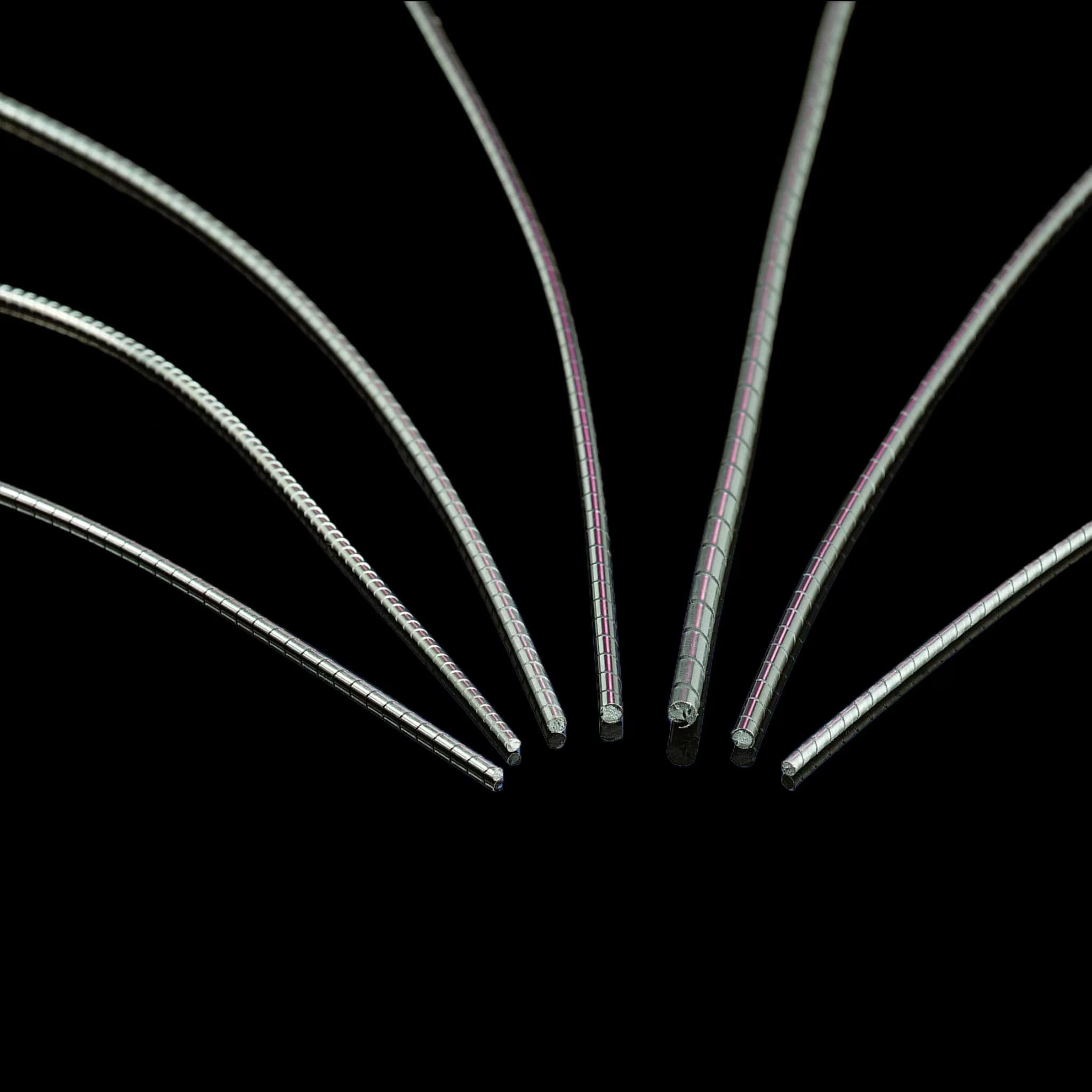

Handa Custom O-Ring Gaskets are manufactured from flat strips of stainless steel and other alloys wound into helical geometries of circular cross-section. Beryllium copper and stainless steel materials are common in the market and can be plated with gold, silver or tin. Can be ordered as needed.

Handa Custom O-Ring Gaskets is typically used in static or slow dynamic applications in low-temperature, H Springs are available in five standard sizes and can be ordered or cut and welded to specific diameters as required. For more information, please contact Handa Shielding.

Custom Manufacturing

Custom Custom O-Ring Gaskets

Custom O-ring gaskets manufacturing involves producing O-ring gaskets that are tailored to meet specific requirements and applications. O-ring gaskets are circular elastomeric seals with a round cross-section, and they are commonly used to prevent the leakage of fluids or gases in various industrial, automotive, aerospace, and household applications.

Product Specs

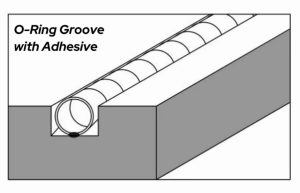

Recommended Groove Size

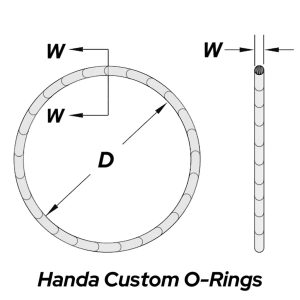

The following is a drawing for size reference.

| Dash No. | Dimensions | |||

| W (mm) | Tol (mm) | ID(mm) | Tol (mm) | |

| HDO-BS-011-033 | 1.78 | ±0.076 | 7.65-50.52 | ±0.508 |

| HDO-BS-034-050 | 1.78 | ±0.076 | 53.7-133.07 | ±0.762 |

| HDO-BS-111-136 | 2.62 | 0.0102 | 10.77-50.47 | ±0.508 |

| HDO-BS-137-154 | 2.62 | ±0.102 | 52.07-94.92 | ±0.762 |

| HDO-BS-155-173 | 2.62 | ±0.102 | 101.27-215.57 | ±0.889 |

| HDO-BS-174-178 | 2.62 | ±0.102 | 221.92-247.32 | ±.040″ |

| HDO-BS-210-234 | 3.53 | ±0.127 | 18.64-75.79 | ±0.508 |

| HDO-BS-235-250 | 3.53 | ±0.127 | 78.97-126.59 | ±0.762 |

| HDO-BS-251-257 | 3.53 | ±0.127 | 129.77-148.82 | ±0.889 |

| HDO-BS-258-270 | 3.53 | ±0.127 | 151.99-228.12 | ±1.02 |

| HDO-BS-271-276 | 3.53 | ±0.127 | 234.54-278.99 | ±.1.14 |

| HDO-BS-277-284 | 3.53 | ±0.127 | 291.69-456.06 | ±1.27 |

Available options

Custom o-rings can be made from many types of these gaskets:

- Handa Spiral-Shield

- Handa Quick-Shield

- Handa Ultra Quick-Shield

- Handa Flexi-Shield*

- Handa Endur-Shield*

- Handa D Multi-Seal

Plating

The gasket is electroplated, 90% tin, 10% lead (edges unplated).

Plating options can be specified by adding a prefix before the part number:

E: Edge tin/lead plating (includes edges) for high humidity or salt-fog environments

BS: RoHS compliant tin plating (Example:HDO-BS-034)

Applications

Materials

These o-rings are fabricated from our standard force Handa Endur-Shield or Flexi-Shield gasket material. The solid core or tubing renders it highly durable, particularly in sliding applications such as connectors. Spiral: Tin/lead plated beryllium copper. (See Options for RoHS compliance). Core: Flexi-Shield: 60 durometer silicone tubing. Endur-Shield: cured silicone adhesive.

Shielding performance

Handa Endur-Shield or Flexi-Shield O-Rings provide shielding quality ranging from 116 dB to 152 dB. The shielding quality of each type might vary based on your specific application.

Compression force

Handa Endur-Shield or Flexi-Shield standard O-Rings necessitate approximately 30 pounds per linear inch for proper compression. The optimal compression of the gasket is 25% of the diameter of the spiral.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote