Do You Know What are RF/EMI Shield Spiral Gaskets?

Radio Frequency (RF) and Electromagnetic Interference (EMI) shield spiral gaskets(RF/EMI Shield Spiral Gaskets) play a crucial role in protecting sensitive electronic devices from electromagnetic interference. These gaskets are designed to offer superior RF/EMI shielding effectiveness, making them indispensable in various industries where electromagnetic compatibility is critical. This article delves into the applications of RF/EMI shield spiral gaskets, highlighting their importance across different sectors.

Table of Contents

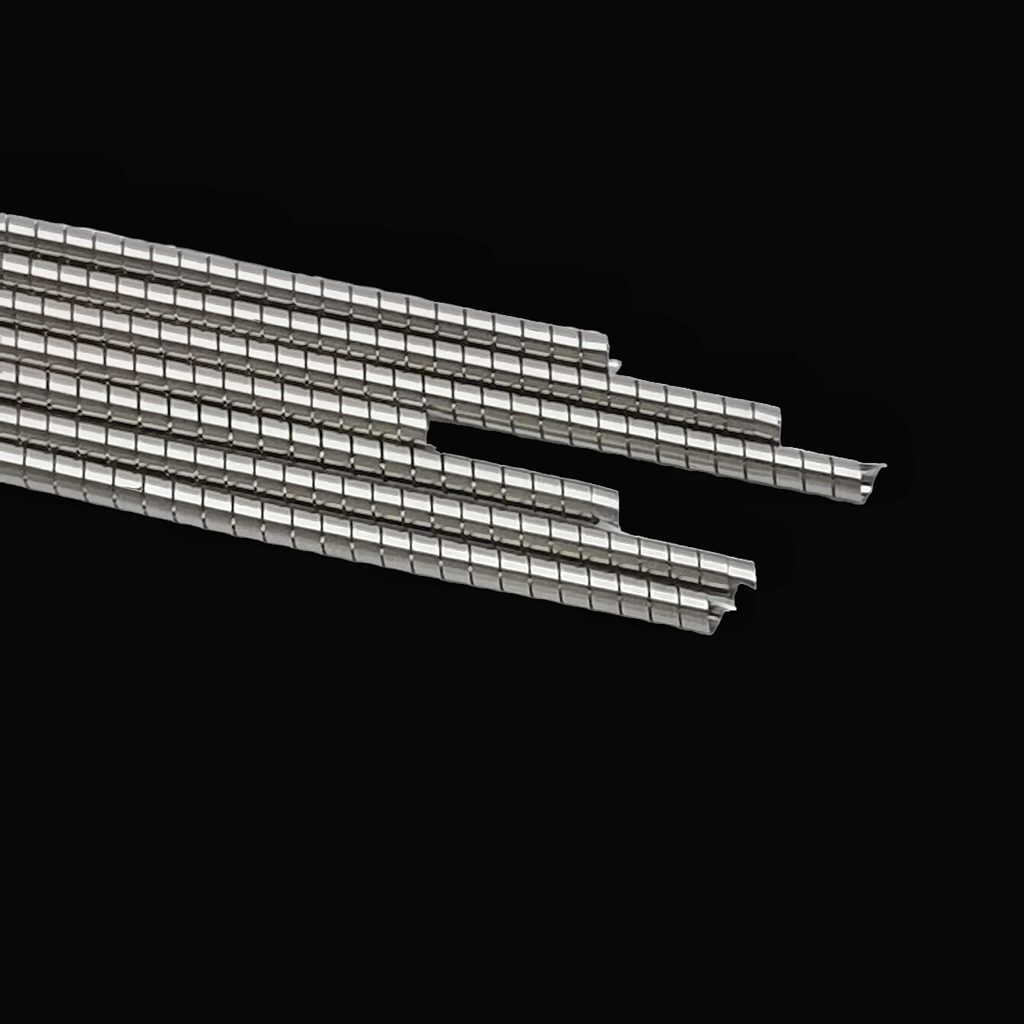

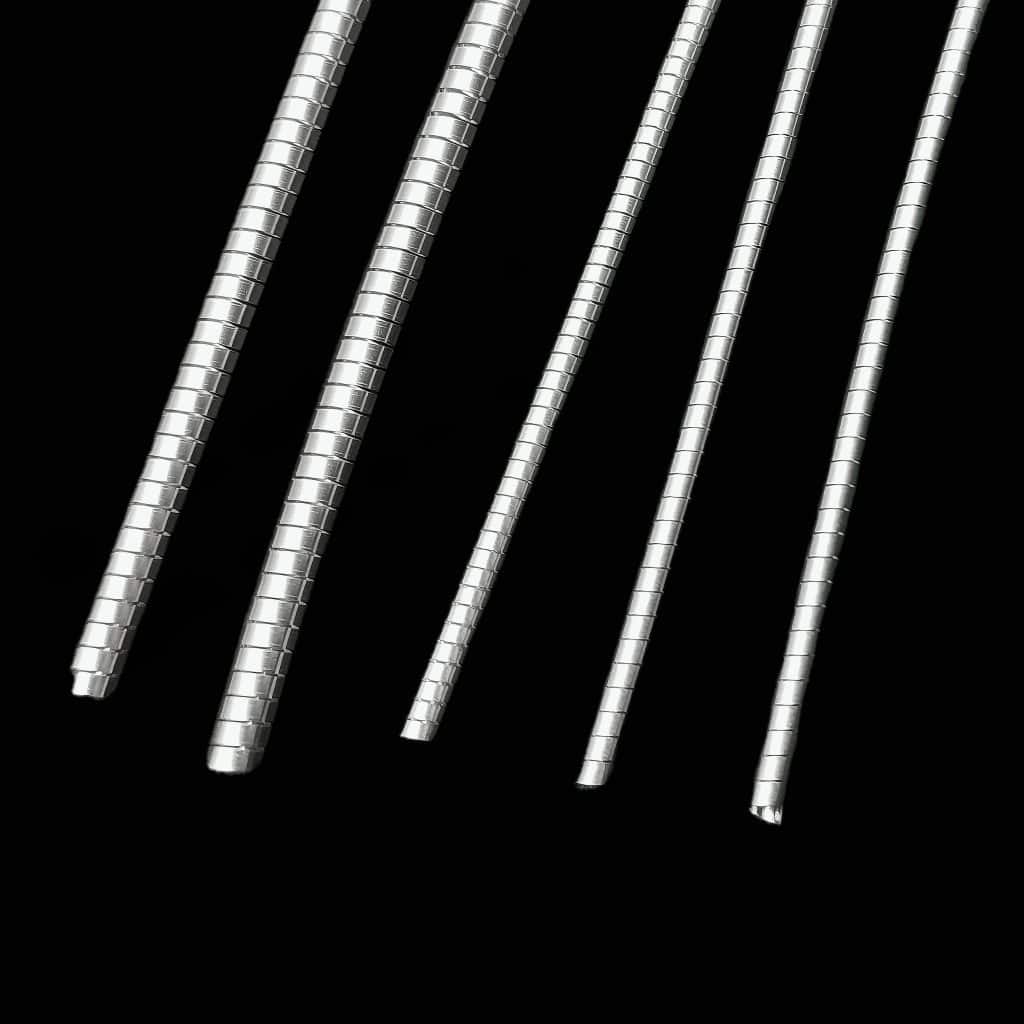

Overview of RF/EMI Shield Spiral Gaskets

RF/EMI shield spiral gaskets are engineered to provide exceptional electromagnetic shielding performance. They are crafted using high elasticity materials like Sn/Ni plated BeCu or stainless steel sheets, which are spiraled to ensure excellent elasticity, flexibility, and high shielding effectiveness. This design allows these gaskets to be highly effective in environments where sensitive equipment requires protection against electromagnetic interference.

Superior RF/EMI Shielding Effectiveness

One of the standout features of RF/EMI shield spiral gaskets is their superior RF/EMI shielding effectiveness, exceeding 100 dB. This level of shielding is crucial for preventing electromagnetic interference from affecting the operation of sensitive electronic components within devices. The shielding effectiveness can be adjusted through variations in the ribbon strip thickness and spiral pitch, offering standard, medium, and low force options to cater to different application needs.

Benefits of RF/EMI Shield Spiral Gaskets

- Effective Shielding: The spiral design provides continuous contact and effective shielding against a wide range of frequencies.

- Flexibility and Durability: Spiral gaskets are flexible and can conform to irregular surfaces, ensuring a reliable seal and long-lasting performance.

- Ease of Installation: They are relatively easy to install and replace, minimizing downtime and maintenance costs.

- Cost-Effective: The use of spiral gaskets can be a cost-effective solution for EMI/RFI shielding compared to other methods.

Wide Range of Applications

The versatility of RF/EMI shield spiral gaskets makes them suitable for a broad spectrum of applications, particularly in environments where electromagnetic compatibility is paramount. Some of the key areas where these gaskets find extensive use include:

- Semiconductor Manufacturing Equipment: Plasma etching equipment, for instance, benefits from the high shielding effectiveness of RF/EMI shield spiral gaskets to protect delicate semiconductor wafers from electromagnetic interference during processing.

- Telecommunication Equipment: The rapid advancement of telecommunications technology necessitates robust EMI shielding solutions to prevent signal degradation and ensure reliable communication.

- Military Equipment: Military electronics often operate in complex electromagnetic environments, making RF/EMI shield spiral gaskets essential for maintaining operational integrity and security.

- Satellite Equipment: Satellites and related ground stations require stringent EMI shielding to safeguard against potential interference, ensuring clear and uninterrupted communication signals.

Materials of RF/EMI Shield Spiral Gaskets

The choice of material is crucial for achieving the desired level of shielding effectiveness, durability, and compatibility with the environment in which the gasket is deployed. Based on the information provided, here are the common materials used in RF/EMI shield spiral gaskets:

High Elasticity Sn/Ni Plated BeCu

- Beryllium Copper (BeCu): Beryllium copper, often referred to as spring brass, is a popular choice for EMI shielding gaskets due to its excellent electrical conductivity and high elastic limit. Its ability to maintain its shape under pressure makes it ideal for applications requiring frequent compression and decompression cycles.

- Nickel (Ni) Plating: Nickel plating enhances the corrosion resistance of beryllium copper, making it suitable for use in harsh environments. The nickel coating also improves the gasket’s solderability, which can be beneficial in certain assembly processes.

Stainless Steel Sheet

- Stainless Steel: Stainless steel is another material commonly used in the manufacture of RF/EMI shield spiral gaskets. It offers good electrical conductivity and is highly resistant to corrosion, making it suitable for a wide range of applications, including those exposed to corrosive environments or high temperatures.

Customization and Ease of Installation

RF/EMI shield spiral gaskets are designed for ease of installation and customization. They can be easily cut and inserted into grooves, accommodating various sizes and shapes required by different applications. Additionally, O-rings are available for precision spot welding, enhancing the sealing capability of these gaskets. This customization ensures that manufacturers can tailor the shielding solution to meet the specific requirements of their products or systems.

Conclusion

RF/EMI shield spiral gaskets represent a cutting-edge solution in the fight against electromagnetic interference, offering unparalleled protection for sensitive electronic devices. Their wide range of applications, from semiconductor manufacturing to military equipment, underscores their significance in today’s increasingly electrified world. As technology continues to evolve, the demand for effective EMI shielding solutions will undoubtedly grow, making RF/EMI shield spiral gaskets an essential component in the arsenal of engineers and designers tasked with creating tomorrow’s technologies.

This comprehensive overview of the applications of RF/EMI shield spiral gaskets highlights their importance in safeguarding electronic devices from electromagnetic interference. By leveraging the unique properties of these gaskets, Handa Shielding can ensure the reliability and longevity of our products, contributing to advancements in technology and innovation.