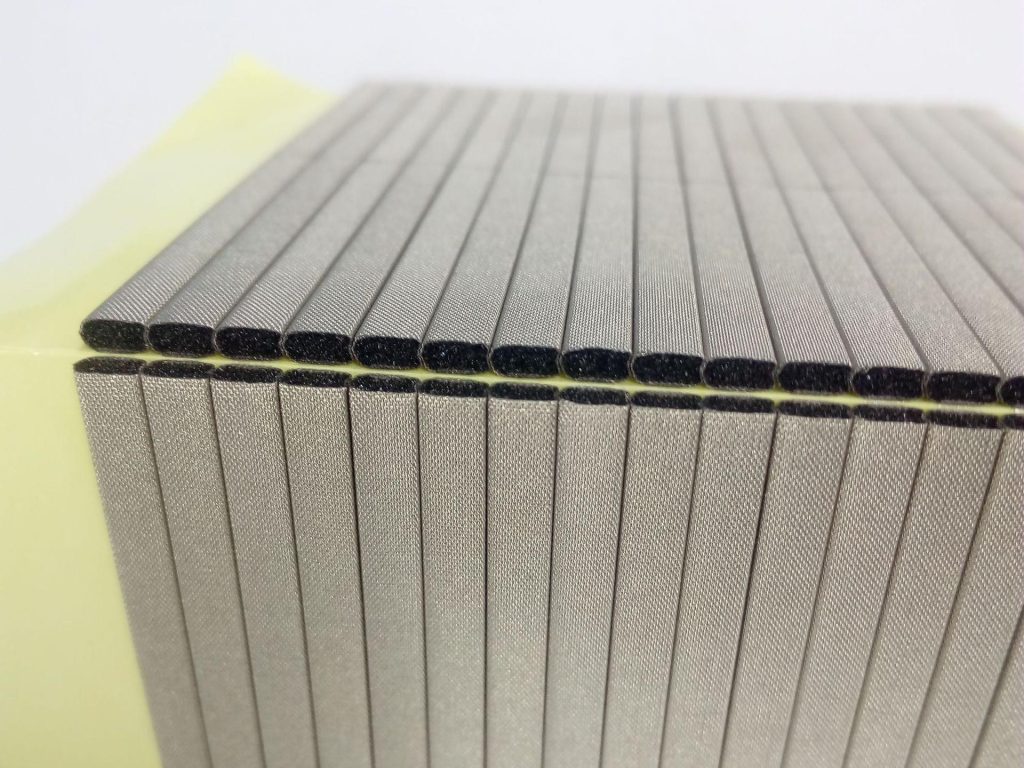

Durable and Lightweight Electrically Conductive Foam for Superior EMI Protection

Electrically conductive foam, often described as a porous material composed of rubber matrix embedded with conductive fillers, provides the ideal combination of lightweight structure and electrical functionality. Its remarkable properties make it a valuable choice for numerous industries that require both cushioning and electrical conductivity.

Table of Contents

Electrically conductive foam

In modern industries, material performance and lightweight solutions are crucial for driving innovation. Among the various advancements in material science, electrically conductive foam has emerged as a highly versatile and efficient material, offering both high conductivity and the benefits of lightweight, flexible foam. Combining electrical conductivity with the characteristics of traditional foams, such as cushioning and energy absorption, electrically conductive foam is now widely used across various sectors. This article will explore the unique properties, manufacturing processes, diverse applications, and future trends of electrically conductive foam.

1. Characteristics of Electrically Conductive Foam

Electrically conductive foam, often described as a porous material composed of rubber matrix embedded with conductive fillers, provides the ideal combination of lightweight structure and electrical functionality. Its remarkable properties make it a valuable choice for numerous industries that require both cushioning and electrical conductivity. Some of the most notable characteristics of electrically conductive foam include:

Lightweight Structure

One of the primary benefits of electrically conductive foam is its lightweight nature. The foaming process significantly reduces the material’s density, making it lighter than solid rubber or metals. This characteristic is crucial for applications where weight reduction is essential, such as in automotive and aerospace industries. By incorporating gas bubbles into the material, foam maintains the necessary strength and resilience but at a much lower weight, enhancing efficiency and reducing the load on mechanical systems.

High Elasticity and Flexibility

Electrically conductive foam retains the flexibility and elasticity typical of rubber materials, even with a high foam ratio. This ensures that the foam can absorb shocks and vibrations effectively, making it suitable for applications such as impact protection, cushioning, and sealing. Despite its lightweight nature, the foam remains flexible enough to conform to different shapes, ensuring a snug fit in various applications.

Excellent Thermal and Acoustic Insulation

The porous structure of electrically conductive foam also endows it with excellent thermal and sound insulation properties. In applications where noise reduction or temperature control is necessary, conductive foam provides an effective barrier. For instance, it can be used in soundproofing panels for the construction industry or insulation pads for electronic components. Its ability to insulate both heat and sound contributes to improved energy efficiency and comfort in various settings.

Chemical Resistance

Another significant advantage of electrically conductive foam is its resistance to chemicals. Depending on the base rubber material used, the foam can be formulated to withstand exposure to harsh chemicals, oils, and other aggressive substances. This makes it an excellent choice for use in industrial environments, particularly in sectors like manufacturing, marine applications, and chemical processing.

Energy Absorption and Shock Resistance

Due to its porous structure, electrically conductive foam is particularly adept at absorbing energy. It can compress under impact or pressure, absorbing and dissipating the energy rather than transmitting it to the rest of the system. This property makes it highly effective in packaging applications, cushioning fragile electronics, or as a protective layer in automotive or industrial machinery.

2. Manufacturing Process of Electrically Conductive Foam

The production of electrically conductive foam involves multiple precise steps, from selecting the base materials to processing the foam into the desired shape and form. Below is a detailed breakdown of the manufacturing process:

Material Selection

The manufacturing of electrically conductive foam begins with the selection of the base rubber matrix, which serves as the foundation for the foam. Common rubber matrices include natural rubber, nitrile rubber, silicone rubber, and neoprene. Each of these materials offers distinct properties that make them suitable for specific applications. For instance:

- Natural Rubber: Known for its elasticity and resilience, often used in automotive and heavy-duty applications.

- Nitrile Rubber: Excellent chemical resistance, commonly used in environments where exposure to oils and chemicals is expected.

- Silicone Rubber: High temperature and weather resistance, ideal for use in extreme environments, including electronics and aerospace.

Conductive Fillers

To achieve electrical conductivity, conductive fillers are incorporated into the rubber matrix. These fillers are typically materials such as carbon black, graphite, carbon nanotubes, or metal powders (e.g., copper or aluminum). The type and concentration of filler used determine the foam’s conductivity, and careful control of this aspect is essential to ensure that the foam meets the specific conductivity requirements of its intended application.

Foaming Agent and Process

A foaming agent is added to the rubber mixture to create the foam’s structure. Foaming agents can be classified into two types: chemical foaming agents and physical foaming agents.

- Chemical Foaming Agents: These agents release gas when exposed to heat or chemical reactions, causing the material to foam. Chemical agents often create fine, uniform cells in the foam, contributing to better insulation and cushioning properties.

- Physical Foaming Agents: These agents rely on physical processes like gas injection or heat to produce bubbles within the material. The foaming process involves heating the rubber mixture, causing the foaming agent to release gas, resulting in a cellular structure.

Mixing and Refining

After adding the foaming agent and conductive fillers, the rubber mixture is thoroughly blended. This step ensures uniform distribution of all components, including the conductive fillers, throughout the matrix. This stage is critical to achieving consistent foam properties, such as uniform conductivity and desired elasticity.

Molding and Forming

Once mixed, the rubber mixture is placed into molds or extruded into the desired shape. Different molding processes can be used, including:

- Extrusion: The mixture is forced through a mold, creating continuous shapes such as sheets or tubes.

- Compression Molding: The mixture is placed into a mold and subjected to heat and pressure, forming the foam into a specific shape.

- Injection Molding: The material is injected into a mold cavity, allowing for more complex shapes and finer details.

Post-Treatment and Curing

After molding, the foam is subjected to a curing process that solidifies the material, ensuring its final shape and stability. The foam is then cooled, shaped as necessary, and may undergo additional processes like cutting, grinding, or coating to meet specific application requirements.

3. Applications of Electrically Conductive Foam

Electrically conductive foam’s unique combination of electrical conductivity, cushioning, and insulating properties makes it suitable for a wide range of applications across various industries. Below are some of the key areas where electrically conductive foam is used:

Automotive Industry

In the automotive sector, electrically conductive foam is widely used for a variety of purposes, from noise reduction and insulation to electrical shielding. For example:

- Seals and Gaskets: Conductive foam is used in door seals, windows, and gaskets to prevent electromagnetic interference (EMI) and provide a waterproof and dustproof seal.

- Seat Cushions: The foam’s shock absorption properties improve passenger comfort while providing electrical insulation in certain automotive components.

Aerospace and Defense

In the aerospace and defense industries, electrical conductivity is crucial for preventing EMI, which can interfere with sensitive systems and electronics. Electrically conductive foam is used to protect onboard electronic systems from external interference, as well as in sealing and cushioning applications within spacecraft and defense equipment.

Consumer Electronics

As the demand for smaller, more efficient electronic devices grows, the need for conductive foam in consumer electronics has expanded. It’s commonly used in:

- Smartphones and Tablets: Conductive foam is used in the protective casings and cushioning for electronics, absorbing shocks and reducing the risk of damage from drops or impacts.

- Laptops and Computers: Foam is also used to provide thermal management, preventing overheating of sensitive components and offering electrical conductivity for EMI shielding.

Medical Devices

In medical devices, electrically conductive foam can be employed to provide EMI shielding, protect sensitive instruments, and act as an insulator. Medical imaging devices, monitors, and diagnostic equipment often rely on conductive foam to maintain optimal functioning and prevent interference from external electrical signals.

Packaging

One of the most common uses for conductive foam is in packaging fragile electronics or equipment. The foam provides superior cushioning, absorbing impacts during shipping, and protects the components from static electricity. It is especially useful in packaging high-tech items like circuit boards, microprocessors, and optical sensors.

4. Emerging Trends and Future of Electrically Conductive Foam

As technology continues to advance, the demand for high-performance, multifunctional materials is increasing. Electrically conductive foam is expected to evolve in several key areas:

Development of High-Performance Materials

Future developments in conductive foam will focus on improving its heat resistance, mechanical strength, and chemical resistance. Materials with enhanced properties will be needed to withstand extreme conditions in industries like aerospace, automotive, and defense, where reliability and durability are paramount.

Sustainability and Eco-Friendly Solutions

As industries strive to reduce their environmental impact, there will be a growing emphasis on sustainable materials. Electrically conductive foam manufacturers are exploring eco-friendly alternatives to traditional synthetic rubbers and foaming agents. Research into biodegradable conductive foams and recyclable materials could lead to environmentally friendly solutions that meet both performance and sustainability criteria.

Integration with Smart Technologies

The integration of conductive foam with sensor technology could lead to the development of smart materials that not only provide shielding and insulation but also monitor system performance and provide feedback. These “smart” foams could have self-healing properties or adapt to changing environmental conditions, offering enhanced functionality and longer lifecycles.

Customization and Advanced Manufacturing Techniques

With advancements in 3D printing and other additive manufacturing methods, the production of custom electrically conductive foams will become more accessible. This will enable manufacturers to design foams tailored to specific requirements in terms of shape, density, conductivity, and elasticity. Custom solutions will become increasingly important for niche applications across industries.

5. Conclusion

Electrically conductive foam represents a cutting-edge solution that combines the best of lightweight foam with electrical conductivity. Its unique properties make it indispensable in industries that require both impact protection and electrical shielding. With its diverse applications and ongoing innovations, conductive foam is set to play a critical role in the future of electronics, automotive, medical devices, and packaging. The continued evolution of this material, driven by advanced manufacturing techniques, eco-friendly considerations, and smart technology integration, ensures that electrically conductive foam will remain a key enabler of high-performance, lightweight, and efficient products in the coming years.

As industries continue to push the boundaries of technology, the demand for advanced materials like electrically conductive foam grows, particularly in sectors that require both lightweight properties and high-performance electrical shielding. A key player in providing these solutions is Handa Shielding, a leading manufacturer of high-quality EMI shielding products. Their expertise in creating precision-engineered components, including conductive foams and other shielding materials, ensures that manufacturers can meet the most stringent demands for electromagnetic interference (EMI) protection. With a commitment to innovation and quality, Handa Shielding stands at the forefront of the materials revolution, helping industries build safer, more efficient products for the future.

You May Also Like

-

Copper foil tape with high conductivity&malleability

EMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Copper foil tape 1. Introduction to Copper Foil Tape2. Properties of Copper Foil Tape3. Types of Copper Foil Tape4. Applications of Copper Foil Tape4.1. Electromagnetic Interference (EMI) Shielding4.2. Grounding Applications4.3. Static Discharge Protection4.4. Printed Circuit Board (PCB) Applications4.5. Stained Glass and Crafting4.6. Solar Panel Applications4.7. Antenna and RF Shielding5. Advantages of Copper Foil Tape6. Conclusion Copper foil tape is a versatile and highly functional material made from thin sheets of copper, typically combined with an adhesive backing. Copper’s inherent properties, such as high conductivity, malleability, and resistance to corrosion, make copper foil tape an ideal material for a wide variety of applications, from electronic shielding to artistic endeavors. In this article, we will explore copper foil tape in depth, discussing its properties, types, uses, and the advantages it offers across different industries. 1. Introduction to Copper Foil Tape Copper foil tape is a thin, flexible, and conductive tape made from copper foil that is typically coated with an adhesive on one side. The tape’s adhesive backing allows it to be easily applied to surfaces, making it a convenient material for various applications. The copper material offers excellent electrical conductivity, which is why it is commonly used for electromagnetic shielding, grounding,......

-

Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding

Mu-Ferro Foil for Electromagnetic Interference (EMI) ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Mu-ferro/mu-metal foil

1. What is Mu-Ferro Foil?2. Composition of Mu-Ferro Foil3. Magnetic Properties of Mu-Ferro Foil4. Applications of Mu-Ferro Foil4.1 Electromagnetic Interference (EMI) Shielding4.2 Magnetic Field Shielding4.3 Transformer and Inductor Design4.4 Aerospace and Defense Applications5. Advantages of Mu-Ferro Foil6. Challenges and Considerations7. Conclusion Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding Mu-Ferro/Mu-metal foil is a specialized material widely used for electromagnetic interference (EMI) shielding and magnetic shielding applications. It is made primarily from a combination of iron (Fe) and nickel (Ni), offering exceptional magnetic properties, particularly high magnetic permeability. The unique characteristics of Mu-Ferro foil make it a key material for industries that require effective protection against electromagnetic radiation and magnetic fields, including electronics, telecommunications, aerospace, medical devices, and military applications. 1. What is Mu-Ferro Foil? Mu-Ferro/Mu-metal foil is a flexible, thin material that is primarily composed of iron and nickel alloys. Its key characteristic is its high magnetic permeability (denoted by the Greek letter "μ"), which enables it to effectively concentrate and guide magnetic fields. This makes Mu-Ferro foil an excellent material for both electromagnetic interference (EMI) shielding and magnetic field containment. The material is commonly used in foil or thin sheet form, which allows for easy integration into various electronic devices......

-

Spring finger contacts in PCB and SMD applications

Spring finger contacts in PCB and SMD applicationsFingerstrips

PCB/SMD spring finger contacts

Spring finger contacts 1. Basic Concepts2. Application Scenarios2.1 Consumer Electronics 1. Basic Concepts Spring finger contacts, also called "spring fingers" ,serve as connectors between PCBs and SMDs (Surface Mount Devices). They are typically employed where frequent insertion and removal or high reliability in connections are essential. Designed to offer low resistance and high-reliability connections, spring fingers also withstand a certain degree of mechanical stress, which adds to their durability in varying applications. 2. Application Scenarios Spring finger contacts are valuable in numerous industries, given their ability to provide stable, dependable connections. Below are some common scenarios: 2.1 Consumer Electronics In devices like smartphones, tablets, and laptops, spring finger contacts connect various small modules, such as SIM card trays, battery connectors, and antenna connectors. These components support the compact designs of consumer electronics by minimizing the need for complex wiring. 2.2 Industrial Equipment In industrial control and automation equipment, spring fingers are used to connect sensors, actuators, and other modules, maintaining stable connections even in harsh environments where mechanical stress or vibration might otherwise compromise the connection. 2.3 Medical Devices Reliable electrical connections are vital in medical devices for both safety and performance. Spring finger contacts are favored for their low......

-

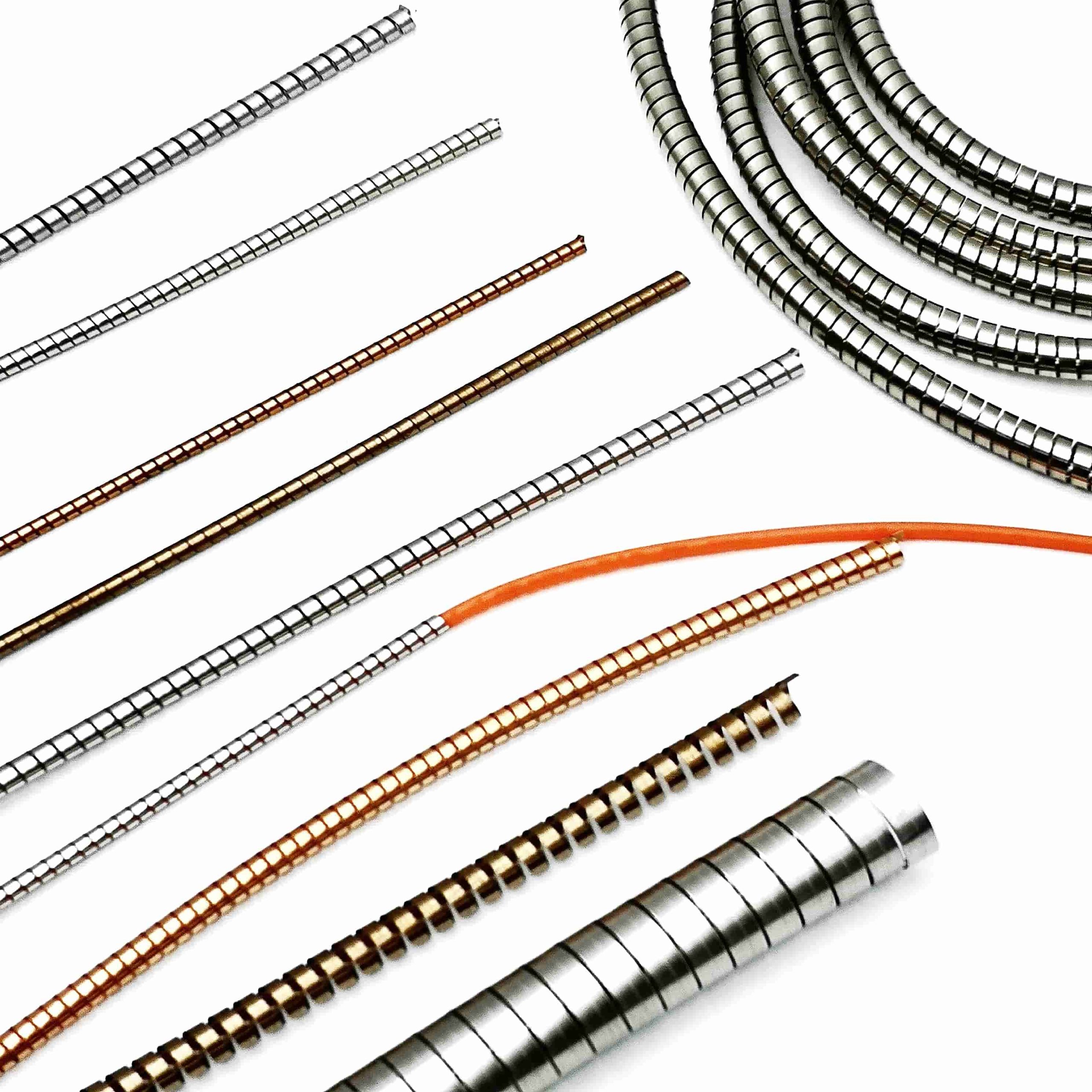

Handa spiral tubes with remarkable performance in EMI shielding applications

Handa spiral tubes with remarkable performance in EMI shielding applicationsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa spiral tubes https://www.handashielding.com/request-a-quote.html Material Properties of Handa Spiral TubesEMI Shielding Performance in Various FrequenciesPerformance in Humid and Corrosive EnvironmentsApplications Across IndustriesInstallation and Maintenance ConsiderationsConclusion and Future Outlook Handa spiral tubes are known for their remarkable performance in EMI shielding applications, particularly in humid or otherwise challenging environments. This functionality is largely due to the unique characteristics of their material composition and surface treatments. These tubes have become invaluable across industries, including telecommunications, aerospace, military, medical, and precision instrumentation, where reliable EMI shielding is crucial. Here is an expanded look at the comprehensive advantages, applications, and technological features of Handa spiral tubes, focusing on their functionality in humid conditions and their material properties. Material Properties of Handa Spiral Tubes The effectiveness of Handa spiral tubes in EMI shielding applications is largely a result of the materials used in their construction. The primary materials are: Beryllium Copper (BeCu): High Conductivity: Beryllium copper is widely recognized for its high electrical conductivity, which enables efficient electromagnetic wave transmission. This quality makes BeCu an excellent material for EMI shielding, allowing it to absorb and reflect interfering signals. Elasticity and Mechanical Resilience: Beryllium copper has exceptional elasticity, which allows the tubes to compress and return......

-

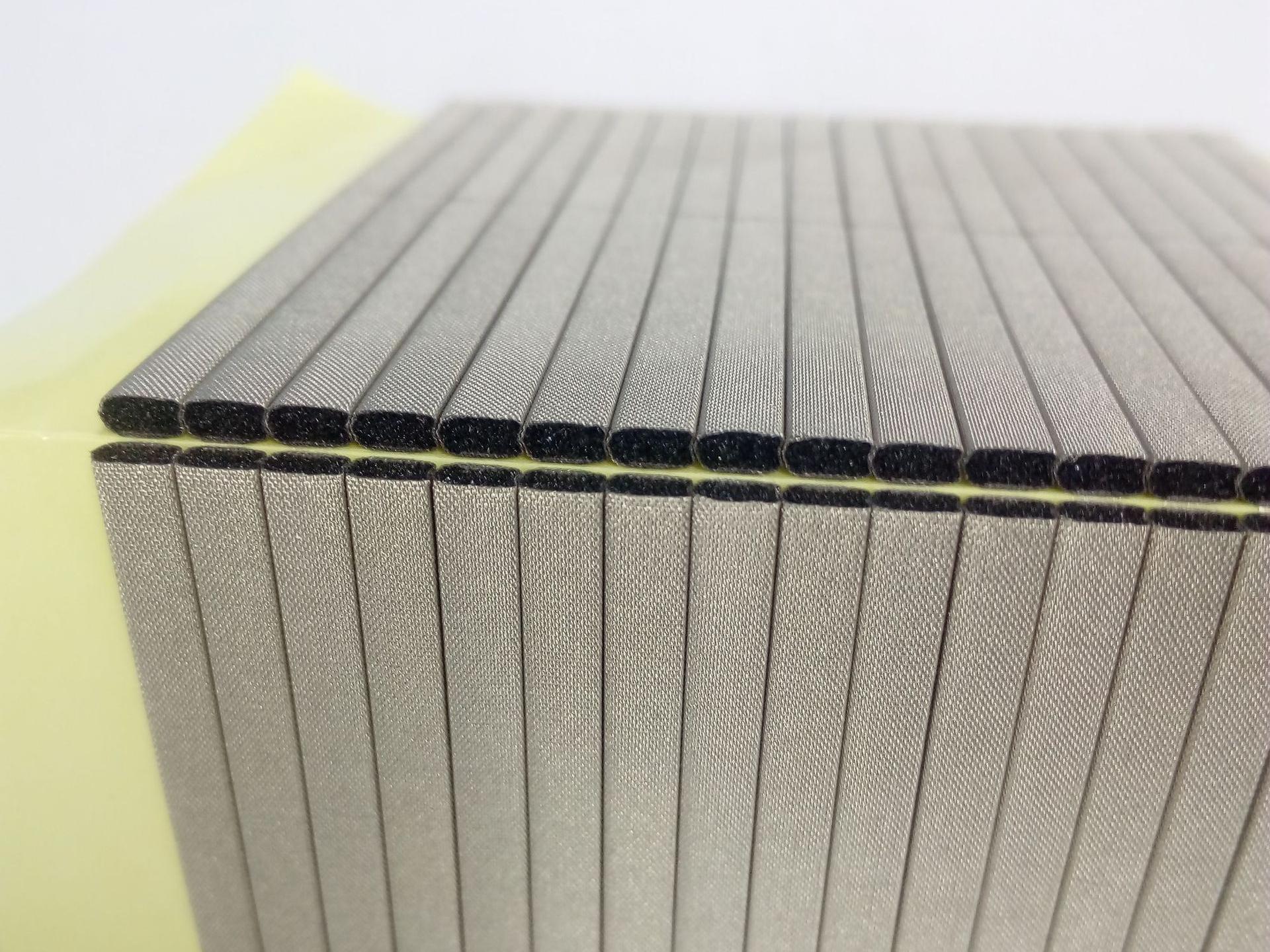

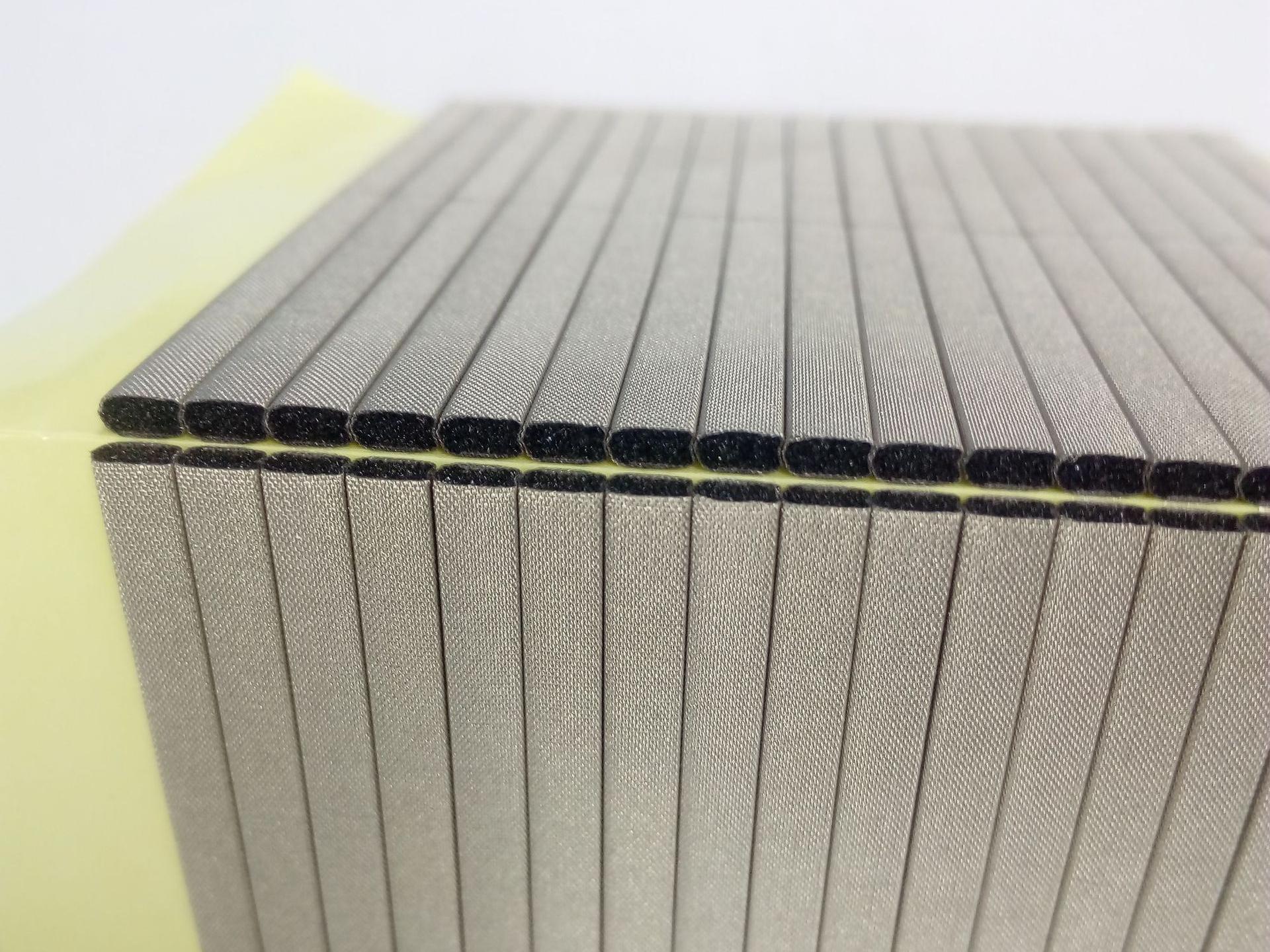

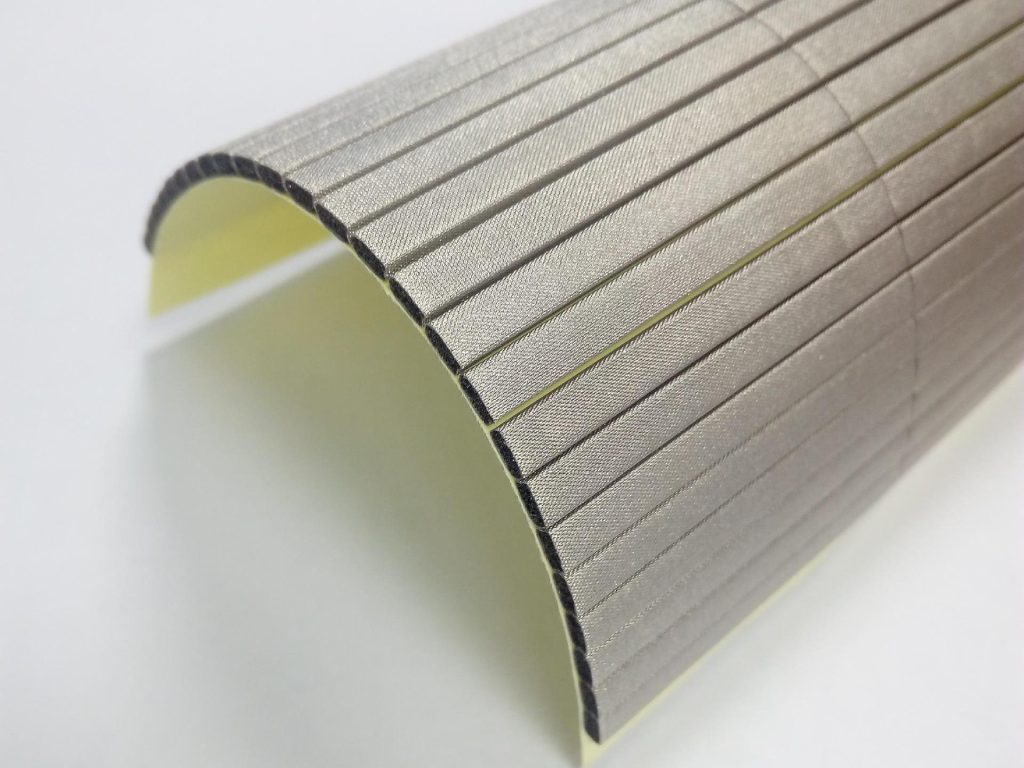

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shieldingEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Spiral shielding gaskets are essential components in various industrial applications, providing electromagnetic interference (EMI) shielding while ensuring reliable sealing. Their effectiveness, however, can be compromised in corrosive environments, making it crucial to enhance their corrosion resistance. This article explores the multifaceted strategies employed to improve the corrosion resistance of spiral shielding gaskets, covering material selection, surface treatment, design optimization, environmental testing, the use of composite materials, and maintenance practices. By understanding these strategies, manufacturers can ensure the durability and reliability of spiral shielding gaskets in demanding conditions. 1. Material Selection2. Surface Treatment3. Design Optimization4. Environmental Adaptability Testing5. Composite Materials6. Maintenance and CareConclusion Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding 1. Material Selection The foundation of a gasket's performance lies in its material. For spiral shielding gaskets, the choice of material directly impacts their corrosion resistance. 1.1 Stainless Steel Alloys Stainless steel is the most commonly used material for spiral shielding gaskets due to its inherent corrosion resistance. Among the various grades, 316L stainless steel stands out for several reasons: Molybdenum Content: The addition of molybdenum enhances 316L's resistance to pitting and crevice corrosion, particularly in chloride-rich environments, which are common in many industrial applications. Low Carbon Content: The low......