Electrical conducting springs

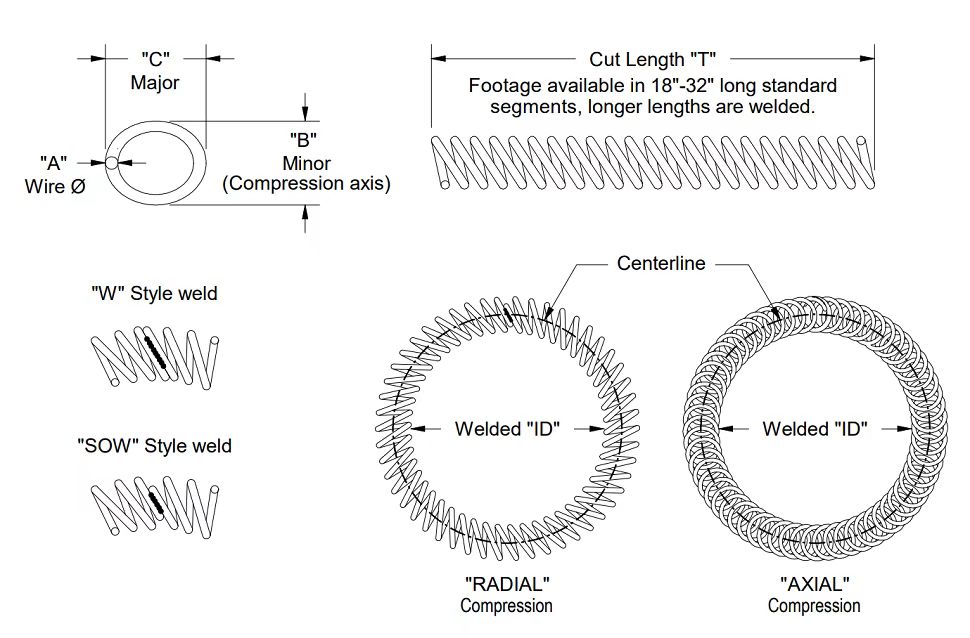

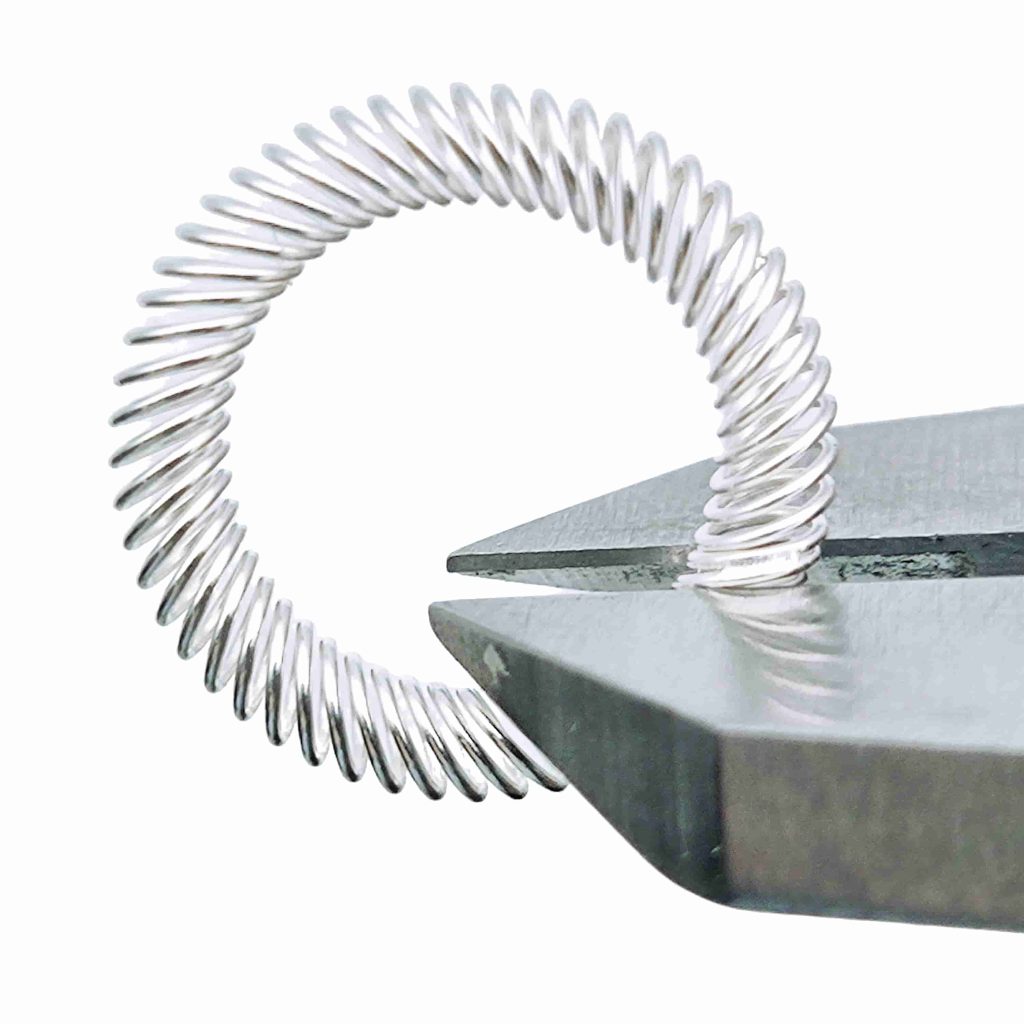

Electrical Conducting Springs, such as the Handa Shielding® canted coil spring are springs specifically designed to conduct electrical current while providing mechanical support. Made from highly conductive materials such as copper alloys or stainless steel, these springs facilitate the flow of electricity through electronic and electrical systems.

They are commonly used in applications where both electrical conductivity and mechanical flexibility are required, such as in connectors, switches, and various electronic devices.

Custom Manufacturing

Custom Electrical conducting springs

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

-

Electrical conducting springs Manufacturing

Electrical Conducting Springs are spring components used to conduct current and are commonly used in electronic equipment, connectors, switches and other electrical systems. Making these springs requires considerations of conductivity, material selection and precise engineering.

Following are the manufacturing steps of conductive springs:

1.Material selection

2.Manufacturing wire

3.Bending and forming

4.Heat treatment

5.Surface treatment

6.Quality control

7.Customization requirements

8.Packaging

Manufacturing Electrical Conducting Springs requires precision engineering and quality control to ensure they reliably conduct electrical current and meet the application’s performance requirements. Therefore, it is recommended to work with Handa Shielding to meet the needs of your specific application.

Materials & Plating

Electrical conducting springs are made from various materials selected for their electrical conductivity, mechanical properties, and durability. The choice of material impacts the performance and suitability of the springs for specific applications.

- Stainless steel (302, 316, 316L)

- Zirconium Copper

- tin plated

- Beryllium copper

- gilded

- nickel plated

- Alloys (X750, 718, 3j21, elgliloy, Hastelloy C276)

- silver plated

Benifits

Electrical conducting springs are integral in various electronic and electrical systems where both reliable electrical performance and mechanical flexibility are essential.

- High Electrical Conductivity

- Mechanical Flexibility

- Durability

- Compact Design

- Reliable Performance

Applications

Handa Shielding® canted coil springs ensure reliable current delivery to motors, even in shock and vibration environments.

Electrical conducting springs are essential components that combine electrical conductivity with mechanical flexibility and contribute to the reliability and efficiency of various systems and devices.

- Energy:Power Substation Disconnects

- Aerospace:Satellite Solar Arrays

- Transportation:EV Battery Connectors

- Industrial:Robot End Effectors/Grippers

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

conductive contact finger springs /conducting canted coil springs The Challenge of Maintaining Reliable ConductivityConductive Contact Finger Springs: A Reliable SolutionConsistent Force Across Wide......

-

Electrical Conducting Springs In the fields of electrical and mechanical engineering, electrical conducting canted coil springs have emerged as pivotal components due to......