Electrically conductive foam

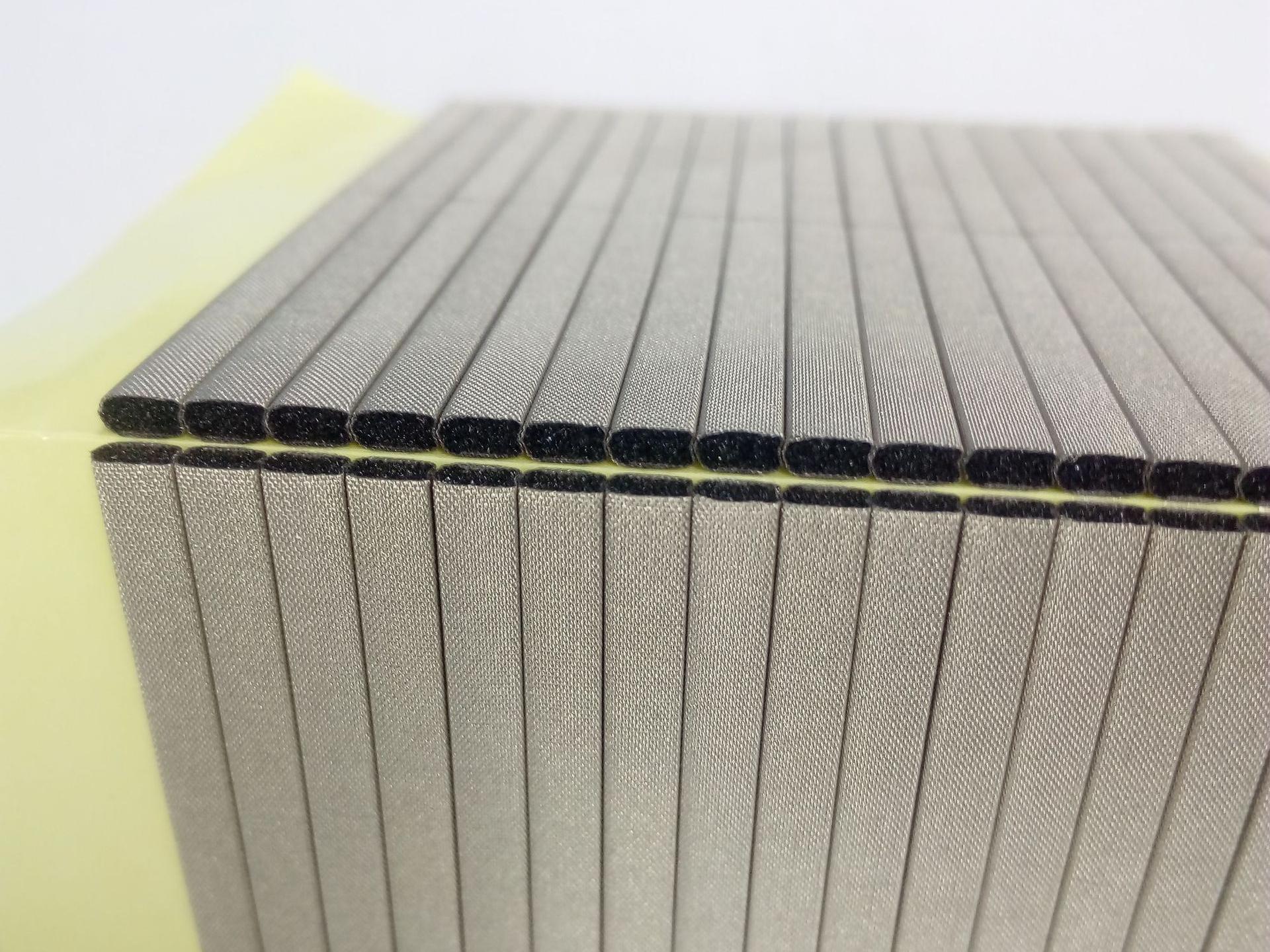

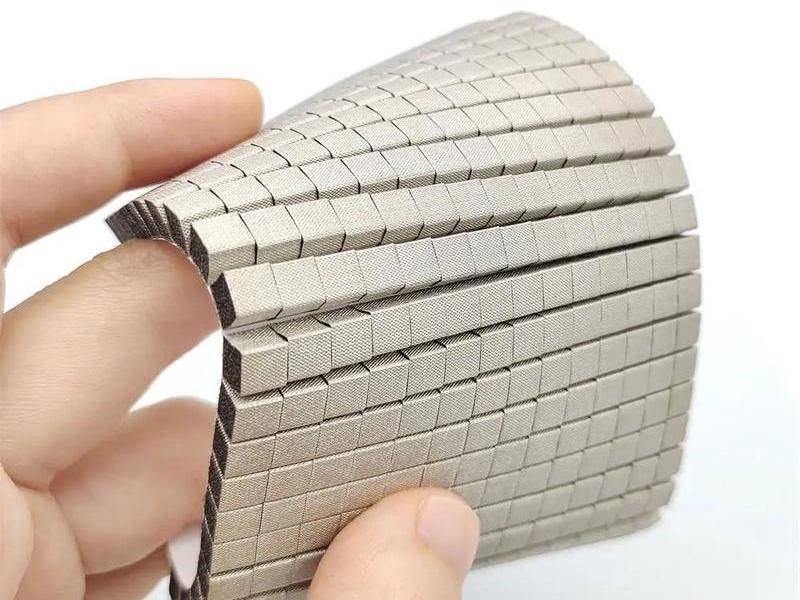

Handa Electrically conductive foam is a specialized material designed to combine the softness and compressibility of foam with the ability to conduct electricity. This unique combination makes it suitable for a range of applications where both physical cushioning and electrical properties are required.

Custom Manufacturing

Custom Electrically conductive foam

Handa Electrically conductive foam is made of polyurethane foam coated with copper and nickel.Compression is 25% to 75%. The maximum application temperature is between 60 and 70 degrees Celsius.

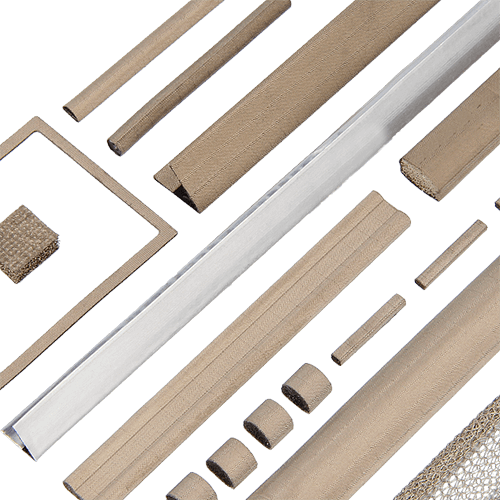

Custom manufacturing of electrically conductive foam involves a tailored process to meet specific application requirements. This process can be broken down into several key steps:

1.With or without self-adhesive

2.Supplied as sheets, strips or die-cuts

3.With water seal

4.Resistant to high temperatures, with cooling holes

5.Reinforced with woven fabric on 1 or 2 sides

6.PSA attachment method option

7.Nickel/copper metalization

8.X-Y-Z axis conductivity

9.Tolerance of ± 0.5 mm

10.I/O static applications/gasket replacement

Electrically conductive foam Manufacturing

Handa Electrically conductive foam is a specialty material made by incorporating conductive particles or additives into the foam matrix. The manufacturing process involves several key steps, which may vary depending on specific requirements and the manufacturer’s technology.

Here is a general overview of how conductive foam is typically produced:

- Foaming: The base foam, often polyurethane or polyethylene terephthalate (PET), is created through a foaming process that introduces gas bubbles, forming a cellular structure.

- Conductive Coating or Mixing: Conductive particles are either mixed into the liquid foam precursor before foaming or coated onto the foam’s surface after production. This can be done through impregnation, spraying, or dipping methods.

- Curing: The foam is cured to set its shape and ensure the conductivity of the added particles.

- Shaping: Cut or molded into specific shapes and sizes according to application requirements.

- Testing: Conductivity and compression set tests are performed to ensure the foam meets specifications.

Material specifications

Electrically conductive foam has specific material specifications that cater to its unique properties and applications. Here are some key specifications based on the reference content:

- Mesh: woven polyester, copper, and nickel coated

- PU coating: polymer resin (polyurethane)

- Conductive foam: polyurethane foam (copper and nickel coated)

- Release liner: CP paper avg 150 μm

- PSA: acrylic ester polyol copolymer + nickel powder

Application

Handa Electrically conductive foam finds application across a broad range of industries due to its unique combination of properties. Here are some key applications:

- Electronics Enclosures

- Automotive Industry

- Military and Aerospace

- Medical Devices

- Audio Equipment

- Smart Sensors

- Antistatic Packaging

- Thermal Management

- Flexible Circuitry and Wearables

- Environmental Sealing

- EMI Shielded Rooms

- Research and Development

Benefits

Electrically conductive foam offers a range of benefits, particularly in applications requiring electromagnetic interference (EMI) shielding, grounding, and weight reduction. Here are the key advantages:

- EMI Shielding

- Lightweight

- Ease of Process and Manufacturing

- Versatility in Compression and Resilience

- Thermal Tolerance

- Adhesive-Free Handling

- Effective Grounding

- Filler Efficiency

- Customizability

- Oil-Resistance and Sensitivity

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

1. Characteristics of Electrically Conductive FoamLightweight StructureHigh Elasticity and FlexibilityExcellent Thermal and Acoustic InsulationChemical ResistanceEnergy Absorption and Shock Resistance2. Manufacturing Process of Electrically......

-

Electrically conductive foam is an innovative material designed to combine the softness, flexibility, and compressibility of traditional foam with the ability to conduct......