Electrically conductive rubber profiles

Electrically conductive rubber profiles in general are known for their excellent weather-, oxidation and ozone resistance。

Custom Manufacturing

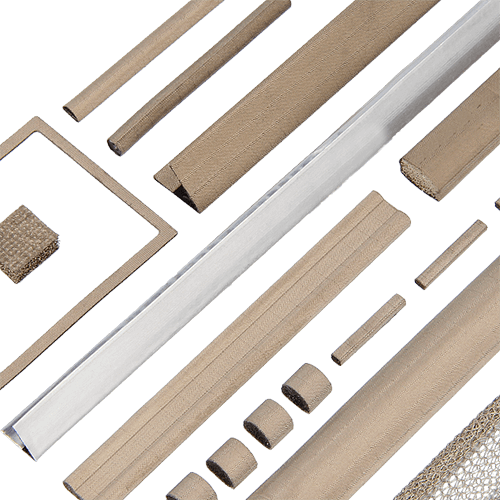

Custom Electrically conductive rubber profiles

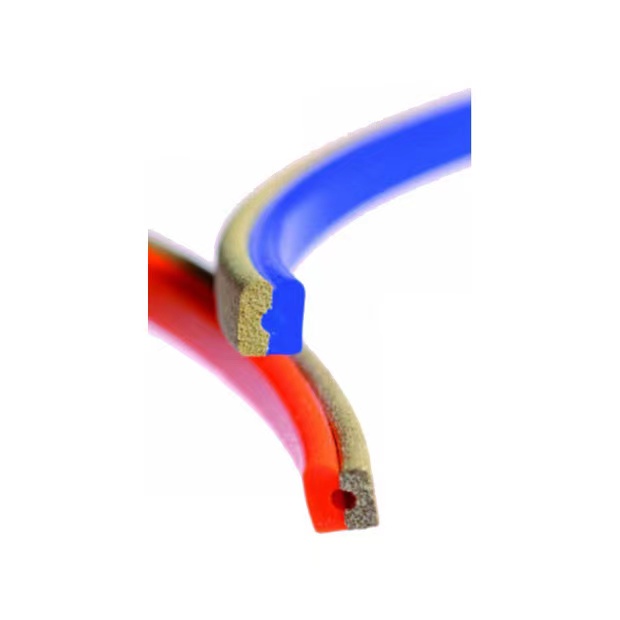

Electrically conductive rubber profiles are typically used for EMI applications. Also used for EMP protection, wave-guide applications and against static electricity. The rubber can be filled with silver, nickel, silvered glass, silvered aluminium or graphite (only for ESD). Commercial EMI applications often call for Nickel-Graphite Conductive Rubberor Graphite Conductive Rubber due to costs, whereas military and aerospace applications often call for Silver Aluminium Silicone Conductive Rubber to meet Mil-G-83528C specifications. In military or aerospace, fluorosilicone versions may also be used for its chemical and fuel resistance.

Electrically conductive rubber profiles Manufacturing

Electrically conductive rubber profiles are specialized components used in a variety of applications requiring electromagnetic interference (EMI) shielding, electrical conductivity and environmental sealing. The manufacturing process of these profiles involves several steps: material selection,

Compounding, extrusion or molding, curing, cutting and forming, adhesive backing (optional), quality control, packaging. Manufacturers can offer a customization service to produce profiles to meet the customer’s exact requirements, which can include different shapes, sizes and hardness levels. Conductive rubber profiles are commonly used in industries such as electronics, telecommunications, aerospace and medical devices, where EMI shielding and environmental sealing are critical. It is important to work with a reputable manufacturer to ensure that conductive rubber profiles meet the necessary specifications for your specific application. Materials, dimensions, and other attributes should be selected to meet the project’s requirements to achieve optimal performance.

Dimensions Measurement Guide

Electrically conductive rubber profiles sizes and specifications may vary depending on manufacturer and specific application requirements. These profiles are available in various shapes and sizes to suit different applications. The following are some common size and specification considerations: width (W), height (H) or thickness (T), length (L), shape, durometer (hardness), conductivity, adhesive, color, customization, resistance Warm nature. Size and specification should be selected to meet the requirements of your project, such as EMI shielding effectiveness, conductivity, and sealing.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote