EMI Helical Spring

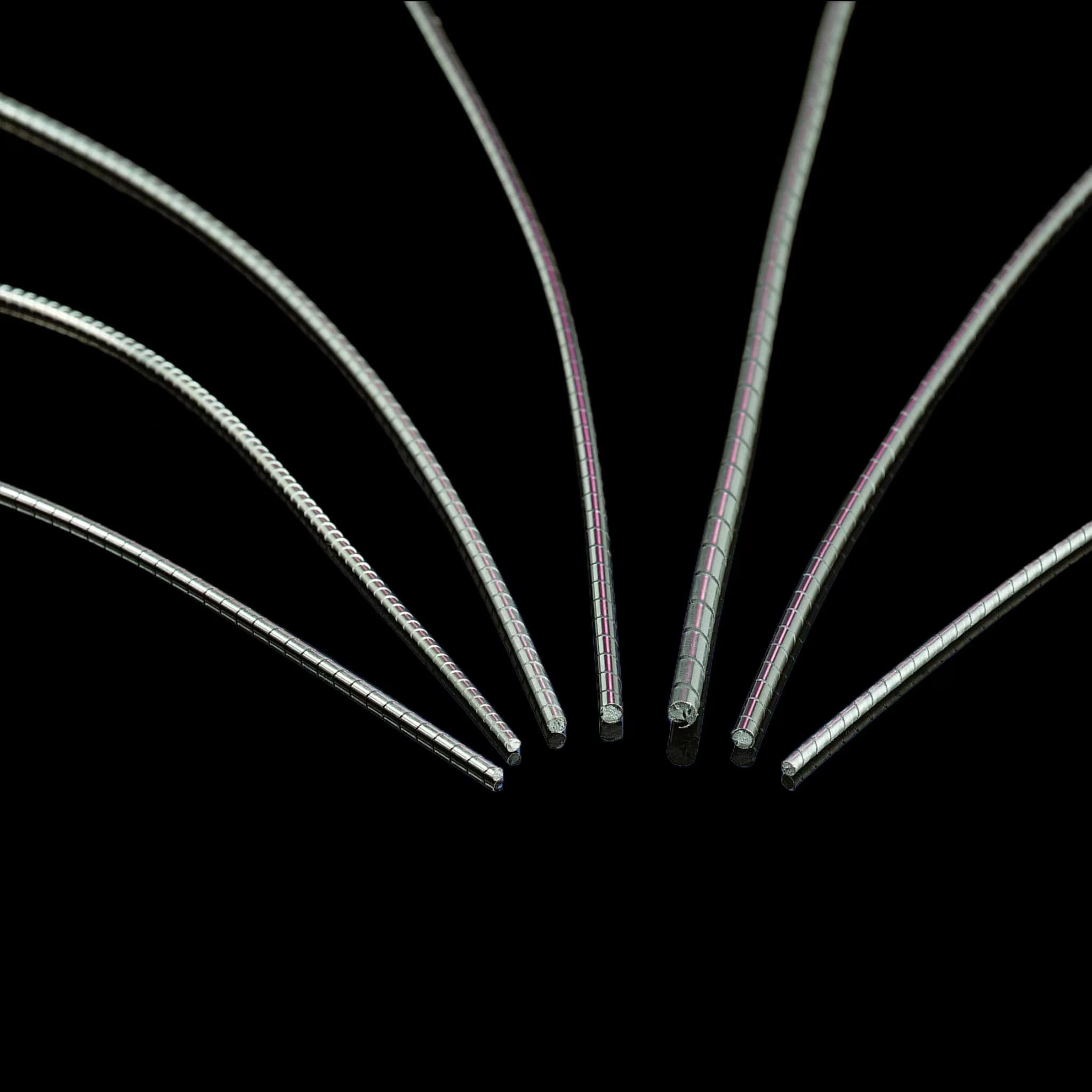

Handa EMI helical spring is a type of spring that is designed to provide electromagnetic interference (EMI) shielding to electronic devices. It is made of a highly conductive metal, such as copper or silver, and is coiled in a helix shape.

Custom Manufacturing

Custom EMI Helical Spring

According to the customer’s usage environment, Handa Shielding provides drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Product Specs

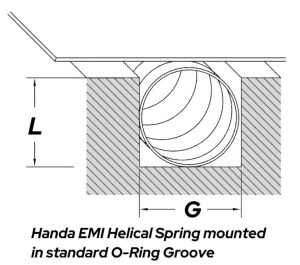

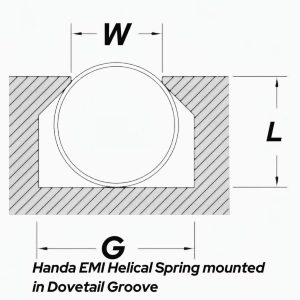

Recommended Groove Size

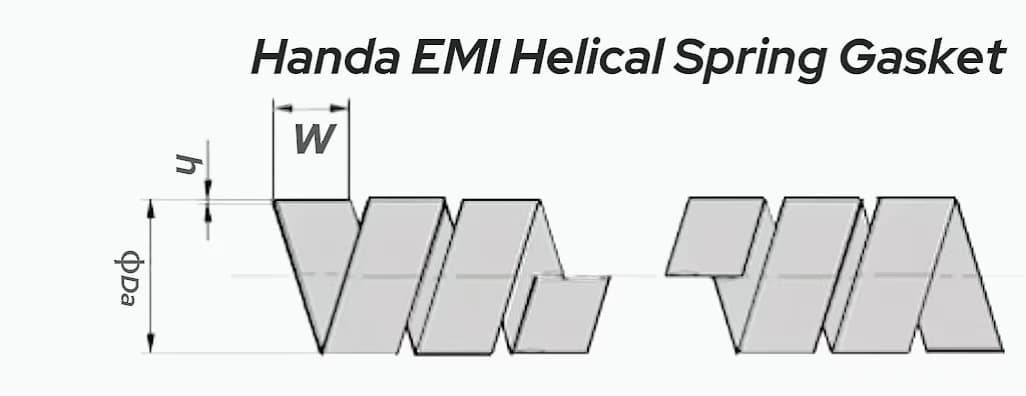

The following is a drawing for size reference.

* We can customize the width, thickness, and outer diameter of the strip according to your needs.

| EMI Helical Spring part numbers (RoHs Tin plated beryllium copper) | Groove Size [mm] | |||||

|---|---|---|---|---|---|---|

| DiameterOD(mm) | Standard Force(“S” Series) | Medium Force(“M” Series) | Low Force(“L” Series) | Depth(L)

+0.05 /-0 (mm) |

Width(G)

+0.18 / -0.13 (mm) |

Width(W)

+0 / -0.05 (mm) |

| 0.86 ± 0.05 | HDH-SBN-086W | HDH-MBN-086W | HDH-LBN-086W | 0.58 | 1.17 | 0.84 |

| 1.19 ± 0.05 | HDH-SBN-119W | HDH-MBN-119W | HDH-LBN-119W | 0.89 | 1.60 | 1.14 |

| 1.60 ± 0.08 | HDH-SBN-160W | HDH-MBN-160W | HDH-LBN-160W | 1.17 | 2.39 | 1.52 |

| 1.78 ± 0.08 | HDH-SBN-178W | HDH-MBN-178W | HDH-LBN-178W | 1.35 | 2.39 | 1.70 |

| 1.98 ± 0.08 | HDH-SBN-198W | HDH-MBN-198W | HDH-LBN-198W | 1.50 | 2.77 | 1.91 |

| 2.39 ± 0.10 | HDH-SBN-239W | HDH-MBN-239W | HDH-LBN-239W | 1.78 | 3.18 | 2.29 |

| 2.62 ± 0.10 | HDH-SBN-262W | HDH-MBN-262W | HDH-LBN-262W | 1.96 | 3.58 | 2.51 |

| 2.77 ± 0.10 | HDH-SBN-277W | HDH-MBN-277W | HDH-LBN-277W | 2.08 | 3.96 | 2.67 |

| 3.18 ± 0.10 | HDH-SBN-318W | HDH-MBN-318W | HDH-LBN-318W | 2.39 | 4.34 | 3.07 |

| 3.53 ± 0.13 | HDH-SBN-353W | HDH-MBN-353W | HDH-LBN-353W | 2.64 | 4.75 | 3.40 |

| 3.58 ± 0.13 | HDH-SBN-358W | HDH-MBN-358W | HDH-LBN-358W | 2.67 | 4.75 | 3.45 |

| 4.37 ± 0.13 | HDH-SBN-437W | HDH-MBN-437W | HDH-LBN-437W | 3.25 | 5.94 | 4.19 |

| 4.75 ± 0.15 | HDH-SBN-475W | HDH-MBN-475W | HDH-LBN-475W | 3.56 | 6.35 | 4.60 |

| 6.35 ± 0.18 | HDH-SBN-635W | HDH-MBN-635W | HDH-LBN-635W | 4.70 | 8.71 | 6.10 |

| 7.92 ± 0.23 | HDH-SBN-792W | HDH-MBN-792W | HDH-LBN-792W | 5.94 | 10.72 | 7.62 |

| 9.53 ± 0.28 | HDH-SBN-953W | HDH-MBN-953W | HDH-LBN-953W | 7.11 | 12.70 | 9.25 |

| 12.70 ± 0.38 | HDH-SBN-1270W | HDH-MBN-1270W | HDH-LBN-1270W | 9.53 | 16.66 | 12.32 |

Materials

The choice of material for an EMI helical spring will depend on the specific requirements of the application, such as the operating environment, the level of EMI shielding required, and the desired level of durability and strength.

- Nickel-plated carbon steel

- 301 | 302 | 304 | 316 | 17-7PH

- Inconel (grades 600, 718, X-750)

- Hastelloy (grades C22, C276, C2000)

- Phosphor bronze

- Beryllium-copper

- Monel (grade 400)

- Stainless Steels

- Exotic Alloys

- Elgiloy/Phynox to AMS5833. Also available compliant to NACE MR0175.

Application Range

Handa EMI Helical Springs have various applications,such as:

- Spring energized Seals (spring energizer) : commonly used for medium to high pressure applications under very slow or static condition.

- Recommended for vacuum and cryogenic sealing application.

- Not suitable for wide gland tolerances, eccentricity, or misalignment.

- EMI shielding function

- Electricity conductivity purposes

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote