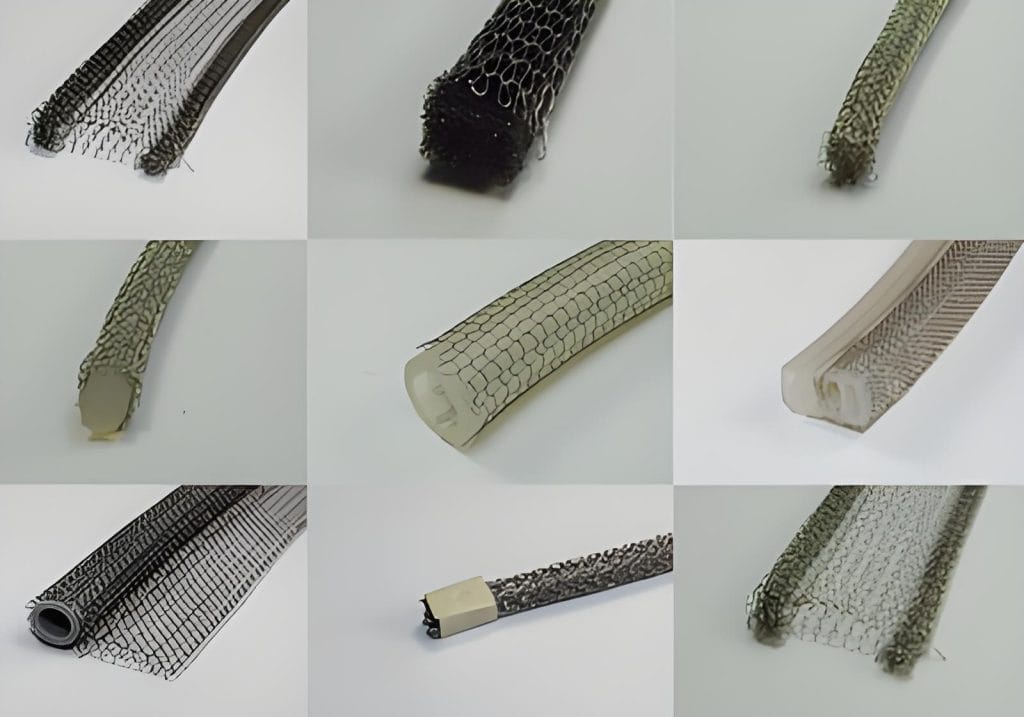

EMI shielding gaskets

Soft EMI/RFI shielding gasket for panels, doors and lids. Economical High frequency shielding gasket (HF shielding gasket) solution.

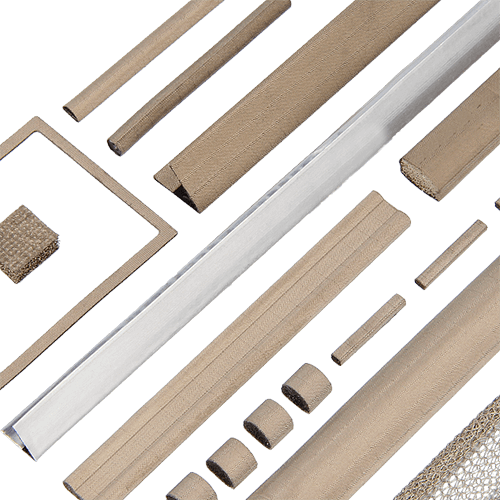

Custom Manufacturing

Custom EMI shielding gaskets

①CNC cut into specific lengths

②Can be made into any shape or as a frame (according CAD drawing)

③Combination with water seal

④UL94V-0 flame retardant foam core

⑤Chemical resistant rubbers like EPDM

⑥Silicone sponge for high temperatures up to 220 °C

⑦Different conductive foils and fabrics

⑧With cut-outs so that the gasket can be easily bend

EMI shielding gaskets Manufacturing

EMI (Electromagnetic Interference) shielding gaskets are important components used to protect electronic equipment and systems from interference and electromagnetic radiation. Manufacturing EMI shielding gaskets involves several key steps: material selection, material compounding, extrusion or molding, curing, cutting and forming, adhesive application (optional), quality control, packaging. EMI shielding gaskets come in many forms, including conductive strips, gaskets, tapes and custom-designed profiles. They are widely used in industries where EMI protection is critical, such as electronics, telecommunications, aerospace and automotive. Customization services are often available, allowing manufacturers to produce EMI shielding gaskets based on a customer’s specific needs, including different sizes, shapes, and adhesive options.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

Knitted metal wire mesh gaskets are engineered using fine metal wires, typically stainless steel or other conductive alloys, that are knitted or woven......