EMI Shielding Springs

Handa EMI Shielding Springs are components designed to block or reduce electromagnetic interference (EMI) in electronic devices. They are made from conductive materials like copper or stainless steel to create a shield that protects sensitive electronics from external electromagnetic signals. These springs combine effective EMI protection with mechanical flexibility and durability, ensuring reliable performance in various applications, including electronics, communications, automotive, and medical devices.

Custom Manufacturing

Custom EMI Shielding Springs

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Product Specs

Specification

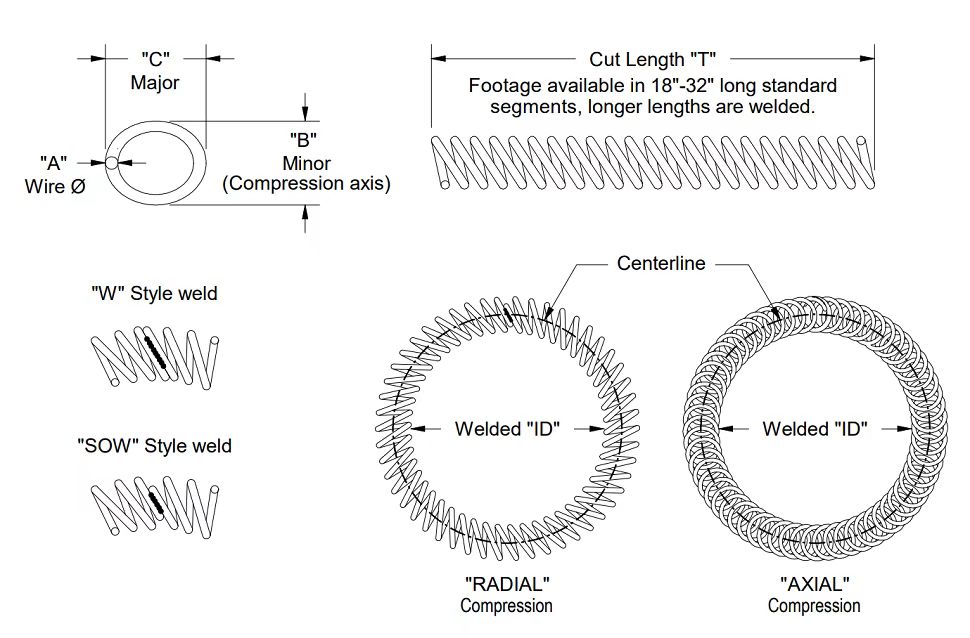

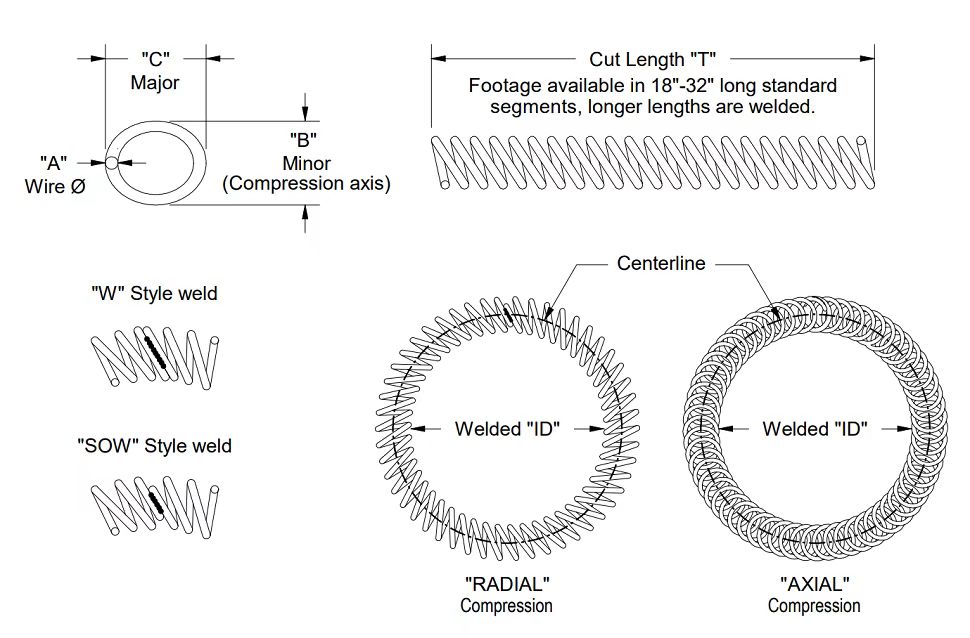

Our EMI Shielding Springs are available in lengths (for simple or complex groove configurations) and welded rings from 0.030” (.76mm) ID. Since every spring is designed to meet the unique requirements of your application, we don’t stock a “standard” size and type. But we do maintain a database of commonly-requested diameters and cross-sections, which can serve as a baseline for streamlined customization.

The table below outlines the standard dimensions for EMI Shielding springs.

These dimensions are subject to standard manufacturing tolerances, which can be provided upon request.

| SERIES | Load type | “A” (Metal wire) |

“B” (Minor) |

“C” (Major) |

“T” (Cut Length) |

“ID” “(Wilded ID)” |

|---|---|---|---|---|---|---|

| HD-CS-L132 | L | 0.08 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-M132 | M | 0.10 | 0.62 | 0.70 | 7.60 | 1.80 |

| HD-CS-H132 | H | 0.12 | 0.65 | 0.75 | 7.70 | 1.80 |

| HD-CS-L000 | L | 0.12 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-M000 | M | 0.15 | 1.40 | 1.55 | 12.90 | 2.70 |

| HD-CS-H000 | H | 0.20 | 1.20 | 1.32 | 12.20 | 2.70 |

| HD-CS-L100 | L | 0.18 | 2.00 | 2.40 | 19.80 | 4.30 |

| HD-CS-M100 | M | 0.35 | 2.00 | 2.40 | 20.10 | 4.40 |

| HD-CS-H100 | H | 0.35 | 2.00 | 2.30 | 19.80 | 4.30 |

| HD-CS-L200 | L | 0.30 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-M200 | M | 0.35 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-H200 | H | 0.40 | 2.80 | 3.20 | 30.10 | 6.80 |

| HD-CS-L300 | L | 0.40 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-M300 | M | 0.50 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-H300 | H | 0.60 | 4.00 | 4.50 | 42.70 | 9.60 |

| HD-CS-L400 | L | 0.50 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-M400 | M | 0.60 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-H400 | H | 0.70 | 5.50 | 6.00 | 61.20 | 14.00 |

| HD-CS-L500 | L | 0.60 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-M500 | M | 0.70 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-H500 | H | 1.00 | 8.20 | 9.20 | 96.40 | 22.50 |

| HD-CS-L600 | L | 0.70 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-M600 | M | 1.00 | 11.40 | 12.80 | 152.00 | 37.00 |

| HD-CS-H600 | H | 1.20 | 11.40 | 12.80 | 152.00 | 37.00 |

EMI Shielding Springs Manufacturing

EMI (Electromagnetic Interference) shielding springs are important components in electronic and electrical systems. They are designed to protect sensitive electronic equipment from external electromagnetic interference and ensure proper operation.

The manufacturing process of EMI shielding springs involves several key steps:

1.Material selection

2.Wire forming

3.Heat treatment

4.Surface treatment

5.Inspection and quality control

6Packaging

7.Customization

It is important to work with Handa Shielding who understand the requirements of your application Specific EMI shielding requirements to produce high quality EMI shielding springs.

Materials & Plating

EMI shielding spring are precision-manufactured from premium copper alloy and stainless steel base wire materials, chosen for their excellent combination of mechanical and electrical properties.

- Stainless steel (302, 316, 316L)

- Zirconium Copper

- tin plated

- Beryllium copper

- gilded

- nickel plated

- Alloys (X750, 718, 3j21, elgliloy, Hastelloy C276)

- silver plated

Key Features and Functions

EMI Shielding Springs play a critical role in protecting sensitive electronics from unwanted electromagnetic signals, ensuring optimal performance and reliability.

- Electromagnetic Interference Shielding

- Conductivity

- Elasticity and Flexibility

- Durability

Applicatiions

EMI Shielding Springs play a vital role in maintaining the performance and reliability of electronic and electrical devices across various industries.

- Electronic Devices: Used in internal components of computers, smartphones, and household appliances.

- Communication Equipment: Employed in radio, telecommunications, and network devices.

- Automotive Industry: Provides shielding in automotive electrical systems.

- Medical Devices: Ensures the accuracy and reliability of medical instruments.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio......