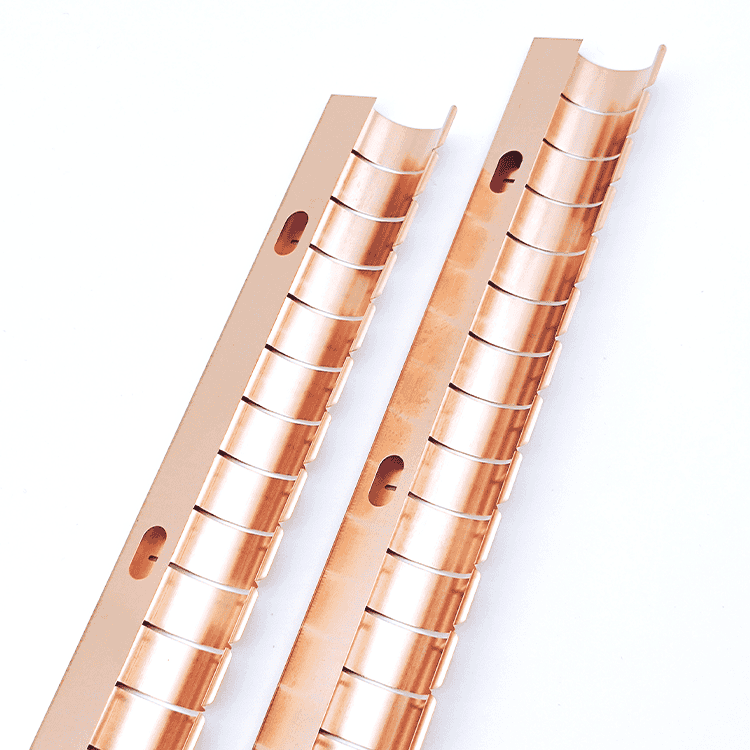

Handa Beryllium-Copper Fingerstrips/Fingerstocks with a variety of benefits

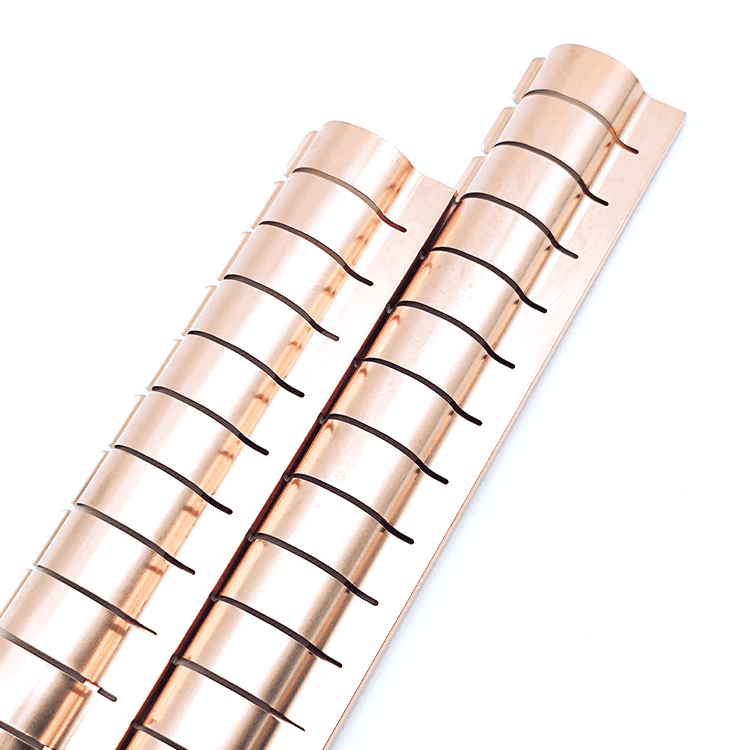

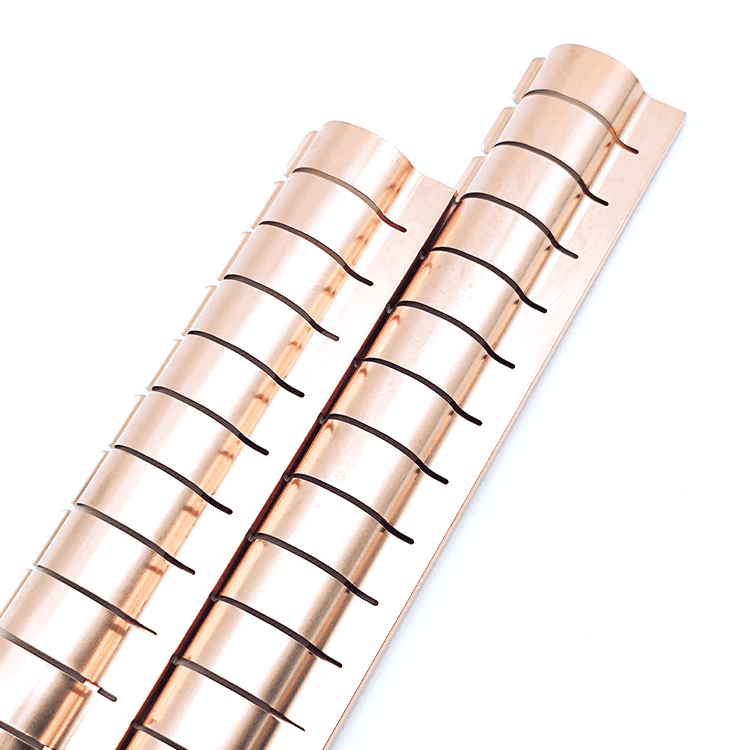

Handa beryllium-copper fingerstrips, also known as fingerstocks, are highly efficient EMI (Electromagnetic Interference) shielding components. These products are essential in various industries, where sensitive electronic equipment requires protection from external electromagnetic and radio frequency interference (RFI). Beryllium-copper is a popular material for this purpose due to its outstanding combination of mechanical strength, electrical conductivity, and durability.

Handa Beryllium-Copper Fingerstrips/Fingerstocks with a variety of benefits

Table of Contents

Introduction to Handa Beryllium-Copper Fingerstrips/Fingerstocks

Handa beryllium-copper fingerstrips, also known as fingerstocks, are highly efficient EMI (Electromagnetic Interference) shielding components. These products are essential in various industries, where sensitive electronic equipment requires protection from external electromagnetic and radio frequency interference (RFI). Beryllium-copper is a popular material for this purpose due to its outstanding combination of mechanical strength, electrical conductivity, and durability.

As electronic devices become smaller and more integrated, the demand for highly effective shielding materials has increased. Handa beryllium-copper fingerstrips/fingerstocks provide a versatile solution for shielding gaps, seams, and other openings where electromagnetic radiation can escape or penetrate. This article will explore the design, features, applications, and benefits of these specialized shielding components.

Overview of Beryllium-Copper as a Material

Before diving into the specifics of Handa’s fingerstrips, it is crucial to understand the material used—beryllium copper. Beryllium copper is a copper alloy with small amounts of beryllium (typically 0.5% to 3%). This combination offers several advantages:

- High Conductivity: Copper is known for its excellent electrical and thermal conductivity, making beryllium-copper an ideal material for EMI shielding.

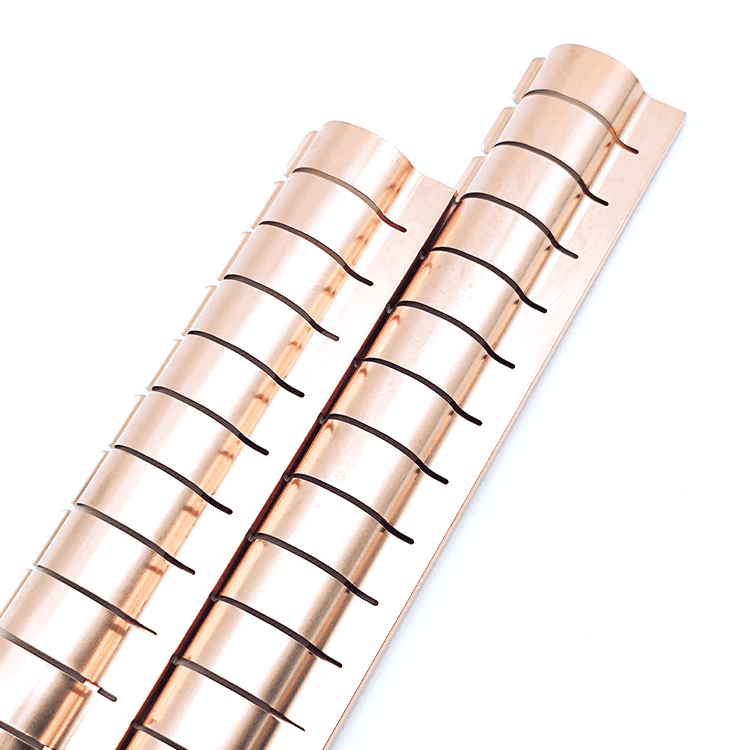

- Strength and Elasticity: The inclusion of beryllium enhances the strength and flexibility of the alloy, allowing the fingerstrips to maintain their spring-like properties over extended periods of use.

- Corrosion Resistance: Beryllium-copper exhibits high resistance to corrosion, even in harsh environments, ensuring the long-term durability of the fingerstrips.

- Fatigue Resistance: The material resists fatigue and mechanical wear, making it suitable for applications that involve frequent opening and closing of shielded components.

Key Features of Handa Beryllium-Copper Fingerstrips/Fingerstocks

Handa beryllium-copper fingerstrips/fingerstocks offer a variety of benefits, making them an optimal choice for shielding applications. Below are some of the key features that set these fingerstrips apart:

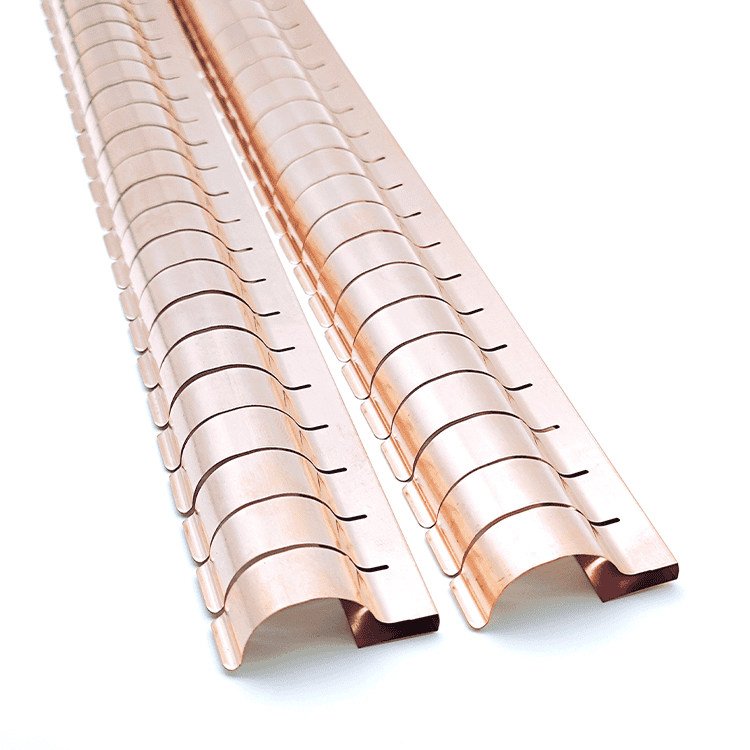

- EMI/RFI Shielding Effectiveness: The primary purpose of fingerstrips is to provide a low-resistance path to ground, reducing the chances of electromagnetic interference (EMI) affecting sensitive electronic systems. The high conductivity of beryllium-copper ensures that the fingerstrips are highly effective at dissipating electromagnetic waves, particularly in high-frequency applications.

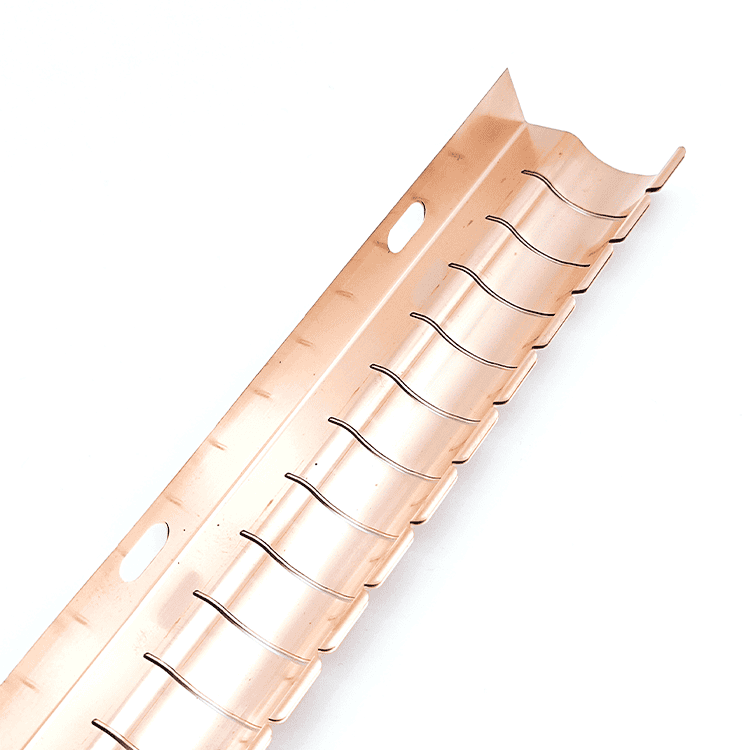

- Flexible Design: The spring-like properties of the fingerstrips allow them to flex and conform to irregular surfaces, ensuring a tight, continuous seal. This flexibility makes them suitable for sealing gaps, seams, and other areas where rigid materials would be less effective.

- Temperature and Corrosion Resistance: Beryllium-copper fingerstrips perform well in a wide range of temperatures, making them suitable for environments where extreme heat or cold might otherwise affect the integrity of the shielding. Additionally, the material’s corrosion resistance ensures long-term reliability, even in harsh or corrosive environments.

- Customizable Shapes and Sizes: Handa beryllium-copper fingerstrips can be manufactured in various shapes, sizes, and configurations to meet the specific needs of different applications. Whether for large enclosures or small connectors, custom fingerstrips can be tailored to fit any requirement.

- Durability: Thanks to their fatigue resistance and mechanical strength, these fingerstrips are highly durable. They can withstand repeated compressions, expansions, and other mechanical stresses without losing their effectiveness.

- Multiple Applications: In addition to shielding, beryllium-copper fingerstrips can serve mechanical purposes, such as latching, grounding, and providing electrical continuity between mating surfaces.

Applications of Handa Beryllium-Copper Fingerstrips/Fingerstocks

Beryllium-copper fingerstrips find applications in a wide variety of industries and sectors. Below are some of the most common applications where these shielding components prove invaluable:

1. Aerospace and Defense

In aerospace and defense industries, where reliability and performance are critical, EMI shielding is essential to prevent interference between sensitive electronic systems. Beryllium-copper fingerstrips are commonly used to shield enclosures in aircraft, satellites, radar systems, and other defense-related equipment. The fingerstrips ensure that electromagnetic radiation from one system does not interfere with the operation of other onboard systems.

2. Automotive Electronics

Modern automobiles feature increasingly complex electronic systems, including infotainment systems, navigation devices, and advanced driver-assistance systems (ADAS). EMI shielding is crucial to ensure that these systems function correctly without interference from other electronic components within the vehicle. Beryllium-copper fingerstrips are used to provide shielding for connectors, control modules, and other electronic systems in cars and trucks.

3. Telecommunications Equipment

Telecommunications infrastructure relies on stable and uninterrupted signals to function properly. EMI can disrupt the transmission of signals in both wired and wireless communication systems. Beryllium-copper fingerstrips are employed in telecommunications equipment to shield cables, antennas, and other components, ensuring optimal signal integrity and reducing the risk of EMI-related issues.

4. Medical Devices

In the medical field, electronic equipment must operate with precision and accuracy. EMI can have serious consequences in medical environments, where it could interfere with the performance of life-saving devices such as pacemakers, defibrillators, and medical imaging systems. Beryllium-copper fingerstrips are used to provide shielding for these devices, ensuring their proper function and protecting patients from the potential hazards of EMI.

5. Industrial Control Systems

Factories and industrial plants often contain large amounts of electronic equipment and machinery, which can generate significant amounts of electromagnetic interference. Beryllium-copper fingerstrips are used to shield industrial control systems, ensuring that production equipment, automation systems, and other electronic components operate efficiently without being affected by EMI.

6. Consumer Electronics

Consumer electronics such as smartphones, laptops, and tablets are becoming more sophisticated and compact. As a result, effective EMI shielding is critical to prevent interference between different components within these devices. Beryllium-copper fingerstrips are often used to shield connectors, antennas, and other internal components in consumer electronics, enhancing performance and user experience.

7. Power Management Systems

Power management systems, including power supplies and distribution units, require effective EMI shielding to prevent interference with the delivery of clean, stable power to sensitive electronic equipment. Beryllium-copper fingerstrips are used to provide reliable shielding in power management systems, ensuring that power fluctuations and electromagnetic interference do not disrupt the operation of connected devices.

Advantages of Using Handa Beryllium-Copper Fingerstrips/Fingerstocks

There are several advantages to using Handa beryllium-copper fingerstrips in EMI shielding applications:

- High Performance: The combination of excellent electrical conductivity and mechanical strength ensures that these fingerstrips provide high-performance EMI shielding in even the most demanding environments.

- Long-Term Durability: Beryllium-copper is known for its durability, and Handa’s fingerstrips are no exception. They can withstand repeated use and mechanical stress without degrading or losing effectiveness.

- Customization Options: Handa offers custom manufacturing options, allowing customers to design fingerstrips tailored to their specific application requirements. This flexibility is particularly useful in industries where standard sizes and shapes may not provide the desired level of protection.

- Cost-Effective: While beryllium-copper fingerstrips may be more expensive than some other shielding materials, their long-term durability and performance often result in cost savings over time. Fewer replacements and repairs are needed, reducing maintenance costs.

- Environmentally Friendly: Beryllium-copper fingerstrips can be manufactured using environmentally friendly processes, and the material is recyclable, making them a sustainable choice for companies looking to reduce their environmental impact.

Installation and Best Practices

The installation of beryllium-copper fingerstrips is a straightforward process, but it is important to follow best practices to ensure optimal performance:

- Measure Correctly: Before installing the fingerstrips, it is important to measure the gaps or seams that need shielding accurately. This will ensure that the fingerstrips fit properly and provide effective EMI protection.

- Use Proper Tools: Cutting and installing beryllium-copper fingerstrips should be done using the correct tools to avoid damaging the material. Proper cutting tools will ensure clean edges and a secure fit.

- Secure Fastening: Ensure that the fingerstrips are securely fastened in place. Loose or improperly installed fingerstrips can result in gaps that allow electromagnetic interference to penetrate the shielded area.

- Regular Inspection: Over time, mechanical wear and environmental factors can affect the performance of EMI shielding. It is important to inspect the fingerstrips regularly for signs of wear or damage and replace them as necessary.

- Grounding: For effective EMI shielding, it is crucial to ground the fingerstrips properly. This will ensure that any electromagnetic energy is dissipated safely and does not affect the performance of the electronic systems.

Conclusion

Handa beryllium-copper fingerstrips/fingerstocks provide reliable, long-lasting EMI shielding for a wide range of industries. Their combination of high electrical conductivity, mechanical strength, and resistance to corrosion makes them an ideal solution for protecting electronic systems from electromagnetic interference. Whether used in aerospace, automotive, telecommunications, or consumer electronics, these fingerstrips offer excellent performance and versatility in critical applications.

You May Also Like

-

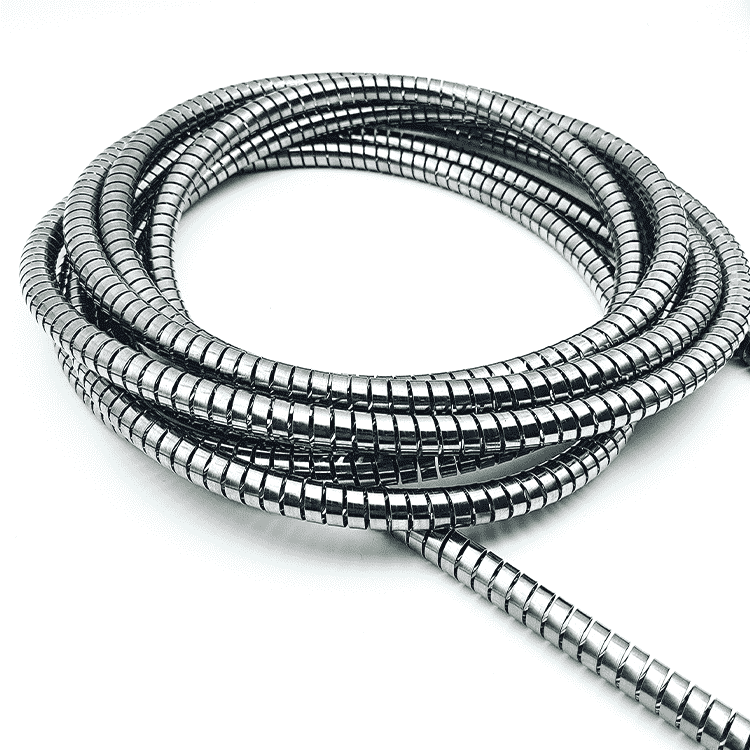

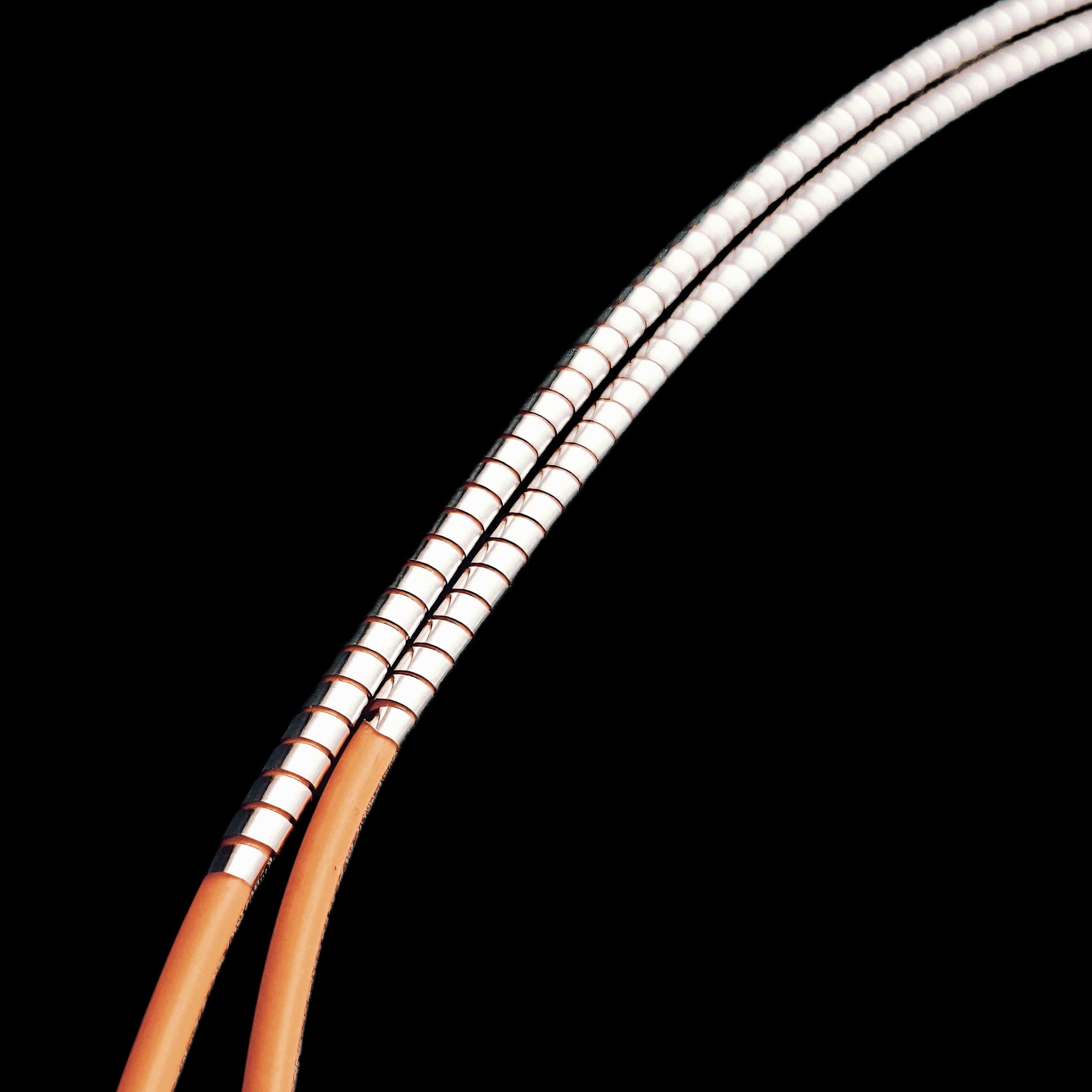

EMI Shielding Helical Springs with Unique Function

EMI Shielding Helical Springs with Unique FunctionEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Handa Shielding offers various types of shielding products. These products come in different shapes and materials, and they each have their own unique function. In this article, we will take a look at the EMI shielding aspect and explore the function and advantages of EMI Shielding Helical Springs, which are designed to protect electronic devices from electromagnetic interference. Understanding Electromagnetic Interference (EMI)What Are EMI Shielding Helical Springs?Key Characteristics of EMI Shielding Helical SpringsStructure and Function of EMI Shielding Helical SpringsMaterials Used in EMI Shielding Helical SpringsApplications of EMI Shielding Helical SpringsInstallation and Usage of EMI Shielding Helical SpringsBest Practices for EMI Shielding Helical SpringsConclusion EMI Shielding Helical Springs with Unique Function Understanding Electromagnetic Interference (EMI) Electromagnetic interference (EMI) refers to unwanted noise or interference in an electrical pathway or circuit caused by external sources. Also known as radio frequency interference, EMI can significantly impact the performance and functionality of electronic devices. Key aspects of EMI: It can cause electronics to operate inefficiently, malfunction, or cease functioning entirely EMI can arise from both natural and man-made sources Proper mitigation strategies are essential to minimize its effects What Are EMI Shielding Helical Springs? EMI (Electromagnetic Interference) Shielding Helical Springs are specialized mechanical......

-

Handa Endur Shield to safeguard sensitive electronic equipment

Handa Endur Shield to safeguard sensitive electronic equipmentEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Handa Endur Shield is a premium electromagnetic interference (EMI) and radio frequency interference (RFI) shielding solution designed to safeguard sensitive electronic equipment from external interference. As the world becomes increasingly reliant on electronics, particularly in critical industries like telecommunications, aerospace, medical technology, and defense, protecting devices from EMI and RFI is crucial. Handa Endur Shield stands out in this domain as a reliable, durable, and customizable product designed for high-performance shielding. What is EMI and Why Does Shielding Matter?Key Features of Handa Endur ShieldMaterials Used in Handa Endur ShieldApplications of Handa Endur Shield Across IndustriesCustomization and Tailored SolutionsConclusion Handa Endur Shield What is EMI and Why Does Shielding Matter? Electromagnetic interference (EMI) refers to the disturbance caused by electromagnetic radiation from one electronic device that affects the functionality of another. This interference can range from mild disruptions to complete system failure, depending on the intensity of the interference and the sensitivity of the affected equipment. RFI (Radio Frequency Interference) is a specific type of EMI that occurs in the radio frequency spectrum. Both EMI and RFI are significant concerns in electronic design, particularly in industries that depend on flawless performance, like aerospace, military, medical, and telecommunications. Shielding is the process......

-

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing Capabilities

Electrically Conductive Rubber Profiles with Excellent Resilience, and Sealing CapabilitiesShielding Gasket Solutions and Materials

Electrically conductive rubber profiles

Electrically conductive rubber profiles represent a unique intersection of material science and engineering, combining the flexibility and sealing properties of traditional rubber with the ability to conduct electricity. This makes them essential in various applications, particularly in sectors where electrical performance and mechanical reliability are critical. These specialized components are manufactured by incorporating conductive fillers, such as carbon black or metal particles, into rubber polymers. This article explores the features, benefits, applications, and manufacturing processes of electrically conductive rubber profiles, shedding light on their importance in modern industrial settings. What Are Electrically Conductive Rubber Profiles?Key Features and BenefitsApplications of Electrically Conductive Rubber ProfilesManufacturing Process of Electrically Conductive Rubber ProfilesConclusion Electrically Conductive Rubber Profiles What Are Electrically Conductive Rubber Profiles? Electrically conductive rubber profiles are rubber components engineered to facilitate the flow of electrical current while retaining the inherent advantages of rubber, such as flexibility, resilience, and sealing capabilities. They are particularly valuable in environments where both electrical and mechanical performance are paramount. Composition and Materials The primary materials used in electrically conductive rubber profiles include: Rubber Polymers: The base material that provides flexibility and durability. Commonly used types include natural rubber, silicone rubber, and neoprene. Conductive Fillers: These materials are......

-

EMI shielding canted coil springs with unique canted coil design

EMI shielding canted coil springs with unique canted coil designHanda Canted Coil Springs

EMI Shielding Springs

EMI shielding canted coil springs, also known as canted coil springs, are innovative components designed to provide effective electromagnetic interference (EMI) and radio frequency interference (RFI) shielding while also serving as mechanical springs. These springs are characterized by their unique canted coil design, which enables them to provide multiple points of contact for superior EMI shielding, mechanical latching, and electrical conductivity. What Are EMI Shielding Canted Coil Springs?Applications of EMI Shielding Canted Coil SpringsMaterials and Construction of EMI Shielding Canted Coil SpringsBenefits of EMI Shielding Canted Coil SpringsStandards Compliance for EMI Shielding Canted Coil SpringsConsiderations When Using EMI Shielding Canted Coil SpringsConclusion https://www.handashielding.com/contact-us.html What Are EMI Shielding Canted Coil Springs? EMI shielding springs are specialized springs that offer both mechanical and electromagnetic shielding capabilities. Their canted coil design features coils arranged at an angle, which creates multiple points of contact when compressed. This allows the spring to function as both a mechanical component and a highly effective EMI/RFI shield. Electromagnetic interference is a significant concern in modern electronic devices, where external or internal EMI can disrupt signals and affect performance. EMI shielding springs are designed to protect sensitive electronic components from EMI and RFI while also providing mechanical and electrical......

-

Multi-use Stick-on Mounting Fingerstrips with Excellent EMI Shielding Effect

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Electromagnetic interference (EMI) can create significant issues for electronic devices and systems, leading to decreased performance, potential malfunction, or even failure. This is where stick-on mounting fingerstrips come in as an essential EMI shielding solution, especially for low-profile, bidirectional applications. These adhesive-backed beryllium-copper strips are designed to be easily installed without the need for specialized tools, providing an efficient and cost-effective way to shield electronics from EMI. In this article, we will explore the features, applications, benefits, and importance of stick-on mounting fingerstrips in EMI shielding. Whether you are working in telecommunications, computer hardware, or any industry where electromagnetic interference poses a risk, stick-on fingerstrips can provide a practical solution. Key Features of Stick-on Mounting Fingerstrips1. Adhesive Backing2. Low-Profile Design3. Beryllium-Copper Construction4. Bi-directional Sealing5. Adjustable SizeApplications of Stick-on Mounting Fingerstrips1. Telecommunications Equipment2. Narrow Electronics Enclosures3. General EMI Shielding Applications4. Computer HardwareBenefits of Stick-on Mounting Fingerstrips1. Easy Installation2. Consistent Sealing3. Flexibility4. Durability5. VersatilityHow Stick-on Mounting Fingerstrips Help with EMI ShieldingMinimizing Electromagnetic InterferenceMaintaining Performance in High-EMI EnvironmentsEnhancing System ReliabilityConclusion Stick-on Mounting Fingerstrips https://www.handashielding.com/contact-us.html Key Features of Stick-on Mounting Fingerstrips When choosing an EMI shielding solution, it’s important to focus on certain key features to ensure that the product you select meets your......