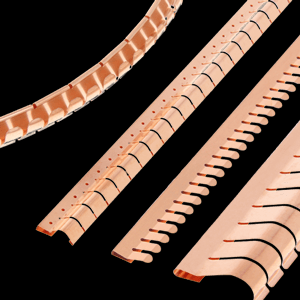

Handa Shielding – Clip-on mounting fingerstrip

EMI shielding products are widely used in various electronic devices to deal with problems such as EMI / RFI and ESD.

The BeCu finger strip has an excellent shielding effectiveness for EMI ,which is widely applied in communication cabinets ,computers, the door of shielding room, medical devices and military equipments.

|

Part Number

|

T

(mm)

|

Width

(mm)

|

Height

(mm)

|

C

(mm)

|

D

(mm)

|

P

(mm)

|

S

(mm)

|

L

(mm)

|

Remark

|

|

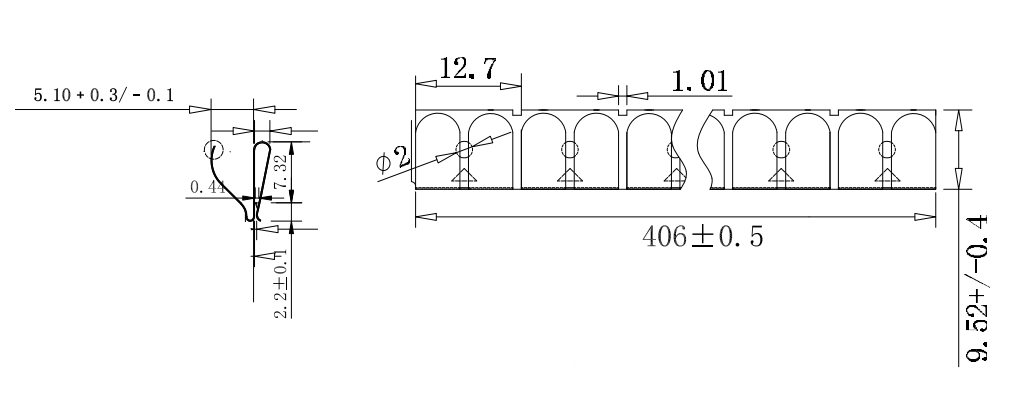

HD-640-01

|

0.127

|

28.40

|

6.6

|

1.7

|

1.00

|

9.52

|

1.01

|

406

|

bright finish

|

|

HD-640-0N

|

0.127

|

28.40

|

6.6

|

1.7

|

1.00

|

9.52

|

1.01

|

406

|

plating Ni

|

|

HD-640-0S

|

0.127

|

28.40

|

6.6

|

1.7

|

1.00

|

9.52

|

1.01

|

406

|

plating Sn

|

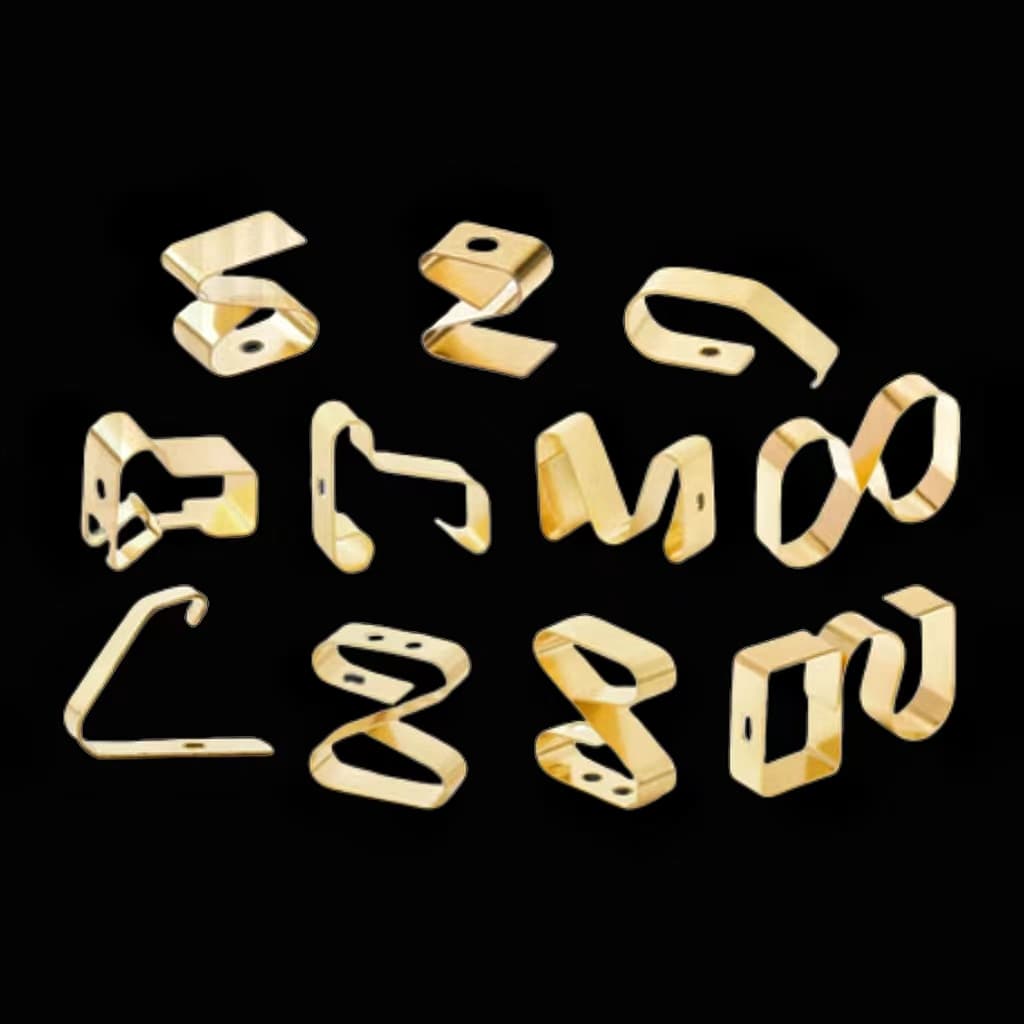

Clip-on mounting fingerstrip gaskets are essential components in the realm of electromagnetic shielding, playing a critical role in ensuring the effective performance of electronic devices and systems. These gaskets, produced by leading manufacturers like Handa Shielding, are designed to provide reliable electromagnetic interference (EMI) shielding and grounding. This article explores the construction, types, features, and applications of clip-on mounting fingerstrip gaskets, with a focus on Handa Shielding’s offerings.

Table of Contents

Introduction

In the world of electronics, electromagnetic shielding is crucial for preventing interference and ensuring the optimal functionality of devices. Fingerstrip gaskets are a key element in this shielding process, providing a conductive pathway that helps maintain signal integrity and reduce EMI. Handa Shielding, a prominent supplier in the shielding industry, offers a range of solutions including both stick-on and clip-on mounting fingerstrip gaskets. While stick-on gaskets are useful for general purposes and fit into confined spaces, clip-on mounting fingerstrip gaskets are engineered for more specialized requirements, particularly in challenging environments.

Clip-on mounting fingerstrip gaskets are especially valuable in high-temperature environments and other demanding conditions where traditional stick-on solutions may be inadequate. This article provides an in-depth look at these gaskets, detailing their construction, various types, and their applications in different settings.

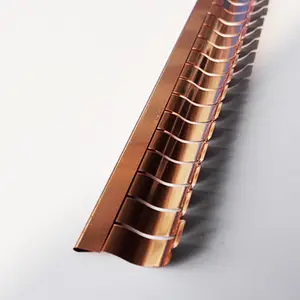

Construction and Materials

Handa Shielding’s clip-on mounting fingerstrip gaskets are primarily constructed from beryllium-copper alloys. This material choice is driven by its exceptional properties:

- Beryllium-Copper Alloys: Beryllium-copper alloys are known for their high tensile strength, excellent electrical conductivity, and resistance to wear and corrosion. Beryllium enhances the hardness and elasticity of copper, making the alloy highly suitable for demanding applications where mechanical robustness and superior electrical performance are essential.

- Electroplating Options: To meet diverse customer needs, the surfaces of these gaskets can be electroplated with various finishes, such as nickel-chrome sulfate, bright nickel, or bright tin. Electroplating not only enhances the aesthetic quality of the gaskets but also improves their resistance to environmental factors and corrosion.

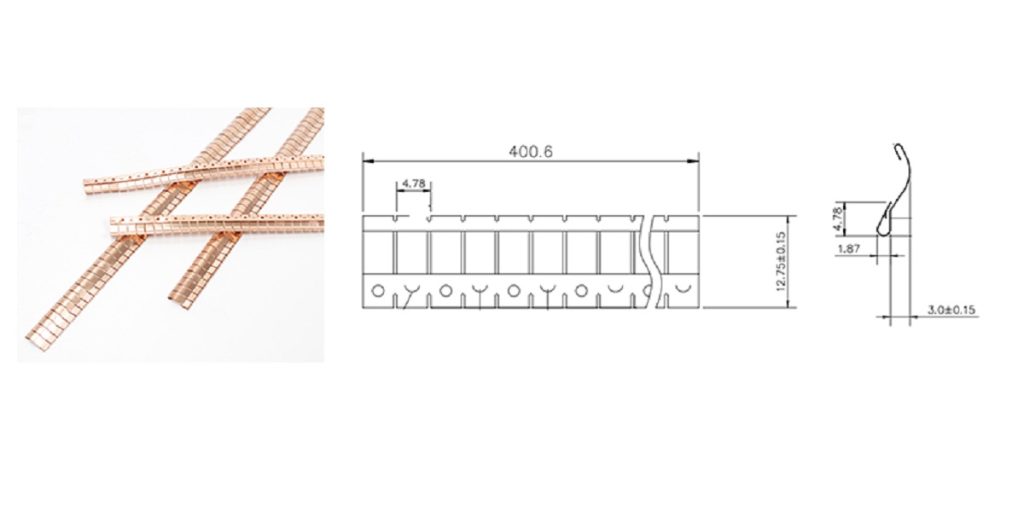

Clip-on mounting fingerstrip gaskets are designed to accommodate edge cards with panel thicknesses ranging from 0.5mm to 1.7mm. This design flexibility allows them to be used in various electronic configurations and mounting situations.

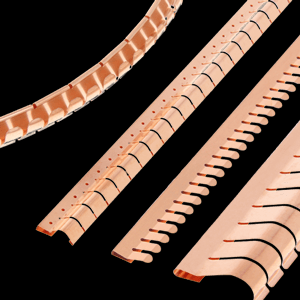

Types of Clip-On Mounting Fingerstrip Gaskets

Clip-on mounting fingerstrip gaskets come in several structural variations, each tailored to address specific application needs:

- Standard Type: This is the basic design of clip-on mounting gaskets, suitable for general applications where a standard size and structure are appropriate.

- Thin Edge Card-Mounted Gaskets: These gaskets feature a reduced height of the arc contact surface, making them ideal for low compression force applications and environments with very limited space. Their compact design enables them to fit into tight areas without compromising performance.

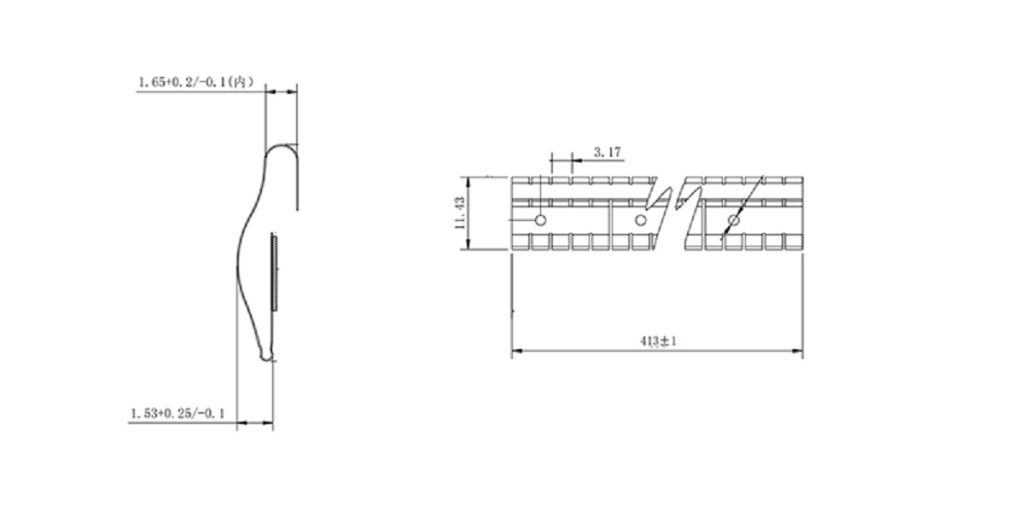

- Reverse Edge Card-Mounted Gaskets: These gaskets have a reverse-folded card-mounting structure, which helps save horizontal space and increase the card-mounting width. This design is particularly useful in extremely narrow application environments.

- Improved Edge Card-Mounted Gaskets: Designed to address misalignment between the installation panel and the mating panel, these gaskets ensure reliable connectivity and effective shielding even when panels are not perfectly aligned.

Main Features of Clip-On Mounting Fingerstrip Gaskets

- Material Excellence: Made from beryllium-copper alloys, these gaskets offer high tensile strength, excellent conductivity, and durability, which are crucial for effective electromagnetic shielding.

- Wide Temperature Range: The performance of beryllium-copper alloys across a broad temperature range makes these gaskets suitable for high-temperature environments, where other types of mounting solutions may fail.

- Customizable Electroplating: Various electroplating techniques can be applied to meet specific requirements for durability and environmental compatibility, providing flexibility for different applications.

- Design Variations: The availability of thin, reverse, and improved designs allows these gaskets to adapt to various mounting scenarios and constraints.

- Space Efficiency: The compact and adaptable designs, especially with thin and reverse gaskets, enable optimal use of space in compact electronic devices.

Typical Applications

Clip-on mounting fingerstrip gaskets are used in a wide range of applications due to their effectiveness and adaptability:

- Shielding Cabinets and Compartments: These gaskets are used in shielding cabinets to create a conductive path that prevents EMI and ensures the proper operation of sensitive electronic components.

- High-Temperature Electromagnetic Shielding: In high-temperature environments, such as industrial settings or high-performance electronics, these gaskets provide reliable shielding without performance degradation.

- Circuit Board Grounding: Effective grounding is critical for the stability and performance of circuit boards. Clip-on mounting fingerstrip gaskets ensure a solid electrical connection between circuit boards and their enclosures or grounding points.

- Telecommunications Equipment: Maintaining signal integrity in telecommunications is vital. These gaskets help in maintaining proper shielding and grounding to prevent signal interference.

- Military Equipment: The robust nature of clip-on mounting fingerstrip gaskets makes them suitable for military applications where reliability and performance under harsh conditions are crucial.

- Small Portable Devices: Their compact and versatile designs make them ideal for small portable electronic devices, where space is limited but effective shielding is still necessary.

Conclusion

Clip-on mounting fingerstrip gaskets are vital components in the field of electromagnetic shielding, offering essential functionality across a wide array of applications. Handa Shielding’s use of beryllium-copper alloys ensures that these gaskets provide high tensile strength, excellent conductivity, and durability, making them well-suited for demanding environments. With various designs, including standard, thin, reverse, and improved types, these gaskets offer versatility in addressing different mounting and environmental challenges.

As technology advances and electronic devices become more compact and sophisticated, the need for effective electromagnetic shielding becomes increasingly important. Clip-on mounting fingerstrip gaskets play a critical role in maintaining the integrity and performance of modern electronics. Whether used in high-temperature environments, telecommunications, military equipment, or small portable devices, these gaskets provide reliable and effective shielding, ensuring the optimal operation of electronic systems.

You May Also Like

-

Electrical Conducting Canted Coil Springs

Electrical Conducting Canted Coil SpringsHanda Canted Coil Springs

Electrical conducting springs

Electrical Conducting Springs In the fields of electrical and mechanical engineering, electrical conducting canted coil springs have emerged as pivotal components due to their unique blend of electrical conductivity and mechanical robustness. This article provides an in-depth examination of canted coil springs, focusing on their design, performance, applications, and customization. By understanding these aspects, engineers can better utilize these springs to enhance the performance and reliability of their systems. The Essence of Electrical Conducting Canted Coil SpringsVersatile ApplicationsPerformance FactorsMaterial ChoicesCustomization and AvailabilityOrientation and DesignConclusion The Essence of Electrical Conducting Canted Coil Springs Electrical conducting canted coil springs are distinguished by their angled coil configuration, which sets them apart from traditional springs. This design feature enables a compact footprint, allowing for the management of more power in less space while maintaining cooler operating temperatures. The coil's angled arrangement not only optimizes space but also improves heat dissipation. This is particularly advantageous in applications where heat management is crucial, as it minimizes heat rise and ensures a consistent, reliable electrical connection even under shock and vibration. The design of electrical conducting canted coil springs involves winding a wire into a helical shape and then angling it slightly. This results in a spring......

-

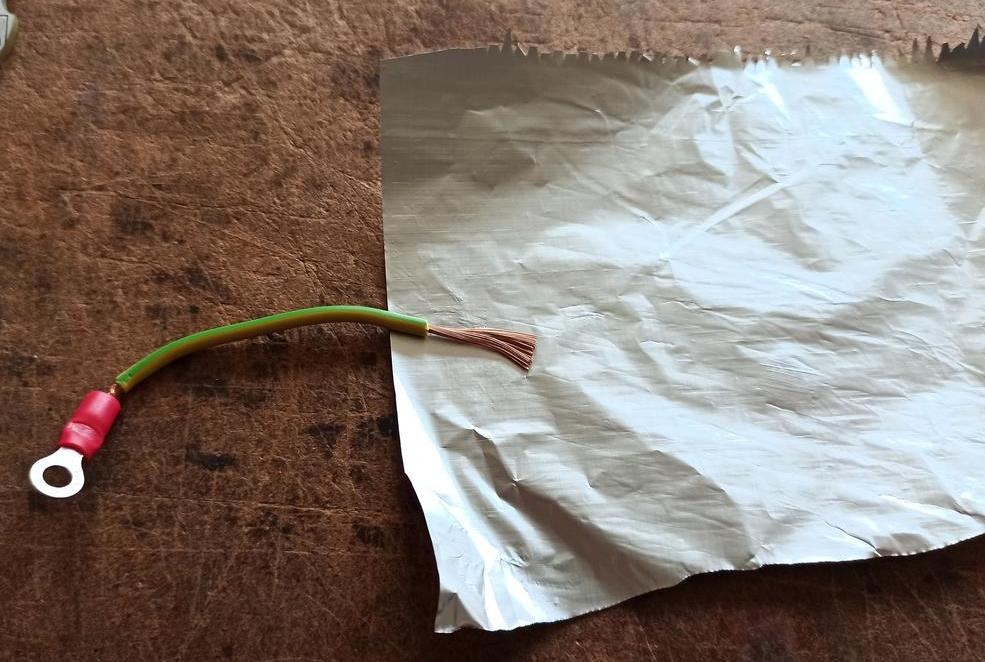

Aluminium Foil in Electromagnetic Shielding

Aluminium Foil in Electromagnetic ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Aluminium foil, a widely recognized material in both household and industrial applications, is particularly valued for its role in electromagnetic shielding. This article delves into the properties, applications, and considerations surrounding the use of aluminium foil for electromagnetic shielding. Its effectiveness and versatility make it a staple in numerous settings, from laboratories to consumer electronics, but it also presents certain challenges that must be addressed for optimal performance. Properties of Aluminium FoilApplicationsConsiderationsConclusion Properties of Aluminium Foil Aluminium foil is renowned for its lightweight and conductive characteristics, which play a crucial role in electromagnetic shielding. Its ability to reflect and absorb electromagnetic waves is central to its effectiveness in minimizing electromagnetic interference (EMI). Specifically, aluminium foil is capable of reflecting over 88% of incident electromagnetic waves in the X-band frequency range, a testament to its efficiency in shielding applications. This reflective property is beneficial for protecting sensitive electronic components from external interference, which is vital in maintaining the integrity and performance of various devices. Applications 1. EMC Shielding In electromagnetic compatibility (EMC) laboratories, the foil is commonly employed to diagnose and address sources of EMI. Its role is primarily temporary, serving as a quick solution to isolate and protect circuits from......

-

Electrical Contact Finger Springs

Electrical Contact Finger SpringsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction to Contact Finger Springs Contact finger springs are crucial components in the field of electronics and electrical engineering. They play a pivotal role in ensuring reliable electrical connections in a wide array of devices and systems. Understanding these components involves delving into their design, function, materials, and applications. This comprehensive exploration will cover all these aspects in detail. Introduction to Contact Finger SpringsDefinition and PurposeDesign and FunctionalityMaterials and ManufacturingApplicationsBenefits and LimitationsFuture Trends and DevelopmentsConclusion Definition and Purpose Contact finger springs, also known as contact springs or finger contacts, are spring-loaded elements designed to provide a stable and consistent electrical connection between two conductive surfaces. Their primary purpose is to maintain a secure and reliable electrical connection by applying a constant force between the contacts, which helps to minimize issues like intermittent connections, wear, and poor conductivity. Design and Functionality 1. Design Elements Shape and Structure: Contact finger springs are typically designed with a specific geometric shape that allows them to compress and return to their original form. Common designs include flat, curved, or cylindrical shapes. The design often resembles a comb or series of fingers, which is why they are sometimes referred to as "finger" springs. Material Composition: The......

-

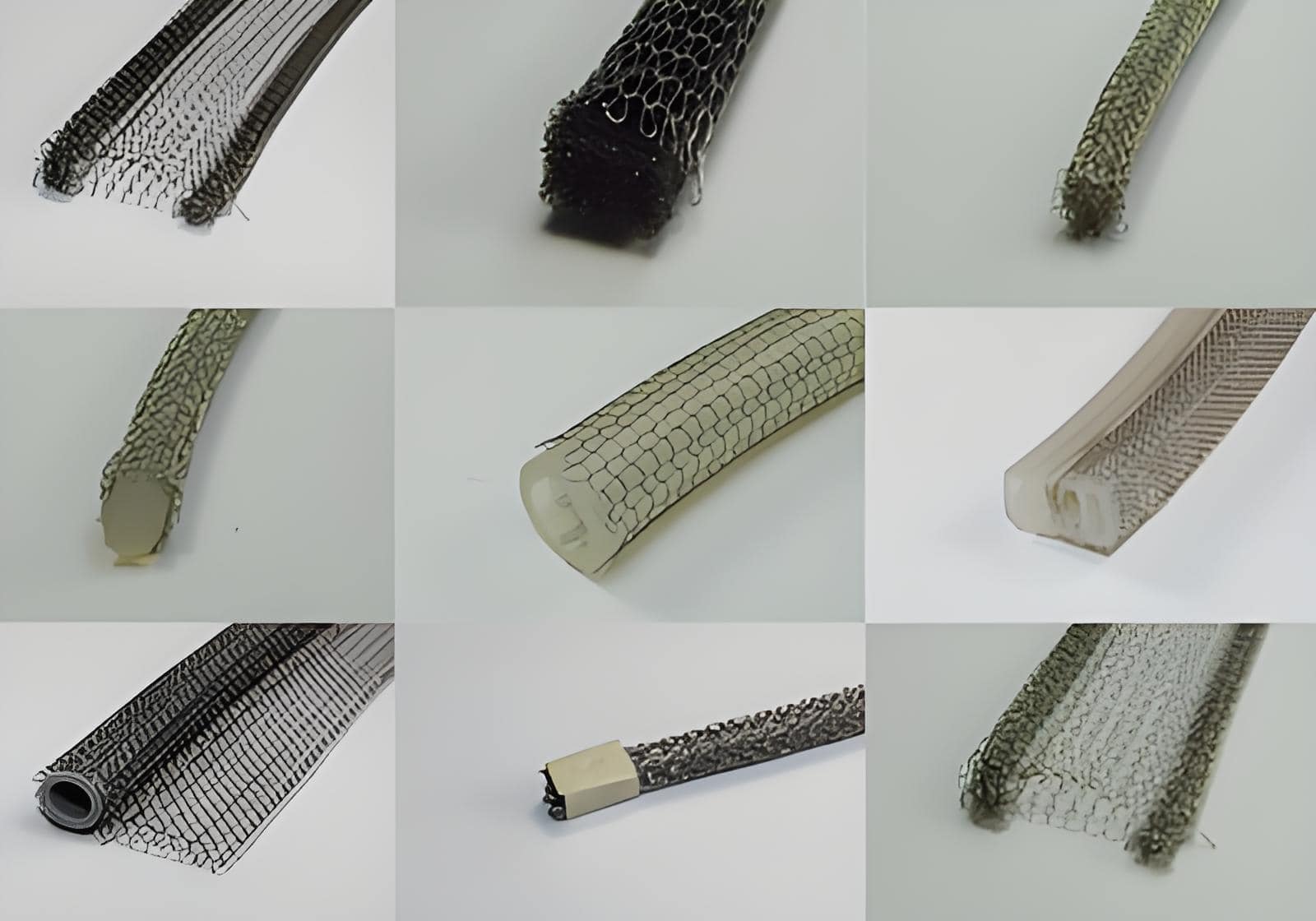

Knitted Metal Wire Mesh Gaskets:a highly versatile method of shielding

Knitted Metal Wire Mesh Gaskets:a highly versatile method of shieldingShielding Gasket Solutions and Materials

EMI shielding gaskets

Knitted metal wire mesh gaskets are engineered using fine metal wires, typically stainless steel or other conductive alloys, that are knitted or woven into a mesh structure. This design enables the gaskets to conform closely to mating surfaces, providing a continuous and reliable conductive path for shielding against EMI. The flexibility and resilience of knitted metal wire mesh gaskets make them suitable for sealing gaps and joints in electronic enclosures, effectively blocking electromagnetic radiation across a wide frequency range. Key Features and BenefitsApplications Across Industries Key Features and Benefits High Shielding Effectiveness: Knitted metal wire mesh gaskets offer high shielding effectiveness due to their dense, conductive mesh structure. They attenuate electromagnetic waves and prevent external interference from disrupting sensitive electronic signals, ensuring optimal device performance. Versatility: Available in various shapes, sizes, and configurations, these gaskets can be customized to fit specific application requirements. They are used in diverse industries such as telecommunications, aerospace, automotive, medical devices, and industrial automation. Durability and Longevity: Constructed from durable materials such as stainless steel, knitted metal wire mesh gaskets exhibit excellent mechanical strength and corrosion resistance. They withstand environmental factors and maintain shielding integrity over extended periods, reducing maintenance costs and downtime. Conductive Resilience:......