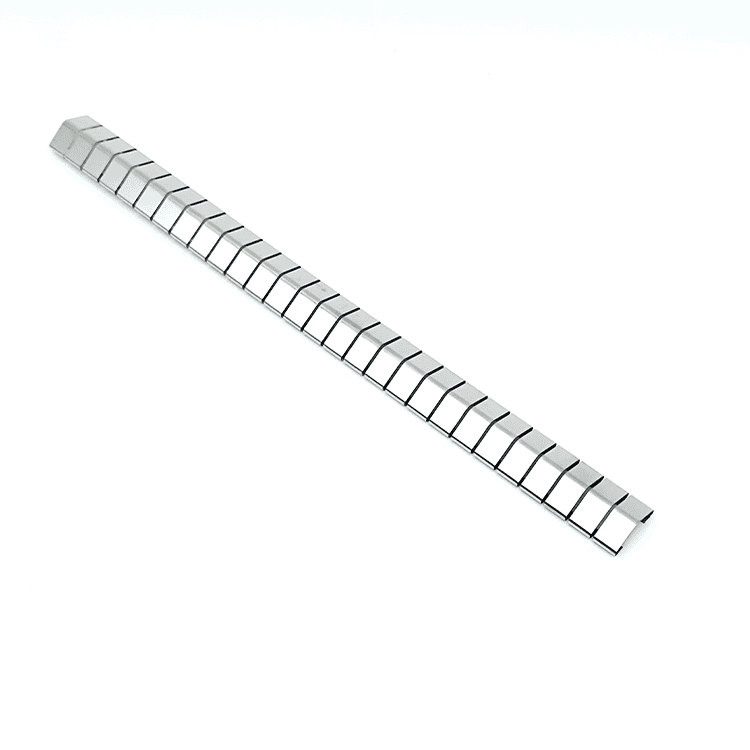

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

Among the various EMI shielding solutions, fingerstock gaskets are particularly notable for their high effectiveness. These gaskets are designed to seal gaps in electronic enclosures, thereby providing a conductive path that blocks EMI. They are an essential component in many industries where electronic reliability is paramount.

In today’s increasingly complex electronic landscape, electromagnetic interference (EMI) shielding has become a critical concern for device manufacturers and designers. One effective solution for addressing EMI issues is the use of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets. These specialized components play a vital role in protecting electronic devices from unwanted electromagnetic radiation and maintaining electromagnetic compatibility (EMC).

Table of Contents

What is EMI Shielding?

Electromagnetic interference (EMI) refers to the disruption of electronic circuits and systems caused by electromagnetic radiation from external sources. This interference can manifest as noise, signal degradation, or complete system malfunctions. EMI can be generated by a variety of sources including electrical devices, communication systems, and even natural phenomena.

To combat EMI, shielding techniques are employed to block or attenuate electromagnetic waves. EMI shielding involves creating a barrier that prevents the interference from penetrating sensitive areas of electronic devices. Effective EMI shielding ensures that devices operate reliably, maintain signal integrity, and meet regulatory standards.

The Role of EMI Shielding Fingerstock Gaskets

Among the various EMI shielding solutions, fingerstock gaskets are particularly notable for their high effectiveness. These gaskets are designed to seal gaps in electronic enclosures, thereby providing a conductive path that blocks EMI. They are an essential component in many industries where electronic reliability is paramount.

Advantages of High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

Fingerstock gaskets offer several benefits, making them a popular choice for EMI shielding applications:

- High Shielding Effectiveness: The primary advantage of fingerstock gaskets is their ability to provide high shielding effectiveness. The conductive fingers create a low-impedance path for EMI, effectively attenuating interference across a broad range of frequencies.

- Flexibility and Compression: Fingerstock gaskets are highly flexible and can conform to irregular surfaces. This flexibility ensures a tight seal and consistent contact pressure, which enhances the gasket’s shielding performance.

- Durability: Constructed from robust materials, fingerstock gaskets are durable and resistant to wear and tear. They maintain their effectiveness over time, even with repeated compressions.

- Low Contact Resistance: The design of fingerstock gaskets ensures low contact resistance, which is critical for maintaining high shielding performance and ensuring reliable electrical connections.

- Ease of Installation: Fingerstock gaskets are relatively easy to install. They can be integrated into various enclosure designs using adhesives or mechanical fasteners, simplifying the assembly process.

Construction and Materials of High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

EMI shielding fingerstock gaskets are typically made from conductive metals such as beryllium copper (BeCu), stainless steel, or aluminum. Beryllium copper alloys are particularly popular due to their excellent electrical spring characteristics and high shielding effectiveness.

The manufacturing process for CuBe fingerstock gaskets involves:

- Stamping and forming the metal fingers

- Post-heat treating to enhance mechanical strength and conductivity

- Precision cutting to achieve tight tolerances

These gaskets are available in various profiles and styles to suit different application needs 1.

Applications of High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

Fingerstock gaskets are utilized in a wide range of industries and applications where EMI shielding is essential:

- Telecommunications: In telecommunications equipment, fingerstock gaskets help shield sensitive components from EMI, ensuring clear and reliable signal transmission.

- Medical Devices: For medical equipment, where accuracy and reliability are critical, fingerstock gaskets provide effective shielding to prevent interference that could compromise patient safety.

- Aerospace and Defense: In aerospace and defense applications, where electronic systems are subjected to extreme conditions, fingerstock gaskets offer robust shielding and reliability.

- Consumer Electronics: Fingerstock gaskets are also employed in consumer electronics such as computers, televisions, and audio equipment to prevent EMI and maintain optimal performance.

- Automotive: In the automotive industry, fingerstock gaskets are used to shield various electronic systems from EMI, ensuring the proper functioning of vehicle components.

Performance Metrics of Fingerstock Gaskets

To assess the performance of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets, several key metrics are considered:

- Shielding Effectiveness: This metric indicates the gasket’s ability to attenuate electromagnetic radiation. It is typically measured in decibels (dB) and reflects how well the gasket blocks EMI.

- Contact Resistance: The resistance encountered when the gasket makes contact with the mating surfaces. Lower contact resistance implies better conductivity and shielding performance.

- Compression Force: The amount of force required to compress the gasket between surfaces. Proper compression is necessary for achieving a tight seal and effective shielding.

- Environmental Resistance: The gasket’s ability to withstand environmental factors such as temperature variations, humidity, and mechanical stress.

- Service Life: The duration for which the gasket maintains its effectiveness. Durability is a critical factor for applications requiring long-term reliability.

Challenges and Considerations

While fingerstock gaskets offer numerous advantages, there are challenges and considerations that must be addressed:

- Cost: High-quality fingerstock/fingerstrip gaskets can be expensive due to the materials and manufacturing processes involved. Balancing cost with performance requirements is essential.

- Installation: Proper installation is crucial for optimal shielding effectiveness. Misalignment or improper compression can reduce the gasket’s performance.

- Compatibility: The choice of materials and design should be compatible with the specific application and environmental conditions.

- Maintenance: Regular inspection and maintenance are necessary to ensure the gasket continues to function effectively over time.

Future Trends in EMI Shielding

As technology advances, the demand for effective EMI shielding solutions, including fingerstock gaskets, will continue to grow. Future trends in EMI shielding may include:

- Enhanced Materials: Development of new materials with improved conductivity and durability to further enhance shielding performance.

- Integration with Smart Technologies: Incorporation of sensors and smart technologies into gaskets to monitor and optimize shielding performance in real-time.

- Miniaturization: Design advancements to accommodate the miniaturization of electronic devices while maintaining high shielding effectiveness.

- Sustainable Solutions: Focus on environmentally friendly materials and manufacturing processes to reduce the ecological impact of EMI shielding solutions.

Case Studies of High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

To illustrate the practical applications and effectiveness of fingerstock gaskets, several case studies can be considered:

- Telecommunications Equipment: A major telecommunications company implemented EMI Shielding Fingerstock Gaskets in their network equipment enclosures. The gaskets successfully reduced EMI, leading to improved signal clarity and reliability. The high shielding effectiveness of the gaskets was critical in meeting industry standards and ensuring uninterrupted service.

- Medical Devices: In a hospital setting, EMI Shielding Fingerstock Gaskets were used in the enclosures of sensitive medical diagnostic equipment. The gaskets provided effective EMI shielding, preventing interference that could have affected the accuracy of diagnostic readings. The durability of the gaskets ensured long-term reliability in a demanding environment.

- Automotive Electronics: An automotive manufacturer integrated fingerstock gaskets into their vehicle control systems to shield against EMI. The gaskets maintained optimal performance of the vehicle’s electronic components, contributing to the overall reliability and safety of the vehicle.

Conclusion

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets play a crucial role in protecting electronic devices from electromagnetic interference. Their unique design, featuring resilient metal fingers and a supportive base, provides exceptional shielding performance across a broad range of frequencies. With advantages such as flexibility, durability, and ease of installation, fingerstock gaskets are widely used in telecommunications, medical devices, aerospace, consumer electronics, and automotive applications.

As technology continues to evolve, the demand for effective EMI shielding solutions will grow. By addressing challenges related to cost, installation, and compatibility, and staying abreast of future trends, manufacturers and users can ensure that EMI Shielding Fingerstock Gaskets remain an essential component in the ongoing battle against electromagnetic interference.

You May Also Like

-

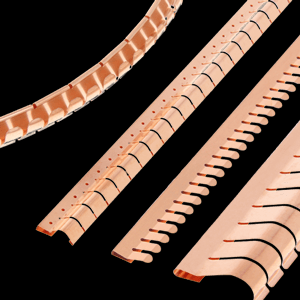

Right-angle shielding fingerstrips/angled fingerstocks

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic systems. These fingerstrips are particularly useful in configurations where electronic components intersect at a 90-degree angle. Their primary role is to ensure effective shielding, maintaining electromagnetic compatibility (EMC) and protecting sensitive electronic equipment from interference. IntroductionDesign and FunctionalitySpecifications and MaterialsInstallation ConsiderationsManufacturing ProcessBenefitsConclusion Design and Functionality Purpose and Importance The main purpose of right-angle shielding fingerstrips is to provide reliable EMI/RFI shielding in electronic setups with perpendicular component arrangements. When electronic devices have components aligned at right angles, traditional shielding solutions might not be effective due to gaps or incomplete coverage. Right-angle fingerstrips address this issue by ensuring continuous shielding across these angular junctions, which is crucial for maintaining the performance and reliability of electronic systems. Applications Right-angle shielding fingerstrips are used in a wide range of applications: Computer Hardware: To shield critical internal components from electromagnetic emissions that could cause operational issues or data corruption. Telecommunications Equipment: To prevent signal interference and ensure the integrity of communication systems. Automotive Electronics: To protect sensitive electronic control systems from EMI that could impact vehicle performance. Shielded Enclosures:......

-

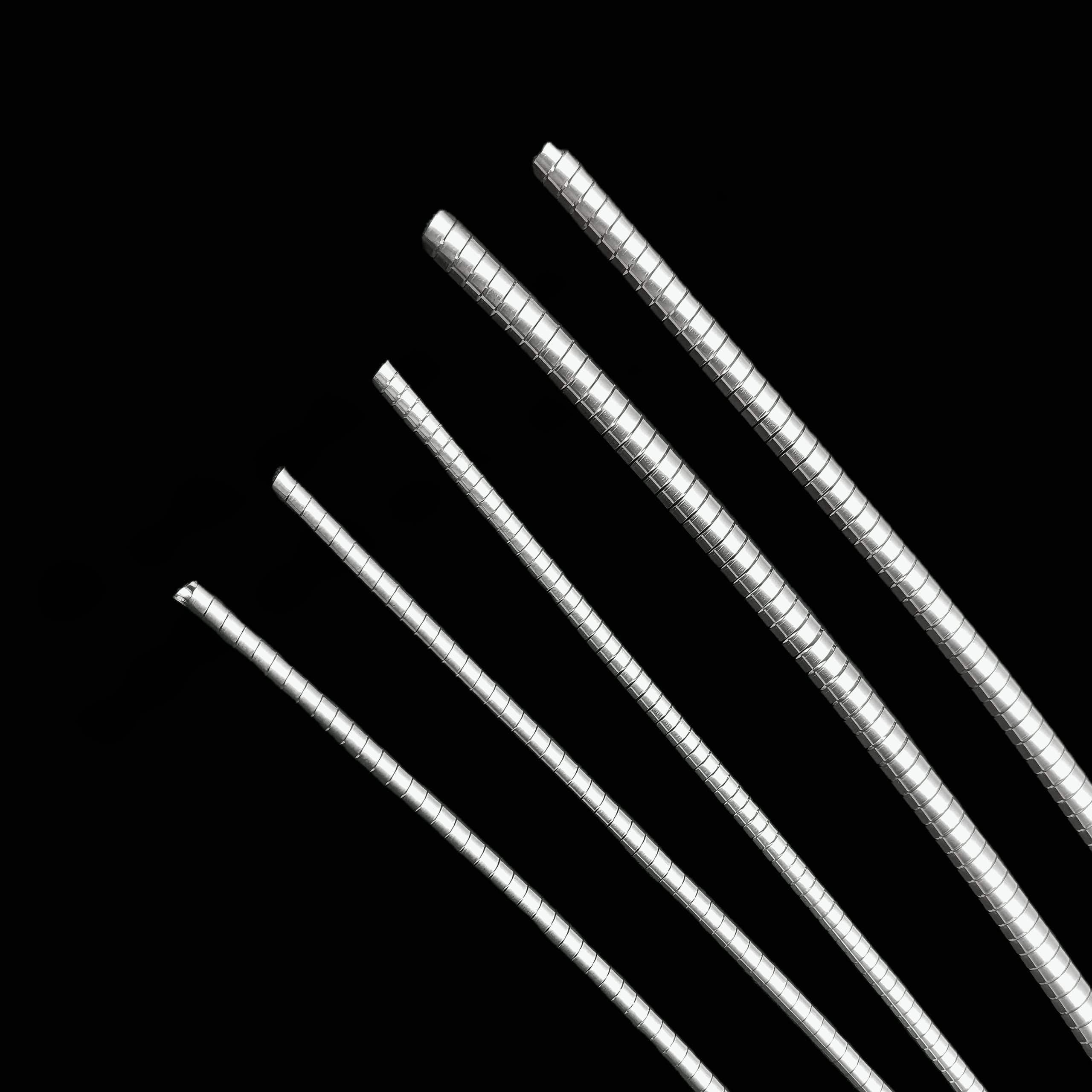

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic Compatibility

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic CompatibilityEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

In today's interconnected world of electronics and telecommunications, maintaining electromagnetic compatibility (EMC) is crucial to ensure optimal performance and reliability of electronic devices. RF/EMI Shield Spiral Gaskets play a pivotal role in achieving this goal by effectively mitigating electromagnetic interference (EMI) that can disrupt signal integrity and functionality. What are RF/EMI Shield Spiral Gaskets?Key Features and BenefitsApplications Across Industries What are RF/EMI Shield Spiral Gaskets? RF/EMI Shield Spiral Gaskets are specialized components designed to provide robust shielding against electromagnetic radiation. They are typically made from conductive materials such as metal alloys or conductive elastomers, crafted into a spiral shape that allows them to conform closely to mating surfaces. This design ensures consistent contact and compression, optimizing the gasket's ability to block EMI effectively. Key Features and Benefits EMI Shielding Effectiveness: The primary function of RF/EMI Shield Spiral Gaskets is to attenuate electromagnetic waves, preventing external interference from disrupting sensitive electronic signals. This capability is crucial for maintaining signal integrity and preventing data corruption in telecommunications, aerospace, medical devices, and industrial automation. Versatility in Applications: These gaskets are available in various sizes, shapes, and materials to suit different application requirements. They are commonly used in:Telecommunications: Ensuring clear and reliable communication by......

-

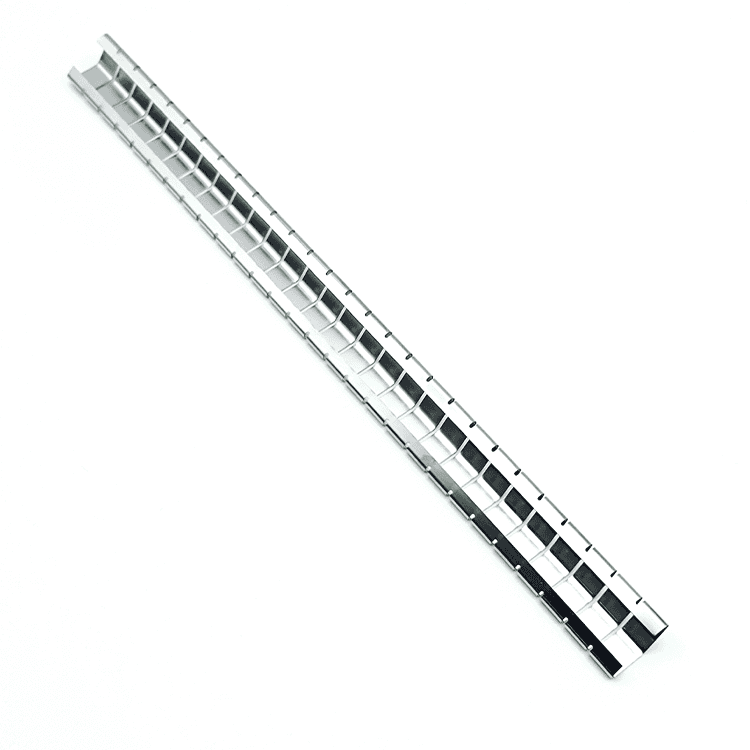

Handa Shielding – Clip-on mounting fingerstrip

Handa Shielding – Clip-on mounting fingerstripFingerstrips

Clip-on mounting shielding fingerstrip

Clip-on mounting fingerstrip gaskets are essential components in the realm of electromagnetic shielding, playing a critical role in ensuring the effective performance of electronic devices and systems. These gaskets, produced by leading manufacturers like Handa Shielding, are designed to provide reliable electromagnetic interference (EMI) shielding and grounding. This article explores the construction, types, features, and applications of clip-on mounting fingerstrip gaskets, with a focus on Handa Shielding’s offerings. IntroductionConstruction and MaterialsTypes of Clip-On Mounting Fingerstrip GasketsMain Features of Clip-On Mounting Fingerstrip GasketsTypical ApplicationsConclusion Introduction In the world of electronics, electromagnetic shielding is crucial for preventing interference and ensuring the optimal functionality of devices. Fingerstrip gaskets are a key element in this shielding process, providing a conductive pathway that helps maintain signal integrity and reduce EMI. Handa Shielding, a prominent supplier in the shielding industry, offers a range of solutions including both stick-on and clip-on mounting fingerstrip gaskets. While stick-on gaskets are useful for general purposes and fit into confined spaces, clip-on mounting fingerstrip gaskets are engineered for more specialized requirements, particularly in challenging environments. Clip-on mounting fingerstrip gaskets are especially valuable in high-temperature environments and other demanding conditions where traditional stick-on solutions may be inadequate. This article provides an in-depth......

-

Electrical Conducting Canted Coil Springs

Electrical Conducting Canted Coil SpringsHanda Canted Coil Springs

Electrical conducting springs

Electrical Conducting Springs In the fields of electrical and mechanical engineering, electrical conducting canted coil springs have emerged as pivotal components due to their unique blend of electrical conductivity and mechanical robustness. This article provides an in-depth examination of canted coil springs, focusing on their design, performance, applications, and customization. By understanding these aspects, engineers can better utilize these springs to enhance the performance and reliability of their systems. The Essence of Electrical Conducting Canted Coil SpringsVersatile ApplicationsPerformance FactorsMaterial ChoicesCustomization and AvailabilityOrientation and DesignConclusion The Essence of Electrical Conducting Canted Coil Springs Electrical conducting canted coil springs are distinguished by their angled coil configuration, which sets them apart from traditional springs. This design feature enables a compact footprint, allowing for the management of more power in less space while maintaining cooler operating temperatures. The coil's angled arrangement not only optimizes space but also improves heat dissipation. This is particularly advantageous in applications where heat management is crucial, as it minimizes heat rise and ensures a consistent, reliable electrical connection even under shock and vibration. The design of electrical conducting canted coil springs involves winding a wire into a helical shape and then angling it slightly. This results in a spring......

-

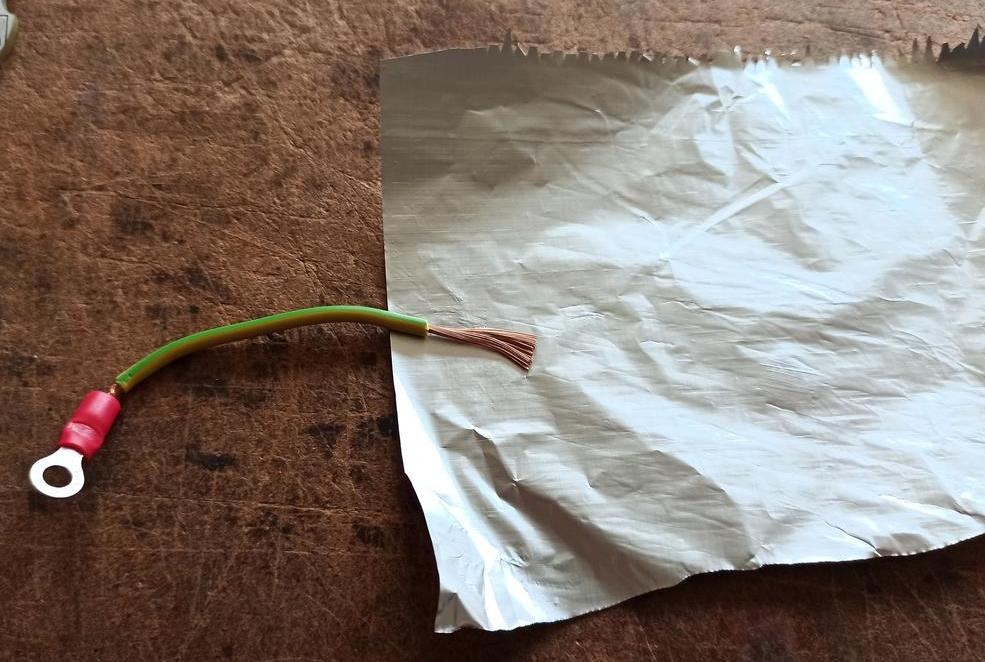

Aluminium Foil in Electromagnetic Shielding

Aluminium Foil in Electromagnetic ShieldingEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Aluminium foil, a widely recognized material in both household and industrial applications, is particularly valued for its role in electromagnetic shielding. This article delves into the properties, applications, and considerations surrounding the use of aluminium foil for electromagnetic shielding. Its effectiveness and versatility make it a staple in numerous settings, from laboratories to consumer electronics, but it also presents certain challenges that must be addressed for optimal performance. Properties of Aluminium FoilApplicationsConsiderationsConclusion Properties of Aluminium Foil Aluminium foil is renowned for its lightweight and conductive characteristics, which play a crucial role in electromagnetic shielding. Its ability to reflect and absorb electromagnetic waves is central to its effectiveness in minimizing electromagnetic interference (EMI). Specifically, aluminium foil is capable of reflecting over 88% of incident electromagnetic waves in the X-band frequency range, a testament to its efficiency in shielding applications. This reflective property is beneficial for protecting sensitive electronic components from external interference, which is vital in maintaining the integrity and performance of various devices. Applications 1. EMC Shielding In electromagnetic compatibility (EMC) laboratories, the foil is commonly employed to diagnose and address sources of EMI. Its role is primarily temporary, serving as a quick solution to isolate and protect circuits from......