導電性スプリング

-

導電バネ 製造

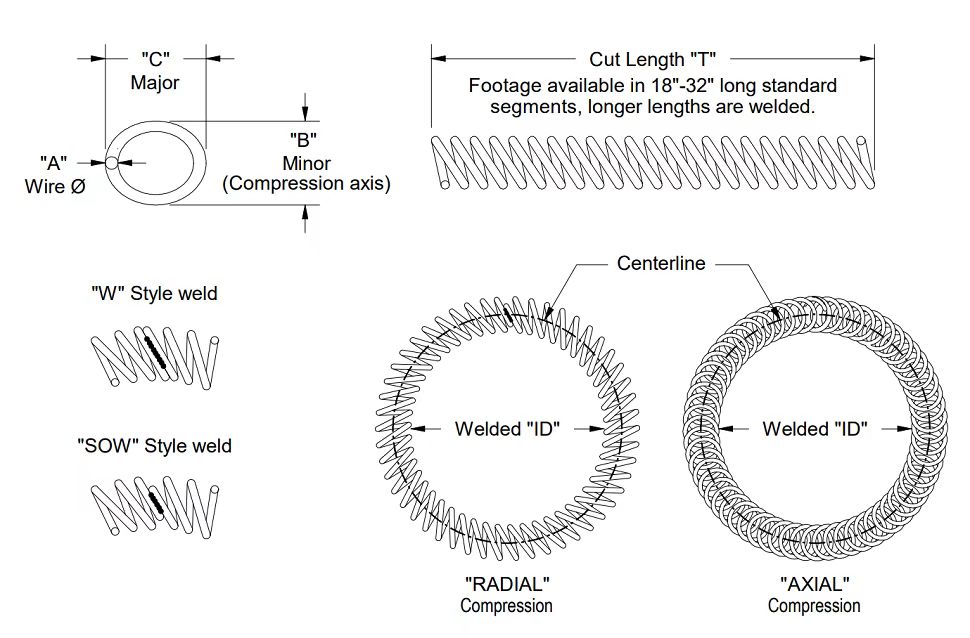

電気伝導スプリングは電流を伝導するために使用されるスプリング部品で、電子機器、コネクタ、スイッチ、その他の電気システムに一般的に使用されています。これらのスプリングを作るには、導電性、材料の選択、精密なエンジニアリングを考慮する必要があります。

以下は、導電性スプリングの製造工程である:

1.素材の選択

2.製造ワイヤー

3.曲げと成形

4.熱処理

5.表面処理

6.品質管理

7.カスタマイズの要件

8.パッケージ

導電性スプリングの製造には、電流を確実に伝導し、アプリケーションの性能要件を満たすための精密なエンジニアリングと品質管理が必要です。そのため、以下の企業との共同開発をお勧めします。 半田シールド お客様の特定のアプリケーションのニーズを満たすために。

素材とメッキ

導電性スプリング は、導電性、機械的特性、耐久性を考慮して選択された様々な材料から作られています。材料の選択は、特定のアプリケーションに対するスプリングの性能と適合性に影響を与えます。

- ステンレス鋼(302、316、316L)

- ジルコニウム銅

- 錫メッキ

- ベリリウム銅

- 金ピカ

- ニッケルメッキ

- 合金(X750、718、3j21、エルグロイ、ハステロイC276)

- 銀メッキ

メリット

導電スプリングは、信頼性の高い電気的性能と機械的柔軟性の両方が不可欠な様々な電子・電気システムに不可欠です。

- 高い導電性

- 機械的柔軟性

- 耐久性

- コンパクト設計

- 信頼できるパフォーマンス

アプリケーション

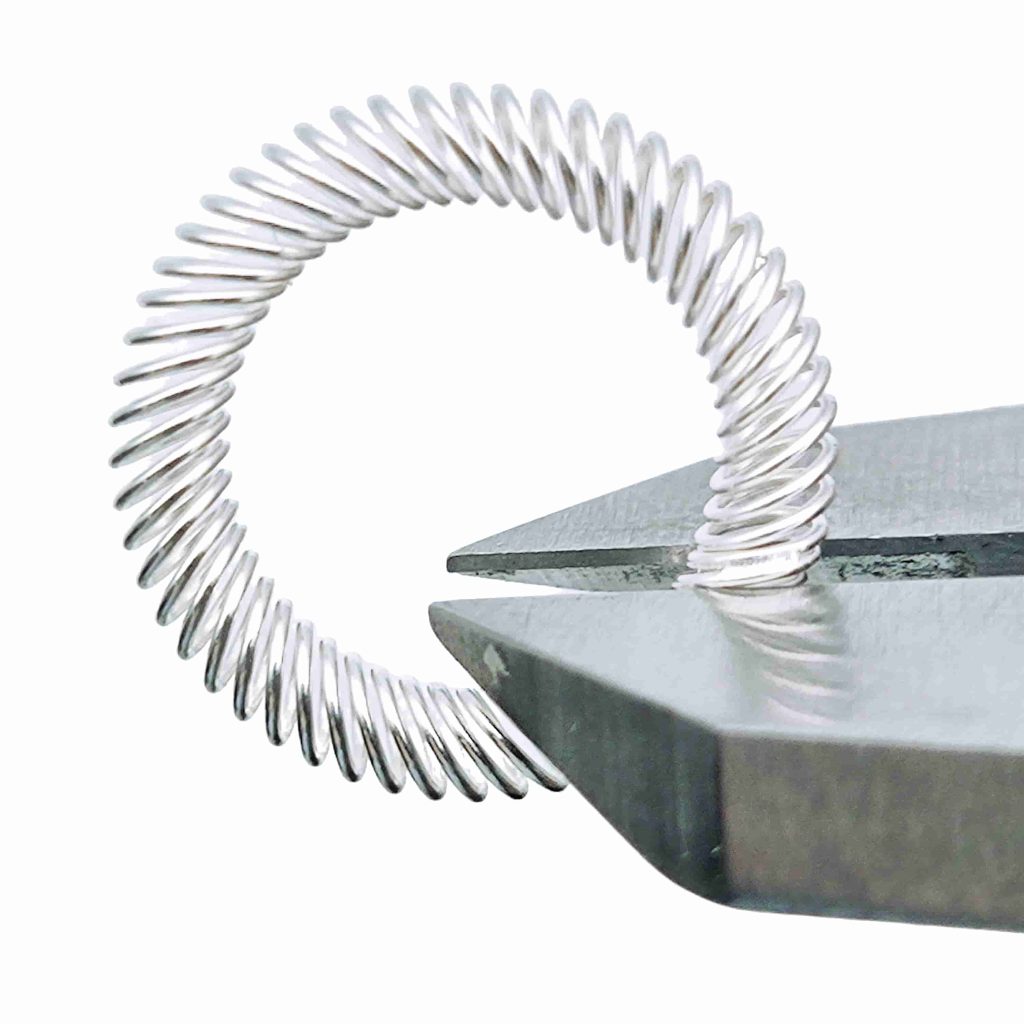

半田シールドコイルスプリング 衝撃や振動のある環境でも、モーターへの信頼性の高い電流供給を保証します。

導電バネは、導電性と機械的柔軟性を兼ね備え、様々なシステムや機器の信頼性と効率性に貢献する重要な部品です。

- エネルギー:変電所の断路

- 航空宇宙:衛星用ソーラーアレイ

- 輸送:EVバッテリーコネクター

- 産業:ロボットエンドエフェクター/グリッパー

最近の製品

-

導電性コンタクトフィンガースプリング / キャントコイルスプリング 信頼性の高い導電性を維持するための課題導電性コンタクトフィンガースプリング:信頼性の高いソリューション広い範囲で安定した力.............

-

導電性スプリング 電気工学や機械工学の分野において、導電性カントコイルスプリングは重要な部品として登場しました。