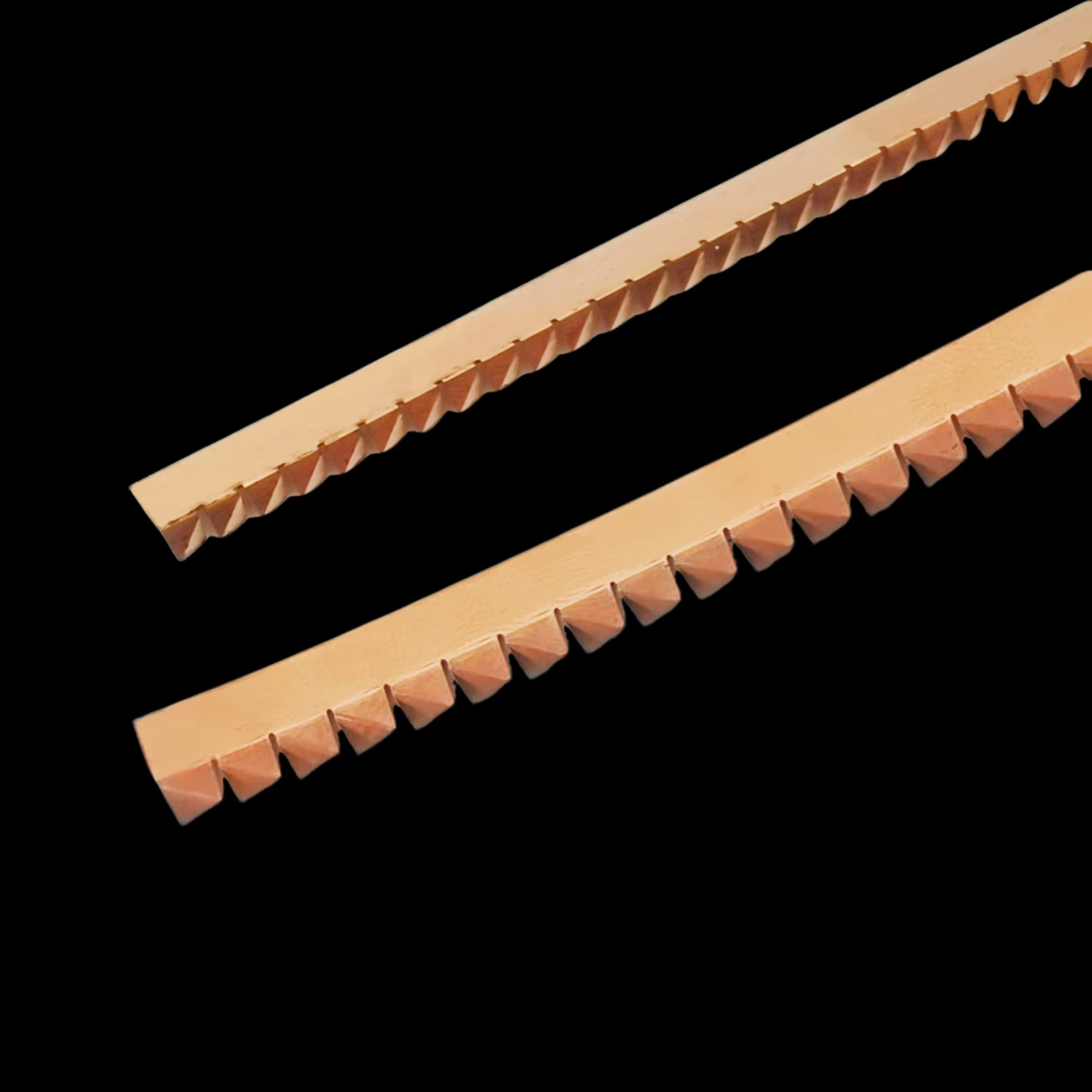

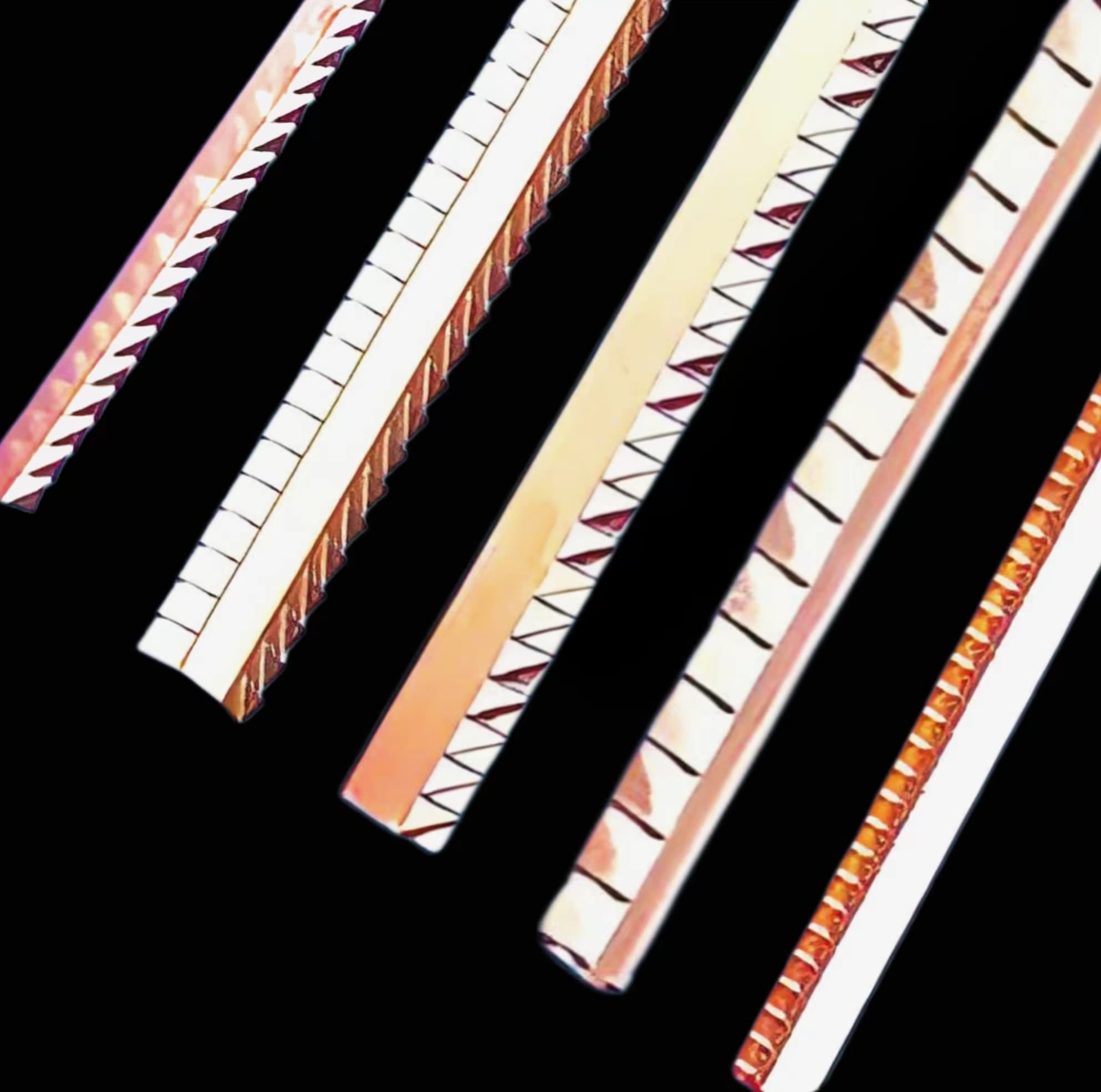

ツイスト取り付けシールドフィンガーストリップ

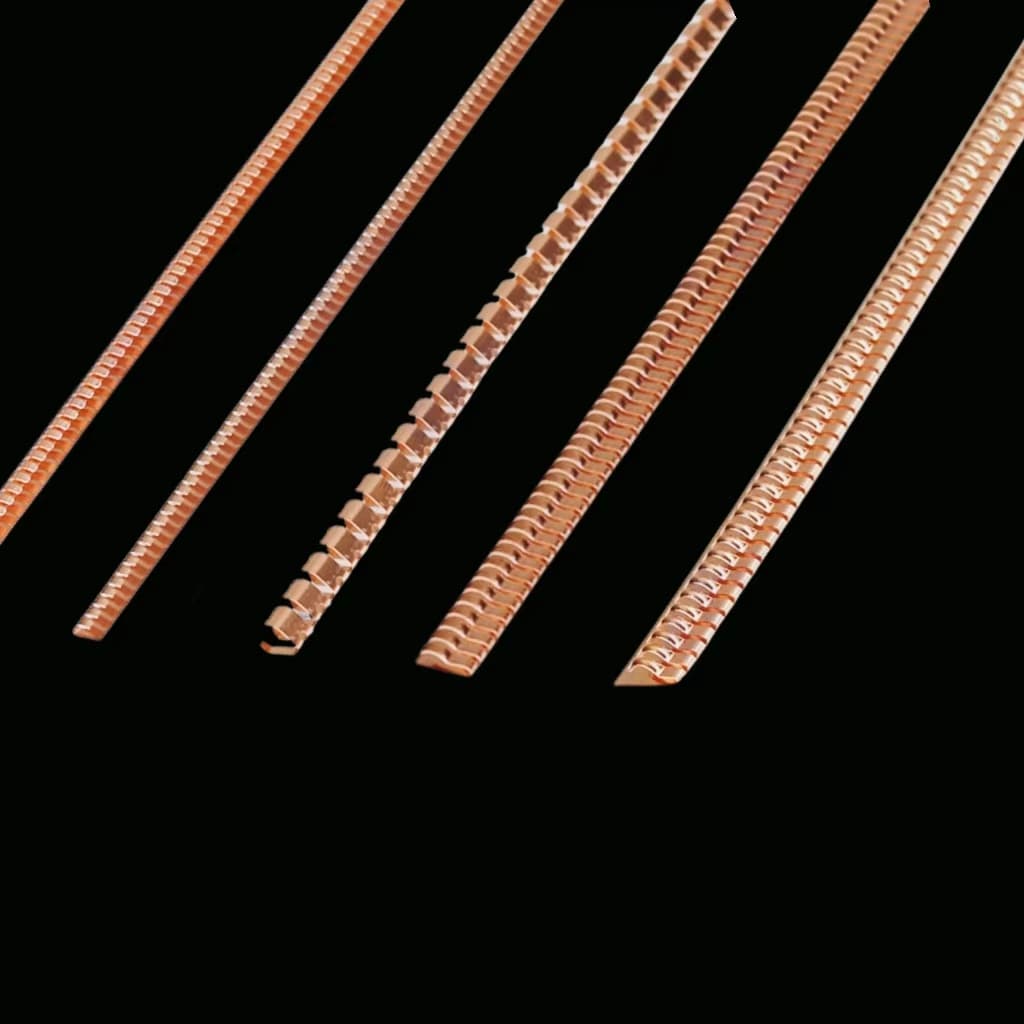

半田ツイスト取付シールドフィンガーストリップ は優れた耐圧縮性、弾力性、耐食性を持つ。優れた 広帯域電磁シールド効果 特に、通信キャビネットやコンピュータ、シールドルームのキャビネット/ルームドア、パネルなどの隙間充填に適しています。

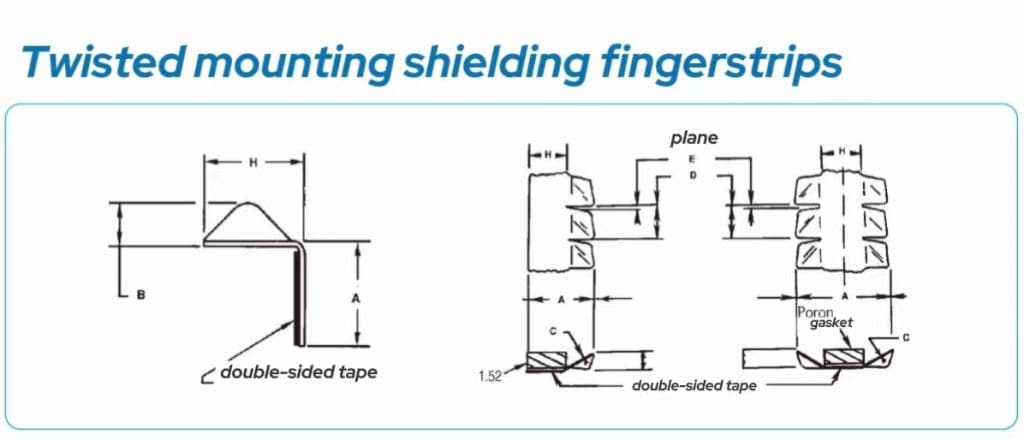

製品仕様

サイズスペック

半田ツイスト取付シールドフィンガーストリップs 寸法はメーカーや製品モデルによって異なります。以下は可能な寸法仕様の一例ですが、具体的な仕様については下記までご確認ください。 半田シールド 特定のアプリケーションの要件を満たすために:

| いや。 | A | B | C | D | E | H | 長さ(mm) | ロール長(mm) | ガスケット |

|---|---|---|---|---|---|---|---|---|---|

| 97-5500 | 5.84 | 0.76 | 0.08 | 2.41 | 0.38 | 3.56 | 609.60 | 7.6 | / |

| 97-5510 | 4.06 | 0.76 | 0.08 | 2.41 | 0.38 | 2.03 | 609.60 | – | / |

| 97-5550 | 8.64 | 1.78 | 0.08 | 4.19 | 0.38 | 4.57 | 609.60 | 7.6 | / |

| 97-5580 | 5.08 | 1.78 | 0.08 | 4.19 | 0.38 | 2.79 | 609.60 | – | / |

| 97-5600 | 12.70 | 1.78 | 0.08 | 4.19 | 0.38 | 4.83 | 609.60 | 7.6 | / |

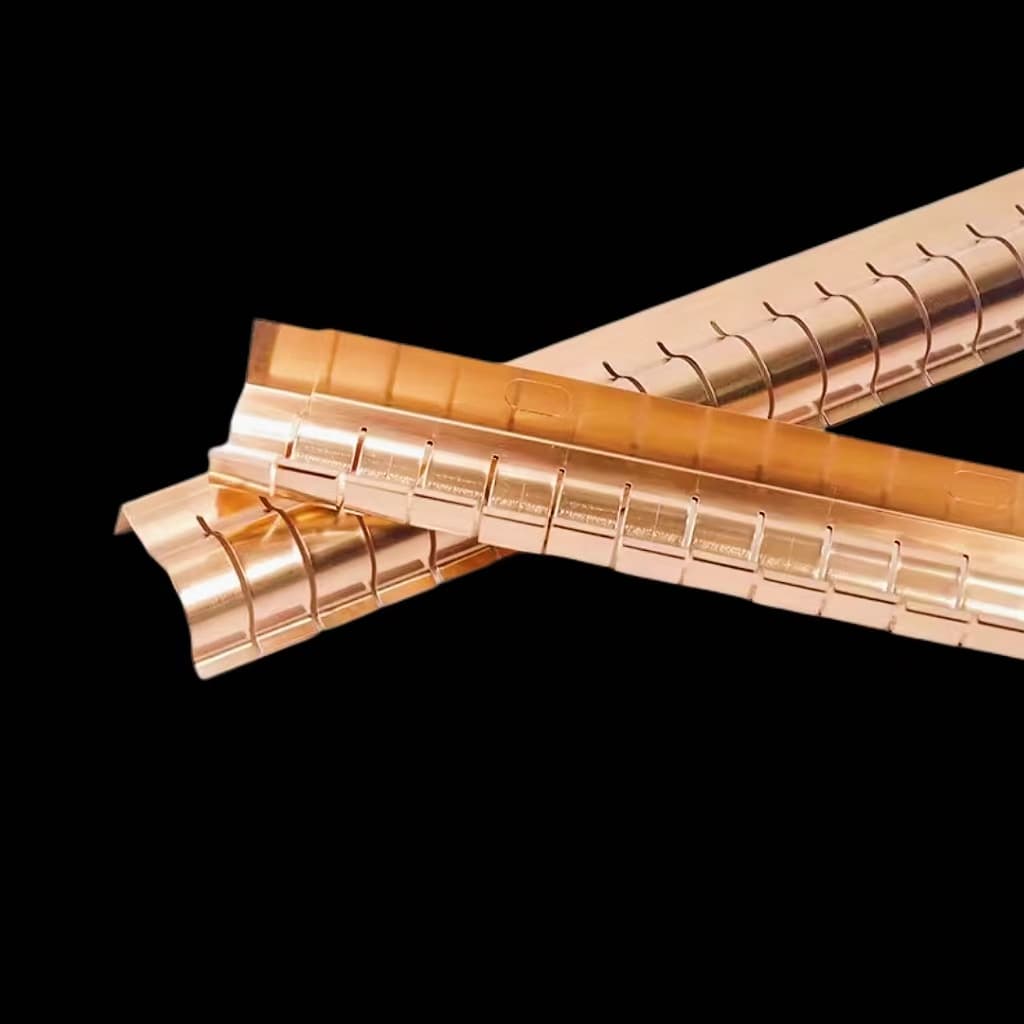

ツイスト実装シールドフィンガーストリップ 製造

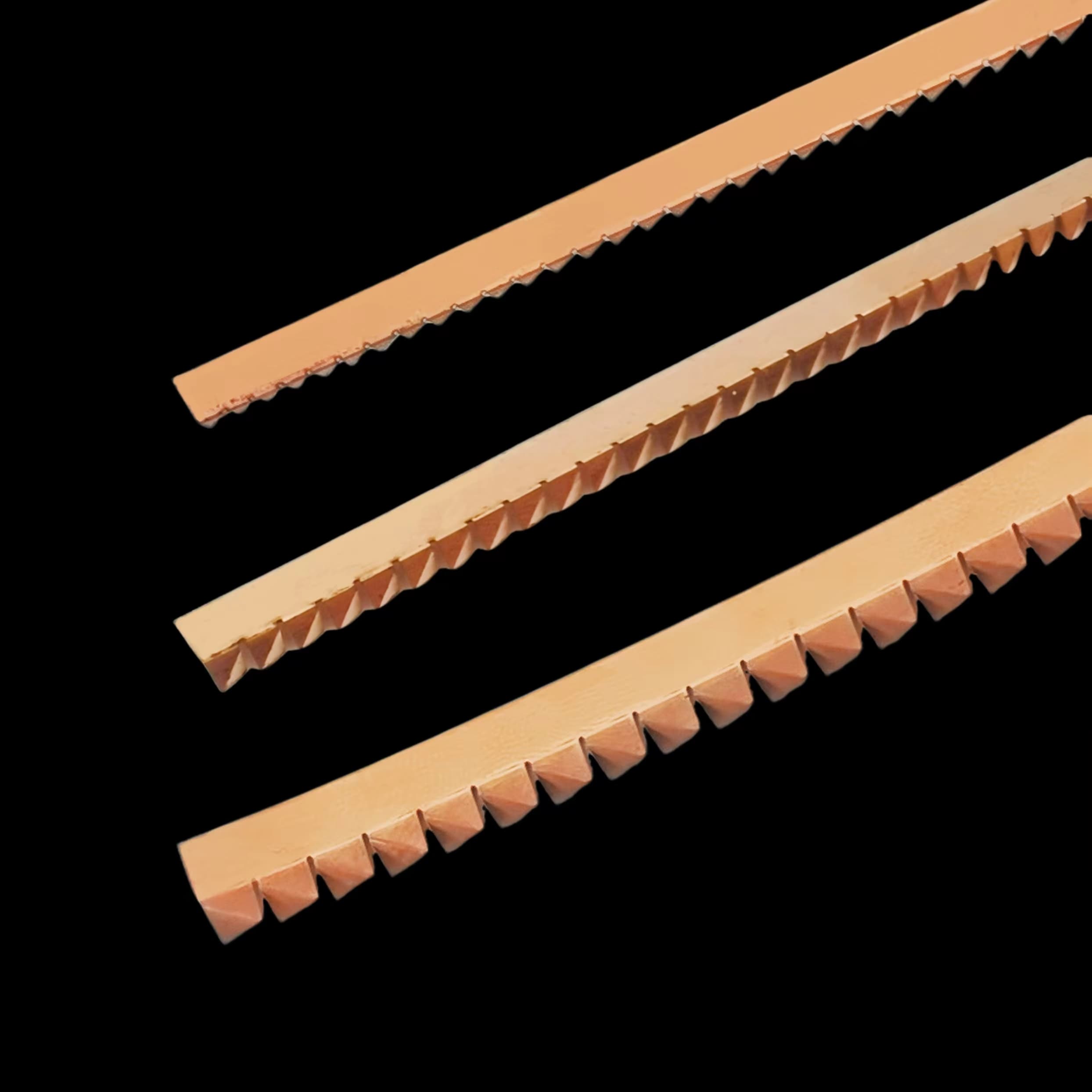

ねじれたフィンガーストリップの製造にはいくつかの工程があり、次のような製品を作ることに重点を置いている。 電磁干渉(EMI)を効果的にシールド 柔軟性と設置のしやすさを維持しながら:

1.材料の選択:ベリリウム銅合金で、高いEMIシールド効果を必要とする用途に最適です。

2.ワイヤーの準備:設計仕様に従って、適切な直径と長さのワイヤーを選択する。

3.コイルを形成する:マンドレルまたはフォーマーにワイヤーを巻き、最初のコイル形状を形成する。

4.熱処理: オプションとして、コイル状のワイヤーを熱処理して硬度と耐摩耗性を高め、スプリングの寿命と性能を向上させる。

5.裁断と成形

(1) 長さに切断する: コイル状のワイヤーを必要な長さにカットする。

(2) 形を整える: ワイヤーの端をねじって、フィンガーストリップの特徴であるねじれた形状を作る。

6.仕上げ

(1) 表面処理: 必要に応じて、メッキやコーティングなどの表面処理を施す。

(2) 包装: 完成したツイストフィンガーストリップをしっかりと梱包する。

7.品質保証

テスト: バネ定数の測定、曲げ試験の実施、さまざまな周波数でのシールド効果の評価などを行う。

メリット

半田ツイスト取付シールドフィンガーストリップ は適度にひねりの効いたデザインで、さまざまな利点がある。

- 省スペース

- 高いEMIシールド性能

- 簡単で安全な取り付け

- 簡単なメッキと溶接

- 高い耐圧縮性

- 簡単なメッキと溶接

- 様々な素材のめっきプロセスをカスタマイズすることができます。

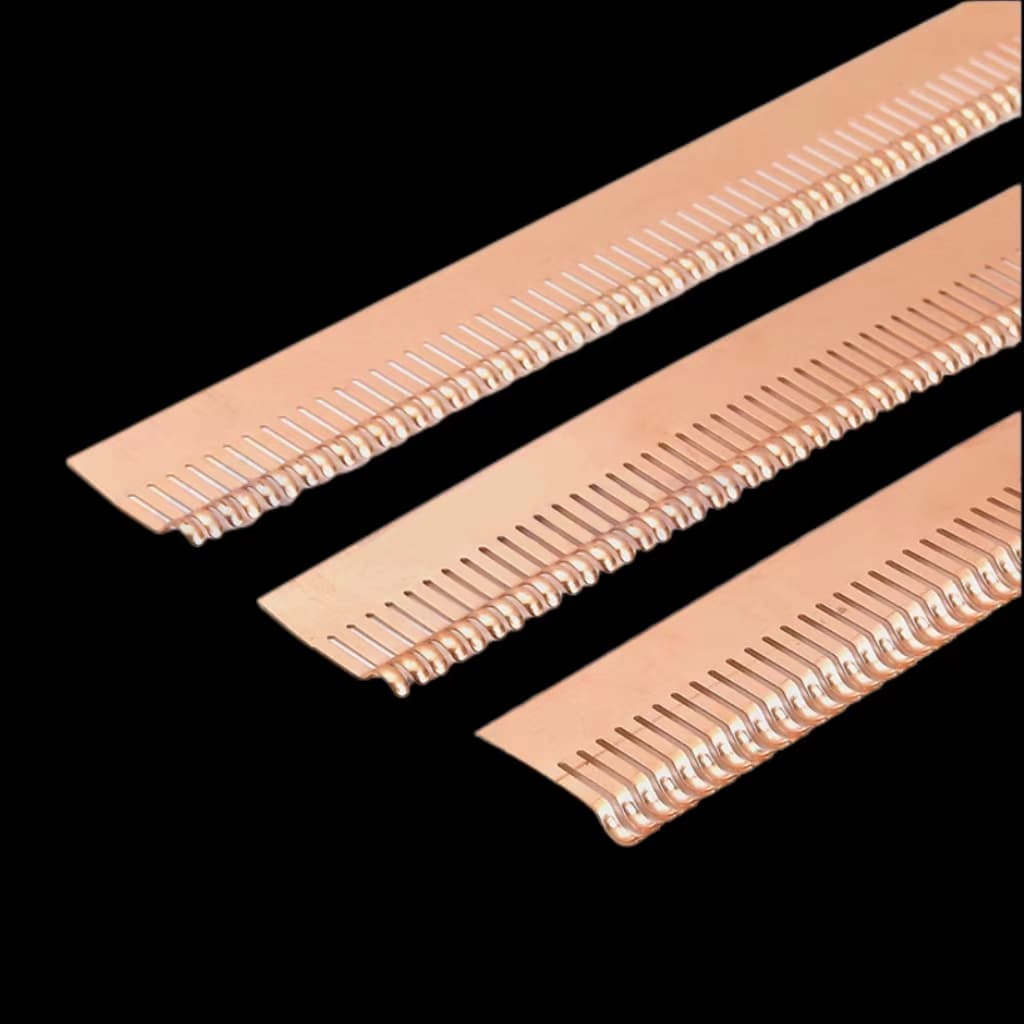

アプリケーション

の構造設計 半田ツイスト取付シールドフィンガーストリップ は、ねじれやねじれの特性を持ち、様々な狭い設置スペースでの使用に非常に適している。

- シールドパネル

- シールドケース

- フラット・パーティション付きボックス

- 電子製品ハウジング

- パネル仕切り付きシールドキャビネット

- 通信基地局設備

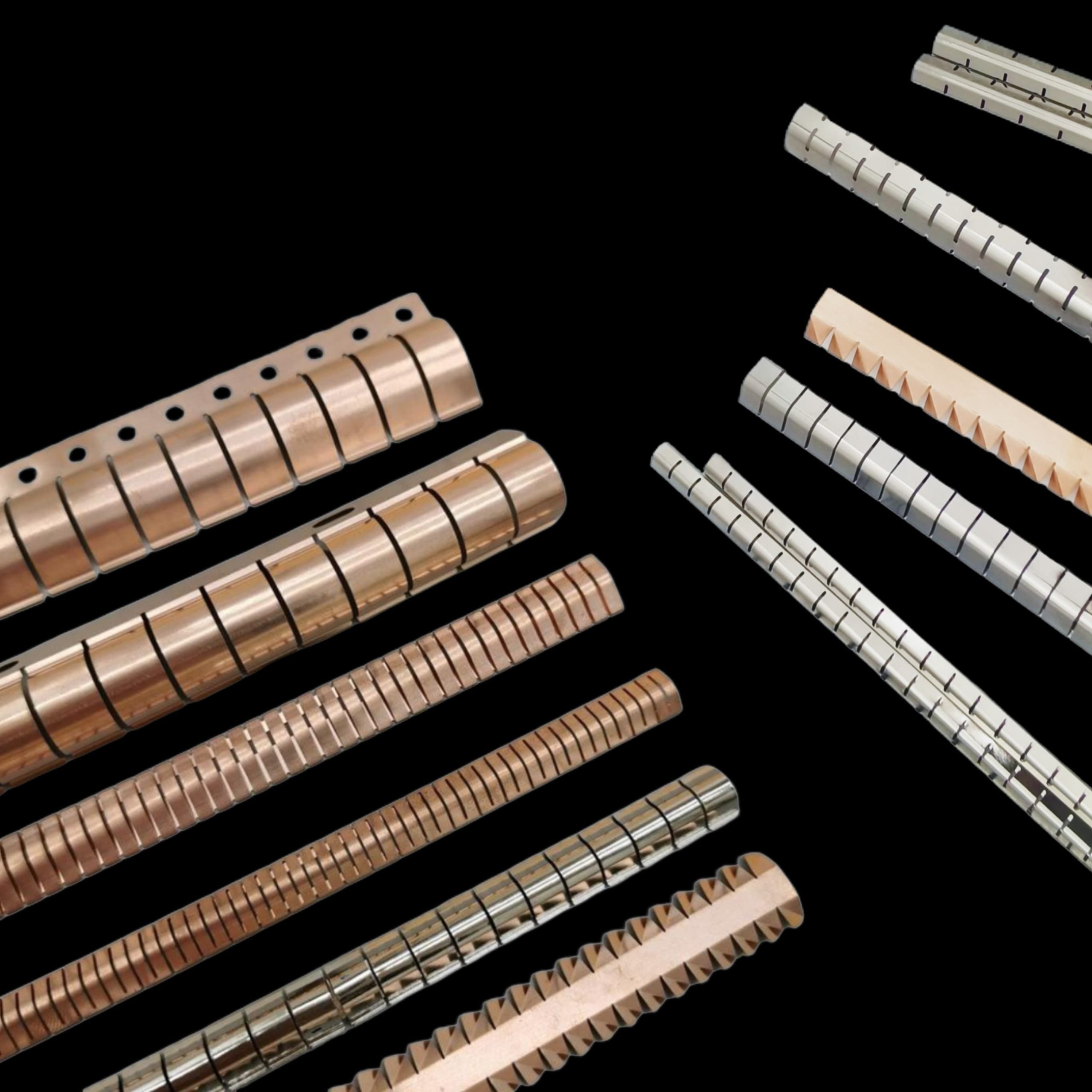

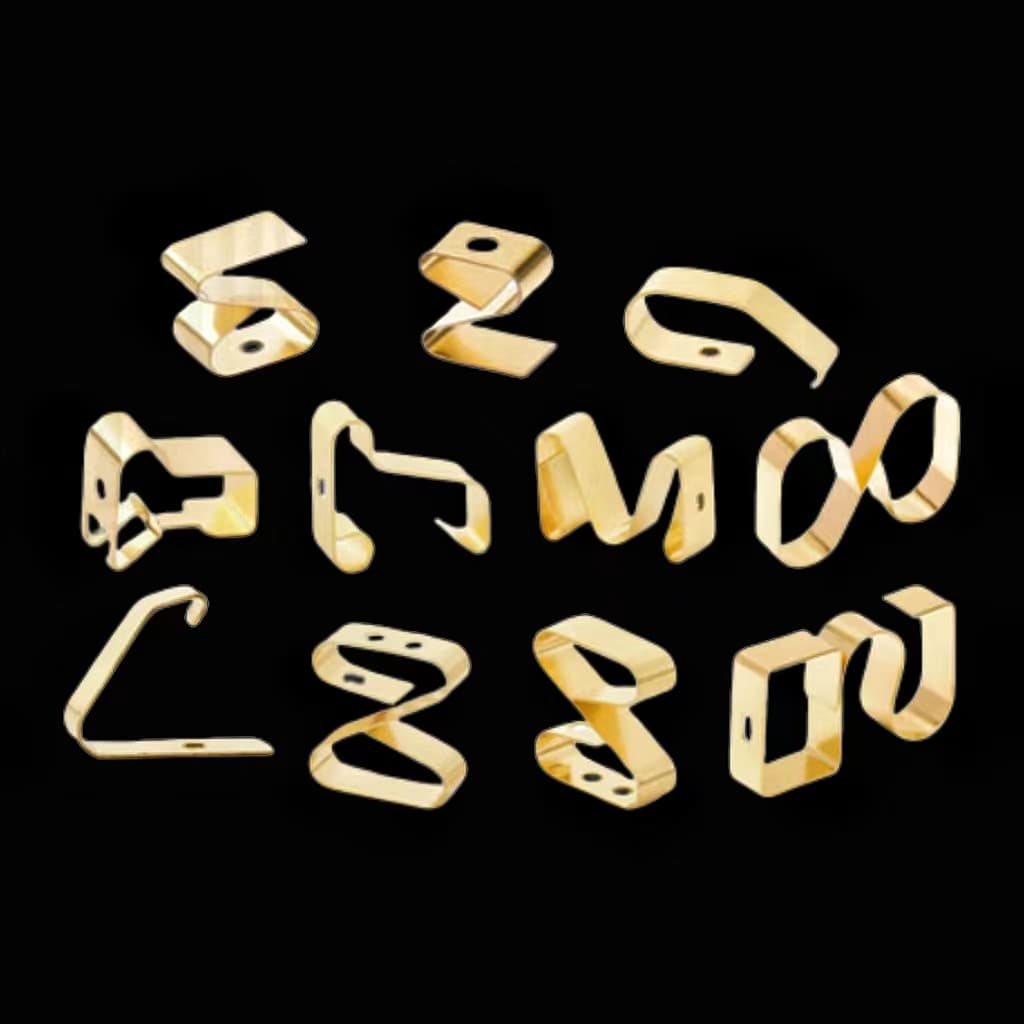

素材とメッキ

半田ツイスト取付シールドフィンガーストリップs それらはまた異なった適用のためのあなたの条件に従ってカスタマイズすることができる。

- ベリリウム銅

- ステンレス

- ベリリウム銅錫メッキ

- リン青銅

- ベリリウム銅ニッケルめっき