Knitted Metal Wire Mesh Gaskets:a highly versatile method of shielding

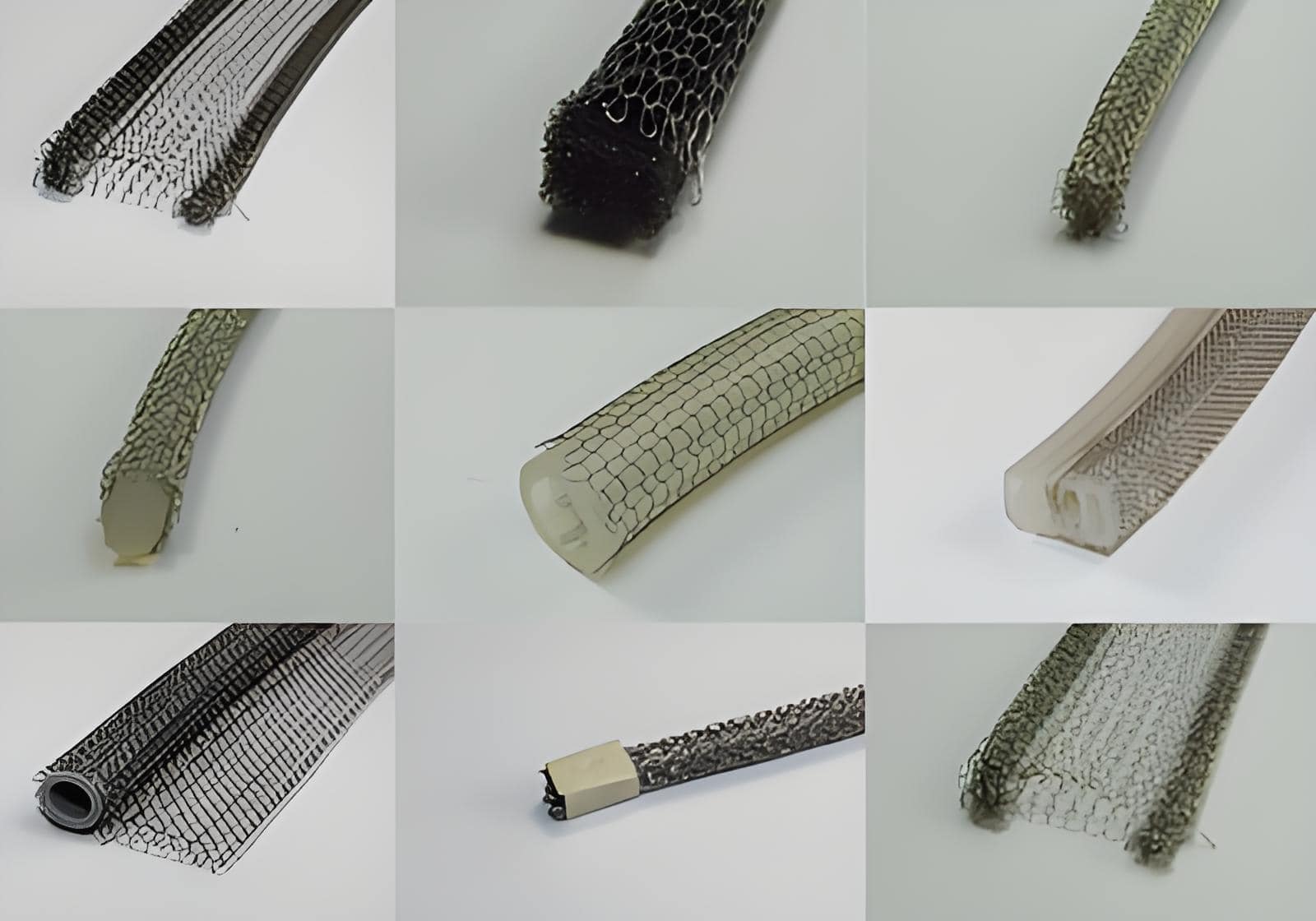

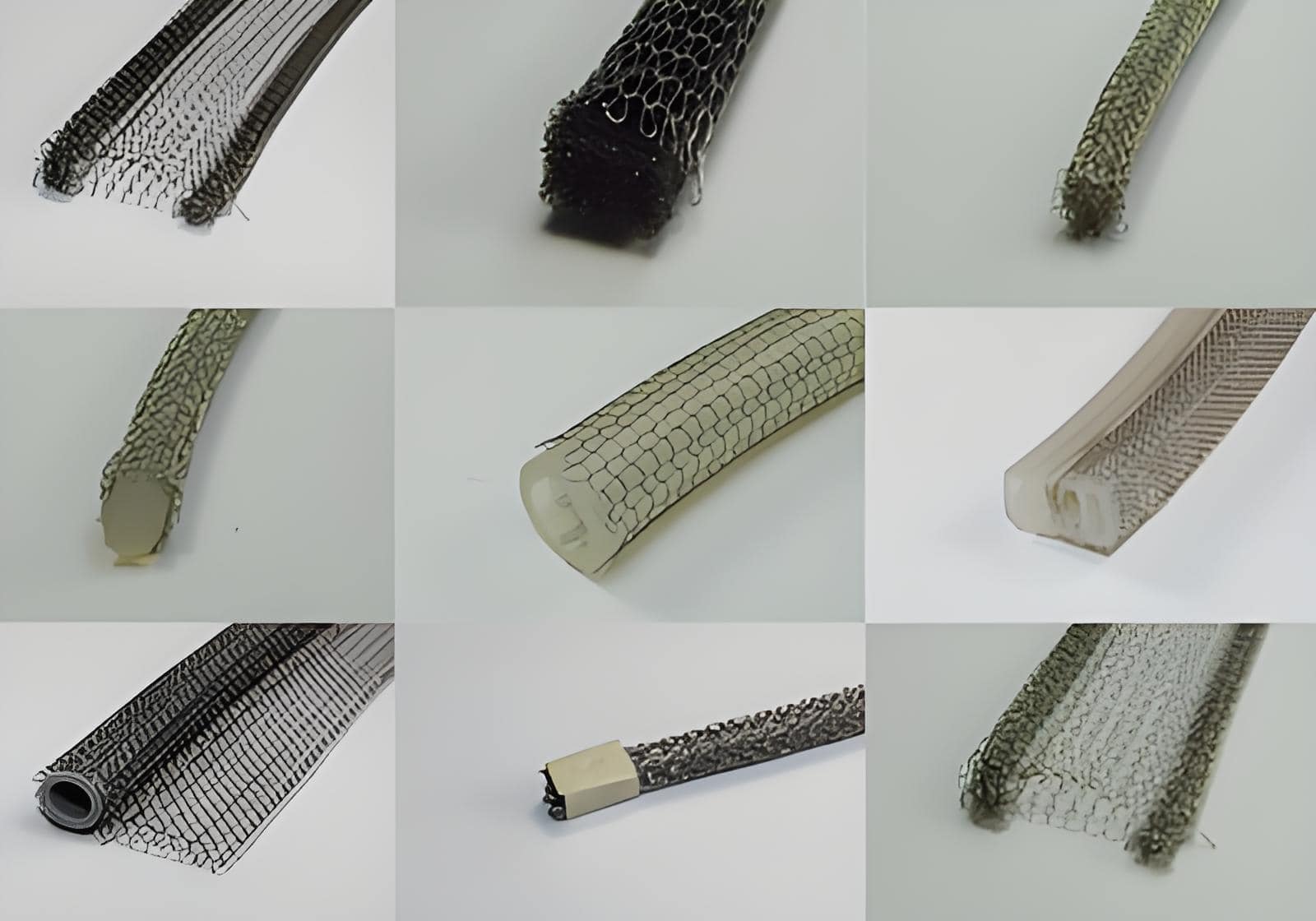

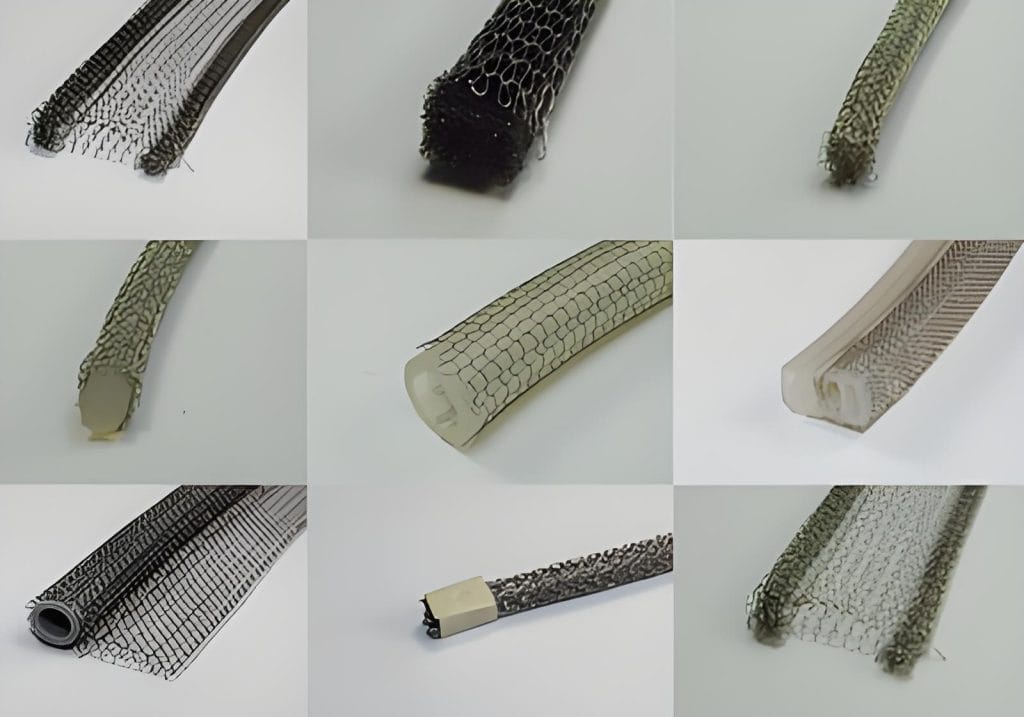

Knitted metal wire mesh gaskets are engineered using fine metal wires, typically stainless steel or other conductive alloys, that are knitted or woven into a mesh structure. This design enables the gaskets to conform closely to mating surfaces, providing a continuous and reliable conductive path for shielding against EMI. The flexibility and resilience of knitted metal wire mesh gaskets make them suitable for sealing gaps and joints in electronic enclosures, effectively blocking electromagnetic radiation across a wide frequency range.

Knitted metal wire mesh gaskets are engineered using fine metal wires, typically stainless steel or other conductive alloys, that are knitted or woven into a mesh structure. This design enables the gaskets to conform closely to mating surfaces, providing a continuous and reliable conductive path for shielding against EMI. The flexibility and resilience of knitted metal wire mesh gaskets make them suitable for sealing gaps and joints in electronic enclosures, effectively blocking electromagnetic radiation across a wide frequency range.

Table of Contents

Key Features and Benefits

- High Shielding Effectiveness: Knitted metal wire mesh gaskets offer high shielding effectiveness due to their dense, conductive mesh structure. They attenuate electromagnetic waves and prevent external interference from disrupting sensitive electronic signals, ensuring optimal device performance.

- Versatility: Available in various shapes, sizes, and configurations, these gaskets can be customized to fit specific application requirements. They are used in diverse industries such as telecommunications, aerospace, automotive, medical devices, and industrial automation.

- Durability and Longevity: Constructed from durable materials such as stainless steel, knitted metal wire mesh gaskets exhibit excellent mechanical strength and corrosion resistance. They withstand environmental factors and maintain shielding integrity over extended periods, reducing maintenance costs and downtime.

- Conductive Resilience: The inherent conductive properties of metal wires used in knitted mesh gaskets ensure reliable electrical continuity and low contact resistance. This contributes to consistent shielding performance and enhances the reliability of electronic systems.

Applications Across Industries

Knitted metal wire mesh gaskets find widespread application across various industries where EMC and EMI shielding are critical:

- Telecommunications: Used in communication equipment, base stations, and antenna systems to ensure clear and uninterrupted signal transmission.

- Aerospace: Essential for shielding avionics, radar systems, and onboard electronics from EMI in aircraft and spacecraft, ensuring safe and reliable operation.

- Medical Devices: Protects medical imaging equipment (MRI, CT scanners), diagnostic devices, and implantable electronics from EMI, preserving accuracy and patient safety.

- Automotive: Shields electronic control units (ECUs), infotainment systems, and sensor networks in vehicles from external electromagnetic interference, enhancing reliability and performance.

In conclusion, knitted metal wire mesh gaskets represent a highly versatile and effective solution for electromagnetic shielding in modern electronic applications. Their ability to provide high shielding effectiveness, durability, and customization options make them indispensable across a wide range of industries. For organizations seeking reliable EMC solutions to protect electronic devices and ensure operational integrity, knitted metal wire mesh gaskets offer a robust and proven method of shielding.

For further information on how knitted metal wire mesh gaskets can benefit your specific application needs, contact our expert team today.