도어 핑거스트립 차폐

제품 사양

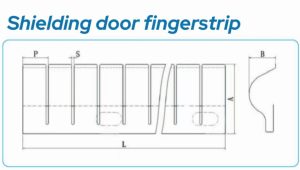

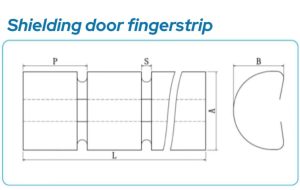

크기 사양

Handa 쉴딩 도어 핑거스트립 치수는 제조업체와 제품 모델에 따라 다릅니다. 이러한 핑거 스트립은 다양한 용도에 맞게 다양한 크기 옵션으로 제공되는 경우가 많습니다. 다음은 몇 가지 가능한 치수 사양이지만 구체적인 사양은 다음 연락처로 확인해야 합니다. 한다 차폐 를 사용하여 특정 애플리케이션의 요구 사항을 충족할 수 있습니다:

| 아니요. | A | B | P | S | T | 길이(mm) |

|---|---|---|---|---|---|---|

| 77-0040 | 26.00 | 10.00 | 9.95 | 1.00 | 0.15 | 407.00 |

| 97-3960 | 17.00 | 4.80 | 10.00 | 0.60 | 0.10 | 199.50 |

| 97-0040 | 19.00 | 4.80 | 10.00 | 0.60 | 0.10 | 199.50 |

| 97-0035 | 29.00 | 10.00 | 10.00 | 1.01 | 0.15 | 407.00 |

| 97-5350 | 28.50 | 6.60 | 9.50 | 1.00 | 0.13 | 406.00 |

| 아니요. | A | B | P | S | T | 길이(mm) |

|---|---|---|---|---|---|---|

| 97-4560 | 4.00 | 2.40 | 3.40 | 0.45 | 0.08 | 98.20 |

| 97-4760 | 4.00 | 2.40 | 3.40 | 0.45 | 0.05 | 301.50 |

| 97-0050 | 6.30 | 1.70 | 13.70 | 1.10 | 0.08 | 413.00 |

| 7-0120 | 1.92 | 1.00 | 3.00 | 0.50 | 0.05 | 235.00 |

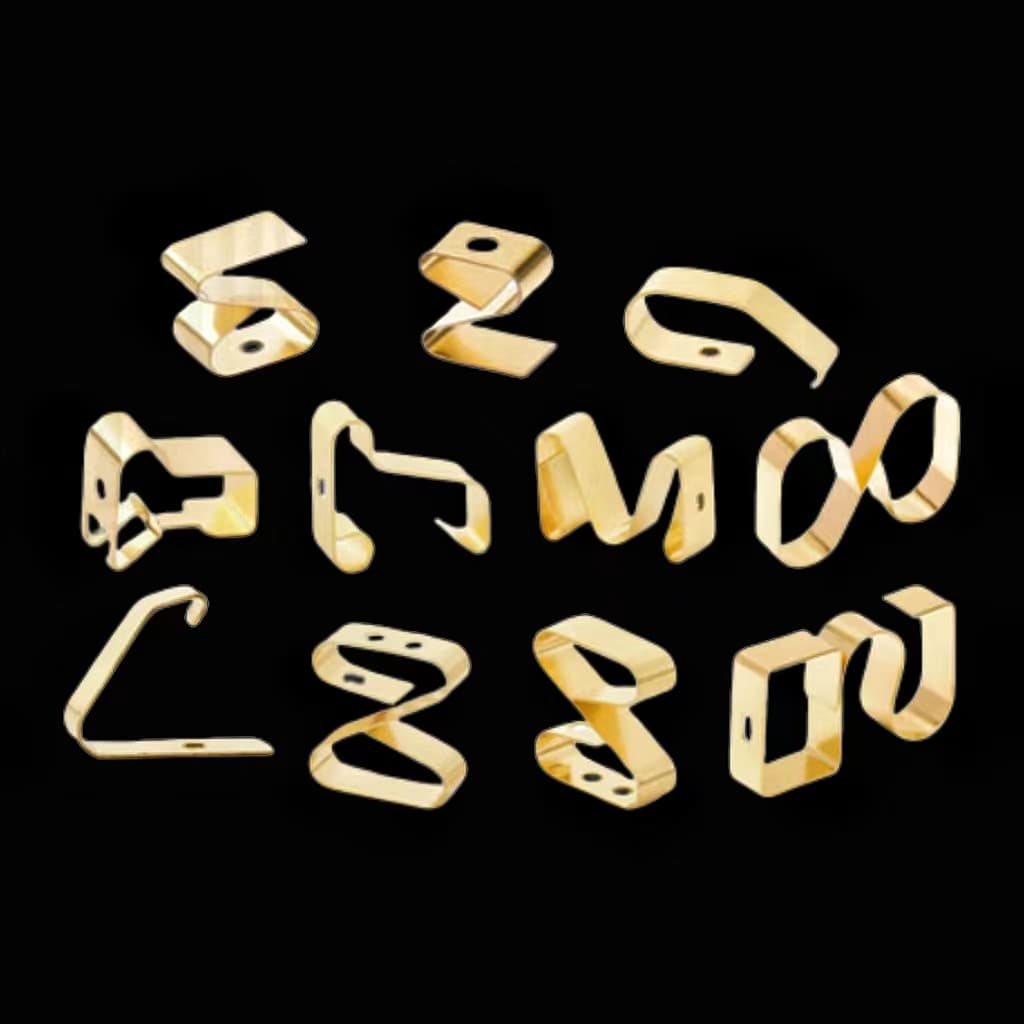

차폐 도어 핑거스트립 제조

제조하려면 도어 핑거스트립 차폐 에는 종종 다음 단계가 포함됩니다:

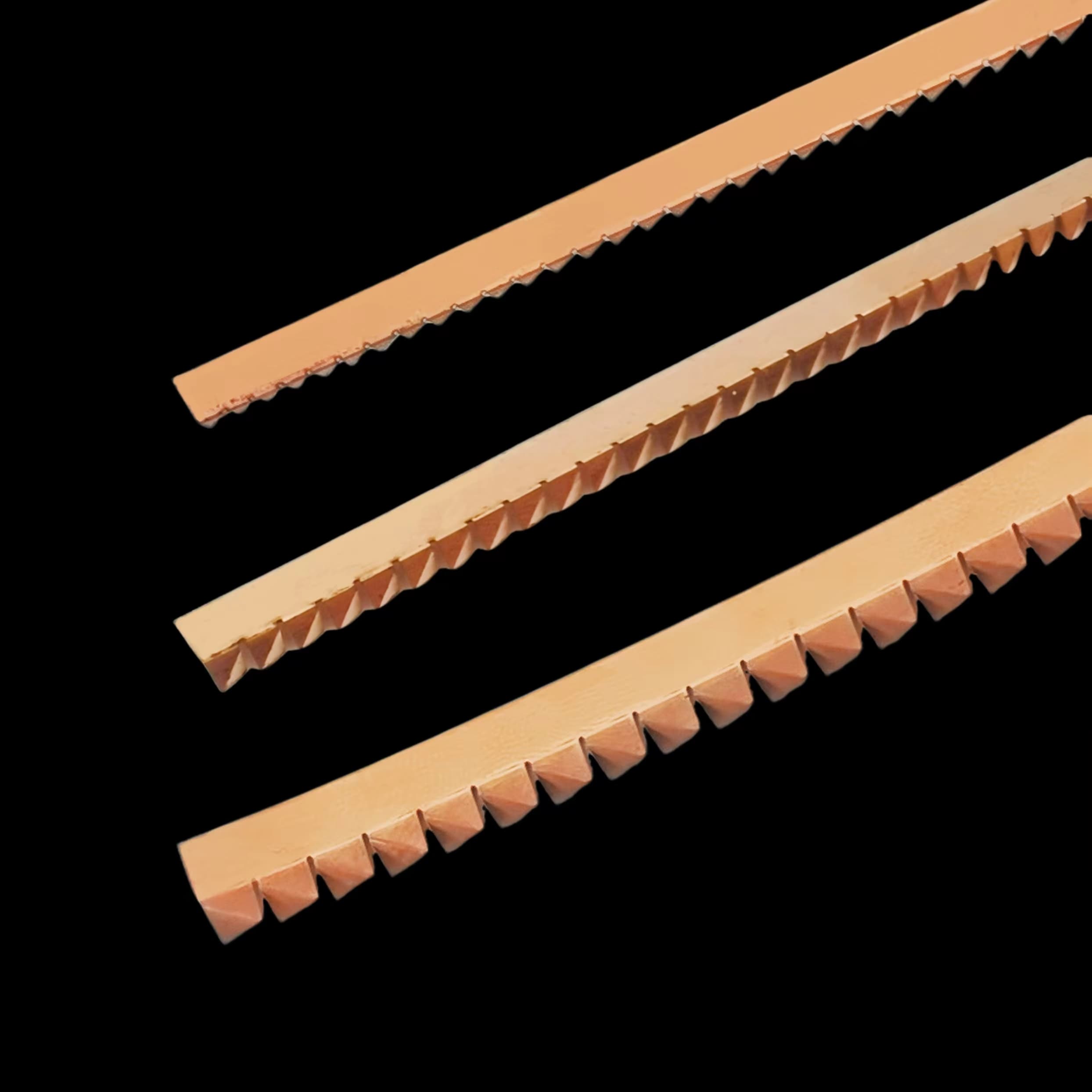

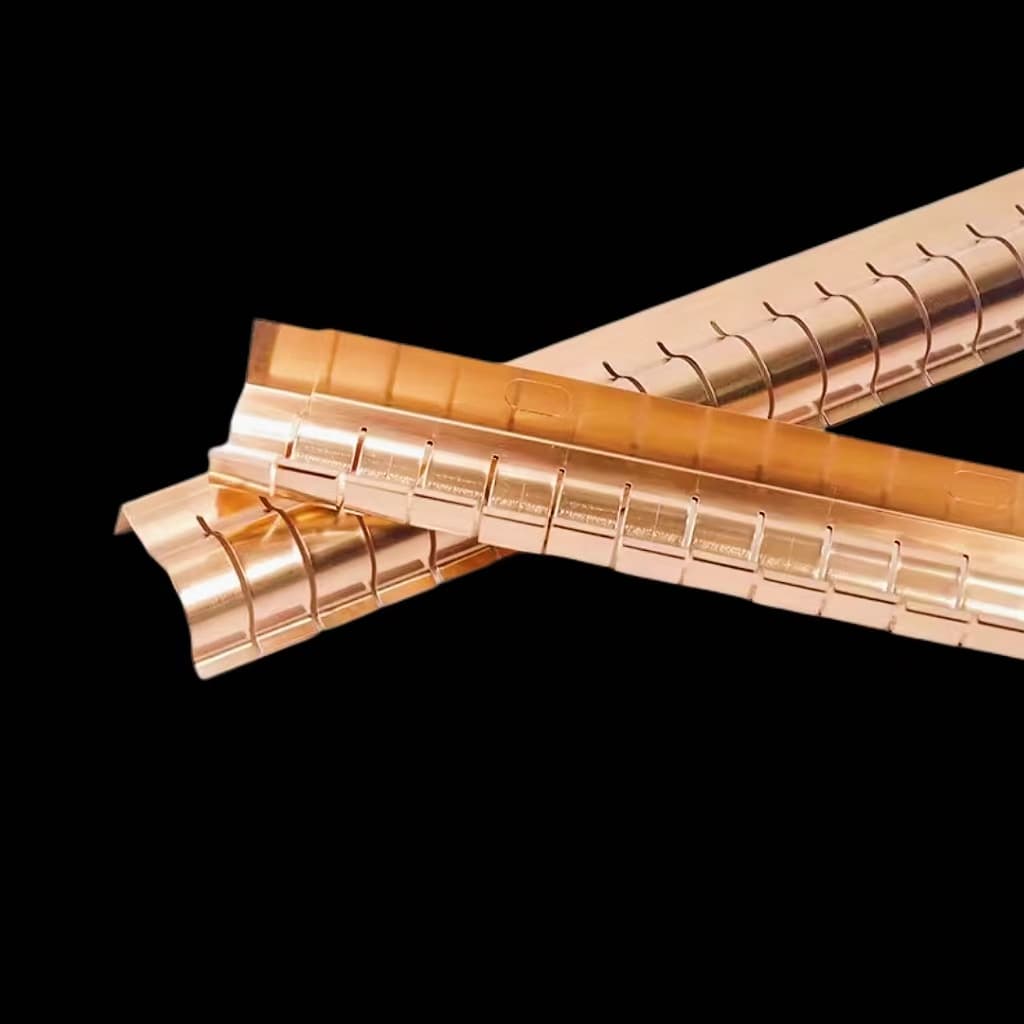

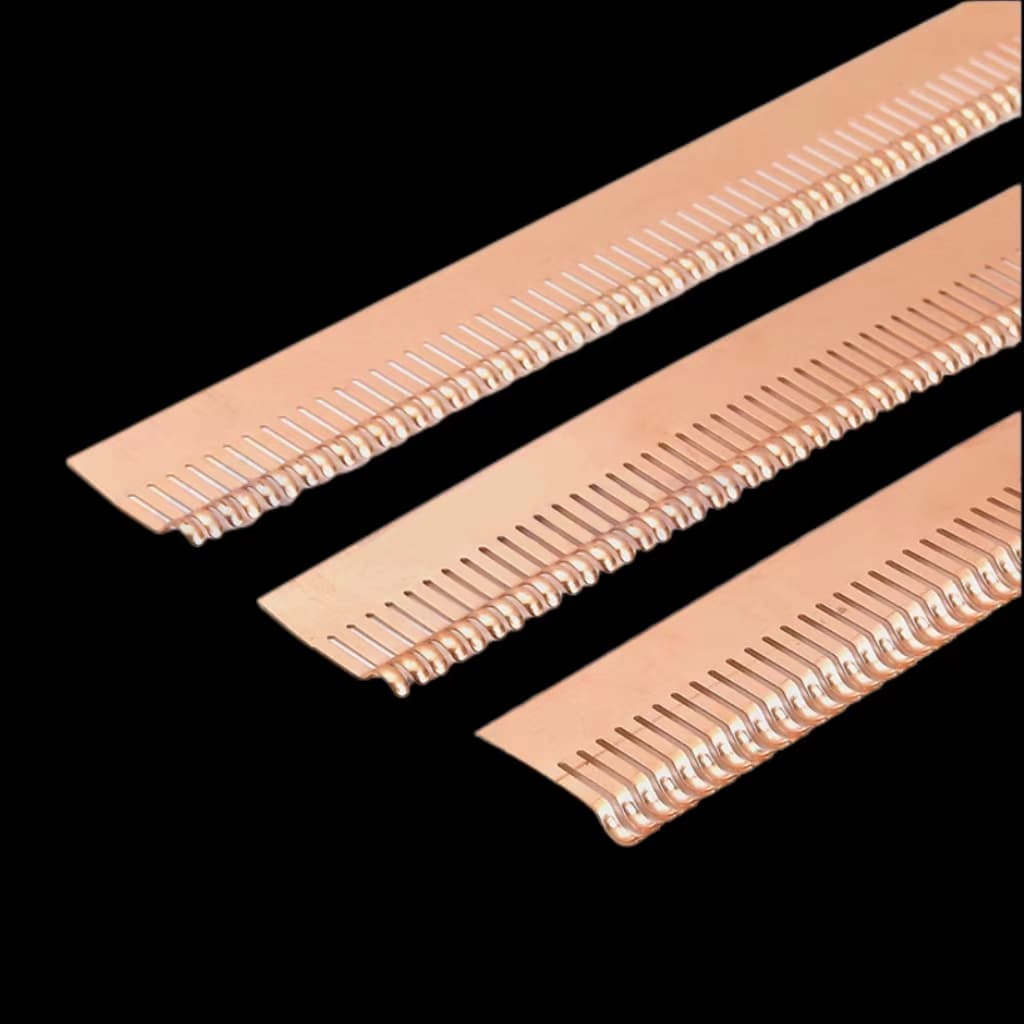

1. 재료 선택:한다 차폐 는 일반적으로 높은 전기 전도성, 내식성 및 피로 강도 때문에 베릴륨 구리(BeCu)를 주요 소재로 선택합니다.

2. 펀칭 또는 에칭:얇은 BeCu 스트립을 원하는 모양으로 펀칭하거나 에칭하여 제조 공정을 시작합니다.

3. 누르기 및 성형하기:모양을 만든 후 스트립을 눌러서 최종 구성으로 만듭니다.

4. 열처리: 성형된 조각에 열처리를 적용하여 '메모리'를 부여하고 기계적 특성을 향상시킵니다.

5. 도금 및 마감:Handa 쉴딩은 특정 애플리케이션 요구 사항에 따라 니켈, 주석, 아연 등 다양한 도금 마감을 제공합니다.

6. 품질 보증:여기에는 전기 전도도, 기계적 강도 및 내식성 테스트가 포함됩니다.

7. 사용자 지정:다양한 애플리케이션의 특정 요구에 맞게 치수, 모양 및 기타 매개변수를 지정하는 등 사용자 지정 옵션을 제공합니다.

8. 포장 및 유통: 완성된 차폐 도어 핑거스트립을 안전하게 포장하여 보관 및 배송 중 손상을 방지합니다.

혜택

Handa 쉴딩 도어 핑거스트립 는 많은 사람들이 찾는 솔루션이 될 수 있는 무수히 많은 장점을 가지고 있습니다. 여기에는 다음이 포함됩니다:

- 고효율 차폐

- 강력한 내구성

- 간편한 설치

- 사양 다양성

- 높은 유연성

- 긴 서비스 수명

- 사용자 친화적인 디자인

애플리케이션

Handa 쉴딩 도어 핑거스트립 는 다양한 산업 분야에서 전자 기기의 무결성과 성능을 유지하는 데 필수적입니다:

- 통신 캐비닛

- 의료 장비:

- 군사 및 항공우주: 보안 시설 및 장비

- 데이터 센터: 차폐 랙 및 캐비닛

- 소비자 가전

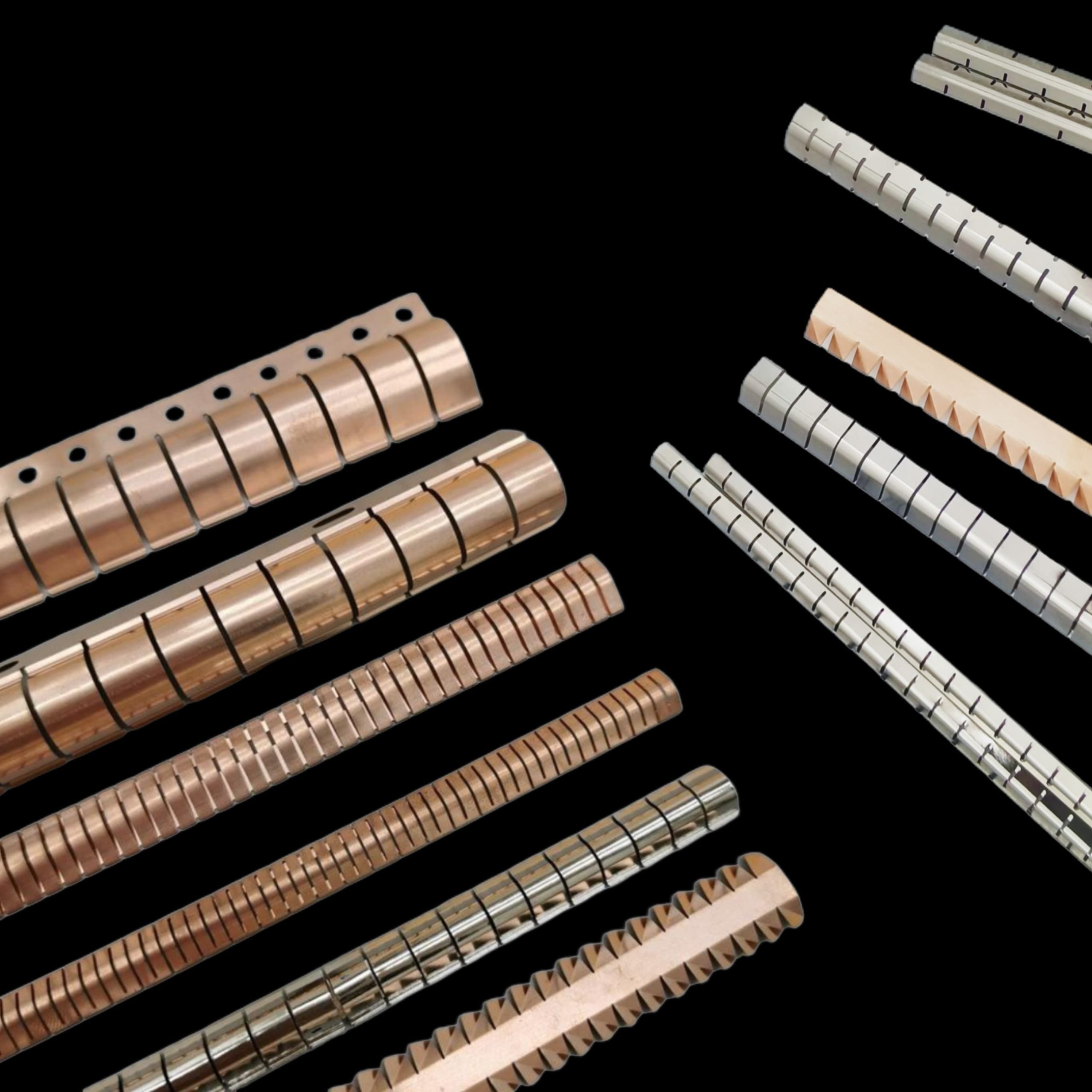

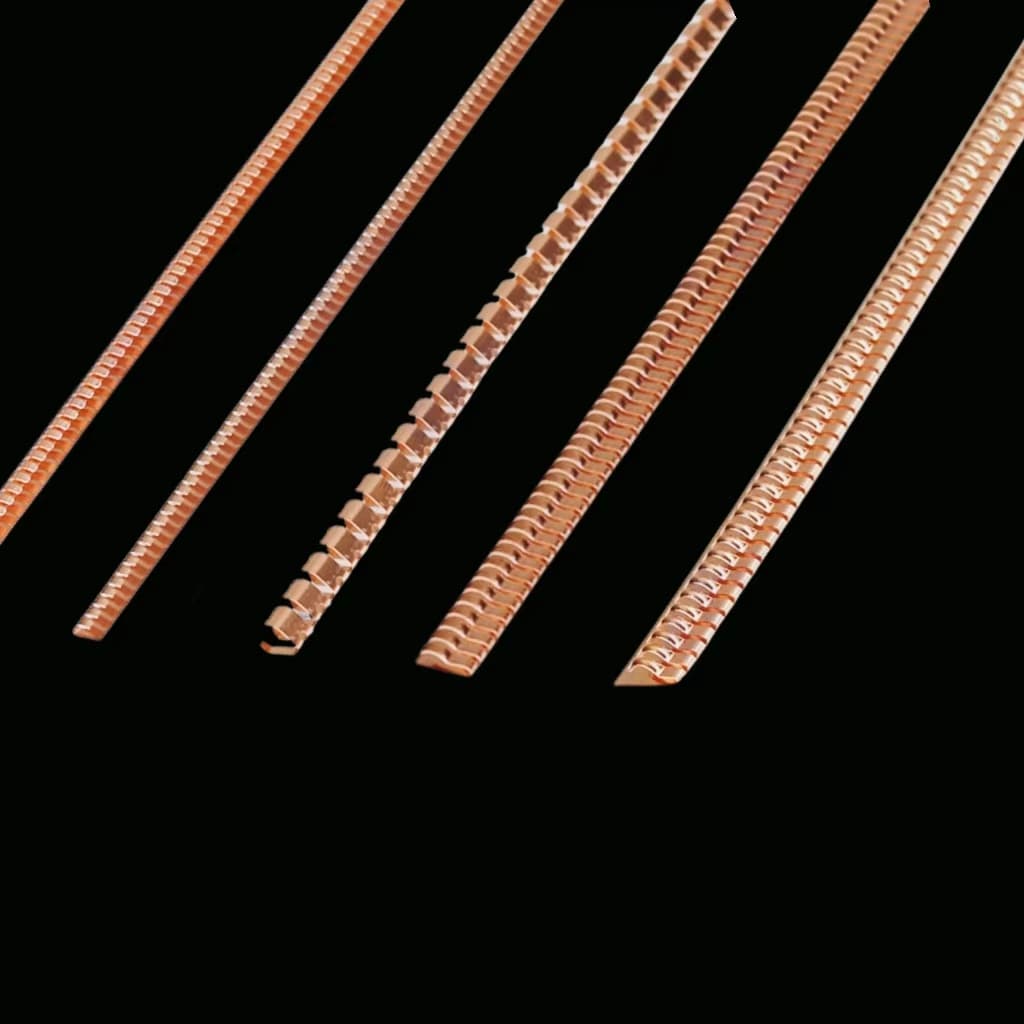

소재 및 도금

Handa 쉴딩 도어 핑거스트립 다음 자료에서 사용할 수 있으며, 다양한 애플리케이션에 대한 요구 사항에 따라 사용자 지정할 수도 있습니다.

- 베릴륨-구리

- 스테인리스 스틸

- 베릴륨-구리 주석 도금

- 인청동

- 베릴륨-구리 니켈 도금

대량 주문이 필요하신가요?

특정 애플리케이션에 맞는 구성 요소를 설계 및 제조할 수 있습니다. 설계하고 제조할 수 있습니다. 수량이 1,000개를 초과하는 경우 견적을 요청하세요.

견적 요청하기