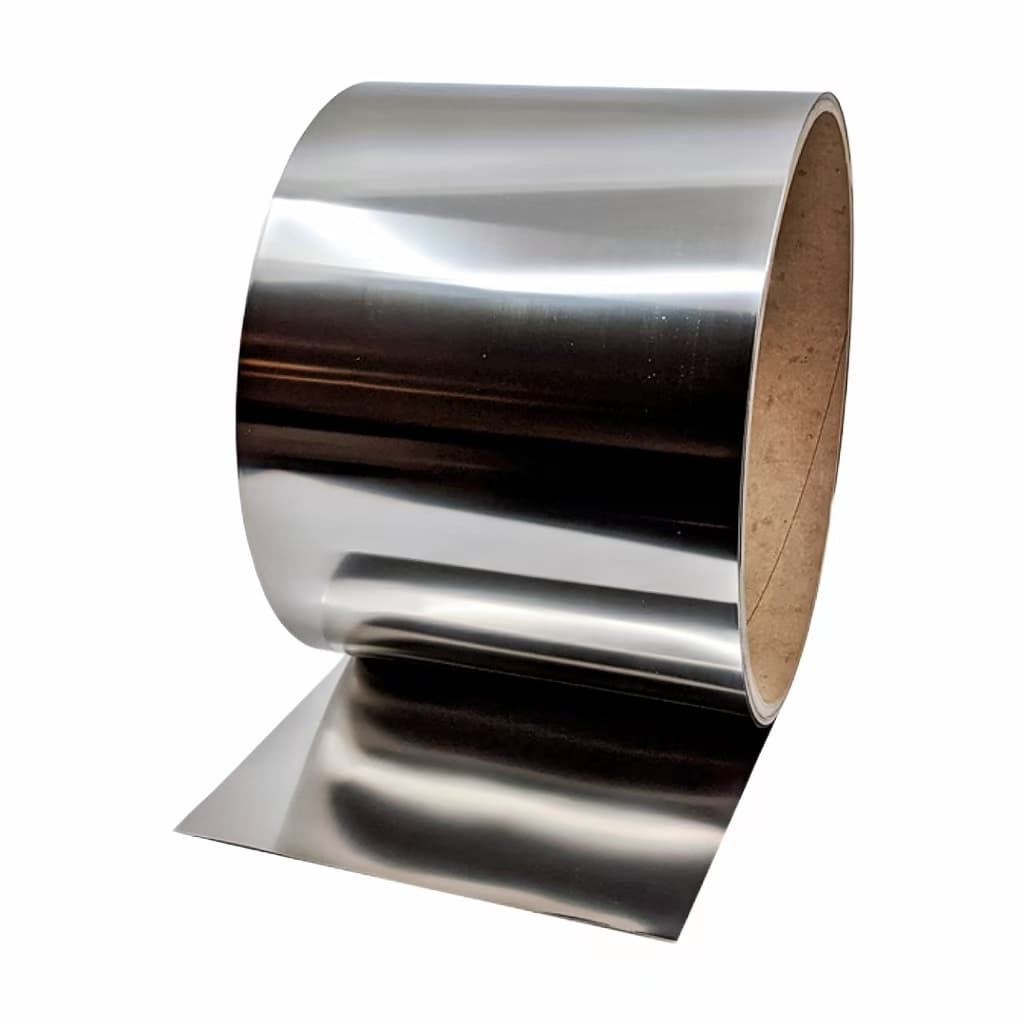

Mu-Ferro Foil for Electromagnetic Interference (EMI) Shielding

Mu-Ferro foil is a versatile material that offers excellent magnetic and electromagnetic shielding properties. With its high magnetic permeability, flexibility, and cost-effectiveness, it is widely used in applications such as EMI shielding, magnetic field shielding, transformer and inductor design, and aerospace and defense systems.

Table of Contents

Mu-Ferro Foil for

Electromagnetic Interference (EMI) Shielding

Mu-Ferro/Mu-metal foil is a specialized material widely used for electromagnetic interference (EMI) shielding and magnetic shielding applications. It is made primarily from a combination of iron (Fe) and nickel (Ni), offering exceptional magnetic properties, particularly high magnetic permeability. The unique characteristics of Mu-Ferro foil make it a key material for industries that require effective protection against electromagnetic radiation and magnetic fields, including electronics, telecommunications, aerospace, medical devices, and military applications.

1. What is Mu-Ferro Foil?

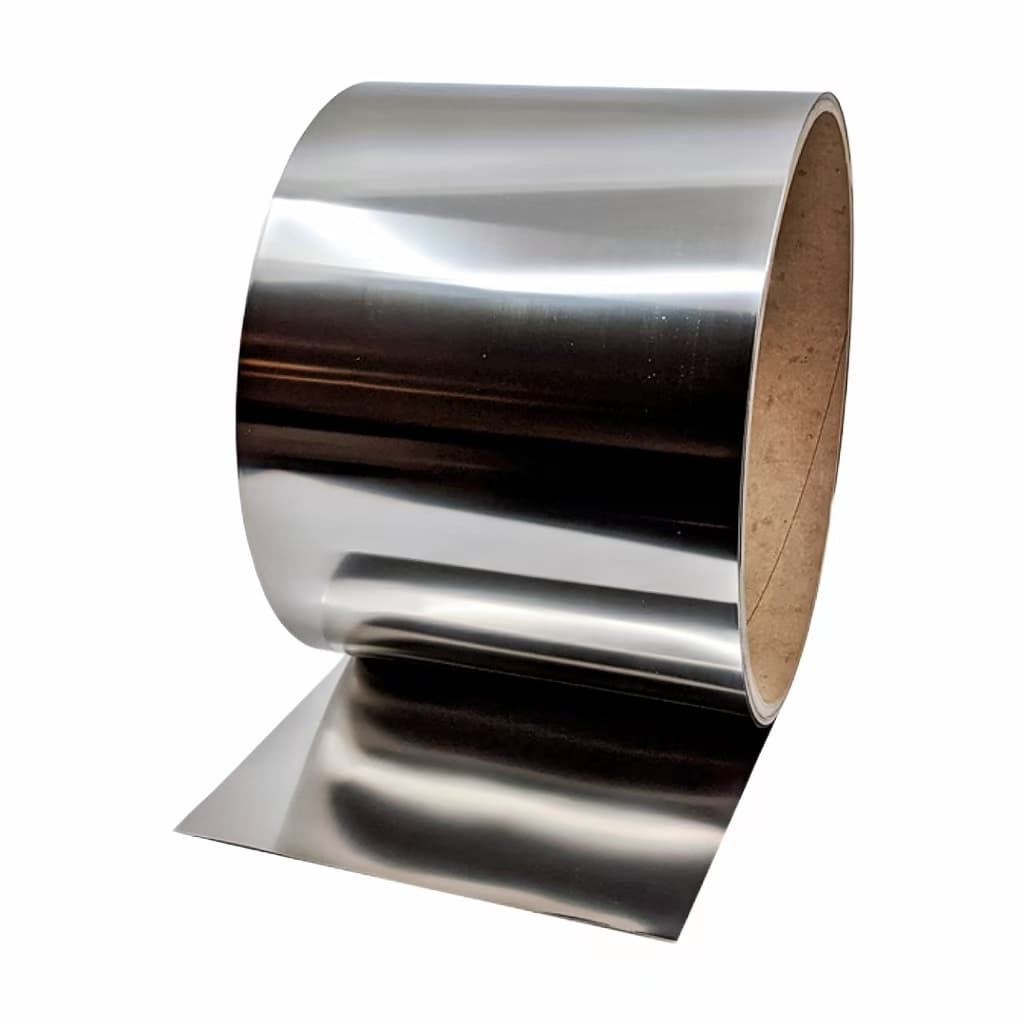

Mu-Ferro/Mu-metal foil is a flexible, thin material that is primarily composed of iron and nickel alloys. Its key characteristic is its high magnetic permeability (denoted by the Greek letter “μ”), which enables it to effectively concentrate and guide magnetic fields. This makes Mu-Ferro foil an excellent material for both electromagnetic interference (EMI) shielding and magnetic field containment.

The material is commonly used in foil or thin sheet form, which allows for easy integration into various electronic devices and systems. Mu-Ferro/Mu-metal foil is highly effective in applications requiring low-frequency shielding, where magnetic fields need to be absorbed and redirected. The foil can also be used to shield against high-frequency electromagnetic interference, making it a versatile material for a wide range of applications.

2. Composition of Mu-Ferro Foil

Mu-Ferro foil is composed of a combination of iron and nickel. These metals are chosen for their excellent magnetic properties. The specific composition of Mu-Ferro foil can vary based on the intended application, but the typical material includes the following components:

- Iron (Fe): Iron is the primary element in Mu-Ferro/Mu-metal foil. It has a high magnetic permeability and is readily available, making it an excellent base material for magnetic shielding. Iron’s high magnetic permeability allows it to concentrate magnetic fields and provide efficient shielding.

- Nickel (Ni): Nickel is added to the composition to improve the material’s corrosion resistance, durability, and strength. Nickel also contributes to the material’s ability to handle high temperatures, making it suitable for use in demanding environments. The combination of iron and nickel creates a strong, durable material with excellent magnetic shielding properties.

- Other Alloying Elements: Depending on the specific needs of the application, other elements may be added to enhance specific properties such as thermal stability, flexibility, or corrosion resistance. For example, manganese or molybdenum may be added to improve the material’s resistance to high temperatures or wear.

The percentage of iron and nickel in Mu-Ferro foil can be adjusted to optimize the material for particular use cases. A higher percentage of nickel typically results in better corrosion resistance and higher temperature stability, while a higher percentage of iron may provide improved magnetic permeability.

3. Magnetic Properties of Mu-Ferro Foil

The primary advantage of Mu-Ferro foil lies in its magnetic properties, specifically its high magnetic permeability. Magnetic permeability is a measure of a material’s ability to conduct magnetic lines of force. Materials with high magnetic permeability, like Mu-Ferro/Mu-metal foil, can attract and guide magnetic fields more effectively than materials with lower permeability.

Mu-Ferro foil is particularly effective in the following ways:

- Shielding Magnetic Fields: Mu-Ferro foil is designed to absorb and redirect magnetic fields, making it ideal for shielding sensitive electronic components or preventing interference in magnetic systems. The material can effectively block or attenuate external magnetic fields, ensuring that devices operating within the shielded area remain unaffected.

- Concentrating Magnetic Fields: In some applications, Mu-Ferro/Mu-metal foil is used to concentrate or focus magnetic fields to achieve desired results. This makes it a critical material in components such as transformers, inductors, and other electromagnetic devices where magnetic fields need to be efficiently managed.

- High Permeability: The high permeability of this foil allows it to absorb and redirect low-frequency magnetic fields, which is particularly important in applications that involve power electronics, motors, and magnetic sensors.

The material’s ability to handle high-frequency electromagnetic interference (EMI) is also significant, although it is more effective at shielding low-frequency magnetic fields. For high-frequency EMI shielding, additional layers or complementary materials may be used in combination with Mu-Ferro foil.

4. Applications of Mu-Ferro Foil

Mu-Ferro foil is used in a wide variety of applications across several industries. Its combination of high magnetic permeability and flexibility makes it suitable for many different shielding and containment tasks. Below are some of the most common applications of Mu-Ferro foil:

4.1 Electromagnetic Interference (EMI) Shielding

One of the primary uses of Mu-Ferro/Mu-metal foil is in EMI shielding. EMI can interfere with the performance of sensitive electronic equipment, causing malfunctions or degradation in functionality. The foil’s ability to absorb and reroute electromagnetic radiation makes it an effective material for protecting devices from unwanted electromagnetic interference.

- Consumer Electronics: In devices such as smartphones, laptops, televisions, and audio equipment, Mu-Ferro/Mu-metal foil is used to shield against EMI from external sources. This ensures that the devices operate smoothly without interference that could affect performance or signal clarity.

- Telecommunications: This foil is used in the telecommunications industry to shield cables, connectors, and other components from EMI, allowing for uninterrupted signal transmission in high-speed data networks.

- Military and Aerospace: Military and aerospace applications require high levels of shielding to protect sensitive equipment from the harmful effects of electromagnetic radiation. Mu-Ferro foil is used in aircraft, satellite systems, and military communications systems to ensure that electronic components are shielded from external EMI.

4.2 Magnetic Field Shielding

Mu-Ferro foil is also widely used in magnetic field shielding applications. It is particularly effective in shielding sensitive equipment from external magnetic fields that could interfere with operation.

- Medical Equipment: In medical devices such as MRI machines, Mu-Ferro foil is used to shield sensitive components from external magnetic fields. It ensures that the device’s magnetic field remains focused and controlled, preventing interference from external sources.

- Power Electronics: In high-voltage transformers, power supplies, and inductors, Mu-Ferro foil is used to shield components from stray magnetic fields. This helps to maintain efficiency and prevent interference in power conversion.

- Sensors and Actuators: In applications involving magnetic sensors or actuators, Mu-Ferro foil can be used to shield the sensor from external magnetic fields, ensuring accurate readings and proper functioning.

4.3 Transformer and Inductor Design

Mu-Ferro foil is commonly used in the design of transformers and inductors due to its high magnetic permeability. These components rely on magnetic fields to function, and Mu-Ferro/Mu-metal foil helps to ensure that the magnetic fields are contained and efficiently guided.

- Power Generation: Mu-Ferro foil is used in the construction of transformers for power generation and distribution. Its high permeability allows for better magnetic field containment, which leads to more efficient power transfer.

- Telecommunication Transformers: In telecommunication systems, transformers are used to step up or step down voltages, and Mu-Ferro foil helps ensure the magnetic field is contained, reducing losses and improving system performance.

4.4 Aerospace and Defense Applications

Mu-Ferro/Mu-metal foil is widely used in the aerospace and defense industries to shield against magnetic fields and electromagnetic interference. Its ability to absorb and redirect magnetic fields is particularly useful in sensitive equipment used in spacecraft, satellites, and military electronics.

- Satellite Systems: In satellites, this foil is used to shield sensitive electronics from external magnetic fields and EMI. This ensures that communication systems, sensors, and other critical components function properly in space.

- Military Equipment: In military electronics, the foil is used to protect sensitive systems from electromagnetic threats, such as electromagnetic pulses (EMP). This helps ensure the continued operation of mission-critical equipment in hostile environments.

5. Advantages of Mu-Ferro Foil

Mu-Ferro/Mu-metal foil offers several advantages that make it a preferred material for various shielding applications:

- High Magnetic Permeability: The primary advantage of Mu-Ferro foil is its ability to absorb and concentrate magnetic fields, making it ideal for magnetic shielding and EMI protection.

- Flexibility: Mu-Ferro foil is available in thin sheets or foils, which allows it to be easily integrated into various devices and systems. Its flexibility makes it suitable for a wide range of applications where traditional rigid shielding materials may not be suitable.

- Cost-Effective: Compared to other materials such as copper or specialized alloys, Mu-Ferro foil is relatively cost-effective. This makes it an attractive choice for large-scale production in industries that require magnetic and EMI shielding.

- Durability: Mu-Ferro foil is highly durable, offering long-term protection against magnetic fields and EMI. It can withstand high temperatures and harsh environmental conditions without degrading.

6. Challenges and Considerations

While Mu-Ferro foil offers many benefits, there are also some challenges and considerations when using it in specific applications:

- Limited High-Frequency Shielding: While Mu-Ferro foil is highly effective at shielding low-frequency magnetic fields, it is less effective at shielding high-frequency EMI. In some cases, additional shielding materials may be required for high-frequency applications.

- Corrosion Resistance: While the nickel content in Mu-Ferro foil provides some corrosion resistance, the material may still be prone to oxidation under certain environmental conditions. In such cases, additional protective coatings or treatments may be needed.

- Thickness and Flexibility: While Mu-Ferro foil is available in thin sheets, its thickness and flexibility may limit its use in some applications. In situations where greater rigidity or higher shielding performance is needed, other materials may be preferred.

7. Conclusion

Mu-Ferro foil is a versatile material that offers excellent magnetic and electromagnetic shielding properties. With its high magnetic permeability, flexibility, and cost-effectiveness, it is widely used in applications such as EMI shielding, magnetic field shielding, transformer and inductor design, and aerospace and defense systems. While it has some limitations in terms of high-frequency shielding and corrosion resistance, its overall performance and durability make it an indispensable material in industries that require effective protection against electromagnetic interference and magnetic fields. As technology advances and the need for reliable shielding increases, Mu-Ferro foil will continue to play an important role in safeguarding sensitive electronic and magnetic systems across various industries.

You May Also Like

-

Spring finger contacts in PCB and SMD applications

Spring finger contacts in PCB and SMD applicationsFingerstrips

PCB/SMD spring finger contacts

Spring finger contacts 1. Basic Concepts2. Application Scenarios2.1 Consumer Electronics 1. Basic Concepts Spring finger contacts, also called "spring fingers" ,serve as connectors between PCBs and SMDs (Surface Mount Devices). They are typically employed where frequent insertion and removal or high reliability in connections are essential. Designed to offer low resistance and high-reliability connections, spring fingers also withstand a certain degree of mechanical stress, which adds to their durability in varying applications. 2. Application Scenarios Spring finger contacts are valuable in numerous industries, given their ability to provide stable, dependable connections. Below are some common scenarios: 2.1 Consumer Electronics In devices like smartphones, tablets, and laptops, spring finger contacts connect various small modules, such as SIM card trays, battery connectors, and antenna connectors. These components support the compact designs of consumer electronics by minimizing the need for complex wiring. 2.2 Industrial Equipment In industrial control and automation equipment, spring fingers are used to connect sensors, actuators, and other modules, maintaining stable connections even in harsh environments where mechanical stress or vibration might otherwise compromise the connection. 2.3 Medical Devices Reliable electrical connections are vital in medical devices for both safety and performance. Spring finger contacts are favored for their low......

-

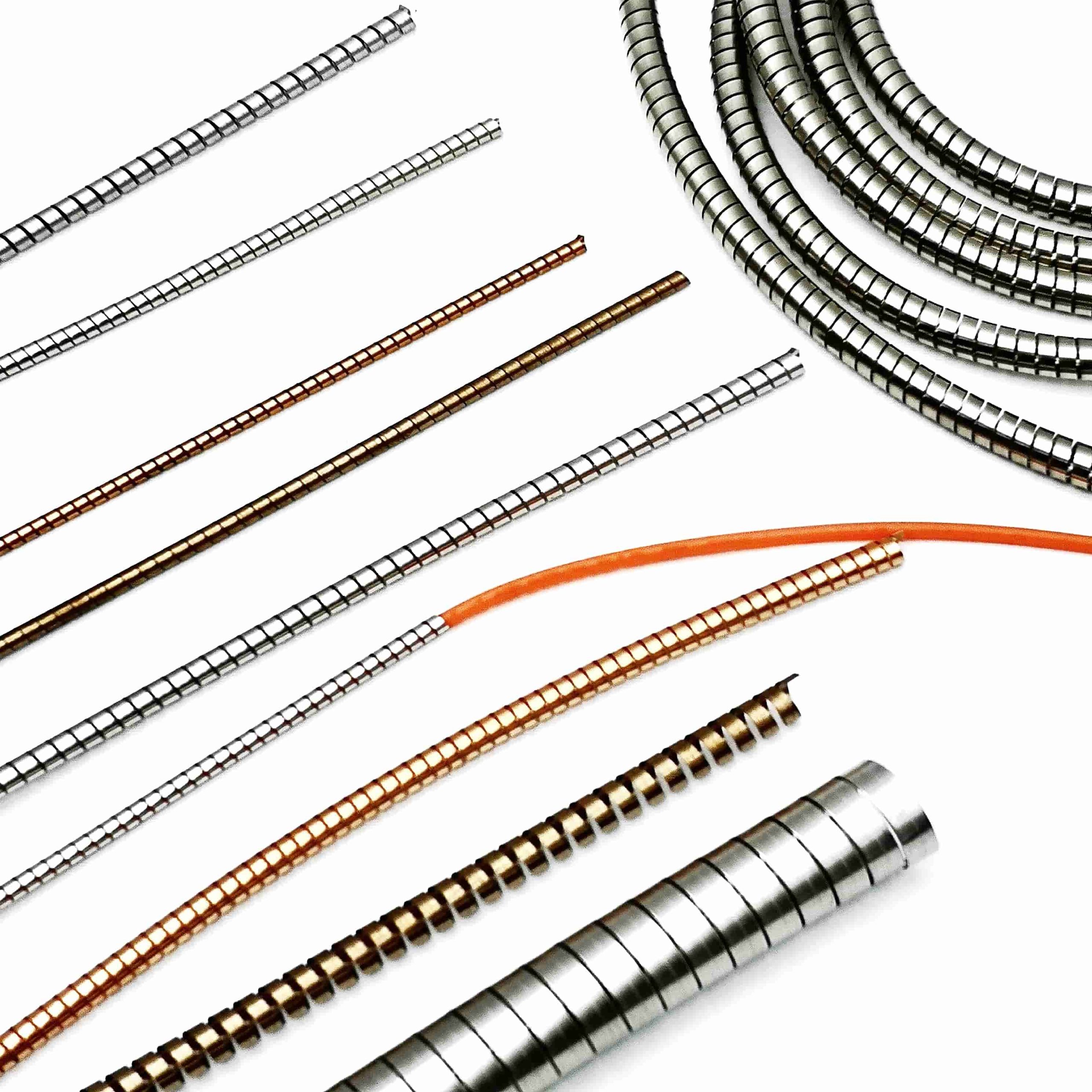

Handa spiral tubes with remarkable performance in EMI shielding applications

Handa spiral tubes with remarkable performance in EMI shielding applicationsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Handa spiral tubes https://www.handashielding.com/request-a-quote.html Material Properties of Handa Spiral TubesEMI Shielding Performance in Various FrequenciesPerformance in Humid and Corrosive EnvironmentsApplications Across IndustriesInstallation and Maintenance ConsiderationsConclusion and Future Outlook Handa spiral tubes are known for their remarkable performance in EMI shielding applications, particularly in humid or otherwise challenging environments. This functionality is largely due to the unique characteristics of their material composition and surface treatments. These tubes have become invaluable across industries, including telecommunications, aerospace, military, medical, and precision instrumentation, where reliable EMI shielding is crucial. Here is an expanded look at the comprehensive advantages, applications, and technological features of Handa spiral tubes, focusing on their functionality in humid conditions and their material properties. Material Properties of Handa Spiral Tubes The effectiveness of Handa spiral tubes in EMI shielding applications is largely a result of the materials used in their construction. The primary materials are: Beryllium Copper (BeCu): High Conductivity: Beryllium copper is widely recognized for its high electrical conductivity, which enables efficient electromagnetic wave transmission. This quality makes BeCu an excellent material for EMI shielding, allowing it to absorb and reflect interfering signals. Elasticity and Mechanical Resilience: Beryllium copper has exceptional elasticity, which allows the tubes to compress and return......

-

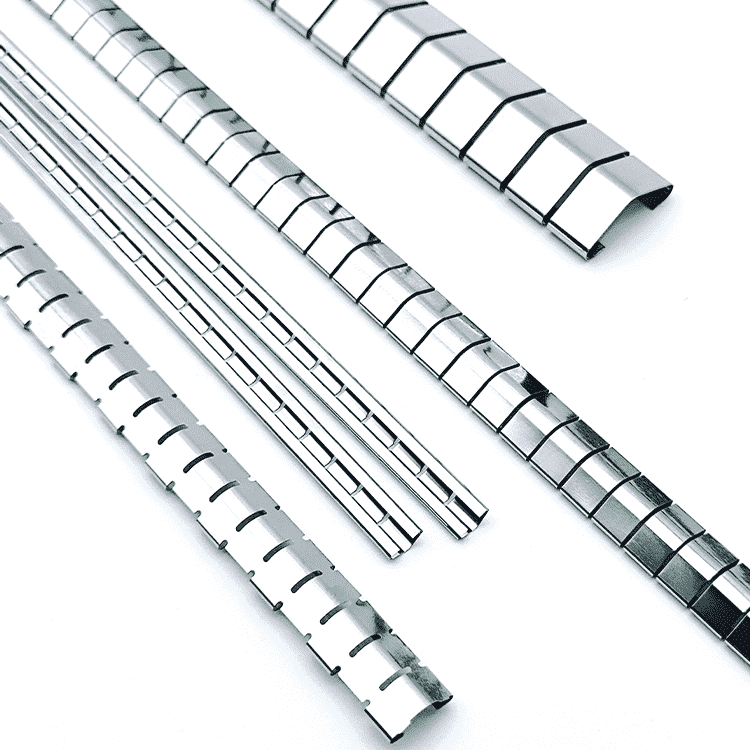

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding

Spiral Shielding Gaskets providing electromagnetic interference (EMI) shieldingEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

Spiral shielding gaskets are essential components in various industrial applications, providing electromagnetic interference (EMI) shielding while ensuring reliable sealing. Their effectiveness, however, can be compromised in corrosive environments, making it crucial to enhance their corrosion resistance. This article explores the multifaceted strategies employed to improve the corrosion resistance of spiral shielding gaskets, covering material selection, surface treatment, design optimization, environmental testing, the use of composite materials, and maintenance practices. By understanding these strategies, manufacturers can ensure the durability and reliability of spiral shielding gaskets in demanding conditions. 1. Material Selection2. Surface Treatment3. Design Optimization4. Environmental Adaptability Testing5. Composite Materials6. Maintenance and CareConclusion Spiral Shielding Gaskets providing electromagnetic interference (EMI) shielding 1. Material Selection The foundation of a gasket's performance lies in its material. For spiral shielding gaskets, the choice of material directly impacts their corrosion resistance. 1.1 Stainless Steel Alloys Stainless steel is the most commonly used material for spiral shielding gaskets due to its inherent corrosion resistance. Among the various grades, 316L stainless steel stands out for several reasons: Molybdenum Content: The addition of molybdenum enhances 316L's resistance to pitting and crevice corrosion, particularly in chloride-rich environments, which are common in many industrial applications. Low Carbon Content: The low......

-

EMI Shielding Finger Stocks to protect sensitive electronic equipment

EMI Shielding Finger Stocks to protect sensitive electronic equipmentEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

EMI Shielding Finger Stocks(Fingerstrips) Introduction to EMI Shielding Finger StocksBasic ConceptsKey Features and Types of EMI Shielding Finger StocksPerformance StandardsApplications of EMI Shielding Finger StocksInstallation MethodsAdvantages of EMI Shielding Finger StocksLimitations of EMI Shielding Finger StocksFuture DevelopmentsConclusion EMI Shielding Finger Stocks(Fingerstrips) are crucial components used in various industries to protect sensitive electronic equipment from electromagnetic interference (EMI). Made from specialized alloys such as beryllium copper, these materials ensure stable signal transmission while preventing external disturbances. This article will delve into the intricacies of EMI Shielding Finger Stocks, exploring their design, types, performance standards, applications, installation methods, advantages, limitations, and future developments. Introduction to EMI Shielding Finger Stocks Electromagnetic interference can significantly impact the performance and reliability of electronic devices. EMI Shielding Finger Stocks are engineered to mitigate these effects, providing a barrier that reflects or absorbs electromagnetic waves. Their unique design allows them to create effective seals in various electronic applications, ensuring that sensitive components remain protected from external interference. Basic Concepts EMI Shielding Finger Stocks consist of resilient metal strips with a "finger-like" structure. This design enhances the ability of the material to conform to irregular surfaces and create a reliable contact. Beryllium copper is often the material of......

-

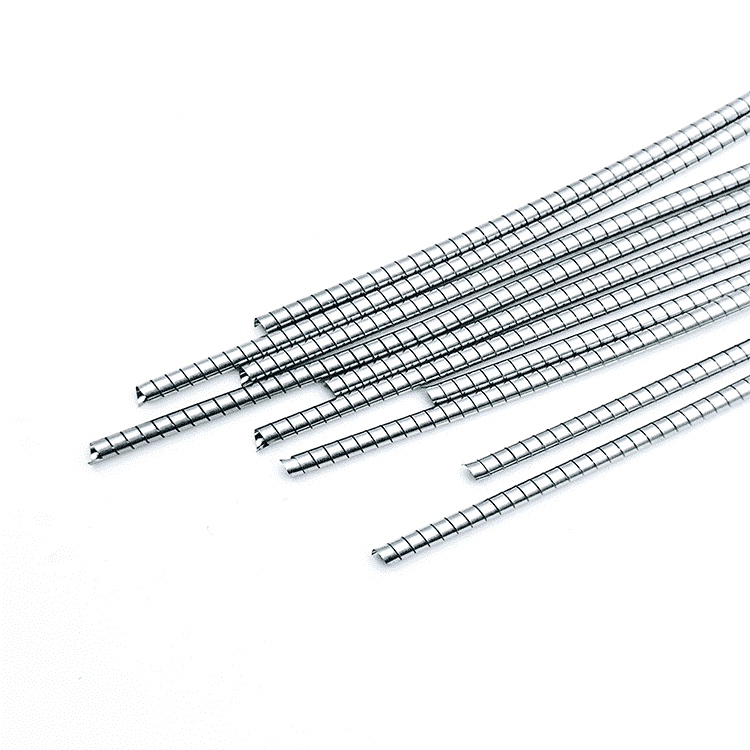

EMI Shielding Spiral Tube Gaskets

EMI Shielding Spiral Tube GasketsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

EMI (Electromagnetic Interference) shielding spiral tube gaskets are critical components in many electronic and industrial applications, designed to protect sensitive equipment from electromagnetic interference while also maintaining structural integrity in challenging environments. One of the primary concerns with these gaskets is their susceptibility to corrosion, which can compromise their effectiveness and longevity. This article explores strategies to enhance the corrosion resistance of EMI shielding spiral tube gaskets, focusing on material selection, surface treatments, design optimization, and maintenance practices. Understanding EMI Shielding Spiral Tube GasketsFunctionality and ImportanceComposite MaterialsAdvantages of Composite MaterialsMaintenance and CareInspectionImportance of Regular InspectionCleaningBenefits of Regular CleaningConclusion EMI Shielding Spiral Tube Gaskets Understanding EMI Shielding Spiral Tube Gaskets EMI shielding spiral tube gaskets are engineered to create a reliable seal between two surfaces, preventing electromagnetic waves from penetrating and interfering with the operation of electronic devices. They are typically made from conductive materials that offer both mechanical flexibility and electrical conductivity. However, the presence of moisture, chemicals, or extreme temperatures can lead to corrosion, undermining their effectiveness. Thus, enhancing corrosion resistance is essential for ensuring their longevity and performance. Functionality and Importance EMI shielding spiral tube gaskets serve multiple functions, including: Electromagnetic Shielding: They block unwanted electromagnetic radiation, preventing......