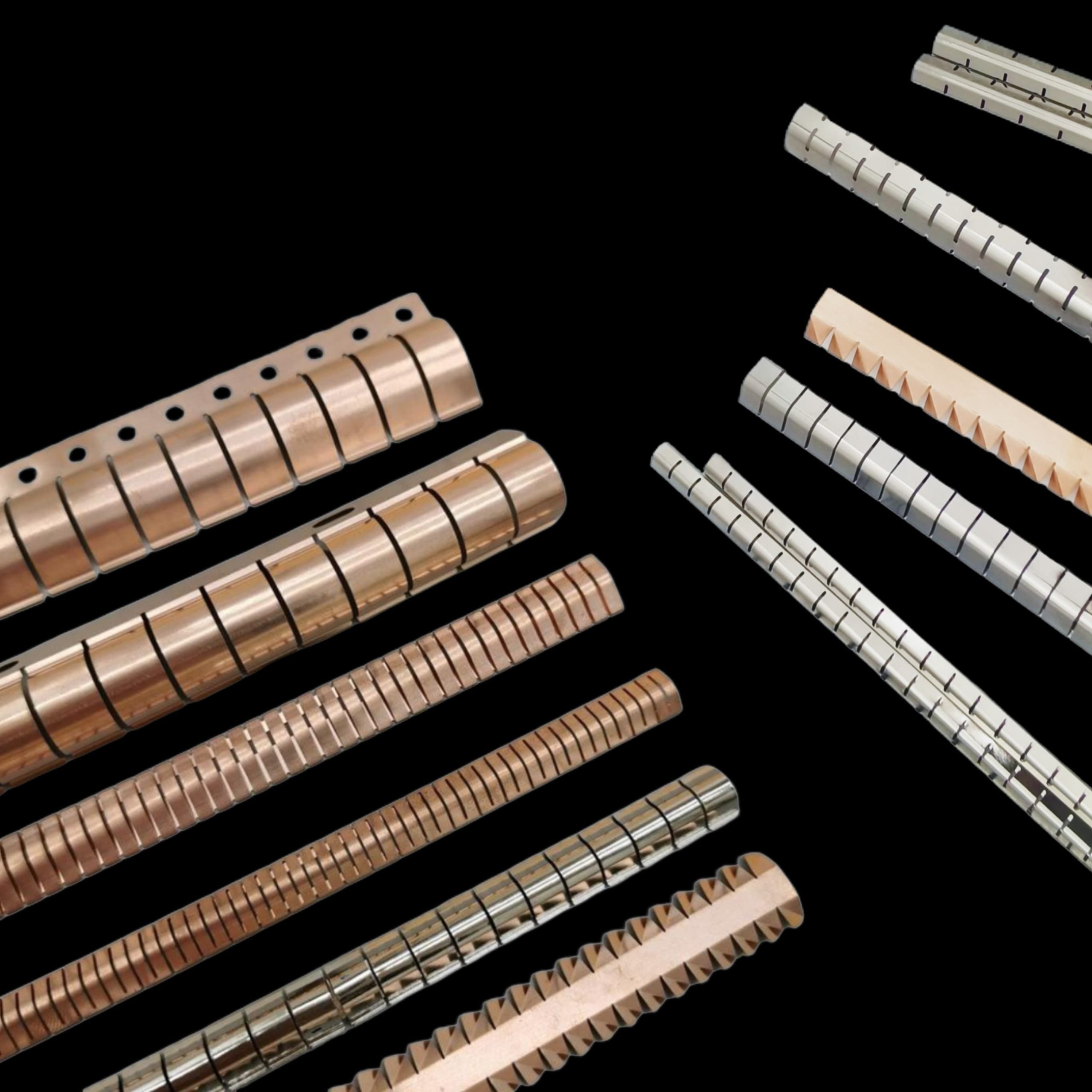

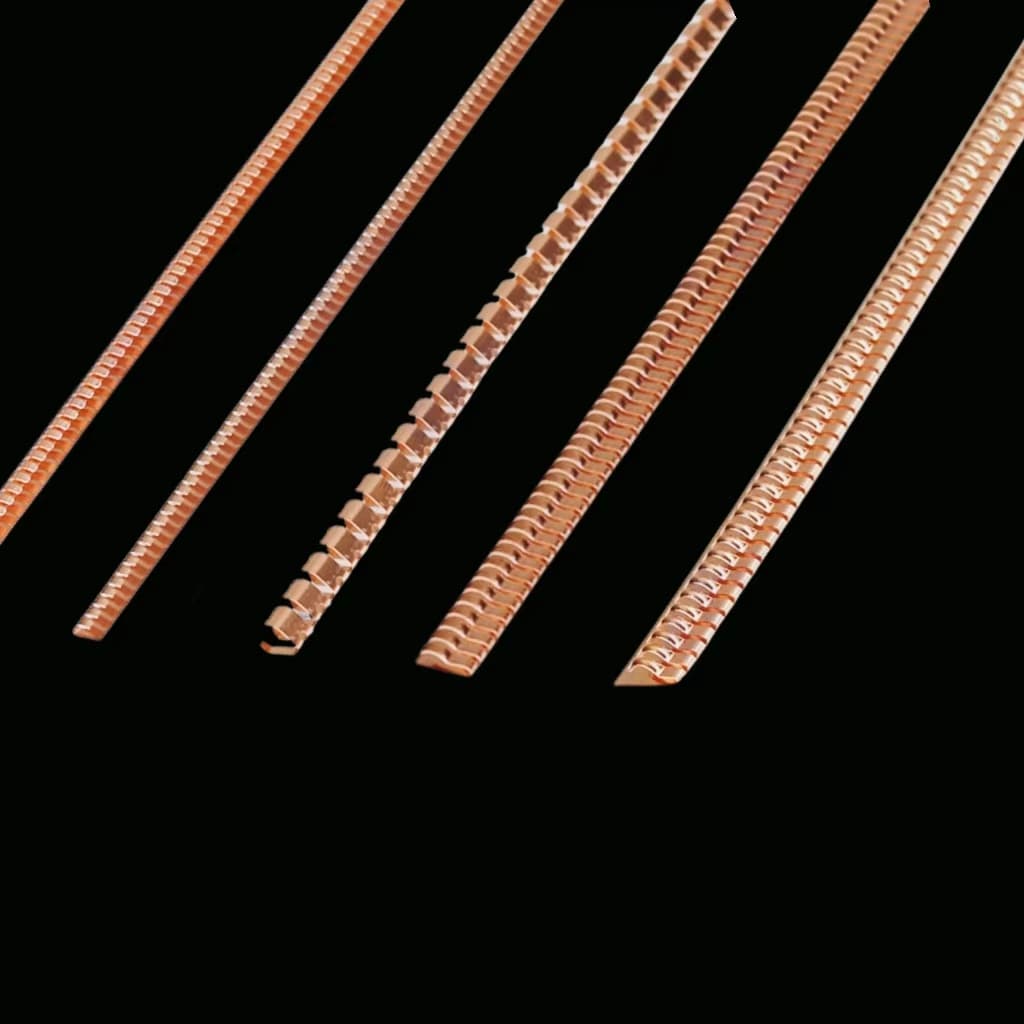

PCB/SMD spring finger contacts

Handa PCB/SMD spring finger contacts, frequently denominated as “spring fingers” or “spring-loaded contacts,” constitute essential components in electronics for establishing dependable connections and grounding on printed circuit boards (PCBs) and surface mount technology (SMT) assemblies.

These spring finger contacts are engineered to guarantee a consistent and secure electrical connection, even under diverse conditions such as vibration, thermal expansion, and mechanical stress.

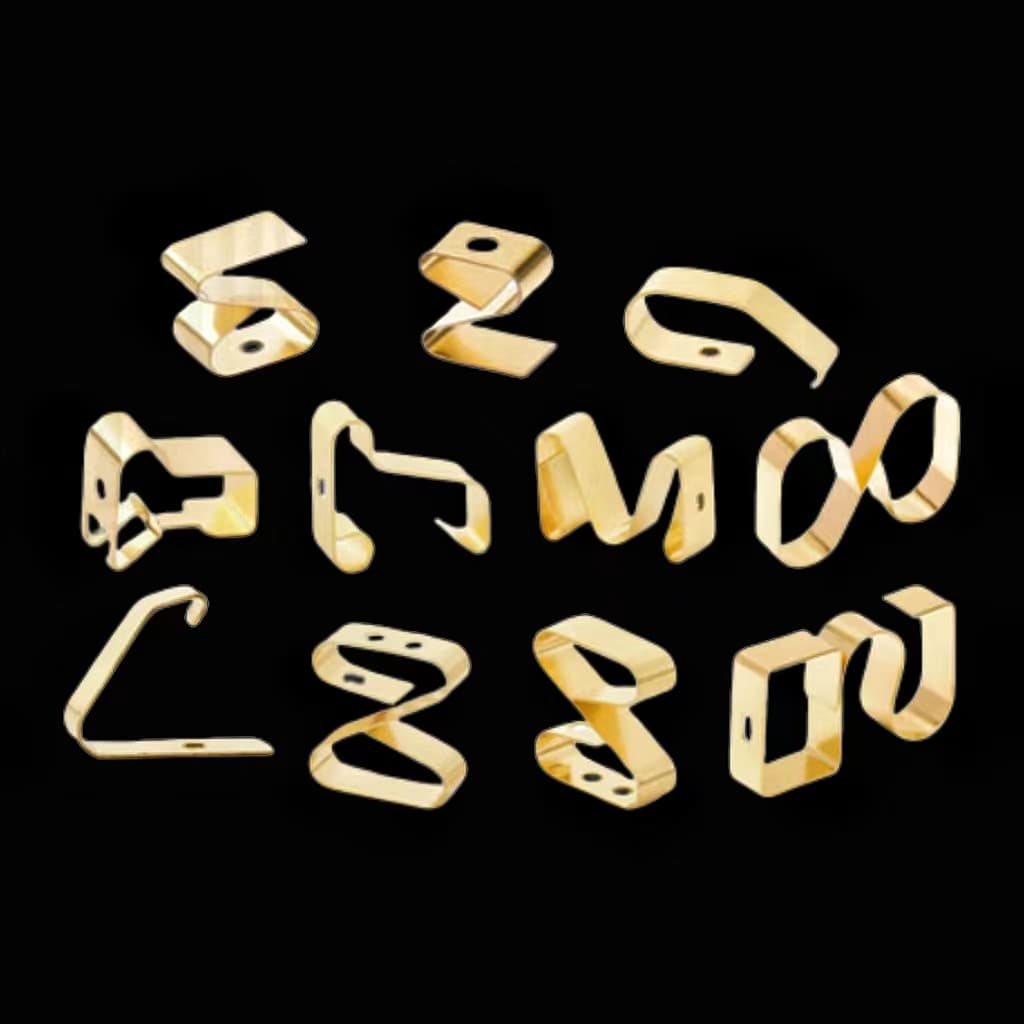

Custom Manufacturing

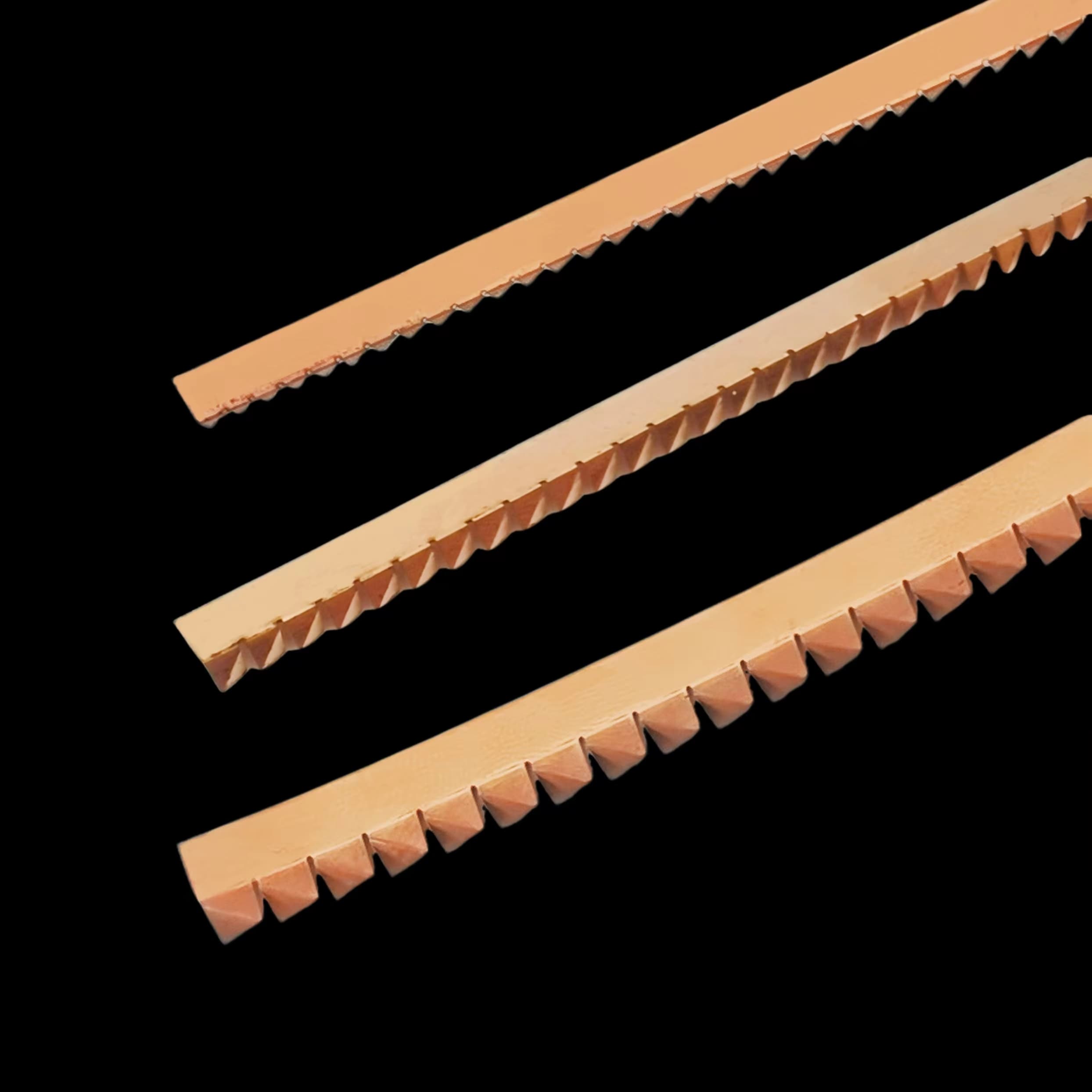

Custom PCB/SMD spring finger contacts

According to the customer’s requirements, Handa Shielding provide drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

PCB/SMD spring finger contacts Manufacturing

Manufacturing PCB/SMD spring finger contacts involves a series of steps aimed at achieving a balance between mechanical resilience, electrical conductivity, and dimensional accuracy:

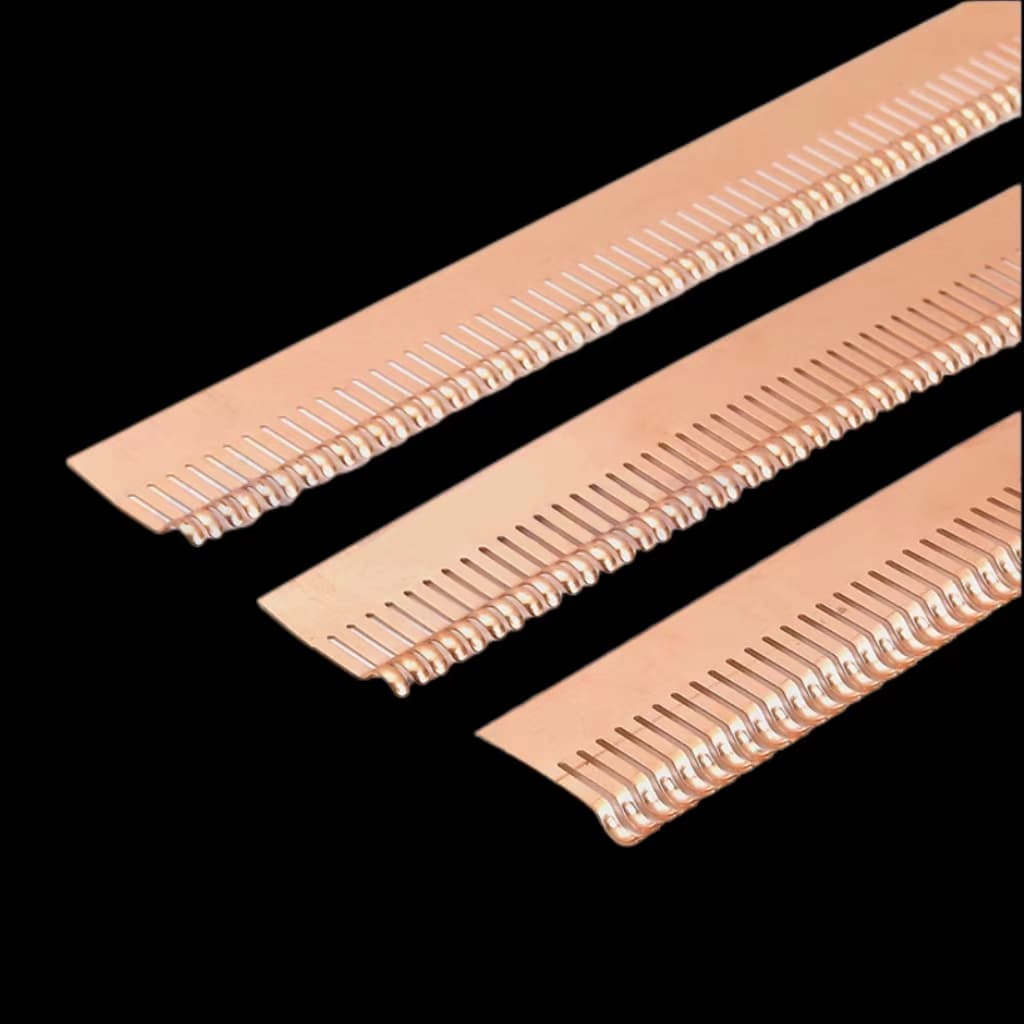

1. Material Selection:The primary material for spring finger contacts is often phosphor bronze, stainless steel, or nickel-plated brass.

2. Raw Material Processing

(1)Wire Drawing: Draw the wire to the desired diameter, ensuring uniformity and consistency in thickness.

(2)Annealing: Heat-treat the drawn wire to soften it and easier to form and work with.

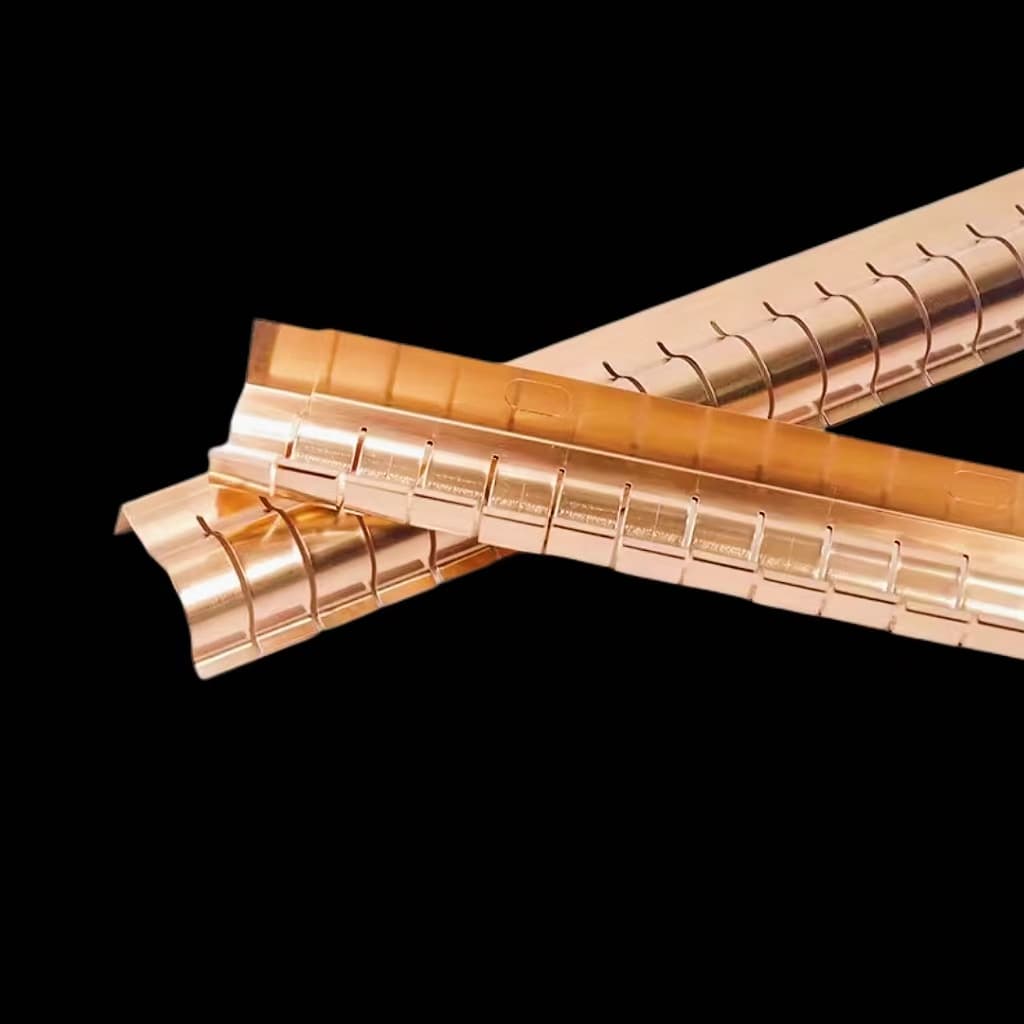

3. Forming the Spring Fingers

(1)Coiling: Wind the annealed wire around a forming tool or mandrel to create the spring fingers.

(2)Trimming: Cut the coiled wire to the required length for the target application.

4. Surface Treatment(Optional): Handa Shielding apply a surface treatment, such as nickel plating, to enhance corrosion resistance and electrical conductivity.

5. Inspection and Testing

(1)Visual Inspection: Check for defects such as kinks, breaks, or uneven coils.

(2)Electrical Testing: Measure the electrical conductivity of the spring fingers to ensure they meet the required standards.

(3)Mechanical Testing: Test the spring fingers for their force exertion capability and durability under cyclic loading conditions.

6. Packaging

(1)Protective Coating: Apply a protective coating if necessary to prevent oxidation.

(2)Packaging: Package the finished products typically in bags or boxes according to the quantity and application-specific requirements.

7. Regular Audits: Implement regular audits and quality checks throughout the manufacturing process.

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote

RECENT PRODUCT

-

Spring finger contacts 1. Basic Concepts2. Application Scenarios2.1 Consumer Electronics 1. Basic Concepts Spring finger contacts, also called "spring fingers" ,serve as connectors......

-

Introduction to Contact Finger Springs Contact finger springs are crucial components in the field of electronics and electrical engineering. They play a pivotal......