Handa Endur Shield

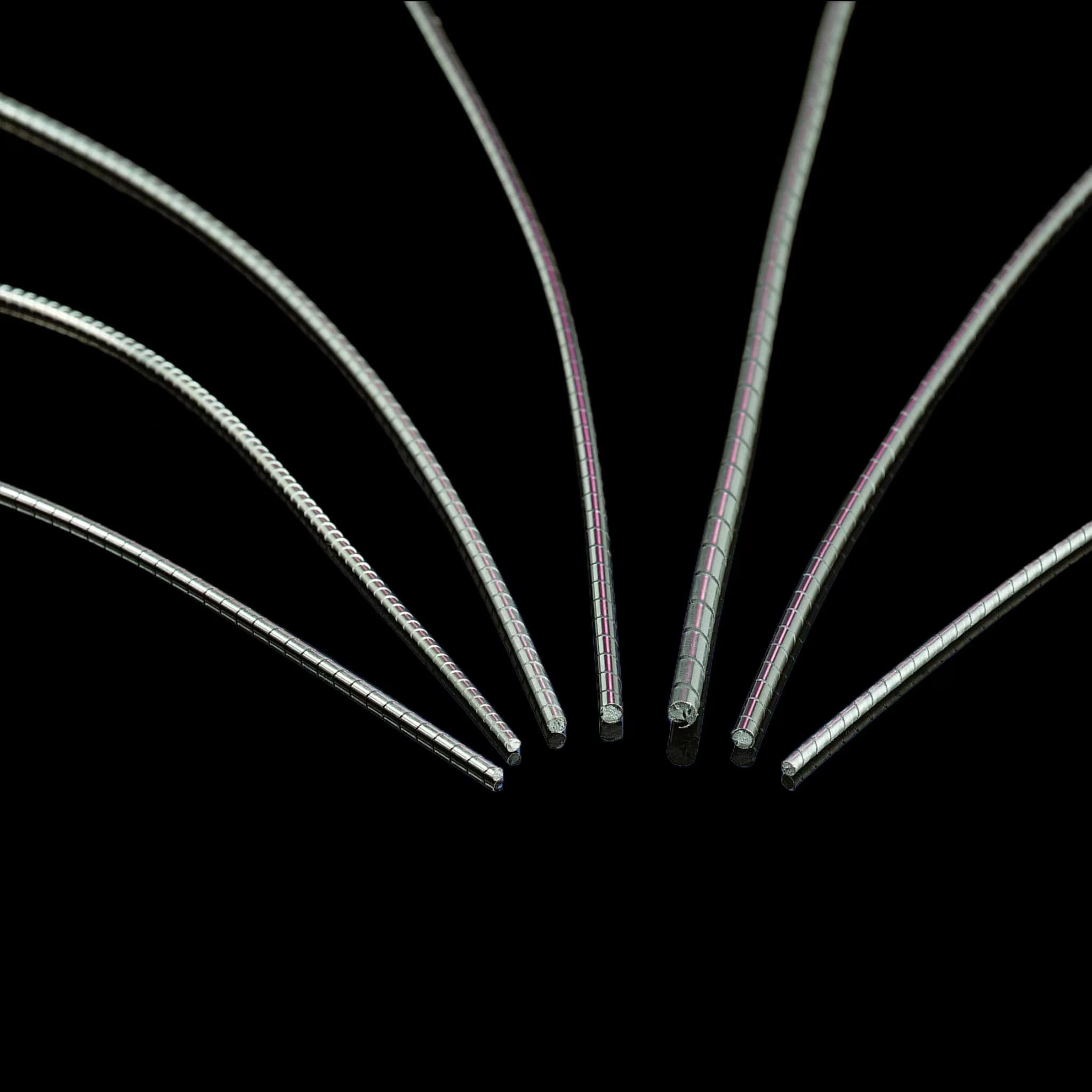

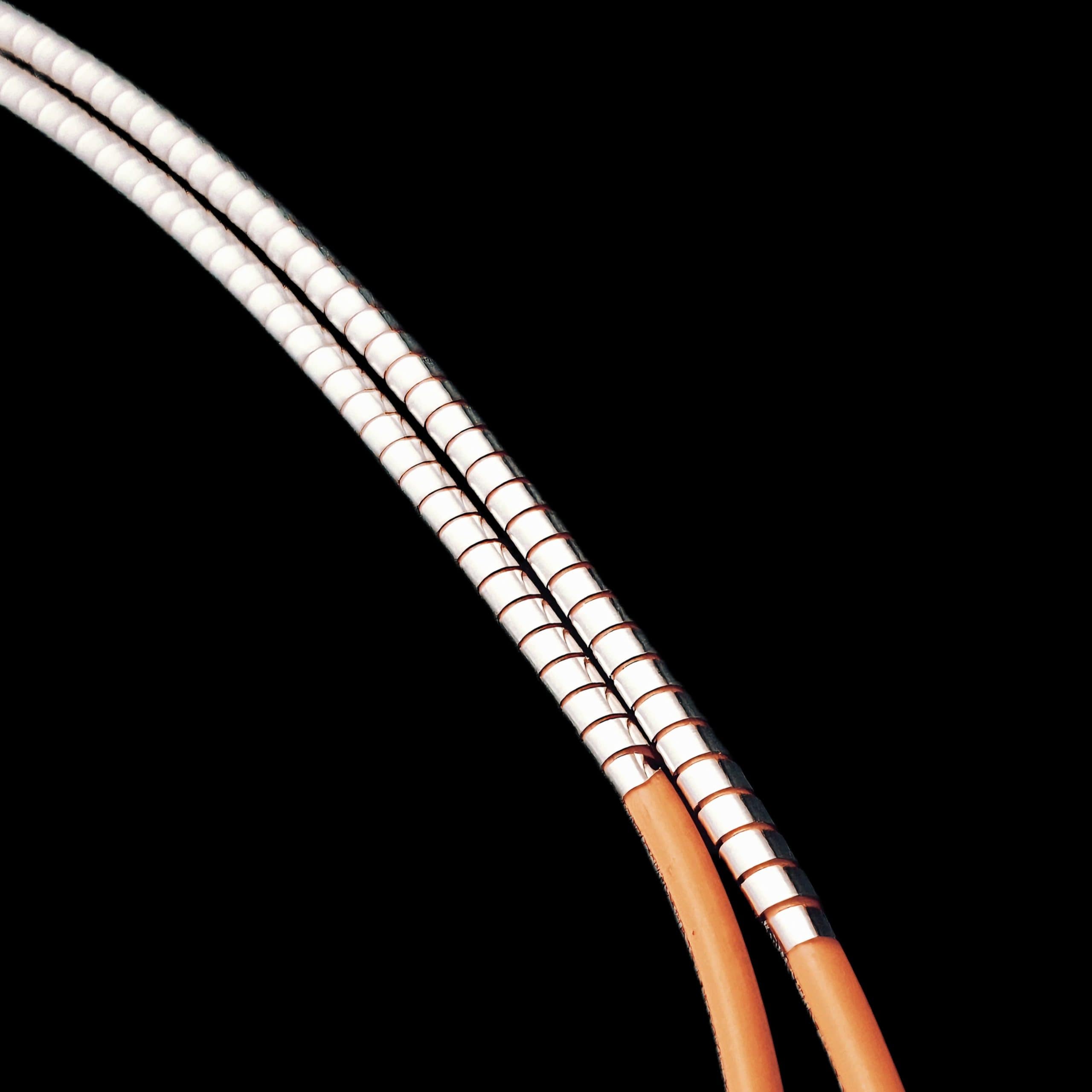

Handa Endur-Shield gasket uses our high shielding tin plated beryllium copper Spira-Shield as its base. We inject a liquid silicone adhesive into the center of the spiral, which hardens and bonds completely to the metal, making this gasket extremely durable when properly used.

Custom Manufacturing

Custom Handa Endur Shield

According to the customer’s usage environment, Handa Shielding provides drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Product Specs

Recommended Groove Size

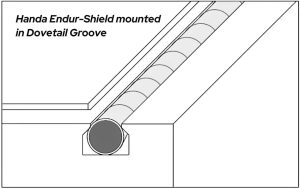

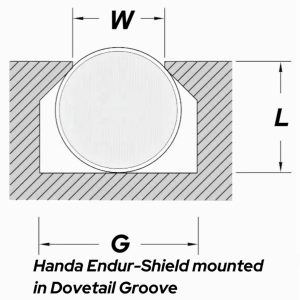

The following is a drawing for size reference.

* We can customize the width, thickness, and outer diameter of the strip according to your needs.

| Spiral-shield part numbers (RoHs Tin plated beryllium copper) | Groove Size [mm] | |||||

|---|---|---|---|---|---|---|

| DiameterOD(mm) | Standard Force(“S” Series) | Medium Force(“M” Series) | Low Force(“L” Series) | Depth(L) +0.05 /-0 (mm) | Width(G) +0.18 / -0.13 (mm) | Width(W) +0 / -0.05 (mm) |

| 0.86 ± 0.05 | HDS-SBS-086A | HDS-MBS-086A | HDS-LBS-086A | 0.58 | 1.17 | 0.84 |

| 1.19 ± 0.05 | HDS-SBS-119A | HDS-MBS-119A | HDS-LBS-119A | 0.89 | 1.60 | 1.14 |

| 1.60 ± 0.08 | HDS-SBS-160A | HDS-MBS-160A | HDS-LBS-160A | 1.17 | 2.39 | 1.52 |

| 1.78 ± 0.08 | HDS-SBS-178A | HDS-MBS-178A | HDS-LBS-178A | 1.35 | 2.39 | 1.70 |

| 1.98 ± 0.08 | HDS-SBS-198A | HDS-MBS-198A | HDS-LBS-198A | 1.50 | 2.77 | 1.91 |

| 2.39 ± 0.10 | HDS-SBS-239A | HDS-MBS-239A | HDS-LBS-239A | 1.78 | 3.18 | 2.29 |

| 2.62 ± 0.10 | HDS-SBS-262A | HDS-MBS-262A | HDS-LBS-262A | 1.96 | 3.58 | 2.51 |

| 2.77 ± 0.10 | HDS-SBS-277A | HDS-MBS-277A | HDS-LBS-277A | 2.08 | 3.96 | 2.67 |

| 3.18 ± 0.10 | HDS-SBS-318A | HDS-MBS-318A | HDS-LBS-318A | 2.39 | 4.34 | 3.07 |

| 3.53 ± 0.13 | HDS-SBS-353A | HDS-MBS-353A | HDS-LBS-353A | 2.64 | 4.75 | 3.40 |

| 3.58 ± 0.13 | HDS-SBS-358A | HDS-MBS-358A | HDS-LBS-358A | 2.67 | 4.75 | 3.45 |

| 4.37 ± 0.13 | HDS-SBS-437A | HDS-MBS-437A | HDS-LBS-437A | 3.25 | 5.94 | 4.19 |

| 4.75 ± 0.15 | HDS-SBS-475A | HDS-MBS-475A | HDS-LBS-475A | 3.56 | 6.35 | 4.60 |

| 6.35 ± 0.18 | HDS-SBS-635A | HDS-MBS-635A | HDS-LBS-635A | 4.70 | 8.71 | 6.10 |

| 7.92 ± 0.23 | HDS-SBS-792A | HDS-MBS-792A | HDS-LBS-792A | 5.94 | 10.72 | 7.62 |

| 9.53 ± 0.28 | HDS-SBS-953A | HDS-MBS-953A | HDS-LBS-953A | 7.11 | 12.70 | 9.25 |

| 12.70 ± 0.38 | HDS-SBS-1270A | HDS-MBS-1270A | HDS-LBS-1270A | 9.53 | 16.66 | 12.32 |

Available options

Custom Sizes

We can manufacture cord gaskets with all sizes of diameters, from 0.86mm up to approximately 50mm. There is no additional cost for a specialized diameter. However, for large cords, the length of the gasket available is smaller.

Plating

Optional plating can be specified by adding a prefix to the reference:

BS: RoHS compliant tin plating (Example: HDS-LBS-178A).

Special Tubing

Possibility of including a specific core (as far as possible according to the sizes).

W: Cordless,

A: Silicone rubber solid,

T: Silicone rubber tube,

F: Silicone foam

Application

Due to its extreme mechanical strength, this gasket is ideal for the manufacture of O-rings and for use as connector seals.

Material

Spiral: Tin-plated Beryllium Copper (RoHS compliance).

Inner Tubing: Cured silicone adhesive.

Shielding Performance

This gasket offers shielding quality from 117 dB to 152 dB. The shielding quality may vary depending on the application.

Compression Force

Optimal compression of the gasket is 25% of the diameter of the spiral.

The compression forces given are approximate:

Standard Force: 5.5 kg/cm

Moderate Force: 1.8 kg/cm

Low Force: 0.3 kg/cm

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote