Handa Flexi Shield

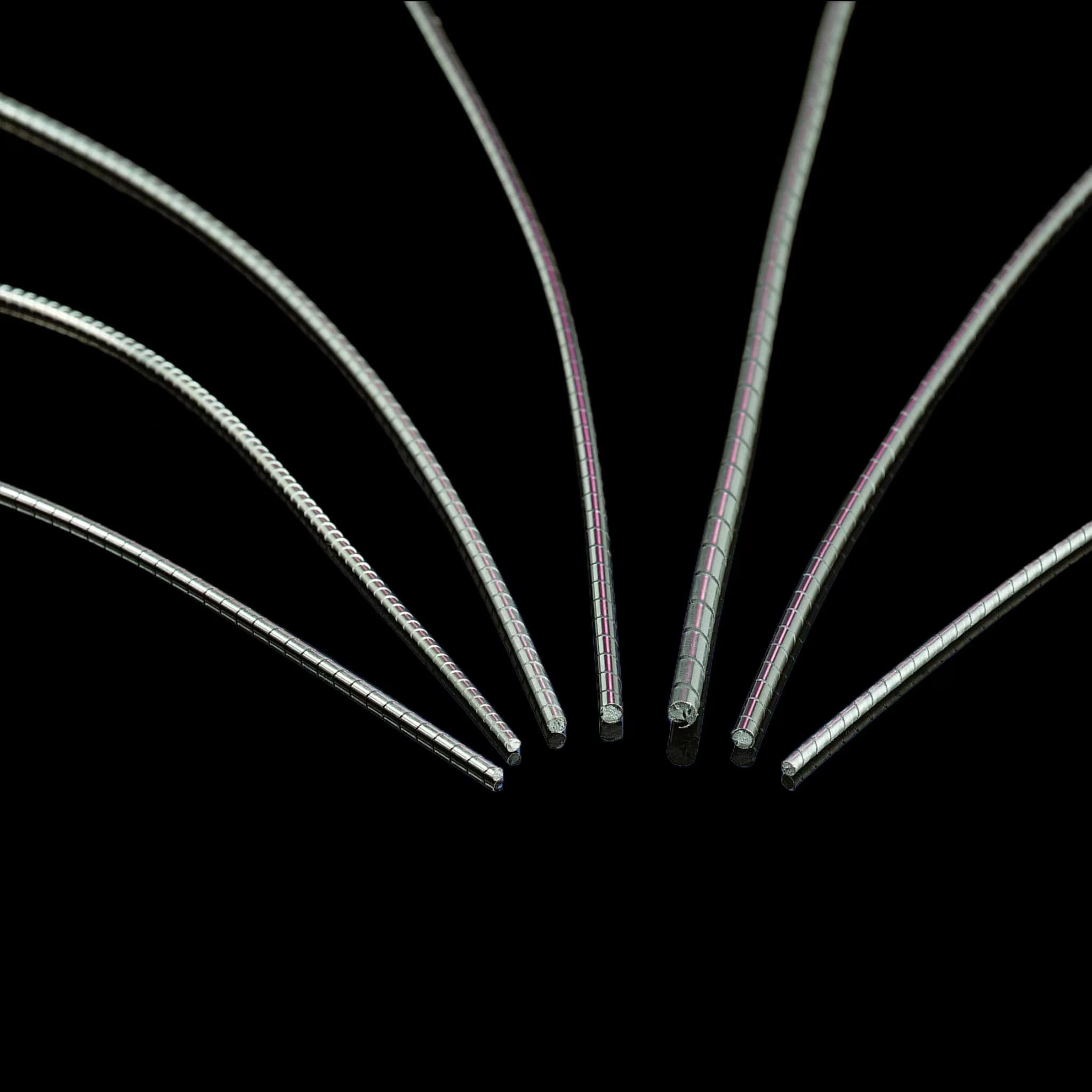

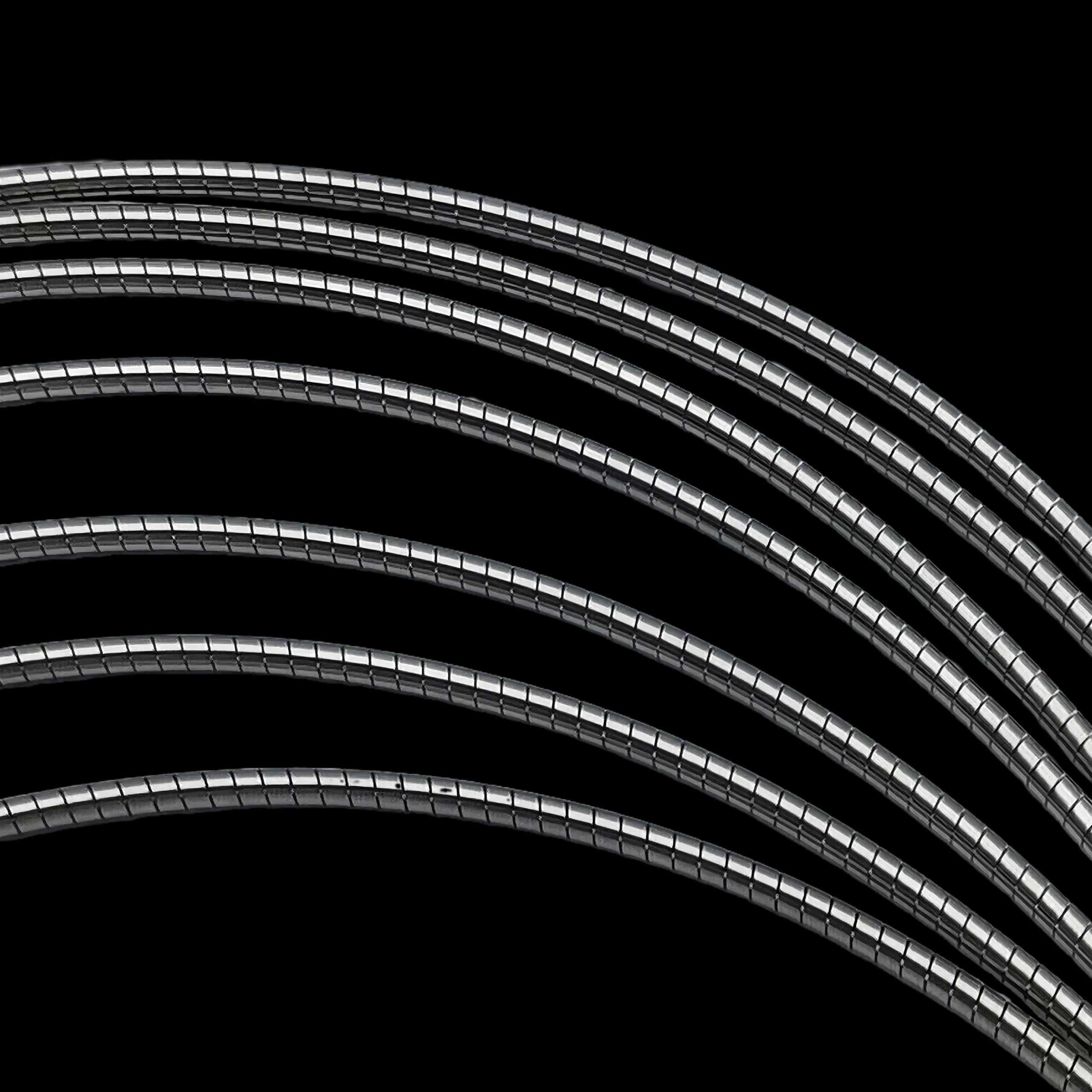

Handa’s Flexi-Shield gasket offers the best of both worlds. This gasket combines the EMI shielding performance of our other spiral gaskets with the ain/wind/dust sealing of an elastomer. special process wraps our highly conductive spiral around a soft silicone tube.

This leads to gaskets that are highly manageable, robust enough for demanding sliding applications, require as little as two pounds of closure force per inch, and provide moderate to high shielding based on the chosen materials.

Custom Manufacturing

Custom Handa Flexi Shield

According to the customer’s usage environment, Handa Shielding provides drawings or dimensions and working conditions requirements for product customization. If necessary, please contact sunny@handashielding.com and a professional engineer will answer your questions. Thank you!

Product Specs

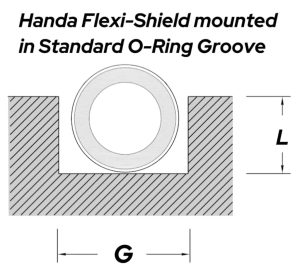

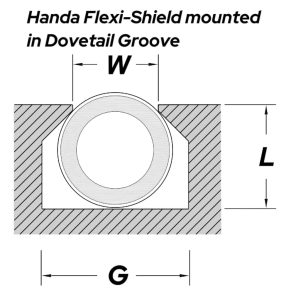

Recommended Groove Size

The following is a drawing for size reference.

* We can customize the width, thickness, and outer diameter of the strip according to your needs.

| Spiral-shield part numbers (RoHs Tin plated beryllium copper) | Groove Size [mm] | |||||

|---|---|---|---|---|---|---|

| Diameter OD(mm) | Standard Force(“S” Series) | Medium Force(“M” Series) | Low Force(“L” Series) | Depth(L) +0.05 /-0 (mm) | Width(G) +0.18 / -0.13 (mm) | Width(W) +0 / -0.05 (mm) |

| 0.86 ± 0.05 | HDS-SSNS-086AH | HDS-MSNS-086AH | HDS-LSNS-086AH | 0.58 | 1.17 | 0.84 |

| 1.19 ± 0.05 | HDS-SSNS-119AH | HDS-MSNS-119AH | HDS-LSNS-119AH | 0.89 | 1.60 | 1.14 |

| 1.60 ± 0.08 | HDS-SSNS-160AH | HDS-MSNS-160AH | HDS-LSNS-160AH | 1.17 | 2.39 | 1.52 |

| 1.78 ± 0.08 | HDS-SSNS-178AH | HDS-MSNS-178AH | HDS-LSNS-178AH | 1.35 | 2.39 | 1.70 |

| 1.98 ± 0.08 | HDS-SSNS-198AH | HDS-MSNS-198AH | HDS-LSNS-198AH | 1.50 | 2.77 | 1.91 |

| 2.39 ± 0.10 | HDS-SSNS-239AH | HDS-MSNS-239AH | HDS-LSNS-239AH | 1.78 | 3.18 | 2.29 |

| 2.62 ± 0.10 | HDS-SSNS-262AH | HDS-MSNS-262AH | HDS-LSNS-262AH | 1.96 | 3.58 | 2.51 |

| 2.77 ± 0.10 | HDS-SSNS-277AH | HDS-MSNS-277AH | HDS-LSNS-277AH | 2.08 | 3.96 | 2.67 |

| 3.18 ± 0.10 | HDS-SSNS-318AH | HDS-MSNS-318AH | HDS-LSNS-318AH | 2.39 | 4.34 | 3.07 |

| 3.53 ± 0.13 | HDS-SSNS-353AH | HDS-MSNS-353AH | HDS-LSNS-353AH | 2.64 | 4.75 | 3.40 |

| 3.58 ± 0.13 | HDS-SSNS-358AH | HDS-MSNS-358AH | HDS-LSNS-358AH | 2.67 | 4.75 | 3.45 |

| 4.37 ± 0.13 | HDS-SSNS-437AH | HDS-MSNS-437AH | HDS-LSNS-437AH | 3.25 | 5.94 | 4.19 |

| 4.75 ± 0.15 | HDS-SSNS-475AH | HDS-MSNS-475AH | HDS-LSNS-475AH | 3.56 | 6.35 | 4.60 |

| 6.35 ± 0.18 | HDS-SSNS-635AH | HDS-MSNS-635AH | HDS-LSNS-635AH | 4.70 | 8.71 | 6.10 |

| 7.92 ± 0.23 | HDS-SSNS-792AH | HDS-MSNS-792AH | HDS-LSNS-792AH | 5.94 | 10.72 | 7.62 |

| 9.53 ± 0.28 | HDS-SSNS-953AH | HDS-MSNS-953AH | HDS-LSNS-953AH | 7.11 | 12.70 | 9.25 |

| 12.70 ± 0.38 | HDS-SSNS-1270AH | HDS-MSNS-1270AH | HDS-LSNS-1270AH | 9.53 | 16.66 | 12.32 |

Available options

Plating

Optional plating can be specified by adding a prefix to the reference:

SN : RoHS compliant nickle plating (Example : HDS-MSNS-178AH)

Special Tubing

Possibility of including a specific core (as far as possible according to the sizes).

W: Cordless,

A: Silicone rubber solid,

T: Silicone rubber tube,

F: Silicone foam

Application

Thanks to the silicone tube present in the center of the spiral, this gasket is also against water, dust and air ingress, as an sealing elastomer seal. It therefore combines the advantages of a shielding gasket with those of a sealing gasket, and for a limited cost.

Material

Spiral: Stainless steel (tin plating optional).

Inner Tubing: 40 ± 5 durometer silicone.

Shielding Performance

We offer stainless steel for moderate shielding quality, and optional tin plating for higher shielding levels. All shielding quality results are based on tests against tin-plated joint surfaces. The shielding quality may vary depending on your specific application.

Stainless Steel (All Forces): 100 dB at 1 GHz

Low Force Tin-Plated Gaskets: 120 dB at 1 GHz

Moderate and Standard Force Tin-Plated Gaskets: 130 dB at 1 GHz

Compression Force

Flexi-Shield gaskets come in three different resilience (as shown below). Optimal compression of the gasket is 25% of the diameter of the spiral. Since the force to compress the gasket is a function of the cube of the thickness of the stainless steel ribbon, the compression forces shown are approximate.

Standard Force: 5.5 kg/cm

Moderate Force: 1.8 kg/cm

Low Force: 0.4 kg/cm

Need a Large Order?

We can design and manufacture a component for your specific application in any quantity. For quantities over 1,000, please request a quote.

Request a Quote