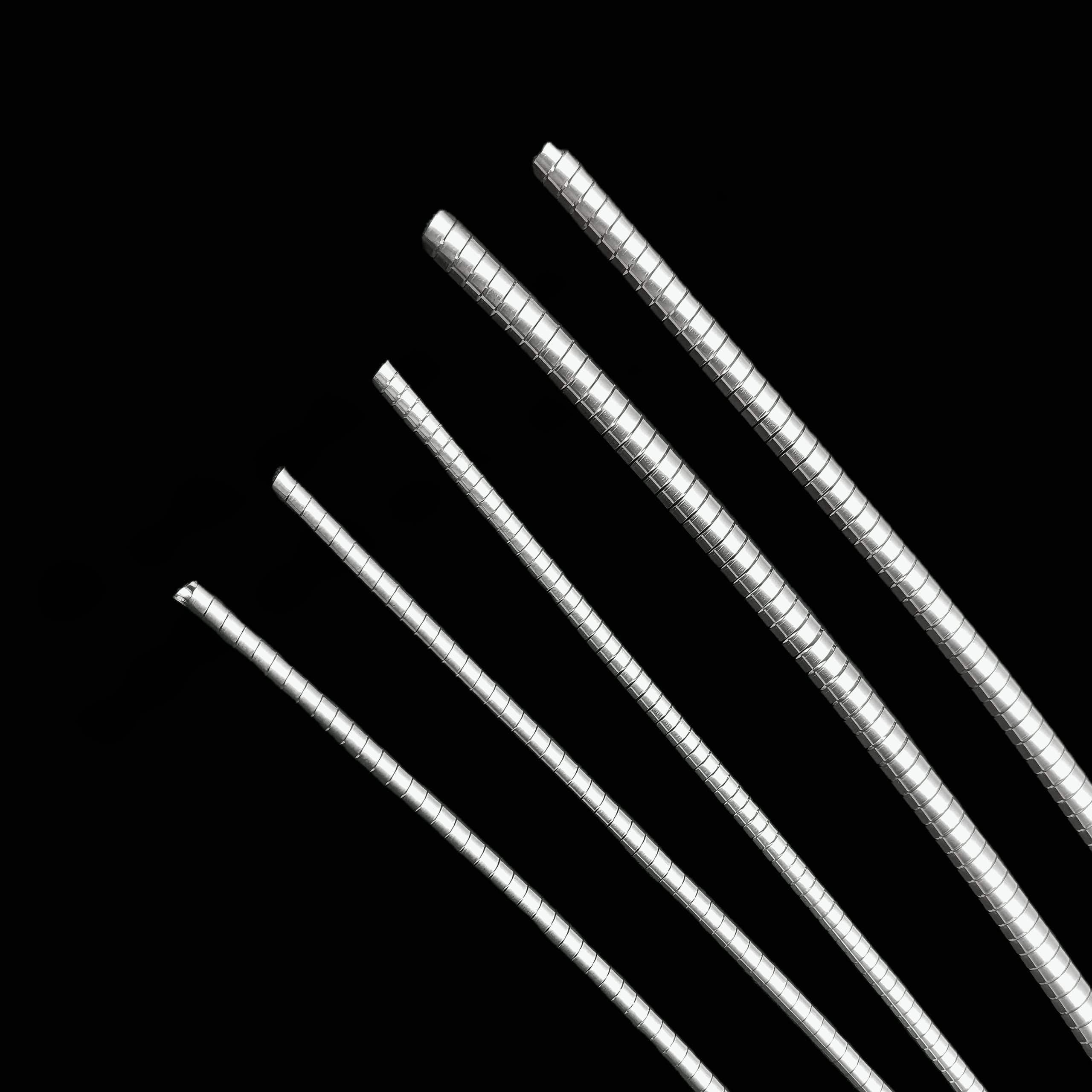

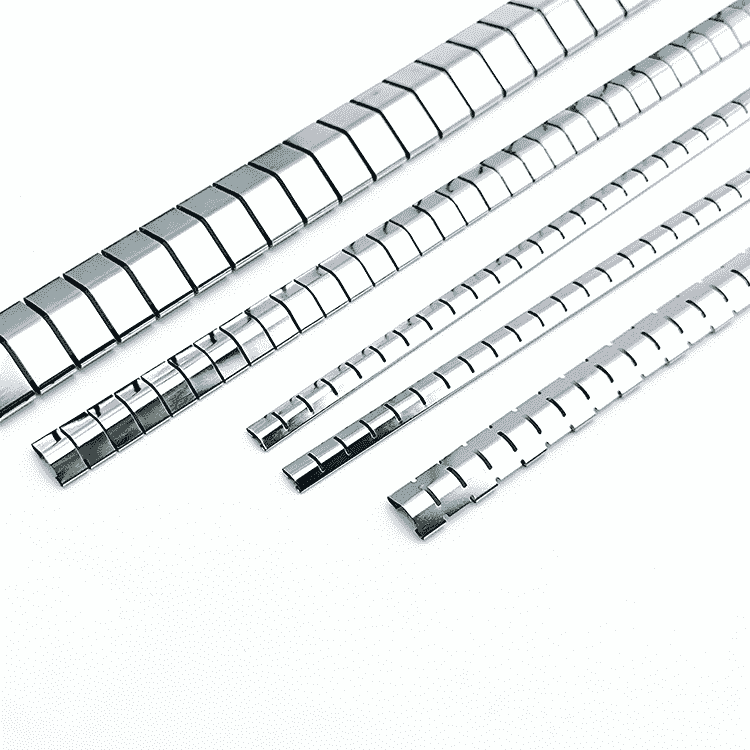

High EMI Shielding Effect Snap-on mounting fingerstrips

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to maintaining the functionality and performance of sensitive electronic devices. Snap-on mounting fingerstrips are designed for easy installation, flexibility, and efficient shielding, making them a popular choice across numerous industries, including telecommunications, military, aerospace, automotive, and consumer electronics.

Snap-on mounting fingerstrips are highly effective Electromagnetic Interference (EMI) shielding components used in various electronic enclosures and assemblies to ensure electromagnetic integrity and prevent radio frequency interference (RFI). With the advancement of electronic systems, EMI shielding has become crucial to maintaining the functionality and performance of sensitive electronic devices. Snap-on mounting fingerstrips are designed for easy installation, flexibility, and efficient shielding, making them a popular choice across numerous industries, including telecommunications, military, aerospace, automotive, and consumer electronics.

This article will provide a detailed exploration of snap-on mounting fingerstrips, focusing on their key features, materials, installation methods, applications, and benefits. Additionally, we will explore why snap-on mounting fingerstrips are an essential component in modern electronics and how they meet the demands of EMI/RFI shielding requirements.

Table of Contents

What are Snap-On Mounting Fingerstrips?

Snap-on mounting fingerstrips are flexible EMI shielding gaskets made from materials such as beryllium copper, phosphor bronze, or other conductive alloys. They are specifically designed to create a secure electrical contact and establish an effective barrier against EMI. Snap-on fingerstrips are installed in grooves or tracks within electronic enclosures, enabling easy integration with various components.

These fingerstrips feature a snap-on design that simplifies installation, requiring only slight pressure to mount them securely into place. This characteristic makes them especially useful in assemblies where access to internal components is required without compromising the shielding performance.

Key Features of Snap-On Mounting Fingerstrips

1. Low Compression Force

One of the primary advantages of snap-on mounting fingerstrips is their low compression force. Unlike some other EMI shielding solutions that require significant force to install, these fingerstrips require minimal pressure to compress, making them ideal for use in sliding applications. The low compression force helps extend the life of both the gasket and the adjacent surfaces by reducing wear and tear during repeated assembly and disassembly.

2. Symmetrical Design

Snap-on mounting fingerstrips often feature a symmetrical design, which enables two-way contact between the fingerstrip and the enclosure surface. This feature ensures a continuous shielding connection across a wide range of surfaces, improving the overall shielding effectiveness. The symmetrical design also makes it easier to install the strips correctly, as there is no specific orientation required.

3. High EMI/RFI Shielding Efficiency

As an EMI shielding solution, snap-on fingerstrips are highly effective at blocking both electromagnetic interference (EMI) and radio frequency interference (RFI). These shielding components create an electrical grounding path and a physical barrier, preventing electromagnetic waves from leaking in or out of the enclosure. This capability is particularly important in sensitive electronic devices and systems that rely on signal clarity and accuracy.

4. Durability and Material Strength

Snap-on mounting fingerstrips are typically made from robust materials such as beryllium copper or other copper alloys. Beryllium copper is renowned for its high conductivity, strength, and resistance to corrosion, making it an ideal material for EMI shielding in demanding environments. This durability ensures that snap-on fingerstrips can withstand repeated use without losing their shielding effectiveness.

5. Versatile Application

The versatility of snap-on mounting fingerstrips allows them to be used in a wide range of electronic enclosures and assemblies. Their flexibility, combined with ease of installation, makes them suitable for applications involving frequent opening and closing of panels, doors, and covers in various electronic devices and cabinets.

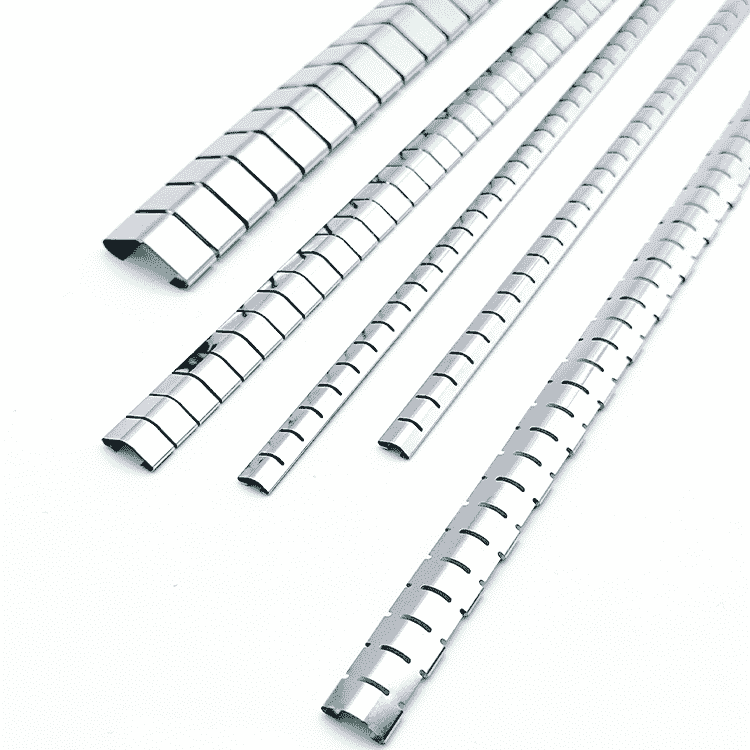

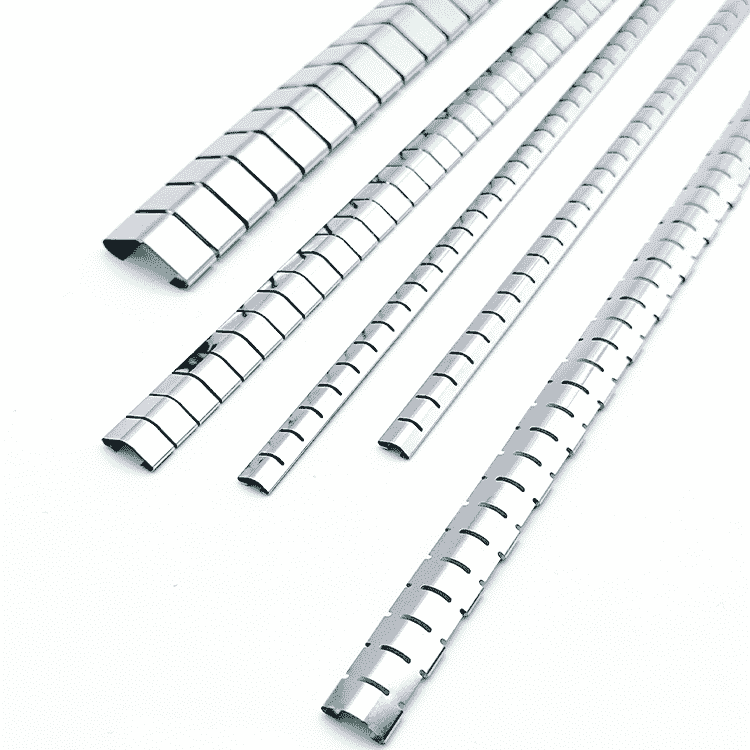

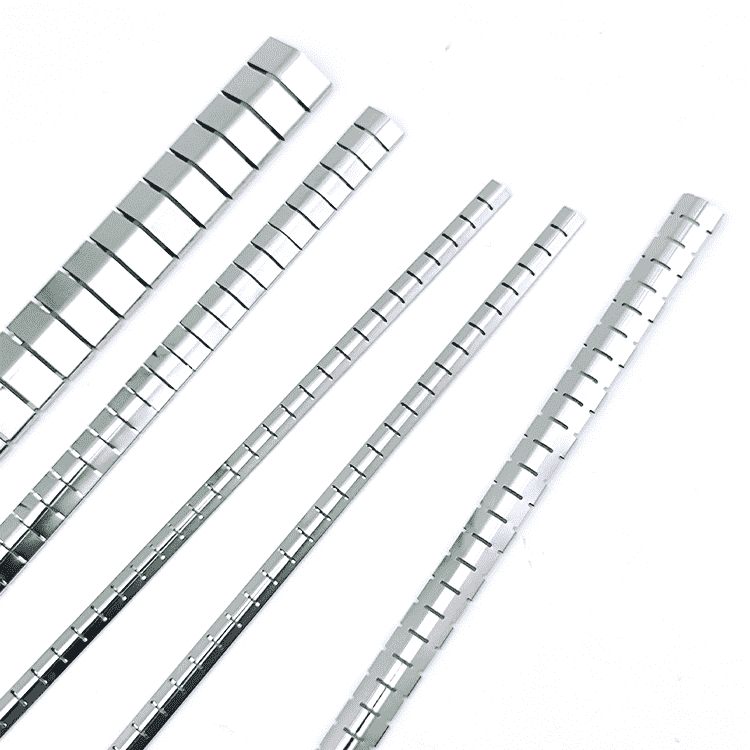

Types of Snap-On Mounting Fingerstrips

Snap-on mounting fingerstrips are available in different configurations and materials, tailored to meet the specific requirements of various applications. Common types include:

1. Conductive Beryllium Copper Fingerstrips

These are the most common type of snap-on fingerstrips, made from beryllium copper, which offers excellent electrical conductivity and resilience. Beryllium copper fingerstrips are often used in high-performance applications that require consistent shielding, even in extreme environmental conditions.

2. Tin-Plated Fingerstrips

Some snap-on mounting fingerstrips come with tin plating, which improves corrosion resistance and enhances the strip’s ability to establish a strong electrical contact with the enclosure surfaces. Tin-plated fingerstrips are often chosen for outdoor applications or environments where moisture and other corrosive elements are present.

3. Clip-On Fingerstrips with Double-Sided Adhesive

For more demanding or specialized applications, snap-on mounting fingerstrips can be provided with double-sided adhesive or mounted on brass tracks with adhesive backing. This adhesive facilitates quick installation and provides additional holding strength. In some cases, the fingerstrips can be scored for easy break-off after installation.

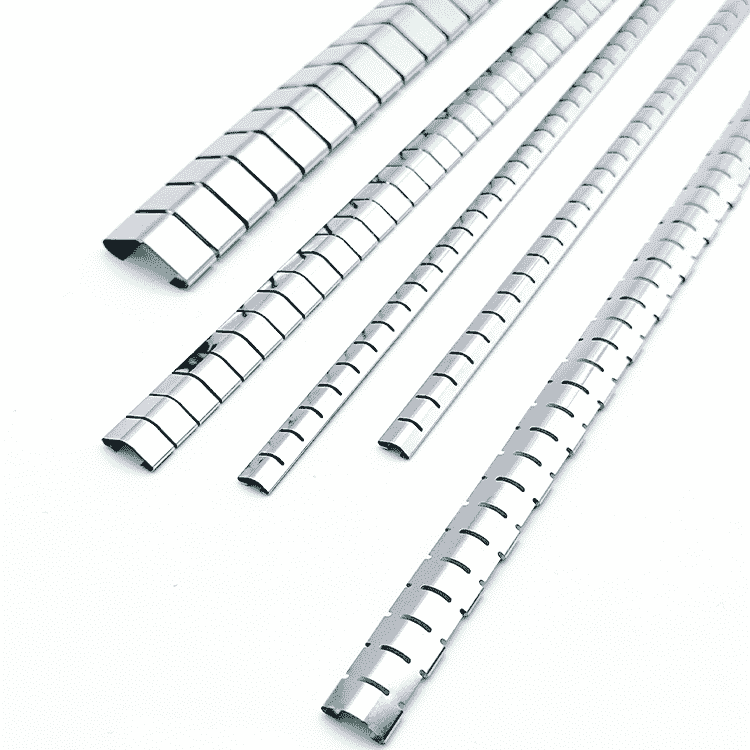

Installation Method of Snap-On Mounting Fingerstrips

One of the key selling points of snap-on mounting fingerstrips is their ease of installation. Their snap-on feature means they can be quickly and easily installed by pressing them into a groove or track along the edge of the enclosure.

Step-by-Step Installation Process:

- Preparation: Ensure the groove or track where the fingerstrip will be installed is clean and free of debris.

- Positioning: Hold the edge of the snap-on fingerstrip in one of the grooves or edges of the enclosure.

- Snap-On: Apply gentle pressure and push the strip in the direction of the second groove until the fingerstrip securely snaps into place.

- Secure Contact: Once snapped into place, the strip establishes continuous contact along the surface, providing effective EMI shielding.

Common Applications of Snap-On Mounting Fingerstrips

Due to their superior EMI/RFI shielding capabilities and easy installation, snap-on mounting fingerstrips are employed in a wide array of applications. They are especially useful in environments where electronic components and assemblies require frequent access or maintenance without compromising EMI shielding.

1. Front Panel Handles

Snap-on fingerstrips are often used in front panel handles to ensure EMI protection while allowing easy access to internal components of the enclosure.

2. Shielded Housings and Doors

In shielded housings, snap-on fingerstrips provide a continuous EMI barrier around doors or access points. They prevent electromagnetic interference from entering or leaving the enclosure when the door is closed, making them essential for devices that must meet stringent EMC (Electromagnetic Compatibility) standards.

3. Sliding Trays and Plug-In Units

For electronic cabinets or devices with sliding trays or plug-in units, snap-on mounting fingerstrips ensure consistent EMI shielding even during movement. This makes them a reliable solution for systems that involve frequent insertion and removal of components.

4. Racks and Communication Cabinets

Telecommunication systems, servers, and other data communication equipment housed in racks or communication cabinets benefit from the EMI shielding offered by snap-on fingerstrips. These strips protect the sensitive electronic components from external interference, ensuring data integrity and minimizing signal loss.

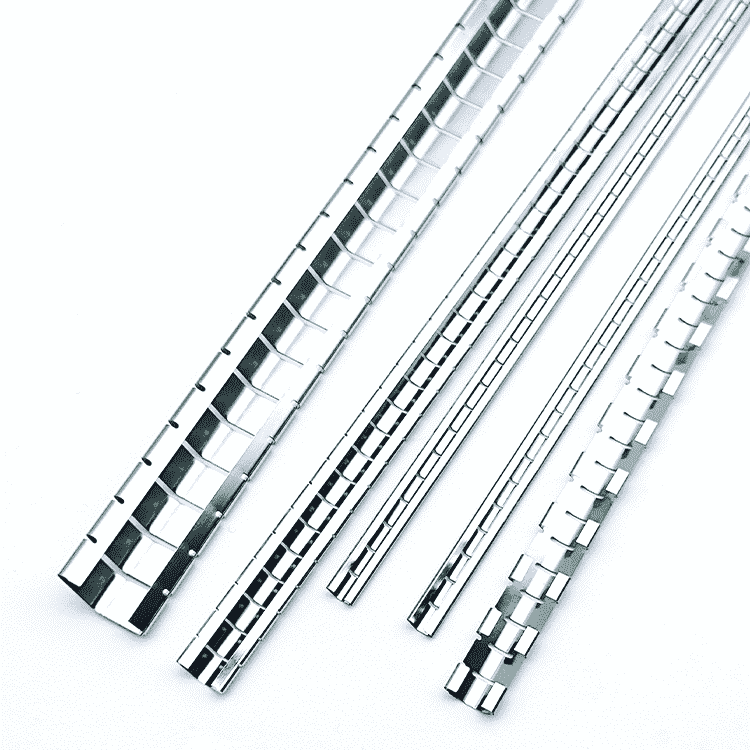

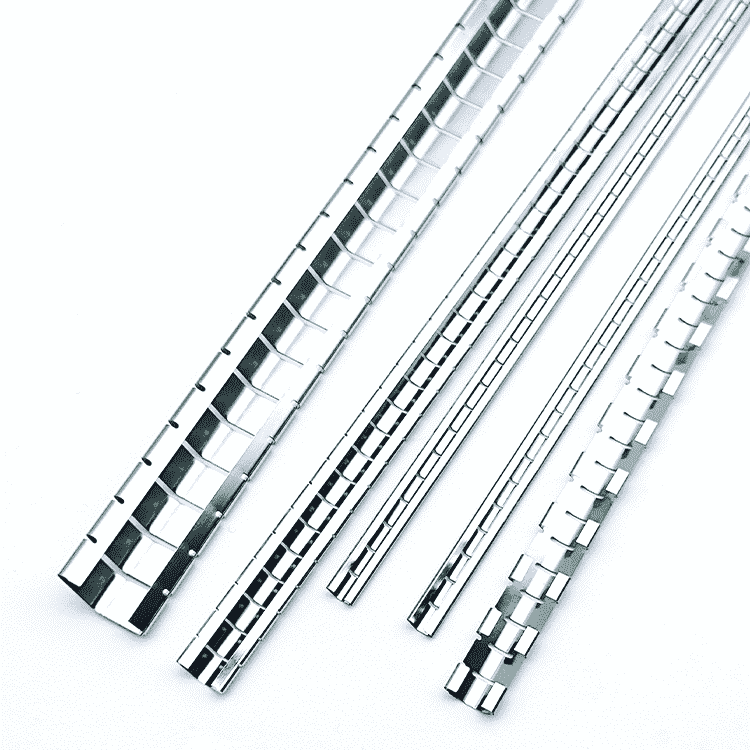

Material Options for Snap-On Mounting Fingerstrips

The material used to manufacture snap-on mounting fingerstrips plays a significant role in determining their effectiveness, durability, and suitability for specific environments. Here are the most commonly used materials:

1. Beryllium Copper

Beryllium copper is a preferred material due to its excellent electrical conductivity, high strength, and corrosion resistance. It is well-suited for high-frequency EMI shielding applications and can withstand harsh operating conditions, including extreme temperatures.

2. Phosphor Bronze

Phosphor bronze is another material used for snap-on mounting fingerstrips, known for its good conductivity and wear resistance. It is often used in applications where mechanical durability is essential alongside EMI shielding.

3. Stainless Steel

For environments where corrosion resistance and durability are paramount, stainless steel snap-on fingerstrips may be used. Stainless steel is less conductive than copper alloys but offers superior resistance to oxidation, making it ideal for outdoor or marine applications.

4. Tin-Plated Alloys

In cases where corrosion resistance and improved electrical contact are required, snap-on mounting fingerstrips can be tin-plated. This additional layer of protection ensures long-term performance in environments where moisture or corrosive chemicals may be present.

Benefits of Using Snap-On Mounting Fingerstrips

Snap-on mounting fingerstrips offer numerous benefits that make them an essential component in a wide variety of electronic and industrial applications.

1. Easy Installation

The snap-on design simplifies installation and eliminates the need for complex tools or mounting mechanisms. This feature is particularly useful for applications requiring frequent access to enclosed components, as the fingerstrips can be easily re-installed without losing their effectiveness.

2. Low Compression Force

By requiring minimal compression force, snap-on mounting fingerstrips reduce wear and tear on both the gasket and the enclosure. This ensures a longer service life and makes them suitable for applications involving repeated motion or assembly.

3. Effective EMI/RFI Shielding

Snap-on mounting fingerstrips provide robust EMI/RFI shielding across a wide frequency range. Their ability to establish a continuous electrical grounding path and physical barrier ensures that electronic devices are protected from unwanted interference.

4. Versatile Application

From automotive electronics to communication systems, snap-on fingerstrips can be used in various industries. Their versatility allows them to be integrated into multiple configurations, making them a flexible solution for modern shielding requirements.

5. Durability

Snap-on fingerstrips are built to withstand harsh environments, ensuring that their shielding properties remain intact even in challenging conditions such as high temperatures, humidity, or corrosive environments.

Conclusion: Snap-On Mounting Fingerstrips in EMI Shielding

Snap-on mounting fingerstrips are essential components in EMI shielding solutions across many industries. Their easy installation, low compression force, and effective shielding make them a go-to choice for engineers and manufacturers dealing with sensitive electronic systems. By using durable materials like beryllium copper, phosphor bronze, and stainless steel, snap-on fingerstrips offer long-lasting protection and maintain the electromagnetic integrity of devices even in the most demanding environments.

Their role in automotive, aerospace, defense, telecommunications, and consumer electronics continues to grow as EMI/RFI shielding becomes more critical in preventing interference and ensuring the smooth operation of electronic devices. With their versatile applications and reliable performance, snap-on mounting fingerstrips remain a cornerstone in modern EMI shielding technologies.

You May Also Like

-

Highly Versatile and Indispensable Conductive Copper Foil Tape

Highly Versatile and Indispensable Conductive Copper Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Copper foil tape

Conductive copper foil tape is a highly versatile and indispensable material widely used in industries ranging from electronics to automotive. Its unique combination of electrical conductivity and adhesive properties allows it to serve as an efficient solution for various applications, particularly in shielding, grounding, and conducting electricity between components. This comprehensive guide explores the key features, applications, types, properties, performance, and industries in which conductive copper foil tape plays a crucial role. Key Features of Conductive Copper Foil TapeTypes of Conductive Copper Foil TapeApplications of Conductive Copper Foil TapeProperties and Performance of Conductive Copper Foil TapeConsiderations for Choosing Conductive Copper Foil Tape Conductive Copper Foil Tape Key Features of Conductive Copper Foil Tape Conductive copper foil tape is designed to meet the high demands of modern electronic and industrial applications. Below are its defining features: 1. Electrical Conductivity One of the primary advantages of conductive copper foil tape is its excellent electrical conductivity. Copper, being one of the most conductive materials, allows electrical signals to flow efficiently across surfaces. This makes the tape an essential component in applications that require grounding, EMI (Electromagnetic Interference) shielding, or electrical signal transmission between two or more components. 2. Chemical Resistance Conductive copper foil......

-

Electrical Conductivity Aluminum Foil Tape

Electrical Conductivity Aluminum Foil TapeEMI tapes, EMC foils, conductive textiles & half conductive non-woven

Conductive aluminium tape

Electrical conductivity aluminum foil tape is a versatile and essential material in various industries, particularly in electronics, electrical engineering, and construction. This article delves deep into the properties, applications, benefits, and selection criteria for electrical conductivity aluminum foil tape, focusing on why it is indispensable for ensuring electrical continuity, shielding, and grounding. https://www.handashielding.com/contact-us.html What is Electrical Conductivity Aluminum Foil Tape?Key Properties of Electrical Conductivity Aluminum Foil TapeApplications of Electrical Conductivity Aluminum Foil TapeBenefits of Using Electrical Conductivity Aluminum Foil TapeSelection Criteria for Electrical Conductivity Aluminum Foil TapeConclusion What is Electrical Conductivity Aluminum Foil Tape? Electrical conductivity aluminum foil tape is a specialized adhesive tape made from thin aluminum foil coated with an electrically conductive adhesive. This tape is designed to offer excellent conductivity across its surface and through its adhesive, making it ideal for applications requiring reliable electrical connections and shielding. The aluminum foil provides a conductive surface, while the adhesive ensures that the tape adheres firmly to various substrates while maintaining electrical conductivity. Key Properties of Electrical Conductivity Aluminum Foil Tape 1. Electrical Conductivity The primary feature of aluminum foil tape is its excellent electrical conductivity. Both the aluminum foil and the conductive adhesive are designed to allow current......

-

High Shielding Effectiveness EMI Shielding Fingerstock Gaskets

High Shielding Effectiveness EMI Shielding Fingerstock GasketsEMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

In today's increasingly complex electronic landscape, electromagnetic interference (EMI) shielding has become a critical concern for device manufacturers and designers. One effective solution for addressing EMI issues is the use of high shielding effectiveness EMI shielding fingerstock/fingerstrip gaskets. These specialized components play a vital role in protecting electronic devices from unwanted electromagnetic radiation and maintaining electromagnetic compatibility (EMC). What is EMI Shielding?The Role of EMI Shielding Fingerstock GasketsAdvantages of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConstruction and Materials of High Shielding Effectiveness EMI Shielding Fingerstock GasketsApplications of High Shielding Effectiveness EMI Shielding Fingerstock GasketsPerformance Metrics of Fingerstock GasketsChallenges and ConsiderationsFuture Trends in EMI ShieldingCase Studies of High Shielding Effectiveness EMI Shielding Fingerstock GasketsConclusion What is EMI Shielding? Electromagnetic interference (EMI) refers to the disruption of electronic circuits and systems caused by electromagnetic radiation from external sources. This interference can manifest as noise, signal degradation, or complete system malfunctions. EMI can be generated by a variety of sources including electrical devices, communication systems, and even natural phenomena. To combat EMI, shielding techniques are employed to block or attenuate electromagnetic waves. EMI shielding involves creating a barrier that prevents the interference from penetrating sensitive areas of electronic devices. Effective EMI shielding ensures......

-

Right-angle shielding fingerstrips/angled fingerstocks

EMI/EMC Shielding | RFI Shielding | EMI Gaskets

Fingerstrips

Introduction Right-angle shielding fingerstrips, also known as angled fingerstrips, are specialized components designed to manage electromagnetic interference (EMI) and radio frequency interference (RFI) in electronic systems. These fingerstrips are particularly useful in configurations where electronic components intersect at a 90-degree angle. Their primary role is to ensure effective shielding, maintaining electromagnetic compatibility (EMC) and protecting sensitive electronic equipment from interference. IntroductionDesign and FunctionalitySpecifications and MaterialsInstallation ConsiderationsManufacturing ProcessBenefitsConclusion Design and Functionality Purpose and Importance The main purpose of right-angle shielding fingerstrips is to provide reliable EMI/RFI shielding in electronic setups with perpendicular component arrangements. When electronic devices have components aligned at right angles, traditional shielding solutions might not be effective due to gaps or incomplete coverage. Right-angle fingerstrips address this issue by ensuring continuous shielding across these angular junctions, which is crucial for maintaining the performance and reliability of electronic systems. Applications Right-angle shielding fingerstrips are used in a wide range of applications: Computer Hardware: To shield critical internal components from electromagnetic emissions that could cause operational issues or data corruption. Telecommunications Equipment: To prevent signal interference and ensure the integrity of communication systems. Automotive Electronics: To protect sensitive electronic control systems from EMI that could impact vehicle performance. Shielded Enclosures:......

-

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic Compatibility

RF/EMI Shield Spiral Gaskets: Essential Components for Electromagnetic CompatibilityEMI/EMC Shielding | RFI Shielding | EMI Gaskets

RF/EMI Shield Spiral Gasket

In today's interconnected world of electronics and telecommunications, maintaining electromagnetic compatibility (EMC) is crucial to ensure optimal performance and reliability of electronic devices. RF/EMI Shield Spiral Gaskets play a pivotal role in achieving this goal by effectively mitigating electromagnetic interference (EMI) that can disrupt signal integrity and functionality. What are RF/EMI Shield Spiral Gaskets?Key Features and BenefitsApplications Across Industries What are RF/EMI Shield Spiral Gaskets? RF/EMI Shield Spiral Gaskets are specialized components designed to provide robust shielding against electromagnetic radiation. They are typically made from conductive materials such as metal alloys or conductive elastomers, crafted into a spiral shape that allows them to conform closely to mating surfaces. This design ensures consistent contact and compression, optimizing the gasket's ability to block EMI effectively. Key Features and Benefits EMI Shielding Effectiveness: The primary function of RF/EMI Shield Spiral Gaskets is to attenuate electromagnetic waves, preventing external interference from disrupting sensitive electronic signals. This capability is crucial for maintaining signal integrity and preventing data corruption in telecommunications, aerospace, medical devices, and industrial automation. Versatility in Applications: These gaskets are available in various sizes, shapes, and materials to suit different application requirements. They are commonly used in:Telecommunications: Ensuring clear and reliable communication by......